Gearboxes have a wide range of applications, such as in wind turbines. Gearboxes are an important mechanical component that is widely used in wind turbines. Its main function is to transfer the power generated by the wind wheel under the action of the wind to the generator and make it get the corresponding speed.

Generally, the speed of the wind wheel is very low, which is far from the speed required by the generator to generate electricity. It must be achieved through the speed-increasing effect of the gear pair of the gearbox, so the gearbox is also called the speed-increasing box.

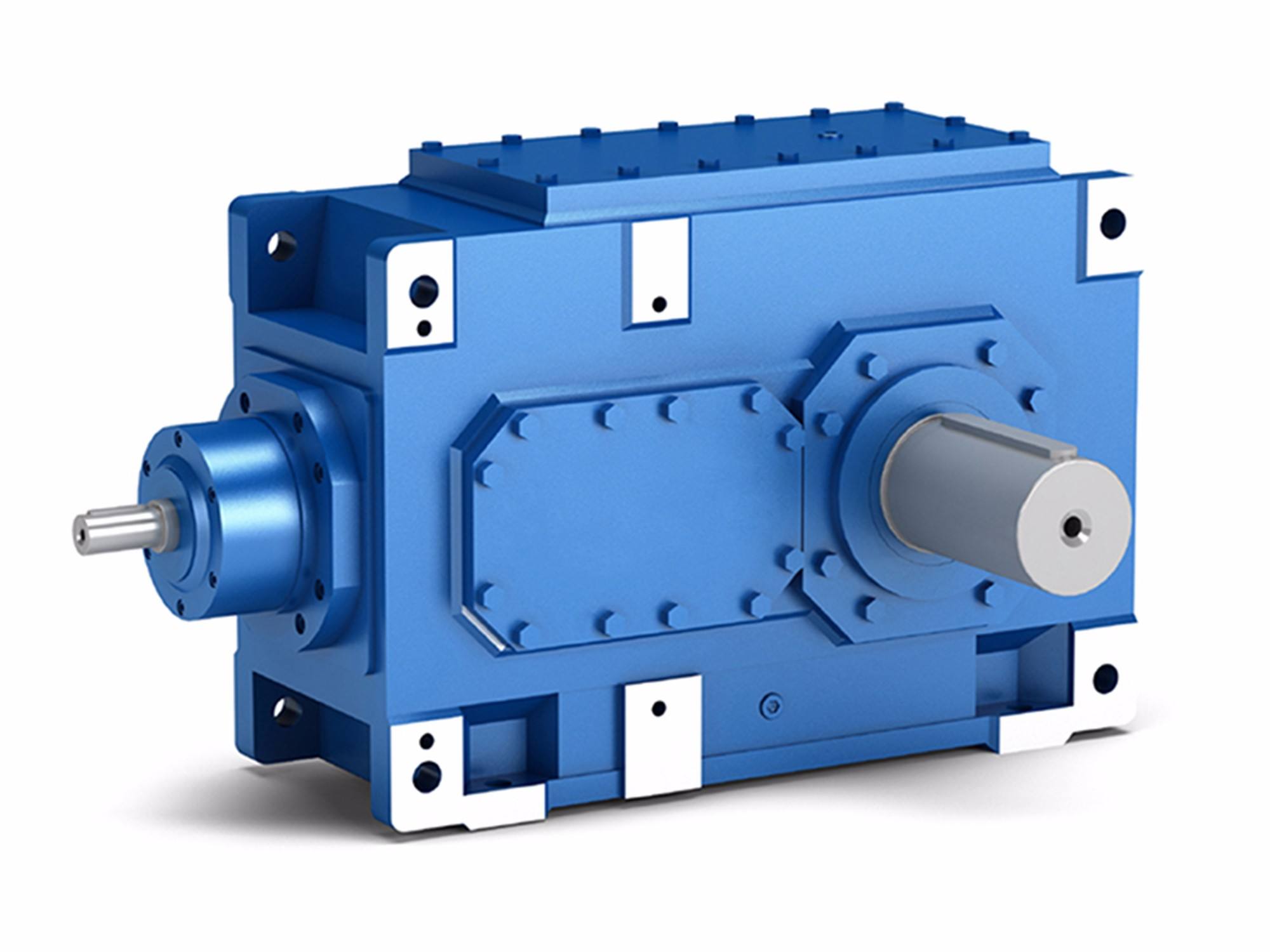

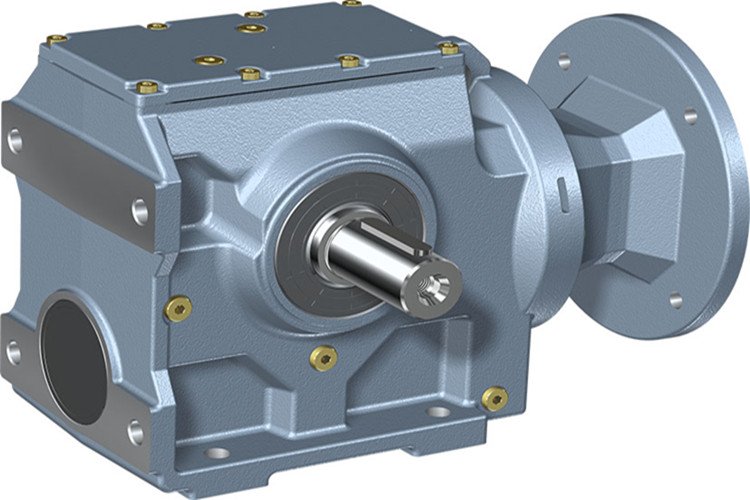

The gear box bears the force from the wind wheel and the reaction force generated during gear transmission, and must have sufficient rigidity to withstand the action of force and torque, prevent deformation and ensure transmission quality. The design of the gearbox housing should be carried out in accordance with the requirements of the wind turbine power transmission layout, processing and assembly conditions, and ease of inspection and maintenance. With the rapid development of the gearbox industry, more and more industries and different companies have used gearboxes, and more and more companies have developed and grown in the gearbox industry.

The gearbox is based on the modular design principle of the unit structure, which greatly reduces the types of parts and components, and is suitable for large-scale production and flexible selection. The spiral bevel gears and helical gears of the reducer are made of high-quality alloy steel by carburizing and quenching. The tooth surface hardness is as high as 60±2HRC, and the tooth surface grinding accuracy is as high as 5-6.

