Since 1913, Marathon Electric has been dedicated to providing customers with quality products for targeted applications. Headquartered in Wausau, Wisconsin USA, the company is composed of two strategic product lines: Motors and Generators.

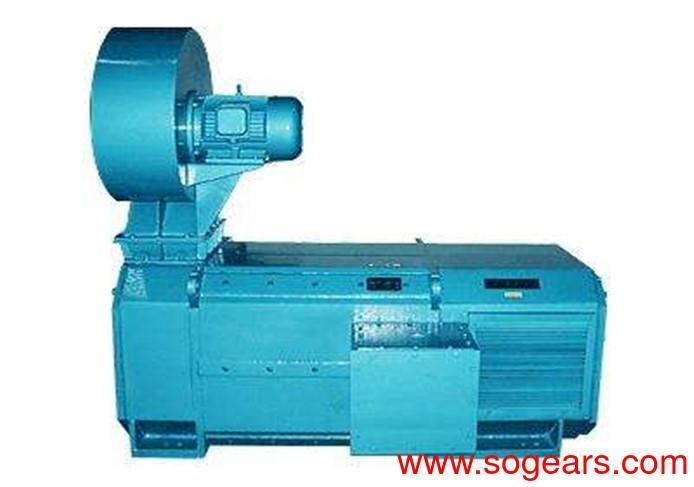

In India, Marathon Electric delivers efficient mechanical power solutions using AC & PM electric motors up to 5.6MW. Marathon Electric India has manufacturing facilities, Marathon Electric India Pvt Ltd at Faridabad & Marathon Electric Motors (India) Ltd at Kolkata.& Marathon Electric Motors(India) Ltd at Ahmedabad.Together, Marathon Electric in India is the Largest Manufacturer & Exporter of Motors. Our strategic product lines include motors and Fans. Our range of Fractional Horsepower motors serves applications such as Heating, Ventilating, Air-conditioning & Commercial Refrigeration (HVAC), General Purpose Applications, Evaporative Coolers & Cooler Kits, Washing Machines & Wet Rice Grinders. Our Integral Horsepower motors range upto 11KV serving a wide range of applications such as pumps, compressors, fans, crushers, conveyors, kilns etc.We also manufacture Propeller, Axial Flow and Centrifugal Flow type of industrial fans used for various purposes.

About Marathon

This commitment is manifested throughout all stages of the manufacturing cycle. From new model development to after-sales service, SKF provides the highest levels of expertise, manufacturing quality and customer service - from concept to utilization.

Learn more about SKF's complete offering for electric motors:

-

SKF helps electric motors manufacturers in achieving the tough demands per each consumer goods motor design.

-

Vehicle include a vast range of electrical accessories.

-

SKF has developed a portfolio of innovative solutions for the electric and hybrid vehicle market that enable robust and efficient E-powertrain drive.

Since 1913, Marathon Electric has been dedicated to providing customers with quality products for targeted applications. Headquartered in Wausau, Wisconsin USA, the company is composed of two strategic product lines: Motors and Generators.

In India, Marathon Electric delivers efficient mechanical power solutions using AC & PM electric motors up to 5.6MW. Marathon Electric India has manufacturing facilities, Marathon Electric India Pvt Ltd at Faridabad & Marathon Electric Motors (India) Ltd at Kolkata.& Marathon Electric Motors(India) Ltd at Ahmedabad.Together, Marathon Electric in India is the Largest Manufacturer & Exporter of Motors. Our strategic product lines include motors and Fans. Our range of Fractional Horsepower motors serves applications such as Heating, Ventilating, Air-conditioning & Commercial Refrigeration (HVAC), General Purpose Applications, Evaporative Coolers & Cooler Kits, Washing Machines & Wet Rice Grinders. Our Integral Horsepower motors range upto 11KV serving a wide range of applications such as pumps, compressors, fans, crushers, conveyors, kilns etc.We also manufacture Propeller, Axial Flow and Centrifugal Flow type of industrial fans used for various purposes.

Electric motors and generators

Looking for a uniquely qualified solutions provider?

Tap into the power of SKF

SKF is helping OEMs meet increasing demands for higher quality products, shorter delivery times, and improved technical support. For end-users, SKF tools, technologies and services are driving overall efficiency and reducing total operating costs. From catalogue and forklift motors to very large electric motors, SKF solutions can help:- Increase efficiency

- Reduce maintenance

- Extend service life

- Reduced risk of current damage

- Improve technical support

-

SKF has a long and vast experience in the electric motor industry. In this highly competitive industry, the profound knowledge of SKF has been used to develop solutions to meet the ever increasing demands for higher quality, shorter delivery times, lower noise levels and improved technical support.

In addition to a wide range of bearings and solution products, customers also have access to excellent engineering services that only SKF can provide. These services could help you build additional value into the motor design and decrease the total cost over time.

