Siemens electric motor works (B) pricing interdisional sales.

Examines siemens electric motor for pricing products transferred between the manufacturing and sales divisions of their Electric Motor Works, where both are profit centers. It is unique in that the organizational linkage between the product costing system and the transfer pricing system is highlighted. The issues raised center around the behavior induced by the transfer pricing system coupled with each manager's incentive to increase divisional profits. In addition the students will have an opportunity to discuss the appropriateness of both the transfer pricing system and the profit center structure of the organization.

Technology development has been long considered to be a primary factor for establishing a competitive edge. This paper deals with dynamic patterns of the technology development and strategic changes of Siemens VDO Electric Motor Co. in China, focusing on the technology development project in the company. The purpose of this paper is to find underlying principles in successfully managing technology development projects which involve collaborative efforts in the context of MNC in developing countries. For this purpose, this paper takes a system-analytic approach to the innovation process and strategic changes. From the process perspective, it explains dynamics of the technology development process of Siemens VDO Electric Motor Co. in China and its strategic changes along various development stages. From the strategy perspective, some underlying principles behind the successful technology development process are identified: the focused-and-phased, the buy-for-make, and the harmonized collaboration-and-competition approaches.

Explores how a cost system can help support a firm's decision to change strategies. In the process, students are exposed to a simple activity-based cost system. Also examines siemens electric motor policy for transferring products between sales and manufacturing divisions. Transfer pricing is based on standard costs generated from their cost system. The case is unique in that the organizational linkage between the product costing system and the transfer pricing system is explored.Siemens electric motor works (A) and (B) combined process oriented costing.

The siemens electric motor has a housing with a rotor which is rotatably movable along a rotary axis, and a fan. A stator winding has a winding end which extends parallel to a direction of a motor rotary axis, where the fan and the winding end face each other freely. The housing has inlet/outlet openings for cooling air conveyed from the fan, where the length of the outlet openings corresponds to an axial length of the fan, along the motor rotary axis. An independent claim is also included for a kitchen appliance comprising an electric motor.

Siemens electrical protection of large synchronous motor and protection unit ontology parameter configuration were introduced briefly. After 2 years of operation observation and accident analysis, find protection configuration is not reasonable, and can't meet the production needs. According to the production field of power system and the actual situation of the equipment operation, some of the motor protection configuration is optimized and the fixed value parameter changes, to ensure the safe and stable operation of equipment.

The system has a motor , electric machine e.g. generator and power electronics e.g. converter for the electrical machine. The motor, electric machine and power electronics are arranged in a common housing . The siemens electric motor is coupled with the electric machine over a shaft, belt, string or gearing. The common interfaces are provided to supply electrical power from external power source and to supply cooling water, respectively. An independent claim is included for motor vehicle.

Since the Modbus RTU wired communication protocol of Siemens variable frequency motors is unstable and lacks a protection mechanism, there is a risk of user information leakage. Aiming at the problems of insufficient flexibility of traditional defense methods and poor defense effects, The present work proposed a new dual detection method based on MODBUS RTU, which combines the dual monitoring mechanism of "Address Resolution Protocol (ARP) request detection" and "ARP response detection". In order to improve detection efficiency, two real-time updated linear tables are introduced, which can effectively deal with the three ARP spoofing methods of updating the ARP buffer. Based on the analysis of the hidden dangers of the Modbus RTU wired communication protocol, a wired connection between the S7-1200 PLC and the variable frequency motor was established, and a real experimental platform was constructed to demonstrate the attack. The intensity of ARP attacks has gradually increased over time.

