how often should gearbox oil be changed?

The oil change period and oil change index of industrial gear oil is a more complicated problem, which is related to the gear running-in condition, the load of the gear, the type and quality of the gear oil, and the importance of the lubrication parts in the machinery. Generally speaking, gearboxes that use less oil can be changed regularly based on practical experience. For example, the American gear manufacturer (AGMA) stipulates that the oil should be changed within 6 months under normal conditions. For the imported reducer that does not directly contact water, the user manual stipulates that the oil should be changed from 4000h to 5000h. Due to different operating conditions, it may be as short as 2000h and as long as 8000h. These regulations generally have a considerable insurance factor.

An oil standard can be viewed. When the oil standard is red and bai (liquid level is low), it needs to be refueled. According to the performance and material of the product, it is generally cleaned and changed every six months. If the oil is refilled, it must be checked every month. ,According to the actual situation.

Replacement steps:

1. Wear work clothes neatly and prepare tools;

2. Align and place the waste oil receiving container under the oil drain bolt at the bottom of the engine;

3. Unscrew the oil filler cap on the top of the engine by hand;

4. Remove the oil drain bolt of the oil pan and start to release the old engine oil;

5. Check whether there is any abnormal metal attachment on the oil drain bolt, and remind the customer or suggest a solution;

6. Clean up the debris and impurities on the oil drain bolt with oil absorbent tissue, and wipe it clean;

7. Disassemble the old filter and dry the oil stains on the filter seat with oil-absorbent tissue paper;

8. Apply engine oil on the filter seal ring of the new machine, and fill the new machine filter with new engine oil;

9. Install and tighten the new filter by hand, and then tighten it three to four turns with the filter wrench;

10. After the old engine oil is completely released, wipe off the oil stains around the oil drain port and install the return oil bolt;

11. Use a clean funnel to fill in new oil from the oil filling port on the top of the engine;

12. After adding to the rated oil volume, wait for 3-5 minutes to pull out the oil dipstick to check, and control the oil volume between the upper and lower scales;

13. Wipe clean the engine oil filler port and surrounding oil stains with oil absorbent tissue, install the oil port cap and tighten it;

14. Start the engine, check the oil pressure, machine filter, oil drain bolt, etc. for oil and gas leakage, and check whether the working conditions of other related parts are normal;

15. After the engine has been idling for 5-15 minutes, pull out the oil dipstick and check again.

Gear oil mainly refers to the lubricating oil of the transmission and rear axle. There are differences between it and engine oil in terms of use conditions, its own composition and performance. Gear oil mainly plays the role of lubricating gears and bearings, preventing wear and corrosion, and helping gears to dissipate heat.

Automobile gear oil is used in gear transmission mechanisms such as automobile steering gears, transmissions, and drive axles. Due to the high surface pressure during gear transmission, gear oils provide lubrication, anti-wear, cooling, heat dissipation, anti-corrosion and anti-rust, washing and gear reduction of gears. Surface impact and noise play an important role.

Introduction:

Gear oil should have good anti-wear, load-resistant performance and suitable viscosity. In addition, it should also have good thermal oxidation stability, anti-foaming properties, water separation properties and anti-rust properties. Since the gear load is generally above 490 MPa (MPa), and the hyperbolic tooth surface load is as high as 2942 MPa, the amount of gear oil accounts for about 6% to 8% of the total amount of lubricating oil. Gear oil is a lubricating oil with excellent performance.

Gear oil is mainly based on petroleum lubricating oil base oil or synthetic lubricating oil, and is an important lubricating oil prepared by adding extreme pressure antiwear agent and oiliness agent. Used in various gear transmissions to prevent tooth surface wear, scratches, sintering, etc., to extend its service life and improve the efficiency of power transmission. The load of the hyperbolic tooth surface is as high as 2942MPa. In order to prevent the wear and abrasion of the tooth surface caused by the rupture of the oil film, extreme pressure anti-wear agents are often added to the gear oil, and sulfur-phosphorus or sulfur-phosphorus-nitrogen additives are commonly used.

