ABB offers a complete range of power and distribution transformers designed to grant the reliability, durability, and efficiency required in utility, industrial, and commercial applications. ABB is a major transformer manufacturer throughout the world and offers both liquid-filled and dry-type transformers as well as services for complete life-cycle support, including replacement parts and components.

Our portfolio allows utilities and industrials to maximize the return on transformer assets by ensuring a high reliability, reducing life cycle costs and ensuring optimized performance while lowering environmental impact.

The following is the product model and its introduction:

R7%15kVAR 400V 50Hz, R7%30kVAR 400V 50Hz, R7%45kVAR 400V 50Hz, R14%15kVAR 400V 50Hz, R14%30kVAR 400V 50Hz, R14%45kVAR 400V 50Hz, NOCH-0030-6X, NOCH-0016-6X, NOCH-0070-6X, NOCH-0120-6X, FOCH-0260-70, FOCH-0320-50, ND07

1. Power transformers

ABB's power transformers are key components in power networks. Their availability and longevity have a major impact on grid reliability and profitability. ABB does not compromise on quality. We ensure that every one of our 20,000 delivered units has undergone rigorous full-acceptance testing. ABB offers a complete range of power transformers and related components and parts. We have delivered more than 20,000 power transformers (over 2,600 GVA), including over twenty 800 kV UHVDC and over five hundred 735 - 765 kV AC units, to all major global markets.

Our entire range is the result of our own research, development and manufacturing, which makes us unique in the industry. This has given us extensive experience in every relevant part of power transformer technology. Customers worldwide can securely rely on the quality and reliability of our products.

2. Distribution transformers

ABB offers a complete range of distribution transformers designed to grant the reliability, durability, and efficiency required in utility, industrial, and commercial applications. ABB's liquid-filled transformers are manufactured in accordance with the most demanding industry and international standards. Transformers can be used for indoor or outdoor applications and can be provided with off-load and on-load tap changers.

Product scope:

Liquid-filled distribution transformers

ANSI and IEC standards

Applications: utilities, renewables, oil & gas, industrial and data centers

3. Dry-type transformers

ABB offers a full range of dry-type transformers with primary voltages through 72.5 kV built according to all major standards including IEC and ANSI. To minimize environmental contamination and fire hazard, customers are specifying dry-type transformers more frequently. These transformers meet strict parameters with respect to electrical system demands and functioning in areas with extreme climatic conditions. ABB's dry and cast transformers are virtually maintenance free and are manufactured in accordance with industry and international standards including ISO 9001.

4. Special application transformers

ABB offers a wide portfolio of special application transformers for both AC and DC voltages. With years of experience, many references from different applications and a global manufacturing footprint, ABB has the experience needed to build the customer's special application transformer.

By using only highest available quality of materials for the core and winding, a reduction of losses has been achieved. For the end-user this means that with lower losses, there is more energy to sell, which makes the payback time of the investment shorter. The lifetime of the transformer is also extended.

This category includes liquid-filled and dry-type transformers for other applications not mentioned, like variable speed drives, furnace transformers, rectifiers, traction transformers, subsea transformers and mobile transformers.

Why ABB?

Broadest portfolio and technology leader of special transformers

Global platform - local production - local service and short delivery time

Less failure - tests per design/cumulated experience - proven design/tests records

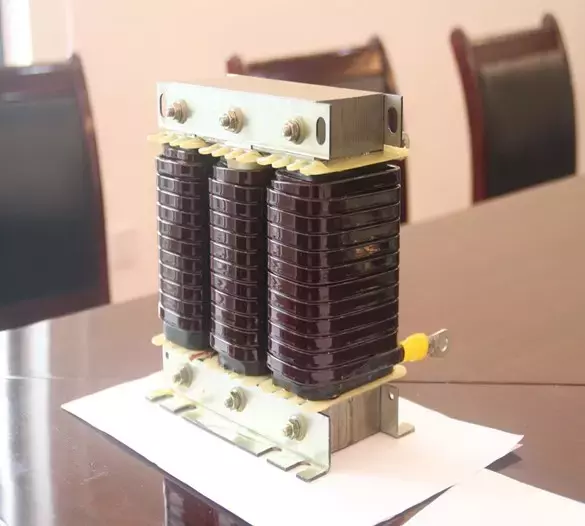

5. Reactors and inductors

ABB’s reactors increase the energy efficiency by improving power quality and reducing costs. By combining low life cycle cost and high efficiency, ABB reactors will boost customers' bottom line. ABB builds today a wide portfolio of reactors with dry-type and liquid-filled technology for both AC and DC voltages. Depending on the load pattern of the line and the balance of reactive power, the ABB reactor is suitable for continuous as well as switched operation.

The reactor design is based on the gapped core concept, which gives a compact design with low losses and low total mass. The concept was introduced in the mid nineteen sixties. By continuing refinements, ABB has learned to master critical operating parameters like vibrations and noise. Today the reactor is a high tech product requiring special skills in both design and manufacture.

Product scope:

10 to 330 MVAR, three-phase

Up to 110 MVAR, single-phase

Up to and including 800 kV

6. Generator step-up transformer (GSU)

The generator step-up transformer (GSU) is a key connection between the power station and the transmission grid, and it is usually running at full load day and night. They must be able to withstand extreme thermal loads without premature aging.

The generator step-up transformer increases the low voltage level of the generator output to the corresponding grid voltage level. This type of generator transformer is installed in the power station, type: single-phase or three-phase.

There are two basic technologies in the design and manufacture of generator transformers: core and shell. The primary and secondary windings of a shell transformer are on the same core post and are wrapped by an iron core. The core transformer is a cylindrical winding wrapped with iron core posts.

