The difference between single stage and two stage gearbox, single stage gearbox, three stage gearbox, two stage gearbox, 2 stage gearbox.

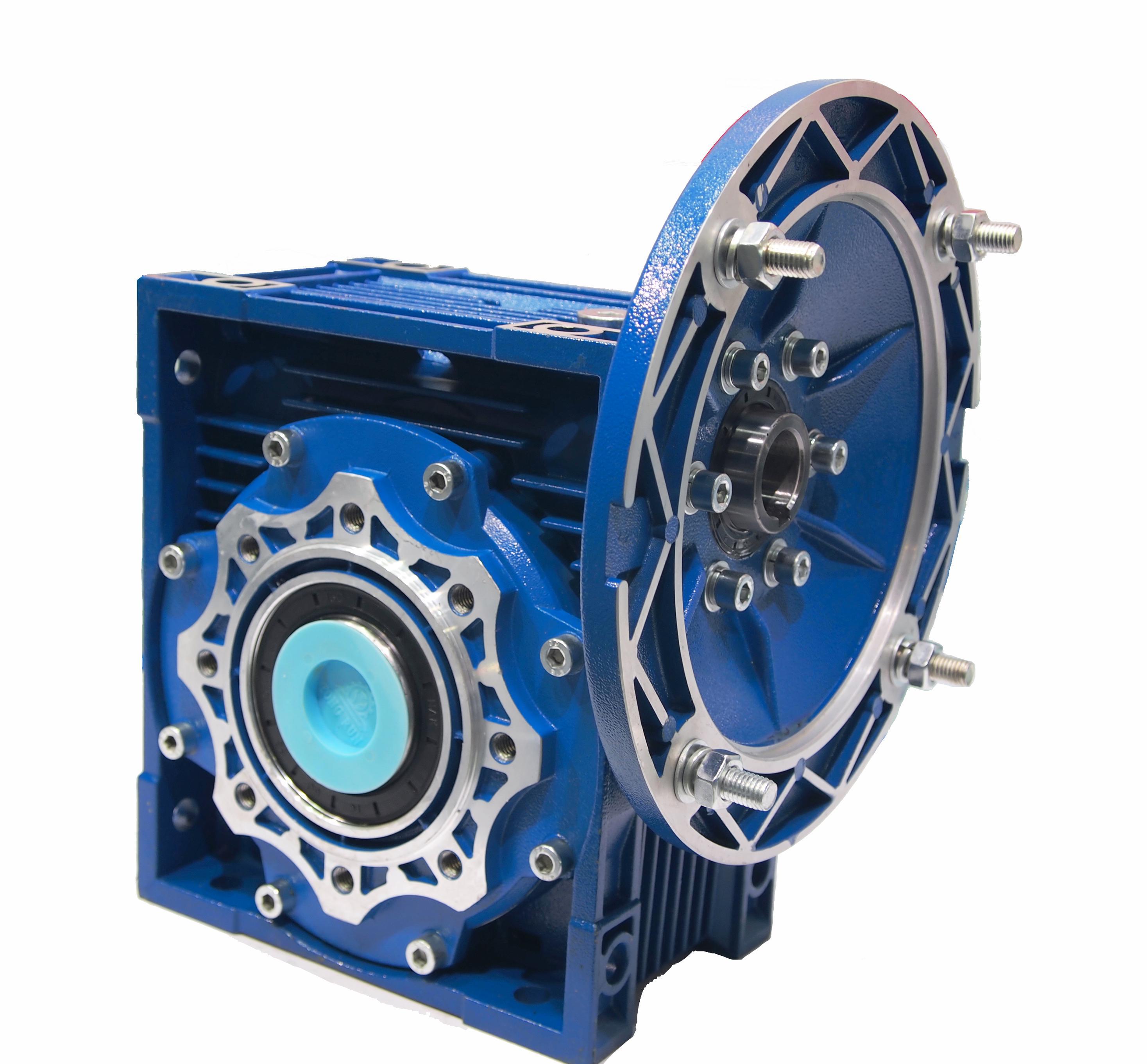

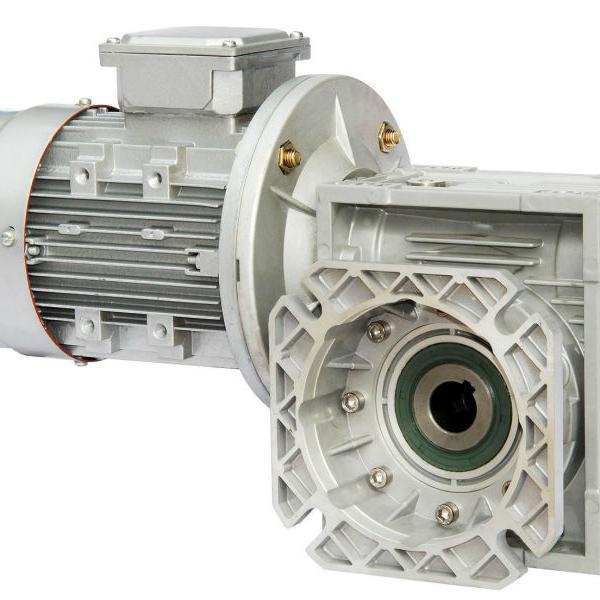

The single-stage reducer is referred to as a single-stage reducer, which can be divided into single-stage worm gear reducer and single-stage gear reducer as well as single-stage RV reducer. The difference between single stage and two stage gearbox. The installation type is divided into horizontal and vertical.