Since the Modbus RTU wired communication protocol of siemens electric motor is unstable and lacks a protection mechanism, there is a risk of user information leakage. Aiming at the problems of insufficient flexibility of traditional defense methods and poor defense effects, The present work proposed a new dual detection method based on MODBUS RTU, which combines the dual monitoring mechanism of "Address Resolution Protocol (ARP) request detection" and "ARP response detection". In order to improve detection efficiency, two real-time updated linear tables are introduced, which can effectively deal with the three ARP spoofing methods of updating the ARP buffer. Based on the analysis of the hidden dangers of the Modbus RTU wired communication protocol, a wired connection between the S7-1200 PLC and the variable frequency motor was established, and a real experimental platform was constructed to demonstrate the attack. The intensity of ARP attacks has gradually increased over time.

In this paper, an electric vehicle drive with a robust and low cost alternating current (AC) induction motor is presented. This approach is applied to an existing commercial utility electric vehicle where previously used direct current (DC) series motor was replaced by the new siemens electric motor. The use of three-phase squirrel cage induction motor requires implementing of voltage source inverter supplied by DC voltage from vehicle battery system. A new DSP based voltage inverter is designed for the proposed drive. The used processor realizes the field oriented control algorithm with torque and flux closed loop control. The proposed drive does not require speed sensor, which make the solution and reliable on speed sensor faults. Motor speed is computed by the processor using speed observer. In this paper system description, control algorithms realization, and speed computation are presented.

After decades of experience in fine-tuning the noise of internal combustion (IC) engines, a new challenge awaits the automotive industry : optimization of the powertrain sound in hybrid and electric vehicles. Although the overall noise level produced by an electric vehicle is significantly lower than for a classical IC-engined vehicle, electrical motor noise is marked by high- frequency components which can be perceived as annoying for both passengers and the environment. Therefore, the importance of predicting noise from electrical drives and motors has received renewed interest. This presentation will highlight how electromagnetic (EM) and vibroacoustic (VA) simulation tools can be coupled in order to predict and optimize the noise levels and frequency content of sound radiated by a typical electrical motor used in automotive drivetrains.