Discover how SKF helps electric motors manufacturers in achieving the tough demands per each consumer goods motor design.

SKF understands your requirements for low noise, silent running, long life, high quality, energy saving, less friction and space saving. SKF bearings are at the very heart of the answer.

Worldwide availability of SKF products is supported by a comprehensive technical advisory service. In committing itself to excellence in products and performance, SKF puts at the service of appliance industry its expertise acquired through years of research and commitment in every industrial segment, from automotive to aerospace, from heavy industry to consumer goods.

This commitment is manifested throughout all stages of the manufacturing cycle. From new model development to after-sales service, SKF provides the highest levels of expertise, manufacturing quality and customer service - from concept to utilization.

Marathon in India is also well known for its brands Marathon,Genteq, AUE & CoolHome

Global Technology Center - India (GTCI)

Regal Beloit Global Technology Center - India, also known as GTCI is located at the very heart of the city of Hyderabad, the city of pearls. The technology center is the global hub for Engineering and Information Technology.

GTCI has world class facility with Engineering and IT teams working collaboratively with Regal Beloit locations globally. This center started its operations in August 2005. Since then the technological improvements and world class delivery has made GTCI a truly competitive advantage for Regal Beloit Corporation.

RBC Marathon Electric is part of Regal Beloit Corporation. Regal Beloit Corporation is a leading manufacturer of electrical and mechanical motion control and power generation products serving markets throughout the world. Regal Beloit is headquartered in Beloit, Wisconsin, and has manufacturing, sales, and service facilities throughout North America and in Mexico, Europe and Asia.

BEVI specializes in high quality energy-efficient electric motors. The combination of the best available materials, high quality sheet metal and the right amount of copper in the rotor/stator makes BEVI’s electric motors highly energy-efficient.

Please let us know your needs and we'll provide a suitable solution.

- Max push/pull load per unit 1000 kN

- Max speed 150 mm/s

- Acme screw length up to 6 m

- 2D / 3D drawings on the jacks

- Limit switches

- Stainless steel acme screw is available as an option

- Screw end, for example, travelling nut, threaded end, flange, attachment eye

We design our electric motors to fit and match our customer’s requirements at our production site. The electric motors can be supplemented with a range of options and accessories or modified with a special design to endure any environment

Read more about electric motors in the Knowledge bank

Fabrika is an electric motor specialist. We sell both Siemens electric motors and our own Fabrika range of electric motors, and we provide a wide range of accessories. We can also customise your motors so you avoid costly processes in your own production. This means that you only need to shop in one place.

We always give you a quick response, professional sparring and products of optimum quality – and you will always talk to a specialist when you call us.

To satisfy customer’s needs, ourproducts are certified by UL, CSA, CE, and CCC; and all materials in our products comply with RoHS requirements. Our lab has been certified by UL and CSA since 2007, being capable of performing UL/CSA certification test in house

With the continuous growth of GW's business, GW’s growing talent strategy that drives the business strategy. The headquarter of GW Industry moved to its new office on December 11. The new headquarter provides more modern, spacious office conditions and complete office facilities, as well as a more comfortable and pleasant office environment for staffs, laying a solid foundation for future sustainable development and continuous expansion of the company's strength. Sincerely hope GW’s business will flourish!

Looking back on the past, we have achieved outstanding results , looking forward to the future and we are full of pride. The new headquarter of GW Industry is a brand new beginning, we will open a new page. We believe that the new starting point will definitely bring us a completely different new world, let us actively improve ourselves, work together more unitedly, and work together for the company and for a better future.

New Headquarter Address: 3F, No. 647, East Longhua Road, Huangpu District, Shanghai,China

Electric motors for vehicles, machines and marine applications

Danfoss Editron electric drivetrains are based on synchronous reluctance assisted permanent magnet technology (SRPM). They are liquid-cooled and designed to work in harsh operating environments such as traction motor in heavy machinery or propulsion motor in marine applications. They can work both as a generator or as a motor.

Main product groups

Compared to conventional technologies, like induction machines (IM) or standard permanent magnet motors (PM), the electric SRPM motors offer smaller dimensions, lighter weight and higher efficiency.

The motors are available in various speed and torque ratings:

EM-PMI with power up to 1,000 kW – high torque with high efficiency

EM-PMI project based machines with power up to 6,000 kW – high torque with high efficiency

EM-PME outer rotor machines with power up to 50 kW – high torque with high efficiency

All permanent magnet motors can be tested with full load against the actual desired workload in our own test laboratory. We can feed the work load cycle of the machine into our testing system and run loading tests in the laboratory. This significantly reduces the testing time at your premises.

Applications

Traction motors for vehicles

Propulsion motors for marine vessels

Variable-speed generators for hybrid vehicle or marine vessels