The bearings of the transmission parts are all domestic well-known brand bearings or imported bearings, and the seals are skeleton oil seals; the structure of the suction box, the larger surface area of the cabinet and the large fan; reduce the temperature rise and noise of the whole machine, and improve the reliability of operation , The transmission power increases. It can realize parallel shaft, right-angle shaft, vertical and horizontal general box. The input methods include motor connection flange and shaft input; the output shaft can be output at right angles or horizontally. Solid shaft and hollow shaft, flange type output shaft are available . The gearbox can meet the installation requirements of a narrow space, and can also be supplied according to customer needs. Its volume is 1/2 smaller than that of a soft-tooth gearbox, its weight is reduced by half, its service life is increased by 3 to 4 times, and its carrying capacity is increased by 8 to 10 times. Widely used in printing and packaging machinery, three-dimensional garage equipment, environmental protection machinery, conveying equipment, chemical equipment, metallurgical mining equipment, iron and steel power equipment, mixing equipment, road construction machinery, sugar industry, wind power generation, escalator and elevator drives, shipbuilding, light High-power, high-speed ratio, high-torque occasions such as industrial field, papermaking field, metallurgical industry, sewage treatment, building materials industry, lifting machinery, conveyor line, assembly line, etc. It has a good price-performance ratio and is conducive to the matching of localized equipment.

The gearbox has the following functions:

1. Accelerate and decelerate, which is often referred to as a variable speed gearbox.

2. Change the transmission direction. For example, we can use two sector gears to transmit the force vertically to the other rotating shaft.

