Bevel Gearboxes

Heavy duty gearbox

heavy duty worm gearbox, heavy gearbox, heavy duty gearbox manufacturers

DCY bevel gearbox reduction nominal center distance is: 160, 180, 200, 224, 250, 280, 315, 355, 400, 450, 500, 560, 630, 710, 800mm; each type has 11 transmission ratios (16, 18, 20, 22.4, 25, 28, 31.5, 35.5, 40, 45, 50), two kinds of rotation, four assembly types, respectively, constitute 660 kinds of heavy duty gearbox.

DCY is a three-stage hard-toothed conical cylindrical gearbox reduction;

DCYK is a three-stage hard-toothed conical cylindrical gear hollow shaft type gearbox reduction;

Bevel gearbox reduction can be widely used in metallurgy, mining, chemical, building materials, lifting, transportation, textile, paper, equipment, plastics, rubber, engineering machinery, energy and other industrial sectors.

Addition to the above applications, there are many others. The overall application of bevel gearboxes are widespread.

The hardened heavy duty gearbox mainly includes the parallel shaft series and the vertical shaft series. The parallel shaft heavy duty gearbox is produced according to the national standard (GBl9004—88). The product is optimized and has the international advanced level in the 1980s. It mainly includes ZDY (single). Four series, ZLY (two-stage), ZSY (three-stage) and ZFY (four-stage), vertical shaft heavy duty gearbox is produced according to national standard (JB/T9002-1999), and the input shaft is perpendicular to the output shaft. Directional transmission, which mainly includes three series of DBY, DCY and DFY.

DCY heavy duty gearbox features: 1. The main parameters such as center distance and nominal transmission ratio are optimized, and the main parts and parts are interchangeable. 2. The gears are made of high-quality alloy steel by carburizing and quenching, and the hardness of the tooth surface reaches HRC54-62. 3, small size, light weight, high precision, large carrying capacity, high efficiency, long life, high reliability, stable transmission, low noise. 4, generally use oil pool run, natural cooling, when the thermal power can not be met, you can use circulating oil lubrication or fan, cooling coil cooling.

heavy duty gearbox is a separate component consisting of a gear drive, a worm drive, and a gear-worm drive enclosed in a rigid housing. It is often used as a reduction gear between the prime mover and the work machine. The function of matching the rotational speed and transmitting torque between the prime mover and the working machine or the actuator is widely used in modern machinery.

heavy duty gearbox is generally used for transmission equipment with low speed and high torque. The motor, internal combustion engine or other high-speed power is driven by the gears with few teeth on the input shaft of heavy duty gearbox to mesh the large gear on the output shaft to achieve the purpose of deceleration. heavy duty gearbox will also have several pairs of identical principle gears to achieve the desired deceleration effect. The ratio of the number of teeth of the large and small gears is the transmission ratio.

The heavy duty gearbox plays a role of matching the rotational speed and transmitting torque between the prime mover and the working machine or the actuator, and is a relatively precise machine. The purpose of using it is to reduce the speed and increase the torque. It has a wide variety of models, different models, and different types of uses. There are many types of heavy duty gearbox. According to the transmission type, they can be divided into gear heavy duty gearbox, worm heavy duty gearbox and planetary gear heavy duty gearbox. According to the different drive stages, they can be divided into single-stage and multi-stage heavy duty gearbox.

According to the gear shape, they can be divided into cylindrical gears. , bevel heavy duty gearbox and cone-cylindrical heavy duty gearbox; according to the transmission arrangement can be divided into expansion, split and coaxial heavy duty gearbox.

Analysis of the reasons for the oil leakage of heavy duty gearbox: 1. The pressure difference between the inside and outside of heavy duty gearbox: During the operation of heavy duty gearbox, the friction of the motion pair is heated and affected by the ambient temperature, so that the temperature of heavy duty gearbox rises. If there is no vent hole or the vent hole is blocked, the pressure inside the machine gradually increases. The higher the internal temperature, the greater the pressure difference from the outside, and the lubricating oil leaks from the gap under the pressure difference. 2. The structure design of heavy duty gearbox is unreasonable.

1) Check that the hole cover is too thin, and it is easy to deform after tightening the bolt, so that the joint surface is not flat and oil leakage from the contact gap;

2) During the manufacturing process of heavy duty gearbox, the casting is not annealed or aging treated, the internal stress is not eliminated, deformation is inevitable, and a gap is generated, resulting in leakage;

3) There is no oil return tank on the tank, and the lubricating oil accumulates in the shaft seal, the end cover, the joint surface, etc., and leaks from the gap under the pressure difference;

4) The design of the shaft seal structure is unreasonable. In the early stage, the oil heavy duty gearbox and the felt ring type shaft seal structure were mostly used, and the felt was compressed and deformed during assembly, and the joint surface gap was sealed. If the journal is not ideally in contact with the seal, the seal will fail in a short period of time due to the extremely poor compensation performance of the felt. Although there are oil return holes in the oil groove, it is easy to block, and it is difficult to play back the oil.