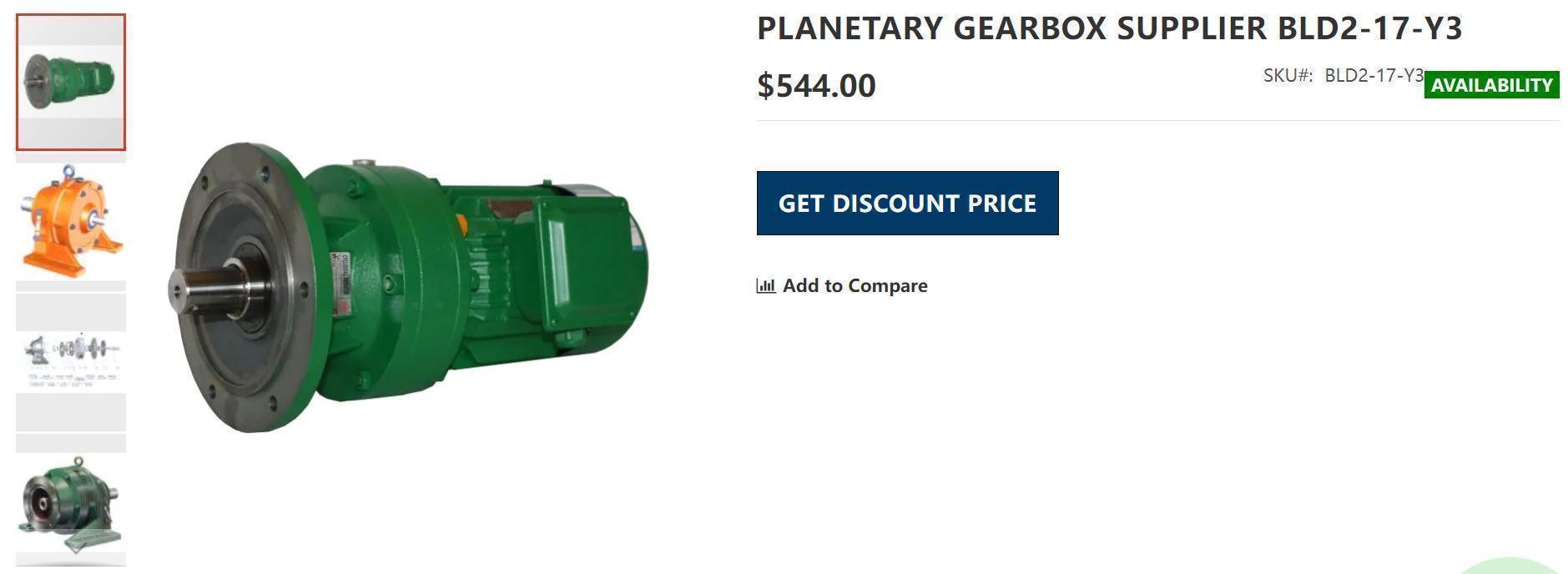

This work is focused to measurement and evaluation of mechanic, electric and control quantities and their potential usage in complex dynamic measurement of mechanisms. The servo motor signals like outputs from converter, control unit and controller were analyzed. The mechatronic stand was designed and assembled for realization of experiment. The mechatronic system included the Siemens Sinamics and Simotion systems together with three phase AC synchronous servo motor series 1FT6. Planetary gearbox, torsion bar and flywheel were connected to the servo motor output shaft. The servo motor operated with three different position functions: polynomial, harmonic and parabolic.

Explores how a cost system can help support a firm's decision to change strategies. In the process, the students are introduced to a simple activity-based cost system. Siemens Electric Motor Works found itself facing an increasingly competitive environment and so made a decision to move from mass production of specialty motors to the production of small lots of custom motors. In doing so, they found their old cost system led them to poor decision making. By switching to a simple activity-based system, more accurate product costs were computed, facilitating better divisional performance.

Hardware device structure of Siemens mine ventilator brushless synchronous motor electric control system and double close-loop control frame based on power factor cos φ and excitation current if were presented.Adjustment process of excitation current varying with load in time under constant power factor control was analyzed.Control programs about ready for start-up and stator power on and subsynchronous excitation on and off were analyzed.In addition,programs about ventilator operation parameter test,failure alarm and failure protection were analyzed.The paper gives some references to professional technicians.

A parking brake is disclosed, comprising a brake-actuating electric motor , a brake actuating output shaft driven by said electric motor and extending along a second axis , a brake-actuating linkage that is adjustably arranged parallel to a first axis that substantially extends perpendicularly to the second axis , and a drive connection from the brake-actuating output shaft to the brake-actuating linkage . The drive connection is configured in the form of a cam-type cam disk or gate guide that translates the rotation of the brake-actuating output shaft into a translational movement of the brake-actuating linkage through an adjusting element that is guided along a surface of the cam disk or gate guide forming a radial profile. The motor axis of the brake-actuating electric motor extends substantially perpendicular to the second axis.

A bushing structure 10 is constructed and arranged to be operatively associated with a shaft 24 of siemens electric motor. The motor has a housing 30 including a generally elliptical recess 32 therein defined along an axis C of the shaft. The bushing structure includes a generally cylindrical bushing member 12 constructed and arranged to engage an end of the shaft so as to locate the shaft with respect to the housing and to prevent lockup of the motor. An endplay member 20 is associated with the bushing member and with the end of the shaft. The endplay member includes a spherical portion constructed and arranged to be received in the elliptical recess so as to control endplay of the shaft.

A siemens electric motoris described for preventing the transmission of noisy vibration of the motor on vehicle body parts on which the motor is mounted by its motor housing. The motor housing is held by a carrier part that surrounds it. The carrier part is surrounded at a radial distance by a mounting part at least in some areas. The mounting part is connected to the carrier part by an elastic sound-absorbing intermediate layer that is subjected substantially to tensile stresses.