3. Change the rotating torque. Under the same power condition, the faster the gear rotates, the smaller the torque on the shaft, and vice versa.

4. Clutch function: We can separate the engine from the load by separating the two originally meshed gears. Such as brake clutch and so on.

5. Distribution of power. For example, we can use one engine to drive multiple slave shafts through the main shaft of the gearbox, so as to realize the function of one engine driving multiple loads.

how much gearbox oil do i need?

Gearbox oil is an oil product that keeps the gearshift system clean, and can play a role in ensuring the normal operation of the gearbox and prolonging the life of the transmission device.

Transmission fluid can basically be used in automatic transmissions on the market. In fact, the design of each automatic transmission has different technical requirements. Even if the same type of transmission is configured in different models, its torque, weight, and speed , Structure, etc. will be different, so the original factory has its own designated special transmission oil. And different transmission oils are one of the reasons that affect the quality of shifting.

The most fundamental difference is the difference in the friction system. HFM-ATF has finer oil molecules and high-efficiency anti-shearing ability. In the semi-clutched state or at the moment of bonding, the oil film acting on the surface of the friction material can play a role. It slips to a very effective suspension state, which can cushion the momentary powerful impact, make the combination smoother and the shift smoother. At the same time, the delicate oil molecules greatly reduce the valve stuck phenomenon and make the valve body work more smoothly.

Transmission oil is an oil product that keeps the gearshift system clean. It serves to lubricate and prolong the life of the transmission. It has a very effective lubrication effect even at low temperatures and reduces oil loss under severe operating conditions. According to the different transmission structure, transmission oil is divided into automatic transmission oil and manual transmission oil.

Why do I need to change the transmission oil regularly?

It should be noted that the automatic transmission oil specified by the manufacturer must be replaced when changing the oil. This is because the internal structure, friction components and sealing components of different automatic transmissions will be different. The original factory oil is based on the transmission The structure and materials of the tank are specially formulated, and other brands of oil may not be suitable even if the quality is good.

In addition, some old oil will remain in the oil passage of the gearbox and the torque converter when changing the gearbox oil. When different oils are added, after two different oils are mixed inside the automatic gearbox, It may reduce the performance of the automatic transmission oil, causing serious damage to the automatic transmission due to malfunctions such as poor lubrication or abnormal operation of the automatic transmission.

Gear oil should have good anti-wear, load-resistant performance and suitable viscosity. In addition, it should also have good thermal oxidation stability, anti-foaming properties, water separation properties and anti-rust properties. Since the gear load is generally above 490 megapascals (MPa), and the hyperbolic tooth surface load is as high as 2942MPa, the amount of gear oil accounts for about 6% to 8% of the total lubricating oil. Gear oil is a lubricating oil with excellent performance.

Gear oil is mainly based on petroleum lubricating oil base oil or synthetic lubricating oil, and is an important lubricating oil prepared by adding extreme pressure anti-wear agent and oiliness agent. Used in various gear transmissions to prevent tooth surface wear, scratches, sintering, etc., to extend its service life and improve the efficiency of power transmission. The load of the hyperbolic tooth surface is as high as 2942MPa. To prevent the wear and abrasion of the tooth surface caused by the rupture of the oil film, extreme pressure anti-wear agents are often added to the gear oil, and sulfur-phosphorus or sulfur-phosphorus-nitrogen additives are commonly used.

Gear oil generally requires the following 6 basic properties:

1. Appropriate viscosity and good viscosity-temperature, viscosity is the most basic performance of gear oil. The viscosity is large, the lubricating oil film formed is thicker, and the anti-load capacity is relatively large.

2. Sufficient extreme pressure and wear resistance

Extreme pressure and anti-wear properties are the most important properties and main characteristics of gear oils.

It depends on the performance of preventing the tooth surface from wearing, scratching and bonding during the movement.

