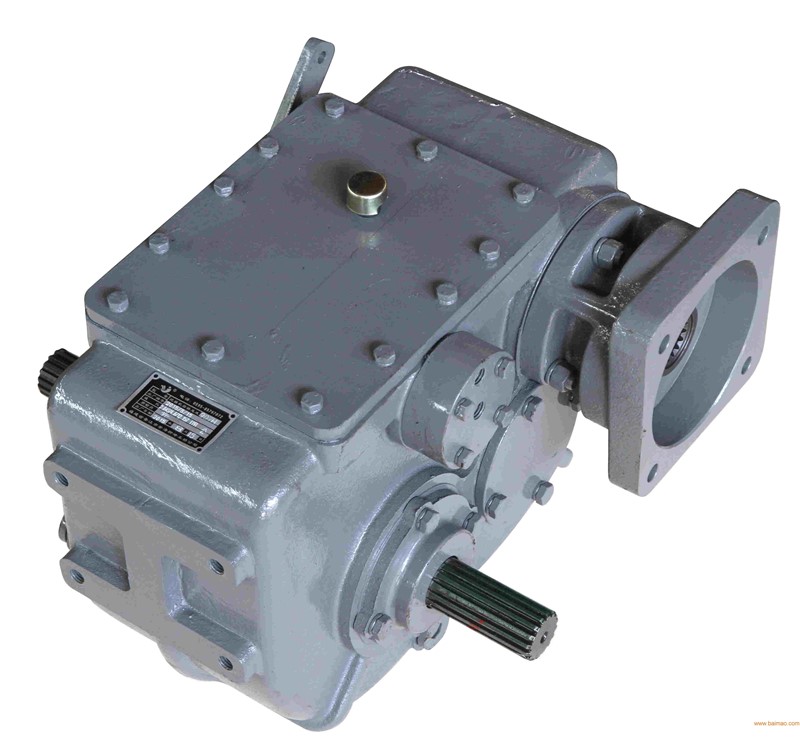

The gearbox of the excavator is composed of a hydraulic torque converter, a planetary gear and a hydraulic control system. The transmission of hydraulic power and the combination of gears are used to achieve variable speed and torque. The function is:

1. Change the transmission ratio;

2. Under the condition that the rotation direction of the engine remains unchanged, the car can run backwards;

3. Use neutral gear to interrupt power transmission so that the engine can be started and idle, and it is convenient for the transmission to shift gears or perform power output.

The function introduction of the gearbox of the excavator:

①Change the transmission ratio and expand the range of torque and speed of the driving wheels to adapt to the frequently changing driving conditions, and at the same time make the engine work under favorable conditions (higher power and lower fuel consumption);

②Enable the car to run backwards under the condition that the rotation direction of the engine remains unchanged;

③Using neutral gear to interrupt the power transmission, so that the engine can be started and shifted, and it is convenient for the transmission to shift gears or perform power output.

The transmission is composed of a variable speed transmission mechanism and an operating mechanism, and a power output device can be installed when needed. There are two ways to classify: according to the transmission ratio change mode and according to the difference of the control mode. When the point is lowered, air bubbles are generated, which causes the braking effect to deteriorate, which is prone to danger. Excavator swing gearbox manufacturers in china.

The swivel mechanism makes the working device and the upper turntable swivel left or right for excavation and unloading. The slewing device of the single-bucket hydraulic excavator must be able to support the turntable on the frame without tilting and make the slewing light and flexible. For this reason, single bucket hydraulic excavators are equipped with slewing support devices and slewing transmission devices, which are called slewing devices.