Why choose ABB?

Short-circuit performance is twice the industry standard

Globally unified technology --bringing continuous, deliverable performance and technology

Through close cooperation with local partners in China, ABB has established a strong production base in power transmission and distribution, automation products and systems. Its business includes a complete series of power transformers and distribution transformers; high, medium and low voltage switches; Electric drive systems and motors; industrial robots, etc. These products have been widely used in industrial and power industries. ABB strives for superior quality, and its companies and products have become the benchmark in the industry. ABB's capabilities in engineering and project management are manifested in various fields such as metal, pulping, chemistry, automotive industry, power industry automation, and building systems.

Transformer is a device that uses the principle of electromagnetic induction to change the AC voltage. The main components are a primary coil, a secondary coil, and an iron core (magnetic core). The main functions are: voltage conversion, current conversion, impedance conversion, isolation, voltage stabilization (magnetic saturation transformer), etc. It can be divided into: power transformer and special transformer (electric furnace transformer, rectifier transformer, power frequency test transformer, voltage regulator, mining transformer, audio transformer, intermediate frequency transformer, high frequency transformer, impact transformer, instrument transformer, electronic transformer , Reactors, transformers, etc.). Circuit symbols often use T as the beginning of the number. Examples: T01, T201, etc.

Working principle:

A transformer consists of an iron core (or magnetic core) and a coil. The coil has two or more windings. The winding connected to the power source is called the primary coil, and the remaining windings are called secondary coils. It can transform AC voltage, current and impedance. The simplest core transformer consists of a core made of soft magnetic material and two coils with different numbers of turns on the core.

The core's role is to strengthen the magnetic coupling between the two coils. In order to reduce the eddy current and hysteresis loss in the iron, the iron core is formed by lamination of painted silicon steel sheets; there is no electrical connection between the two coils, and the coils are wound by insulated copper wires (or aluminum wires). One coil connected to AC power is called the primary coil (or primary coil), and the other coil connected to the electrical appliance is called the secondary coil (or secondary coil). The actual transformer is very complicated. There are unavoidable copper loss (heating of the coil resistance), iron loss (heating of the core), and magnetic leakage (air-closing magnetic induction wire). To simplify the discussion, only the ideal transformer is introduced here. The conditions for an ideal transformer to be established are: ignore the magnetic flux leakage, ignore the resistance of the primary and secondary coils, ignore the core loss, and ignore the no-load current (the current in the primary coil when the secondary coil is open). For example, when the power transformer is running at full load (the output power of the secondary coil) is close to the ideal transformer situation.

Transformers are stationary electrical appliances made using the principle of electromagnetic induction. When the primary coil of the transformer is connected to an AC power source, an alternating magnetic flux is generated in the core, and the alternating magnetic field is generally expressed by φ. Φ in the primary and secondary coils is the same, φ is also a simple harmonic function, and the table is φ = φmsinωt. According to Faraday's law of electromagnetic induction, the induced electromotive forces in the primary and secondary coils are e1 = -N1dφ / dt and e2 = -N2dφ / dt. In the formula, N1 and N2 are the number of turns of the primary and secondary coils. It can be seen from the figure that U1 = -e1 and U2 = e2 (the physical quantity of the original coil is represented by the subscript 1 and the physical quantity of the secondary coil is represented by the subscript 2). The complex effective values are U1 = -E1 = jN1ωΦ, U2 = E2 = -jN2ωΦ, Let k = N1 / N2, called the transformer's ratio. According to the above formula, U1 / U2 = -N1 / N2 = -k, that is, the ratio of the effective value of the transformer primary and secondary coil voltages is equal to the turns ratio and the phase difference between the primary and secondary coil voltages is π.

By purpose:

1) Power transformer: used for step-up and step-down voltage of power transmission and distribution system.

2) Instrument transformers: such as voltage transformers, current transformers, measuring instruments and relay protection devices.

3) Test transformer: It can generate high voltage and conduct high voltage test on electrical equipment.

4) Special transformers: such as electric furnace transformers, rectifier transformers, adjustment transformers, capacitor transformers, phase-shifting transformers, etc.

Divided by core form:

1) Core transformer: Power transformer for high voltage.

2) Amorphous alloy transformer: Amorphous alloy iron core transformer is a new type of magnetically conductive material, which reduces the no-load current by about 80%. It is a distribution transformer with ideal energy saving effect, especially suitable for load rates in rural power grids and developing regions Lower places.

3) Shell-type transformers: special transformers for large currents, such as electric furnace transformers, welding transformers; or power transformers for electronic instruments and televisions, radios, etc.

The role of the reactor:

1. Reactors are suitable for reactive power compensation and harmonic management systems, which can improve the power factor and filter harmonics to suppress distortion of the voltage waveform of the power grid, thereby changing the quality of the power grid and ensuring the safe operation of the power system.

2. The incoming reactor is used to limit the current surge caused by sudden changes in grid voltage and operating overvoltage, smooth the spikes contained in the power supply voltage, or smooth the voltage defects generated during commutation of the bridge rectifier circuit. Interference, and can reduce the pollution of the power grid by the harmonic current generated by the rectifier unit.

3. DC reactor (also known as smooth wave reactor) is mainly used for the DC side of the converter. The DC current with AC component flows in the reactor. The main purpose is to limit the AC component superimposed on the DC current to a specified value, keep the rectified current continuous, reduce the current ripple value, and improve the input power factor.

4. The main role of the output reactor is to compensate the influence of the long-line distributed capacitance, and can suppress the output harmonic current, improve the output high-frequency impedance, and effectively suppress dv / dt. Reduce the high-frequency leakage current, protect the inverter, and The effect of equipment noise.