The main objective of this paper is to make a hardware/software system that could simulate an electric engine on a tablet with the Android operating system, having at our disposal the SIMATIC S7-1200 automate with the software program TIA Portal v11, implementing in this a PID for controlling the simulated electric motor. For simulating the siemens electric motor on the tablet we used components that implement physics functions provided by modern software instruments like Box2D library and Engine.

Methods, devices and computer program products automatically package an object, such as, for example, whole muscle meat pieces, in a covering material, such as, for example, netting. The devices include a pusher assembly, an electric motor, preferably a servo motor with a gear box, that drives a linear drive assembly. The devices can include a programmably adjustable index and/or speed profile for the pusher assembly.

In one aspect, a submarine with a boat hull and a propulsion drive for the submarine the propulsion drive is arranged outside the boat hull and comprises a housing and a first electric motor, with the housing embodying a channel for a flow of water through the channel in a main direction of flow from an inlet to an outlet of the channel, and with the first siemens electric motor featuring a rotor which is arranged in the channel and is supported rotatably around an axis of rotation in the housing, with the rotor being embodied in the shape of a ring with a ring inner side and a ring outer side, and with blades for propelling the submarine being arranged on the ring inner side of the rotor.

A multi-speed permanent magnet D.C. electric motor systemincludes at least one permanent magnet DC electric motorconfigured to operate at at least one speed. A current limiting device Ris constructed and arranged to lower electrical input power to the motorso that a speed of the motor is reduced, when the motor is powered together with the current limiting device, as compared to a speed of the motor powered absent the current limiting device. Switching structure K, K, Kis associated with the current limiting device to selectively operate the motor at at least three discrete speeds, even though the motor is configured for at least one-speed.

A primary part of siemens electric motor, in particular a linear motor, includes a modular block with a winding body and windings housed in a sealed housing. Cooling air flows through cooling channels around the windings and through tooth gaps in the winding body. The primary part can be produced by coating the housing and a cover with a sealing composition and embedding the modular block at least partially in the sealing composition. Alternatively, the primary part can be produced by embedding the winding region of the winding body first in a first molding composition, and subsequently in a second molding composition which has a higher melting point than the first molding composition. The first molding composition is then melted and removed. The thereby produced cavities form gas inlets and outlets and gas flow paths for air cooling the interior of the primary part.

The braking method uses field-oriented regulation of the current regulator supplying the siemens electric motor, with switching to a non field-oriented regulation upon failure of the orientation angle signal, in which measured motor currents are transformed into current vector values, combined with an impedance value for providing a set of voltage vector values used by the current regulator. An Independent claim for a device for braking an electric drive motor supplied via a current regulator is also included.

The invention relates to an electromotive drive comprising siemens electric motor, having a driving pinion which meshes with a toothed wheel to form a first gear speed. A worm is connected to an output shaft of the toothed wheel in a fixed manner, enabling a worm wheel to be driven. The worm and the worm wheel form a second gear speed, and the shaft of the worm wheel forms the output shaft of the electromotive drive. The output shaft of the electromotive drive can be rotatably driven between a starting position and an end position. When the siemens electric motor is not fed by a current, the output shaft of the toothed wheel can be rotatably driven by a pull-back spring in the rotational direction towards the starting position. The second gear speed is a non-self-locking gear speed.

The device has a motor , a drive regulator and an integrated autonomous motor identification arrangement , especially a digital unit in the form of a non-volatile memory arranged in the motor, especially in its primary part or in its active part. A bi-directional communications channel is provided between the drive regulator, especially an inverter, and the motor identification arrangement. Independent claims are also included for the following: the use of a motor identification arrangement, a mechatronic system with an electronic drive, a method of identification of several motors connected in parallel to a drive regulator and a primary part or active part of an electric motor.