1 Introduction single stage gearbox design.

The single-stage reducer can be divided into single-stage worm gear reducer and single-stage gear reducer and single-stage RV reducer. The installation type is divided into horizontal and vertical. The difference between single stage and two stage gearbox. RV reducer is installed with a kind of installation method, commonly known as universal type. The single-stage reducer consists of a gear or a worm gear transmission. The latter unit is used to transmit the prime mover power to the working machine and to operate the working machine at the required speed. There are many types and types of reducers, the most common ones are gear reducers and worm gear reducers.

Support difference between single stage and two stage gearbox.

The shaft-supporting device has a small friction loss in order to automatically rotate the shaft in the reduction casing. The difference between single stage and two stage gearbox. Therefore, the shaft cannot be supported directly on the reduction housing, but it is supported on a special accessory bearing. The bearings can usually be two types of plain bearings and rolling bearings.

3. Lubrication problems

The difference between single stage and two stage gearbox. The lubrication method of the reducer is generally lubricated by the oil pool and naturally cooled. Circulating oil lubrication is only used if the load capacity of the reducer exceeds the thermal power. Lubricating oil is selected. When the peripheral speed of the high-grade gear in the reducer is greater than 2.5m/s, or when the ambient temperature exceeds 35~50 degrees Celsius, the medium-duty industrial gear oil No. 320 is recommended. If the manufacturer of the reducer has requirements or other provisions for the oil used in the reducer produced, it shall be selected in accordance with the requirements or regulations of the reducer manufacturer.

The amount of oil injection, oil tank lubrication in the tank should be the standard parameters of the parameters or refer to the reducer manufacturer's instruction manual. If circulating oil lubrication is used, it is recommended to control the oil volume at 0.5L/KW, or calculate the heat balance and bonding strength.The difference between single stage and two stage gearbox. When starting the oil supply, the reducer is placed for a period of time (ie, no working time) for more than one day, and it is a gearbox with full load starting. It should be lubricated with circulating oil and supplied with lubricating oil to the required lubrication before starting. If the oil pool is immersed in oil lubrication, it is recommended to manually start from the window to supply the upper half of the gear oil.

Replace the lubricating oil of the reducer.The difference between single stage and two stage gearbox. After the first use of the work for 300 to 600 hours, the lubricant should be replaced. After that, the speed reducer will work for 4,000 to 6,000 hours before replacing the lubricant. The bearing is lubricated and is splash-lubricated. The lubricating oil is the lubricating oil used in the gears inside the box.

4. Troubleshooting

The most common occurrence of gearbox failures is gear damage, secondary bearings, and gear failure again, which explains the position and importance of the gear problem in the reducer.The difference between single stage and two stage gearbox. Under normal circumstances, when the gear reducer is inspected and repaired, it needs to be shut down for maintenance, which is relatively troublesome. Therefore, the research on the maintenance and fault diagnosis of the gear reducer without disintegration and non-stop can have extremely important technical and economic effects.

When the drive shaft, gears and bearings of the reducer are working, vibration will occur regardless of whether there is a fault. In the event of a fault, the amplitude of the vibration produced will increase and the energy distribution of the vibration signal will change. Therefore, it is often one of the more effective methods to use the vibration analysis method to diagnose the fault of the gear reducer. Typical faults such as tooth surface wear, pitting, shaft bending and broken teeth can be analyzed from the vibration characteristics of the gear reducer.The difference between single stage and two stage gearbox. When the gear reducer manufactures or installs the gears, the gears may be distracted from the inner axis, and the gears of the final reducer may fail or the gears may be faulty.