Working conditions:

The contact area between gears is very small, basically line contact, and there is both rolling friction and sliding friction during the movement. In this way, the working conditions of gear oil are very different from other lubricating oils. Due to the small contact area between the gears, the pressure it bears is great. The tooth surface pressure of reducer gears of some heavy-duty machinery can reach 400-1 000 MPa. The use conditions of hyperbolic gears in automobile transmissions are more demanding and the load is heavier. The pressure at the contact parts can be as high as 1000-4 000 MPa. Under such a high pressure, the lubricating oil is easily squeezed out from between the teeth, and it is easy to cause scratches and wear on the tooth surface. For this reason, the gear oil must have the performance of keeping the tooth surface in a state of boundary lubrication and elastohydrodynamic lubrication under high load.

Proper viscosity is the main quality indicator of gear oil. A high viscosity has a high load-bearing capacity, but too high a viscosity will also bring difficulties to circulating lubrication, increase the movement resistance of the gear, and cause heat to cause power loss. Therefore, the viscosity should be appropriate, especially for oils with extreme pressure antiwear agents. The load resistance performance of these oils mainly depends on extreme pressure antiwear agents, and the viscosity of such oils should not be too high. It must have good thermal oxidation stability, good wear resistance, load resistance, good anti-foam performance, good anti-emulsification performance, good rust and corrosion resistance, and good shear stability.

In addition, there are other performance requirements, such as good low temperature fluidity, adaptability to sealing materials, storage stability, open gear oils also require adhesion, etc.

effect:

(1) Lubricate the transmission system, reduce the wear of gears and other moving parts, ensure the normal movement of the transmission system, and extend the service life.

(2) Reduce the friction and transmission loss of the gear transmission servo, and improve the mechanical efficiency.

(3) Cool the transmission parts. Gear transmission, due to the contact friction of the tooth surface, will generate a lot of heat. If it is not dissipated in time, it will cause high temperature locally on the tooth surface. In severe cases, it will also cause ablation and bonding. The gear oil continuously takes away the heat during the circulation lubrication process, and radiates it through the air and the transmission mechanism housing to ensure the normal operation of the transmission components.

(4) Prevent corrosion and rust.

(5) Reduce tooth surface impact and transmission noise.

(6) Gear oil has a washing effect and can continuously wash away the contaminants and solid particles on the surface of the gear.

Gear oil generally requires the following 6 basic properties:

1. Appropriate viscosity and good viscosity-temperature, viscosity is the most basic performance of gear oil. The viscosity is large, the lubricating oil film formed is thicker, and the anti-load capacity is relatively large.

2. Sufficient extreme pressure and wear resistance

Extreme pressure and anti-wear properties are the most important properties and main characteristics of gear oils.

It depends on the performance of preventing the tooth surface from wearing, scratching and bonding during the movement.

Anti-wear and load-resistance performance Because the gear load is generally above 490MPa, and the hyperbolic tooth surface load is as high as 2942MPa, in order to prevent the rupture of the oil film from causing tooth surface wear and abrasion, extreme pressure anti-wear agents are generally added to the gear oil. In the past, sulfur-chlorine type, sulfur-phosphorus-chlorine type, sulfur-chlorine-phosphorus-zinc type, sulfur-lead type and sulfur-phosphorus-lead type additives were commonly used. Sulfur-phosphorus or sulfur-phosphorus-nitrogen type additives are commonly used.

3. Good demulsibility

The emulsification and deterioration of gear oil in contact with water will seriously affect the formation of lubricating oil film and cause scratches and wear.

4. Good oxidation stability and thermal stability

Good thermal oxidation stability guarantees the service life of the oil.

5. Good anti-foaming property

If the generated foam cannot disappear quickly, it will affect the formation of the oil film at the gear mesh. The entrained foam will reduce the actual working oil and affect the heat dissipation.

6. Good rust and corrosion resistance

Corrosion and rust not only destroy the geometric characteristics and lubrication state of the gear, but the products of corrosion and rust will further cause the deterioration of the gear oil, resulting in a vicious circle.

Gear oil should also have other properties, such as adhesion and shear stability. At present, most of the extreme pressure additives used in my country's medium and heavy-duty industrial gear oils are mainly sulfur-phosphorus type and the quality level of similar foreign products is comparable.