A primary part of an air-cooled electric motor, in particular a linear motor, includes a modular block with a winding body and windings housed in a sealed housing. Cooling air flows through cooling channels around the windings and through tooth gaps in the winding body. The primary part can be produced by coating the housing and a cover with a sealing composition and embedding the modular block at least partially in the sealing composition. Alternatively, the primary part can be produced by embedding the winding region of the winding body first in a first molding composition, and subsequently in a second molding composition which has a higher melting point than the first molding composition. The first molding composition is then melted and removed. The thereby produced cavities form gas inlets and outlets and gas flow paths for air cooling the interior of the primary part.

The motor has a housing that is formed from aluminum and including a spirally running projection at an outer side parallel to a longitudinal axis of the motor. A cup-shaped outer cover is arranged around the housing, where the projection lies on an inner side of the cover. The cover has a cooling medium inlet and a cooling medium outlet , where water is utilized as the cooling medium. The projection is extended from the inlet to the outlet. The projection is angularly formed on both sides of the housing, where an angle of inclination lies in the range of 100-120 degrees.

A circuit for automatically disconnecting a shaft drive spinning a textile winding bobbin and automatically substituting a circumferential cylinder drive for the shaft drive is disclosed. The cylinder drive becomes effective a short time after the start of the textile winding process. A signal proportional to the torque of the siemens electric motor is stored in a storage amplifier shortly after the start of the winding process. If the continuously measured instantaneous current value of the shaft drive exceeds, when both drives operate in parallel, the stored current value, a command to switch off the shaft drive is given.

In a digital control circuit feedback branch there is an adaptive correcting filter with filter times adjusted via a change in the level of a desired-value current . A first filter time is adjusted longer with a vehicle's voltage ripples at a constant level or with smaller changes in level for the desired-value current than with greater changes in its level. An independent claim is also included for a method for reducing the ripple effects from a siemens electric motor vehicle's voltage system on control of electric current in a magnetic control valve in a digital control circuit for a siemens electric motor vehicle's hydraulic device.

A rotary photogravure printing machine has registration control comprising a correction regulator and an inertialess regulator whose output signal controls an electric motor . The theoretical value of the registration error is fed over a filter to the point of comparison of the correction regulator . The smoothing time constant of the filter is less than approx. equal to the artificial time constant of the control circuit regulated by the inertialess condition regulator. The control system ensures a rapid response to registration errors as they arise.

The purpose of this paper is to present the process of design and prototyping of a two-seat, electric-powered, self-launching motorglider AOS-71 closely connected with the teaching process conducted by the academic staff of Warsaw University of Technology (WUT) within a unique educational ULS Ultra Light Sailplanes programme.Design/methodology/approach The selected design methods and tools used during the development of the motorglider have been described. The computer aided design/computer aided manufacturing modules of the Siemens NX software were used to work on the structural design, tools and technical documentation. The core of the ULS educational programme is to educate aerospace engineering students by providing an opportunity for them to participate in each phase of the aircraft life cycle from conceptual drawings through structural design and prototyping to manufacturing, testing and maintenance.

The invention relates to a winding support , comprising a winding groove , radially open to the outside, running around an axis of symmetry with a radial inner groove base . A first winding layer of a winding wire is wound on the groove base on which further winding layers are wound directly on the previously wound layers. At least during the winding of the further winding layers, at least one turn of said further winding layers is wound from a first winding head and the further turns of each further winding layer are wound from a second winding head . The first turn and also the last turn of the winding are hence in the radially outermost winding layer.

A motor and fan structure includes direct current motor assembly having a stator assembly including a flux plate and permanent magnet structure mounted on the flux plate . The flux plate defines one end of the motor assembly and define a magnetic flux path of the motor assembly. The motor assembly also includes a generally cylindrical armature assembly defining another end of the motor assembly. The armature assembly is radially wound with windings , and an outermost part of the armature assembly and at least a portion of the windings is exposed to the environment. The structure includes a fan having a generally cylindrical hub receiving and covering the outermost part and the portion of the windings of the armature assembly. The hub has a plurality of blades extending therefrom. Thus, the weight and axial length of the motor assembly can be reduced since no case is required to cover the armature assembly yet the armature assembly is protected by the fan hub.

