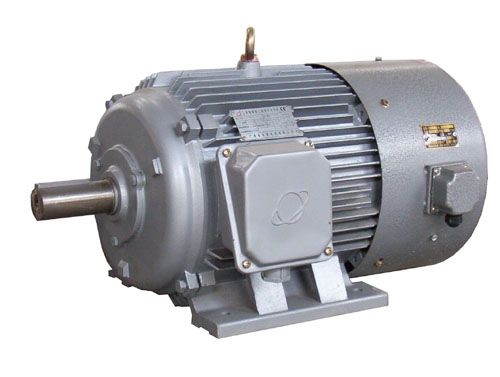

Three-phase induction motor is an AC motor in which the rotating magnetic field formed by the stator winding interacts with the magnetic field of the induced current in the rotor winding to generate electromagnetic torque to drive the rotor to rotate. It is a kind of induction motor.

Working principle of three-phase induction motor:

A three-phase induction motor model has three-phase symmetric windings embedded in the stator slots, and guide bars are placed in the rotor slots. The two ends of all the guide bars are respectively short-circuited with two short-circuit rings to form a closed rotor winding.

If the rotor speed is zero at the beginning, the rotor bar cutting the rotating magnetic field will generate induced electromotive force e2. Since the rotor bar is short-circuited, a short-circuit current i2 will appear in the rotor conductor. According to the right-hand rule: the direction of the induced electromotive force in the rotor conductor under the N pole and the direction of the active component of the current enter the paper; under the S pole, it flows out of the paper. The rotor current i2 interacts with the air gap magnetic field to generate electromagnetic force, the direction of which is determined by the left-hand rule. The torque produced by electromagnetic force is called electromagnetic torque. Under the action of electromagnetic torque, the rotor will rotate in the direction of the rotating magnetic field.

Since the electromotive force and current on the rotor side are generated by electromagnetic induction, this kind of motor is called an induction motor. In addition, if the rotor speed is the same as the synchronous speed of the rotating magnetic field, there will be no induced electromotive force in the rotor bar, and there will be no electromagnetic force and electromagnetic torque. Therefore, when the induction motor is running normally, between the rotor speed and the rotating magnetic field speed There are always differences, so induction motors are also called asynchronous motors.

Characteristics of three-phase induction motors:

International interchangeability: adopts the international standard size established by the IEC (International Electrotechnical Commission), with international interchangeability.

Excellent characteristics: Due to the low inertia of the rotating part, the large acceleration torque, and the short starting and stopping time, the working efficiency of the machine with frequent starting and stopping can be improved.

Low vibration and noise: Perfect mechanical structure design, excellent processing and assembly, and precision balance, almost no vibration and noise.

Convenient maintenance: high-grade oil-sealed bearings are used, no need to change lubricating grease, easy maintenance.

Small and light weight: the frame size is reduced, the body is small and light, the space is saved, the transportation and installation are easy, and the design and construction are convenient. 3 phase induction motor supplier in philippines

Class E/B/F insulation materials: use heat-resistant, moisture-resistant, chemical-resistant E/B/F-class insulation materials, which are safe and durable, and have the longest life.

Speed regulation of three-phase induction motor:

In recent years, with the rapid development of power electronic technology, microelectronic technology, computer technology and automatic control technology, the speed control technology of three-phase induction motors has also developed rapidly and is becoming more and more perfect. There is a trend to replace DC motors for speed control. In industrial applications, wherever DC motors can be used for speed control, AC speed control can be used instead. Since induction motors generally do not have a commutator, they can be made into a large-capacity, high-speed, high-voltage speed control system that DC motors cannot achieve. In addition, for most of the fans and pumps that do not need speed control, AC After the speed is adjusted, energy can be greatly saved, so it is of great significance to study the speed and energy saving of induction motors.

It can be seen that to change the speed n of the induction motor, the following three methods can be used:

(1) Variable pole speed regulation. Change the number of pole pairs p to change the synchronous speed ns of the stator rotating magnetic field to achieve speed regulation.