Anti-wear and load-resistance performance Because the gear load is generally above 490MPa, and the hyperbolic tooth surface load is as high as 2942MPa, in order to prevent the rupture of the oil film from causing tooth surface wear and scratches, extreme pressure anti-wear agents are generally added to the gear oil. In the past, sulfur-chlorine type, sulfur-phosphorus-chlorine type, sulfur-chlorine-phosphorus-zinc type, sulfur-lead type and sulfur-phosphorus-lead type additives were commonly used. Sulfur-phosphorus or sulfur-phosphorus-nitrogen type additives are commonly used.

3. Good demulsibility

The emulsification and deterioration of gear oil in contact with water will seriously affect the formation of lubricating oil film and cause scratches and wear.

4. Good oxidation stability and thermal stability

Good thermal oxidation stability guarantees the service life of the oil.

5. Good anti-foaming property

The generated foam cannot disappear quickly, which will affect the formation of the oil film at the gear mesh. The entrained foam will reduce the actual working oil and affect the heat dissipation.

6. Good rust and corrosion resistance

Corrosion and rust not only destroy the geometric characteristics and lubrication state of the gear, but the products of corrosion and rust will further cause the deterioration of the gear oil, resulting in a vicious circle.

Gear oil should also have other properties, such as adhesion and shear stability. At present, most of the extreme pressure additives used in my country's medium and heavy-duty industrial gear oils are mainly sulfur-phosphorus type and the quality level of similar foreign products is comparable.

Working conditions:

The contact area between gears is very small, basically line contact, and there is both rolling friction and sliding friction during the movement. In this way, the working conditions of gear oil are very different from other lubricating oils. Due to the small contact area between the gears, the pressure it bears is great. The tooth surface pressure of reducer gears of some heavy-duty machinery can reach 400-1 000 MPa. The use conditions of hyperbolic gears in automobile transmissions are more demanding and the load is heavier. The pressure at the contact parts can be as high as 1000-4 000 MPa. Under such a high pressure, the lubricating oil is easily squeezed out from between the teeth, and it is easy to cause scratches and wear on the tooth surface. For this reason, the gear oil must have the performance of keeping the tooth surface in a state of boundary lubrication and elastohydrodynamic lubrication under high load.

Proper viscosity is the main quality indicator of gear oil. A high viscosity has a high load-bearing capacity, but too high a viscosity will also bring difficulties to circulating lubrication, increase the movement resistance of the gear, and cause heat to cause power loss. Therefore, the viscosity should be appropriate, especially for oils with extreme pressure antiwear agents. The load resistance performance of these oils mainly depends on extreme pressure antiwear agents, and the viscosity of such oils should not be too high. It must have good thermal oxidation stability, good wear resistance, load resistance, good anti-foam performance, good anti-emulsification performance, good rust and corrosion resistance, and good shear stability.

effect:

(1) Lubricate the transmission system, reduce the wear of gears and other moving parts, ensure the normal movement of the transmission system, and extend the service life.

(2) Reduce the friction and transmission loss of the gear transmission servo, and improve the mechanical efficiency.

(3) Cool the transmission parts. Gear transmission, due to the contact friction of the tooth surface, will generate a lot of heat. If it is not dissipated in time, it will cause high temperature locally on the tooth surface. In severe cases, it will also cause ablation and bonding. The gear oil continuously takes away the heat during the circulation lubrication process, and radiates it through the air and the transmission mechanism housing to ensure the normal operation of the transmission components.

(4) Prevent corrosion and rust.

(5) Reduce tooth surface impact and transmission noise.

(6) Gear oil has a washing effect and can continuously wash away the contaminants and solid particles on the surface of the gear.

use

1.Accelerate and decelerate, which is often referred to as a variable speed gearbox.

2. Change the transmission direction, for example, we can use two sector gears to transmit the force to the other rotating shaft vertically.

3. Change the rotating torque. Under the same power condition, the faster the speed of the gear, the smaller the torque on the shaft, and vice versa.

4. Clutch function: We can achieve the purpose of separating the engine from the load by separating the two originally meshed gears. For example, the brake clutch and so on.

5. Power distribution. For example, we can use one engine to drive multiple slave shafts through the gearbox main shaft, so as to realize the function of one engine to drive multiple loads.