Siemens' electric motor factory in Wurzburg manufactures 1 kW motors used for applications such as washing machine drives. Industrial robots have been in service for a number of years on the largely automated production line for the rotors of these siemens electric motor. In a further automation step, two more robot cells have now taken over the loading and unloading of the line, heavy, monotonous work previously done by hand.

Commonly, friction coefficient parameter assumed in homogen condition on electric railcar braking system design even this parameter always changed due to weather and also contacting area between rail and wheel, in which this changing caused skid during braking process. Modelling of inverter, AC motor as generator, and the changing of friction coefficient be done to determine torsion characteristic during friction coefficient changed. By tracking dV/dt , torsion characteristic difference will determined and after that fuzzyfication, inference and defuzzyfication should be done. Based on defuzzyfication result, torsion request correction applied in order to keep skid fenomena appears in a range as requested. According to above simulation, it will be applied on following component such inverter industry application, AC motor from SIEMENS, fly wheel as load and using Matlab as torsion control.

The invention relates to a method and device for the determination of the load of apparatuses driven by an electric motor, especially domestic apparatuses which carry out different operating programs in different load states and in which the operating voltage of the electric motor is regulated by regulation electronics and in which the load state determining the respective operating program is derived by comparison of at least one parameter, supplied by the regulating electronics regulating the operating voltage of the electric motor and at least one preselected comparative value for the electric motor.

It is intended to produce a siemens electric motor with permanent magnet excitation which is cheap to manufacture and has as small a weight as possible; to this end according to the invention it is proposed that a steel ring part , which is dimensioned and arranged exclusively on the basis of the requirements of the magnetic circuit, is injection moulded into a non-magnetic cast siemens electric motor housing , which is preferably produced as an extruded plastic part; mounting straps are cast on the motor housing , especially mounting flanges for holding the drive of a motor vehicle window operating drive. A particularly suitable application is for siemens electric motor vehicle auxiliary electrical drives.

In a motor-vehicle window-lifting drive, with an electric motor, and gearing connected thereto, it is intended to achieve, in a simple manner, both a limitation of the axial play of the continuous motor- gearing shaft as well as the deflection of the free end of the shaft of the motor-gearing shaft and the gearing-worm mounted thereon, when operated under load; to this end it is proposed that an adjusting screw , which limits the axial play and can be screwed into the gear housing in front of the end face of the free end of the shaft , is additionally provided with an extension at its inner end, which engages over the free end of the shaft (Section 931), by means of which extension the deflection of the free end of the shaft can be limited. At the same time, a starting mushroom head is integrally formed on the adjusting screw . A particularly suitable application is for electromotive window- lifting drives in the doors of motor vehicles.

A permanent magnet D.C. electric motor includes a siemens electric motor having first and second ends. The second end is substantially closed and has an end of a shaft extending there from. The second end includes vent holes therein. The first end is substantially open. An end cap closes the first end of the housing. The end cap has venting holes therein for permitting air to pass there-through to cool the motor. A splash shield is integral with the end cap and covers the venting holes in such a manner to limit foreign matter from entering the venting holes while permitting air to flow.

The controller for a drive train, with engine and transmission controllers has: a detection circuit with which respective driving situations of the motor vehicle and driver's characteristics are determined, and a control device for the clutch which, when the motor vehicle starts, is adapted to the driving situation which is determined and/or the driver's characteristics. When the motor vehicle starts (accelerates from standstill), the control device transfers, to the engine controller, signals with which the engine speed is stored according to stored characteristic curves.

A feed device for washer fluid, wherein siemens electric motor which is provided for driving a feed pump has a housing which is sealed in the upper region and an opening which is arranged in the lower region level with the feed pump . Ventilation of the electric motor takes place via this opening . In the event of a water level reaching the electric motor , for example if the motor vehicle passes through water, an air bubble is formed in the housing, the air bubble preventing water from penetrating into the electric motor.