Swivel device

The upper turntable is one of the three major components of hydraulic excavators. In addition to the engine, hydraulic system, driver's cab, counterweight, fuel tank, etc. on the turntable, there is also a very important part-the slewing device. The slewing device of the hydraulic excavator is composed of a turntable, a slewing support and a slewing mechanism. The outer seat ring of the slewing device is connected with the turntable with bolts, the toothed inner seat ring is connected with the underframe with bolts, and rolling bodies are arranged between the inner and outer rings. The vertical load, horizontal load, and overturning moment of the excavator working device acting on the turntable are transferred to the underframe through the outer race, rolling element and inner seat of the slewing support. The housing of the slewing mechanism is fixed on the turntable, and a pinion gear is used to mesh with the ring gear on the inner race of the slewing support. The pinion can rotate around its own axis and revolve around the centerline of the turntable. When the return mechanism works, it is like Swivel the bottom frame.

The slewing device of the hydraulic excavator must be able to support the turntable on the fixed part (getting off). Can not tip over, and should make the rotation light and flexible. For this reason, hydraulic excavators are equipped with a slewing support device (playing a supporting role) and a slewing transmission device (driving the turntable to slew), and they are collectively referred to as the slewing device of the hydraulic excavator.

The gearbox is a mechanism used to change the speed and torque from the engine. It can change the transmission ratio of the output shaft and the input shaft in a fixed or stepwise manner. The gearbox consists of a variable speed transmission mechanism and a control mechanism, and some cars also have a power output mechanism. Most of the transmission mechanisms are driven by ordinary gears, and some are driven by planetary gears. Ordinary gear transmission transmission mechanisms generally use slip gears and synchronizers.

Features

(1) Change the transmission ratio to meet the traction requirements of different driving conditions, make the engine work in favorable conditions as much as possible, and meet the possible driving speed requirements. Change the speed of the car and the torque on the driving wheels of the car in a larger range. Due to the different driving conditions of the car, the driving speed and driving torque of the car are required to be able to vary within a wide range. For example, the vehicle speed on the highway should be able to reach 100km/h, while in the urban area, the vehicle speed is often around 50km/h. When an empty car is driving on a straight road, the driving resistance is very small, and when it is fully loaded uphill, the driving resistance is very high. The characteristic of automobile engines is that the range of speed change is small, and the range of torque change cannot meet the needs of actual road conditions.

(2) Realizing reverse driving to meet the needs of reverse driving. To realize reverse driving of a car, the engine crankshaft generally can only rotate in one direction, and the car sometimes needs to be able to travel backwards. Therefore, the reverse gear set in the gearbox is often used to realize the reverse driving of the car.

(3) Interrupt the power transmission, and interrupt the power transmission to the driving wheels when the engine is started, idling, the car is shifted or needs to be stopped for power output.

(4) To achieve neutral gear, when the clutch is engaged, the gearbox may not output power. For example, it can be ensured that the driver releases the clutch pedal and leaves the driver's seat when the engine is not stalled.

principle

Mechanical gearboxes mainly apply the speed reduction principle of gear transmission. Simply put, there are multiple sets of gear pairs with different transmission ratios in the gearbox, and the shifting behavior of a car when driving is to make different gear pairs in the gearbox work through the operating mechanism. For example, at low speed, let the gear pair with large transmission ratio work, and at high speed, let the gear pair with small transmission ratio work.

1. Divided according to the change mode of the transmission ratio, the transmission can be divided into three types: stepped, stepless and integrated.

(a) Stepped transmission: There are several selectable fixed transmission ratios and gear transmission. It can be divided into two types: ordinary gear transmission with fixed gear axis and planetary gear transmission with partial gear (planetary gear) axis rotation.

(b) Continuously variable transmission: the transmission ratio can be continuously changed within a certain range, and the common ones are hydraulic, mechanical and electric.

(c) Integrated transmission: It is composed of a stepped transmission and a continuously variable transmission, and its transmission ratio can be continuously changed in the range of several segments between the maximum value and the minimum value.

2. According to the operation mode, the transmission can be divided into three types: forced operation, automatic operation and semi-automatic operation.

(a) Forced-operated transmission: the driver directly manipulates the gear lever to shift gears.