DFY heavy duty gearbox is a four-stage cylindrical heavy duty gearbox Features:

1. The gear is made of high-strength low-carbon alloy steel by carburizing and quenching. The hardness of the tooth surface is up to HRC58-62. The gears are all CNC grinding technology with high precision and good contact.

2. High transmission rate: single stage is greater than 96.5%, double level is greater than 93%, and third level is greater than 90%.

3. Smooth operation and low noise.

4, small size, light weight, long service life, high carrying capacity.

5, easy to dismantle and easy to install.

ZFY heavy duty gearbox specific models: ZFY180, ZFY200, ZFY224, ZFY250, ZFY280, ZFY320, ZFY360, ZFY400, ZFY450, ZFY500, ZFY560, ZFY630, ZFY710 ZFY heavy duty gearbox speed ratio: 100,112,125,140,160,180,200,224,250,280,315,355,400,450,500 The company is also equipped with ZFY heavy duty gearbox accessories, including high-speed shaft, first-speed intermediate shaft, second-speed intermediate shaft, third-speed intermediate shaft, intermediate gear, main shaft, large gear, box and other accessories.

In the high-speed part, the high-speed part of the bevel heavy duty gearbox is a Gleason arc-toothed helical tooth profile. The high-speed shaft is vertically coupled with the gear, no axial stress, longer service life and greater torque.

The first input shaft, the first output shaft, the first intermediate drive shaft, the intermediate shaft and the output shaft are each equipped with a gear to mesh with the front stage to realize the transmission of the speed. heavy duty gearbox is a power transmission mechanism, and the gear is utilized. The speed converter decelerates the number of revolutions of the motor to the desired number of revolutions and obtains a mechanism for greater torque. In the current mechanisms for transmitting power and motion, the range of applications of heavy duty gearbox is quite extensive. It can be seen in almost all kinds of mechanical transmission systems, often used for deceleration and torque increase, for material conveying, lifting, turning, conveying, hammering, cleaning, metal processing, wood processing, extrusion, Rolling, mixing, shearing, pressing, milling, etc., excellent performance, long service life, environmentally friendly and energy-saving products. The pinion parameters of these products are in line with the national standard.

DCY series heavy duty gearbox is a high-quality hard-tooth surface heavy duty gearbox, which is a vertical axis arrangement device. The input shaft and the output shaft are arranged in a vertical direction. They are mainly used for belt conveyors and various transportation machinery. They can also be used for metallurgy, mining, coal. Processing equipment, chemical, building materials, light industry, petroleum, chemical, lifting transport, ship, food, fertilizer, energy, paper and other equipment in the slow transmission, smooth transmission, excellent performance.

N indicates that the priority rotation direction of heavy duty gearbox is counterclockwise, D indicates the belt conveyor type code, C indicates the three-stage transmission, and Y indicates the hard-toothed gear.

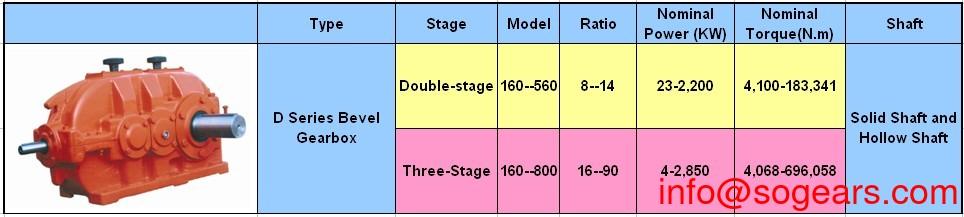

1, DBY, DBYK, DCZ type heavy duty gearbox each have 12 kinds of specifications, the nominal center distance is: 160, 180, 200, 224, 250, 280, 315, 355, 400, 355, 400, 450, 500, 560mm; There are five kinds of transmission ratios (8, 10, 11.2, 12.5, 14), two kinds of rotation directions, and (7) types of assembly, which respectively constitute 240 kinds of heavy duty gearbox. 2, DCY, DCYK, DCZ type heavy duty gearbox each have 15 kinds of specifications, nominal center distance: 160, 180, 200, 224, 250, 280, 315, 355, 400, 450, 500, 560, 630, 710, 800mm; Each type has 11 transmission ratios (16, 18, 20, 22.4, 25, 28, 31.5, 35.5, 40, 45, 50), two kinds of rotation, (seven) types of assembly, respectively, 660 kinds of deceleration Device. heavy duty gearbox series can meet the full power requirements of TD and |Dx belt conveyors and other transportation machinery and the working range of 0.8 to 6.5m/s belt speed.