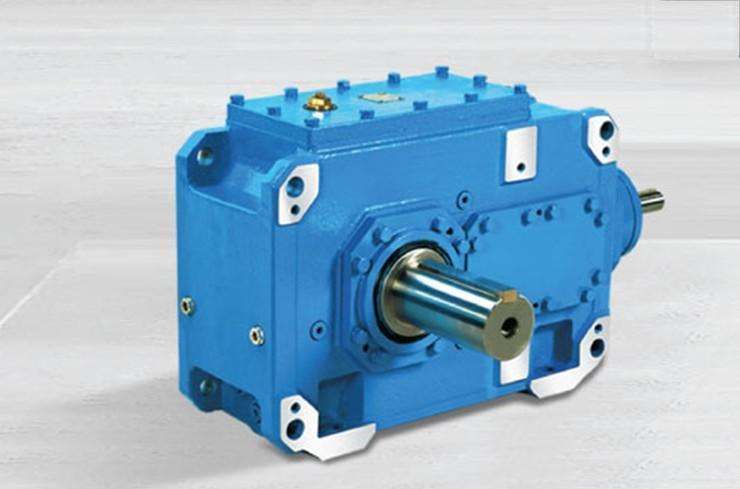

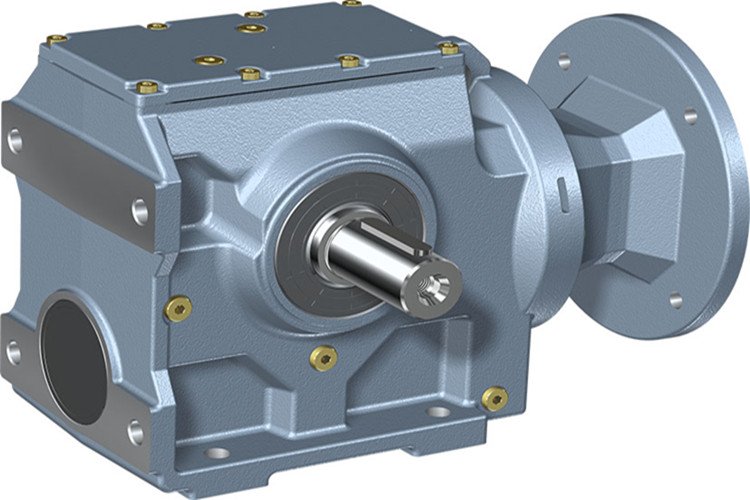

Gearboxes have a wide range of applications, such as in wind turbines. Gearboxes are an important mechanical component that is widely used in wind turbines. Its main function is to transmit the power generated by the wind wheel under the action of the wind to the generator and make it get the corresponding speed.

Generally, the speed of the wind wheel is very low, which is far from the speed required by the generator to generate electricity. It must be achieved through the speed-increasing effect of the gear pair of the gearbox, so the gearbox is also called the speed-increasing box.

The gearbox has the following functions:

1. Accelerate and decelerate, which is often referred to as a variable speed gearbox.

2. Change the transmission direction. For example, we can use two sector gears to transmit the force vertically to the other rotating shaft.

3. Change the rotating torque. Under the same power condition, the faster the gear rotates, the smaller the torque on the shaft, and vice versa.

4. Clutch function: We can separate the engine from the load by separating the two originally meshed gears. Such as brake clutch and so on.

5. Distribution of power. For example, we can use one engine to drive multiple slave shafts through the main shaft of the gearbox, so as to realize the function of one engine driving multiple loads.

The bearings of the transmission parts are all domestic well-known brand bearings or imported bearings, and the seals are skeleton oil seals; the structure of the suction box, the larger surface area of the cabinet and the large fan; reduce the temperature rise and noise of the whole machine, and improve the reliability of operation , The transmission power increases. It can realize parallel shaft, right-angle shaft, vertical and horizontal general box. The input methods include motor connection flange and shaft input; the output shaft can be output at right angles or horizontally. Solid shaft and hollow shaft, flange type output shaft are available . The gearbox can meet the installation requirements of a narrow space, and can also be supplied according to customer needs. Its volume is 1/2 smaller than that of a soft-tooth gearbox, its weight is reduced by half, its service life is increased by 3 to 4 times, and its carrying capacity is increased by 8 to 10 times. Widely used in printing and packaging machinery, three-dimensional garage equipment, environmental protection machinery, conveying equipment, chemical equipment, metallurgical mining equipment, iron and steel power equipment, mixing equipment, road construction machinery, sugar industry, wind power generation, escalator and elevator drives, shipbuilding, light High-power, high-speed ratio, high-torque occasions such as industrial field, papermaking field, metallurgical industry, sewage treatment, building materials industry, lifting machinery, conveyor line, assembly line, etc. It has a good price-performance ratio and is conducive to the matching of localized equipment.