An electric motor is an electrical machine that converts electrical energy into mechanical energy. Most electric motors operate through the interaction between the motor's magnetic field and electric current in a wire winding to generate force in the form of torque applied on the motor's shaft.

Electric motors can be powered by direct current (DC) sources, such as from batteries, or rectifiers, or by alternating current (AC) sources, such as a power grid, inverters or electrical generators. An electric generator is mechanically identical to an electric motor, but operates with a reversed flow of power, converting mechanical energy into electrical energy.

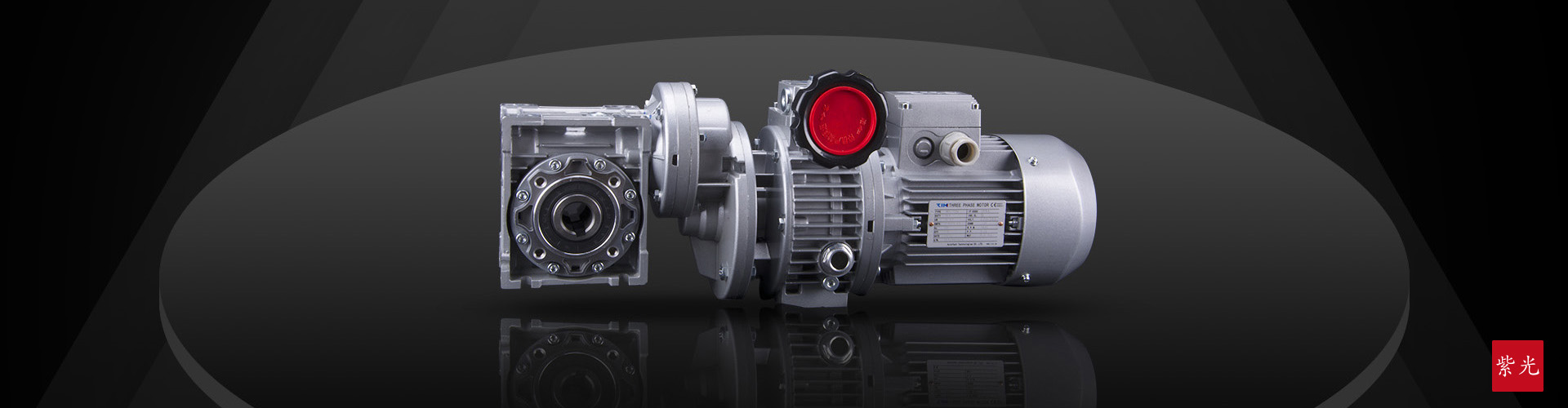

Electric motors may be classified by considerations such as power source type, internal construction, application and type of motion output. In addition to AC versus DC types, motors may be brushed or brushless, may be of various phase (see single-phase, two-phase, or three-phase), and may be either air-cooled or liquid-cooled. General-purpose motors with standard dimensions and characteristics provide convenient mechanical power for industrial use.

The largest electric motors are used for ship propulsion, pipeline compression and pumped-storage applications with ratings reaching 100 megawatts. Electric motors are found in industrial fans, blowers and pumps, machine tools, household appliances, power tools and disk drives. Small motors may be found in electric watches. In certain applications, such as in regenerative braking with traction motors, electric motors can be used in reverse as generators to recover energy that might otherwise be lost as heat and friction.

Electrically, a motor consists of two components which move relative to each other and which together form a magnetic circuit:

Field magnets - This part creates a magnetic field which passes through the armature. It is usually a set of electromagnets surrounding the rotor, consisting of wire windings on a ferromagnetic iron core which guides the magnetic field. Alternatively it can be one or more permanent magnets.

Armature - This is the part through which the electric current flows which develops the force. Like field coils, it consists of wire windings on a ferromagnetic core. When electric current passes through the wire the magnetic field from the field magnet exerts a force on it, called the Lorentz force, turning the rotor.

One of these components is mounted on the stator, the stationary part of the motor attached to the frame, the other is on the rotor, the part that turns. The field magnet is usually on the stator and the armature on the rotor, but in some types of motor these are reversed.

Mechanically, a motor consists of these parts

Rotor

In an electric motor, the moving part is the rotor, which turns the shaft to deliver the mechanical power. The rotor usually has conductors laid into it that carry currents, which the magnetic field of the stator exerts force on to turn the shaft. Alternatively, some rotors carry permanent magnets, and the stator holds the conductors.

There must be an air gap between the stator and rotor so it can turn. The width of the gap has a significant effect on the motor's electrical characteristics. It is generally made as small as possible, as a large gap has a strong negative effect on performance. It is the main source of the low power factor at which motors operate. The magnetizing current increases and the power factor decreases with the air gap, so narrow gaps are better. Very small gaps may pose mechanical problems in addition to noise and losses.