DCY heavy duty gearbox DCY heavy duty gearbox 1 heavy duty gearbox DBY160-560 DCY160-8 mobile DFY160-710 conical cylindrical heavy duty gearbox Shandong heavy duty gearbox Euron heavy duty gearbox DBY160-560 conical cylindrical heavy duty gearbox, DCY160-8 moving conical cylindrical heavy duty gearbox, DFY160-710 conical cylindrical heavy duty gearbox, for the input shaft and output shaft arranged in the vertical direction of the transmission. It is mainly used in belt conveyors and various transportation machinery. It can also be used in the transmission mechanism of various general machinery such as coal, metallurgy, mining, chemical industry, building materials, light industry and petroleum.

The conical cylindrical heavy duty gearbox has strong bearing capacity, small volume and low noise, and is suitable for mechanical transmission in which the input shaft and the output shaft are arranged at right angles. The gear is made by carburizing, quenching and grinding. It has 6 grade precision and hardness up to HRC54-62. Mainly used in transportation machinery, metallurgy, mining, chemical, coal, building materials, light industry, petroleum and other general machinery. Claim : 1. Input shaft *** high speed is not more than 1500r/min 2. The circumferential speed of the gear is not more than 20m, s 3. The working environment temperature is -40-+45 degrees. When the ambient temperature is lower than 0 degrees, the lubricating oil is heated before starting.

effect:

1. Reduce the speed and increase the output torque at the same time. The torque output ratio is multiplied by the motor output and the reduction ratio, but it should be noted that the rated torque of heavy duty gearbox cannot be exceeded.

2. Deceleration also reduces the inertia of the load, and the reduction of inertia is the square of the reduction ratio.

Application field:

heavy duty gearbox is a mechanical transmission device in many fields of the national economy. The product categories involved in the industry include various types of gear heavy duty gearbox, planetary gear heavy duty gearbox and worm heavy duty gearbox, as well as various special transmission devices, such as speed increase devices and speed control. Devices, and various types of composite transmissions including flexible transmissions. The product service field covers metallurgy, nonferrous metals, coal, building materials, ships, water conservancy, electric power, engineering machinery and petrochemical industries.

China's gearbox industry has a history of nearly 40 years. In all areas of the national economy and the defense industry, heavy duty gearbox products have a wide range of applications. Food light industry, electric machinery, construction machinery, metallurgical machinery, cement machinery, environmental protection machinery, electronic appliances, road construction machinery, water conservancy machinery, chemical machinery, mining machinery, transportation machinery, building materials machinery, rubber machinery, petroleum machinery and other industries heavy duty gearbox products have strong demand.

The market with great potential has spawned fierce competition in the industry. In the brutal market competition, enterprises in the gearbox industry must speed up the elimination of backward production capacity, vigorously develop high-efficiency energy-saving products, make full use of the national energy-saving products, benefit the project policy opportunities, and increase product renewal efforts. Adjust the product structure and pay attention to the national industrial policy to cope with the complex and volatile economic environment and maintain a good momentum of development.

Due to the harsh operating environment of heavy duty gearbox, there are often faults such as wear and leakage. The main ones are: 1. The bearing chamber of heavy duty gearbox is worn, which in turn includes the wear of the bearing housing of the housing, the bearing chamber of the housing, and the bearing chamber of the transmission; 2. The shaft diameter of the gear shaft of heavy duty gearbox is worn, and the main wear parts are in the shaft head and keyway; 3. The bearing position of heavy duty gearbox drive shaft is worn; 4. heavy duty gearbox joint surface leaks.

There are 15 specifications for DBY and DCY heavy duty gearbox, and the nominal center distance is 160, 180, 200, 224, 280, 315, 355, 400, 450, 500, 560, 630, 710, 800mm; 11 transmission ratios (16, 18, 20, 22.4, 25, 28, 31.5, 35.5, 40, 45, 50;), two directions of rotation, four assembly forms.