(b) Automatically operated transmission: the selection of transmission ratio and gear shifting are carried out automatically. The driver only needs to manipulate the accelerator pedal, and the transmission can control the actuators according to the load signal of the engine and the vehicle speed signal to realize the shift of gears.

(c) Semi-automatically operated transmission: It can be divided into two types, one is automatic shifting of some gears, and manual (mandatory) shifting of some gears; the other is to select gears in advance with a button and depress the clutch When the pedal or the accelerator pedal is released, the actuator shifts gears by itself.

According to the structure, the walking can be divided into two types: combined type and integral type. The underframe of the combined walking frame is a frame structure, the cross beam is an I-beam or a welded box beam, which is inserted into the track frame hole. The track frame usually adopts an open "∏" cross section at the bottom, and the two ends are fork-shaped to install the drive wheels. , Guide wheels and supporting wheels.

The advantage of the combined walking frame is when it is necessary to change the stability of the excavator and reduce the ground pressure. It is not necessary to change the structure of the underframe to install a widened beam and a lengthened crawler frame, thereby installing crawlers of different lengths and widths. His shortcomings are that the cross-section of the track frame is weakened more, the rigidity is poor, and the weakened section is prone to cracks.

constitute

The gearbox is composed of two parts: a variable speed transmission mechanism and a variable speed control mechanism. The main function of the variable speed transmission mechanism is to change the value and direction of torque and speed; the main function of the control mechanism is to control the transmission mechanism to realize the change of the transmission ratio, that is, to realize the gear shift to achieve the variable torque.

Structural features

The simple transmission has the advantages of high efficiency, simple structure and convenient use, but it has a small number of gears and a small range of i (small traction and speed range). It is only suitable for some car workers with few gears. If the range of i is increased, the size of the transmission is increased and the shaft span is increased. In order to increase the number of gears without making the shaft span too large, a component transmission can be used. The so-called component transmission is usually composed of two simple transmissions. The one with more gears is called the main transmission, and the less one is called the auxiliary transmission.

The excavator uses a diesel engine to convert the chemical energy of diesel fuel into mechanical energy. The hydraulic plunger pump converts the mechanical energy into hydraulic energy. The hydraulic energy is distributed to the various executive components (hydraulic cylinder, slewing motor + reducer, walking motor + Reducer), the hydraulic energy is converted into mechanical energy by the various actuators to realize the movement of the working device, the rotary movement of the slewing platform, and the walking movement of the whole machine.

The transmission form of the slewing device of the full-rotation hydraulic excavator includes direct transmission and indirect transmission.

1. Direct transmission. Install a driving pinion on the output shaft of a low-speed high-torque hydraulic motor to mesh with the rotating gear.

2. Indirect transmission. An indirect transmission structure in which a high-speed hydraulic motor drives a rotary ring gear through a gear reducer. It has a compact structure, a large transmission ratio, and the force of the gear is better. The axial piston hydraulic motor has basically the same structure as the same type of hydraulic oil pump, and many parts can be used in common, which is convenient for manufacturing and maintenance, thereby reducing the cost. However, a brake must be installed to absorb the larger rotational moment of inertia, shorten the operating cycle time of the excavator, and improve production efficiency.

Turntable structure

The main load-bearing part of the turntable is the main beam 3 of the phase frame structure welded by steel plates with great torsion and bending rigidity. The boom and its hydraulic cylinder are supported on the lugs 1 of the main beam. Large excavators use double lugs for boom support, while small excavators use single lugs. There are lining plates and supporting rings 2 under the main beam, which are connected with the slewing support, and small frames are welded on the left and right sides as additional bearing parts.

The flange of the wheel edge of the support roller supports the crawler belt to prevent the crawler belt from falling off laterally. In order to arrange several rollers on a limited length, several of the rollers are often made without outer flanges, and the rollers with or without outer flanges are arranged alternately.

The lubricating grease for lubricating the sliding bearing and the oil seal is added from the screw plug hole in the middle of the roller body, usually only once during a major repair period, which simplifies the usual maintenance work of the excavator.