4 stage gearbox

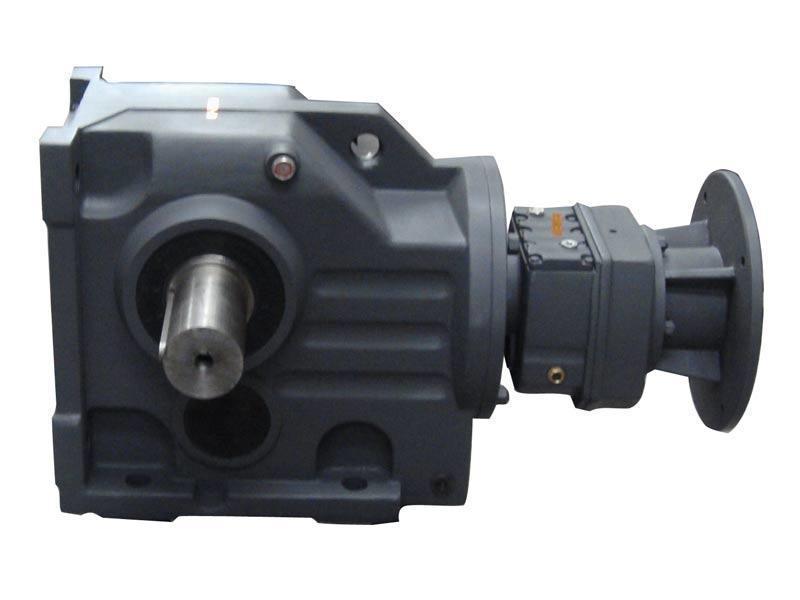

1. The two-stage reducer is also called a two-stage worm gear reducer. It is divided into a two-stage cast iron worm gear reducer and a two-stage RV worm gear reducer. Compared with the single-stage reducer, it has one more transmission. The utility model has the advantages of wide application range, durability, large transmission ratio, small integrated body, strong self-locking ability, simple structure and easy manufacture.

2. Maintenance

In the normal use of the two-stage reducer, the original accuracy will vary with the working time. single stage gearbox design pdf, In order to maintain the stable working performance of the reducer, it is necessary to do daily maintenance work. The lubricating performance of the worm gear reducer should be kept well. The difference between single stage and two stage gearbox. This is an extremely important task in the maintenance of the reducer. Because the worm gear and the worm have a large relative sliding speed at the meshing position, causing great friction. And heat, causing wear and gluing between the teeth.

Since the material of the worm wheel gear is much softer than the worm material, when the glue occurs, the metal on the surface of the worm wheel sticks to the spiral surface of the worm, and the working tooth surface of the worm wheel forms a groove mark. When the lubricating oil is not clean or the lubricating oil is insufficient, but it is not replaced or replenished in time, it will affect the formation of the oil film between the metals. In the case of such poor lubrication, if the reducer is still forced to operate, not only will the frictional heat be increased, but the transmission efficiency of the worm will be affected, and the wear of the worm gear teeth will also increase.

The difference between single stage and two stage gearbox. This can be seen. Lubrication is the most basic condition for ensuring the normal operation of the worm gear reducer, because the oil can form an oil film on the contact surface of the worm gear, thereby avoiding direct contact between the metals and effectively reducing wear. This reduces wear, improves transmission efficiency, extends the service life of the worm gear reducer, and ensures smooth operation of the reducer.

3. Precautions single stage planetary gearbox.

The two-stage reducer can be installed in two ways: a horizontal reducer and a vertical reducer. The horizontal reducer is divided into two types: the worm stop type and the lower type. The transmission ratio is generally 1/10~1/.The difference between single stage and two stage gearbox. Between 80. When the peripheral speed of the worm is less than 4 m/s, the worm is usually used in the lower form. When the peripheral speed of the worm is greater than 4 m/s, 2 stage planetary gearbox, the form of the worm is usually used. When the worm is under, the oil level should be lower than the root of the worm thread and does not exceed the minimum ball center of the rolling bearing on the worm shaft to avoid increasing power loss. 3 stage gearbox animation, When the worm is on, the depth of the worm wheel immersed in the oil is also limited to the super tooth height.

The workplace, transmission efficiency, load capacity, and lubricant grade used in the two-stage reducer must meet the values specified in the specifications of the reducer. When the worm gear reducer is officially put into use, the height of the lubricating oil surface should meet the design requirements.The difference between single stage and two stage gearbox. And check the oil supply status of each lubricating oil point at any time. Regularly check the impurities, moisture and viscosity changes in the lubricant. If it is found that the standard is exceeded or not met, the lubricating oil should be treated in time. two stage helical gearbox design pdf, When replacing the lubricating oil, the bearing and oil pool should be carefully washed. In the normal operation of the worm gear reducer, the temperature of the bearing and the oil pool and the noise check of the reducer should be done. If an abnormal situation is found, stop the search immediately and wait until the abnormality is removed before putting it into use again.

NER GROUP CO.,LIMITED

Mobile:+86-13053534623

.png) http://www.bonwaygroup.com/

http://www.bonwaygroup.com/.png) https://twitter.com/gearboxmotor

https://twitter.com/gearboxmotor.png) https://www.facebook.com/sogears1993

https://www.facebook.com/sogears1993Viber/Line/Whatsapp/Wechat: 008613053534623

E-mail:

Address: No.5 Wanshoushan Road, Yantai, Shandong Province, China (264006)