(2) Frequency conversion speed regulation. Change the power supply frequency f1 to change the synchronous speed ns of the stator rotating magnetic field to achieve speed regulation.

(3) Variable slip speed regulation. Changing the slip rate s of the motor to achieve speed regulation can be divided into methods such as reducing stator voltage speed regulation, rotor circuit series resistance speed regulation and cascade speed regulation.

Application fields of three-phase induction motors:

Three-phase induction motors are mainly used in computer peripheral equipment, lathe systems, photoelectric combined devices, valve control systems, nuclear reactors, surface grinders, CNC machine tools, automatic winding machines, electronic clocks, and medical equipment.

Find here high quality 3 phase electric induction motors

Three-phase AC has three sources of AC power, all out of phase with each other.The three phase Squirrel cage induction motors are classified into 6 different standard types.Speed control of 3 phase induction motor by stator frequency.Split phase induction motor in hindi, rotating magnetic field in 3 phase induction motor, 3 phase asynchronous motor, 3 phase 4 pole motor, 3 phase induction motor for sale.

3 phase squirrel cage induction motor

There are two types of 3 phase squirrel cage induction motor based on the type of construction of Rotor.Speed control of 3-phase induction motor using rotor impedance.Three phase slip ring induction motor could be used for industrial wires where variable speed and high starting torque are prime requirements.types of three phase induction motor we supplying is for Squirrel Cage Induction Motor. Slip Ring Induction Motor or Wound Rotor Induction Motor or Phase Wound Induction Motor. 50 Hz or 60 Hz cage induction motors, also electromagnetic field, Aggregate, Cement, Chemical, Oil, Gas Food and cement etc.

A three-phase asynchronous motor is a type of induction motor. It is a type of motor powered by 380V three-phase alternating current (phase difference 120 degrees) at the same time. Because the rotor and stator of the three-phase asynchronous motor rotate in the same direction but different The speed of rotation, there is a slip rate, so it is called a three-phase asynchronous motor. The speed of the rotor of the three-phase asynchronous motor is lower than that of the rotating magnetic field. 3 phase induction motor supplier in philippines. The rotor winding generates electromotive force and current due to the relative movement between the magnetic field and the magnetic field, and interacts with the magnetic field to generate electromagnetic torque to realize energy conversion.

Compared with single-phase asynchronous motors, three-phase asynchronous motors have better running performance and can save various materials. According to the different rotor structure, three-phase asynchronous motors can be divided into two types: cage type and winding type. The cage rotor asynchronous motor has simple structure, reliable operation, light weight and low price, and has been widely used. Its main disadvantage is the difficulty of speed regulation. The rotor and stator of the wound three-phase asynchronous motor are also provided with three-phase windings and connected to an external rheostat through slip rings and brushes. Adjusting the resistance of the rheostat can improve the starting performance of the motor and adjust the speed of the motor.

basic structure:

The three-phase asynchronous motor consists of two basic parts: a fixed stator and a rotating rotor. The rotor is installed in the inner cavity of the stator and supported on two end covers with the aid of bearings. In order to ensure that the rotor can rotate freely in the stator, there must be a gap between the stator and the rotor, which is called an air gap. The air gap of the motor is a very important parameter, and its size and symmetry have a great influence on the performance of the motor. Figure 2 shows the components of a three-phase cage asynchronous motor.

stator

The stator is composed of a stator three-phase winding, a stator core and a frame.

The stator three-phase winding is the circuit part of the asynchronous motor. It plays a very important role in the operation of the asynchronous motor and is a key component for converting electrical energy into mechanical energy. The structure of the stator three-phase winding is symmetrical. Generally, there are six outlet terminals U1, U2, V1, V2, W1, W2, which are placed in the junction box on the outside of the base and connected into a star (Y) or delta ( △).

The stator core is a part of the magnetic circuit of the asynchronous motor. Because the main magnetic field rotates relative to the stator at a synchronous speed, in order to reduce the loss caused in the core, the core is made of 0.5mm thick high-permeability silicon steel sheets, and the silicon steel sheets are coated with insulation on both sides Paint to reduce the eddy current loss of the core.