WP type Archimedes worm heavy duty gearbox has the characteristics of compact structure, convenient installation, stable and reliable operation, no noise (especially single-head worm) and self-locking. heavy duty gearbox is widely used in relatively small equipment in mining, lifting, transportation, chemical, light industry and other industries. The applicable conditions of heavy duty gearbox are as follows: the sliding speed of the worm wheel is not more than 7.5 m / s; the speed of the high speed shaft is not more than 1500 rpm. The working environment temperature is -40 to 40 °C, and it can be operated in both forward and reverse directions.

1. There are two basic types of input shaft connection (single input shaft and double input shaft) and two types of motor flanges. 2. The output shaft structure has two basic types (single output shaft, double output shaft) and hollow output shaft. 3. The output and input shaft position directions have the input shaft at the bottom and the top; the output shaft is up and down; the input shaft is up and down. 4, 2 or 3 heavy duty gearbox can be used to form a multi-stage heavy duty gearbox to obtain a great gear ratio

Oil level check: 1. Turn off the power to prevent electric shock. Waiting for heavy duty gearbox to cool down; 2. Remove the oil level screw plug to check whether the oil is full; 3. Install the oil level screw plug.

Oil inspection:

1. Turn off the power to prevent electric shock. Waiting for heavy duty gearbox to cool down;

2. Open the oil drain plug and take the oil sample;

3. Check the viscosity index of the oil: If the oil is obviously turbid, it is recommended to replace it as soon as possible;

4. For heavy duty gearbox with oil level screw plug: Check the oil level, if it is qualified; install the oil level screw plug.

Oil replacement: After the cooling, the viscosity of the oil increases and the oil is difficult to drain. The heavy duty gearbox should change the oil at the operating temperature. 1. Turn off the power to prevent electric shock. Wait for heavy duty gearbox to cool down without burning danger; Note: The gearbox should remain warm when changing oil; 2. Place an oil pan under the oil drain plug; 3. Open the oil level screw plug, the aerator and the oil drain plug; 4. Remove all oil; 5. Install the oil drain plug; 6. Inject new oil of the same grade; 7. The amount of oil should be consistent with the installation location; 8. Check the oil level at the oil level screw plug; 9. Tighten the oil level plug and ventilator.

1. Use heavy duty gearbox introduction: The bevel heavy duty gearbox is used for the transmission of the input shaft output shaft in a vertical direction. Mainly used in belt conveyors and other transportation machinery, but also used in metallurgy, mining, chemical, coal, building materials, light industry, petroleum and other general machinery, in addition to large-scale heavy duty gearbox, mainly used in the cement industry. 2. Scope of application: The maximum speed of the input shaft of heavy duty gearbox is not more than 1500r/min The peripheral speed of the gear is not more than 20m/s The working environment temperature is -40~45°C. When the ambient temperature is lower than 0 °C, the lubricating oil should be heated before starting (other distribution heat pipes) Conical cylindrical heavy duty gearbox form and marking

1. Form: The DBY type is a two-stage transmission heavy duty gearbox similar to the zdy heavy duty gearbox, but the difference is that the first stage drive is a Gleason spiral bevel gear, and the second drive is an involute cylindrical bevel gear. heavy duty gearbox can be divided into four assembly forms I, II, III and IV according to the output shaft form (see the assembly form diagram below). The rotation direction of the output shaft can be divided into clockwise (S) and counterclockwise (N). (facing the output shaft). 3. Mark The gear unit's marking code includes the gear unit model, nominal center distance, nominal gear ratio, assembly type and output shaft rotation direction. Tag example: heavy duty gearbox DBYK224–11.2–IS The form code is DBYK Nominal center distance is 224mm Nominal transmission ratio 11.2 Assembly form is the first type The output shaft rotates clockwise The backstop must be configured separately (see the backstop mounting dimensions for dimensions) D is the belt conveyor type code, B-secondary transmission, Y-hard tooth surface gear, K-hollow shaft

Conical cylindrical heavy duty gearbox assembly form diagram Conical cylindrical heavy duty gearbox mainly has two types of DBY heavy duty gearbox and DCY heavy duty gearbox, which is an external gear transmission mechanism with input and output shafts in vertical state, conical cylindrical heavy duty gearbox and cylindrical heavy duty gearbox In the similar characteristics, the main transmission parts are made of high quality alloy steel. The gear is made by carburizing, quenching and grinding, with 6 levels of precision. The product has the advantages of high carrying capacity, long life, small size, high efficiency and light weight.

The best service from our transmission drive expert to your inbox directly.

Our Service

Get in Touch

Yantai Bonway Manufacturer Co.ltd

ANo.160 Changjiang Road, Yantai, Shandong, China(264006)

T+86 535 6330966

W+86 185 63806647