The frame is also called the case. Its main function is to support the stator core and to withstand the reaction force generated by the entire motor during operation. The heat generated due to internal losses during operation is also dissipated through the frame. The frame of medium and small motors is generally made of cast iron. Large motors are often formed by welding steel plates due to the inconvenient pouring of the large body.

Rotor

The rotor of an asynchronous motor is composed of a rotor core, a rotor winding and a rotating shaft.

The rotor core is also a part of the magnetic circuit of the motor, which is also laminated with silicon steel sheets. Different from the stator core punching sheet, the rotor core punching sheet is slotted on the outer circle of the punching sheet, and the outer cylindrical surface of the laminated rotor core is uniformly formed with many slots of the same shape for placing the rotor windings.

The rotor winding is another part of the asynchronous motor circuit. Its function is to cut the stator magnetic field, generate induced electric potential and current, and force the rotor to rotate under the action of the magnetic field. Its structure can be divided into two types: cage winding and winding winding. The main features of these two types of rotors are: the cage rotor has a simple structure, is convenient to manufacture, economical and durable; the wound rotor has a complex structure and is expensive, but the rotor circuit can introduce an external resistor to improve the starting and speed regulation performance.

The cage rotor winding is composed of a guide bar placed in the rotor slot and end rings at both ends. In order to save steel and improve productivity, the guide bars and end rings of low-power asynchronous motors are generally cast from molten aluminum at one time; for high-power motors, because the quality of cast aluminum is not easy to guarantee, copper bars are often inserted into the rotor core slot In the middle, the end rings are welded on both ends. The windings of the cage rotor are closed by itself and do not need to be powered by an external power source. It looks like a cage, so it is called a cage rotor.

working principle:

When a symmetrical three-phase alternating current is applied to the three-phase stator windings, a rotating magnetic field that rotates clockwise along the inner circular space of the stator and rotor at a synchronous speed n1 is generated. Because the rotating magnetic field rotates at a speed of n1, the rotor conductor is stationary at the beginning, so the rotor conductor will cut the stator rotating magnetic field to generate induced electromotive force (the direction of the induced electromotive force is determined by the right-hand rule). Because the two ends of the rotor conductor are short-circuited by the short-circuit ring, under the action of the induced electromotive force, an induced current that is basically the same as the direction of the induced electromotive force will be generated in the rotor conductor. The current-carrying conductor of the rotor is subjected to electromagnetic force in the stator magnetic field (the direction of the force is determined by the left-hand rule). The electromagnetic force generates electromagnetic torque on the rotor shaft and drives the rotor to rotate along the direction of the rotating magnetic field.

Through the above analysis, it can be concluded that the working principle of the motor is: when the three-phase stator windings of the motor (each phase differs by 120 degrees in electrical angle) are connected to the three-phase symmetrical alternating current, a rotating magnetic field will be generated. The rotating magnetic field cuts the rotor windings, thereby Induction current is generated in the rotor winding (the rotor winding is a closed path), and the current-carrying rotor conductor will generate electromagnetic force under the action of the stator rotating magnetic field, thereby forming an electromagnetic torque on the motor shaft, driving the motor to rotate, and the direction of rotation of the motor The direction of the magnetic field is the same.

NER GROUP CO.,LIMITED is a professional manufacturer and exporter of gearbox reducers, gear motors and electric motors for several years from China.

We believe that we can cooperate with you on this business and please contact us if you are interested.

You are welcomed to visit our catalogue website for more information:

www.sogears.com

Mobile:+86-18563806647

www.guomaodrive.com

https://twitter.com/gearboxmotor

Viber/Line/Whatsapp/Wechat: 008618563806647

E-mail:

No.5 Wanshoushan Road, Yantai, Shandong,China(264006)

Gear reduction motor, reduction gearbox manufacturer, visit www.bonwaygroup.com Email: