Variable speed control of 3 phase induction motor manufacturers india

We use die-casting technology to ensure the stable.3 Phase Ac Induction Motor is made of high quality cast iron.With optimized construction design,they can ensure the requirement of structure rigidity and intensity.Silicon steel plate is used in stator core and rotor core,it has good insulation on surface,low loss which ensures the higher efficiency.High quality insulation material combines the perfect insulation system which makes the insulation completely without clearance,high rigidity of the winding end,it can endure switching and reversing intensity,F class insulation makes the motor with higher heat stability and longer life.

The design of bearing and motor construction focuses on motor type,force on the motor,speed,lubricate type,including bearing,design of oil sea and lubricant etc.It has the advantage of credible performance and easy maintenance.Variable speed control of 3 phase induction motor manufacturers india.For the frame size from 250 and below,we generally use closed bearing;frame size above 250 we use open type.Bearing.Regreasing can be done during running.Perfect primer ensures the motors with good apperance and the motors are durable.We can also use special corrosion protection coating.

Motor Frame Size 60mm/70mm/80mm/90mm/104mm

Motor Type Induction motor/reversible motor/torque motor/speed control motor/damping motor/brake motor

Output Power 6w/10w/15w/20w/25w/40w/60w/90w/120w/140w/180w/250w or customized

Output Shaft 6mm/8mm/10mm/12mm/15mm,round shaft/D-cut shaft/key-way shaft or customized

Voltage Type Single Phase 110V 4P

Single Phase 220V 4P

Three Phase 220V 4P

Three Phase 380V 4P

Frequency 50Hz/60Hz

Accessories Terminal box/Fan/Thermal protector/Electromagnetic brake

Gearbox Frame Size 60mm/70mm/80mm/90mm/104mm

Gear Ratio 3-200k

MOTOR FRAME SIZE 60 mm / 70mm / 80mm / 90mm / 104mm

MOTOR TYPE INDUCTION MOTOR / REVERSIBLE MOTOR / TORQUE MOTOR / SPEED CONTROL MOTOR

SERIES K series

OUTPUT POWER 3 W / 6W / 10W / 15W / 25W / 40W / 60W / 90W / 120 W / 140W / 180W / 200W (can be customized)

OUTPUT SHAFT 8mm / 10mm / 12mm / 15mm ; round shaft, D-cut shaft, key-way shaft (can be customized)

Voltage type Single phase 100-120V 50/60Hz 4P Single phase 200-240V 50/60Hz 4P

Three phase 200-240V 50/60Hz Three phase 380-415V 50/60Hz 4P

Three phase 440-480V 60Hz 4P Three phase 200-240/380-415/440-480V 50/60/60Hz 4P

Accessories Terminal box type / with Fan / thermal protector / electromagnetic brake

Above 60 W, all assembled with fan

GEARBOX FRAME SIZE 60 mm / 70mm / 80mm / 90mm / 104mm

GEAR RATIO 3G-300G

GEARBOX TYPE PARALLEL SHAFT GEARBOX AND STRENGTH TYPE

Right angle hollow worm shaft Right angle spiral bevel hollow shaft L type hollow shaft

Right angle solid worm shaft Right angle spiral bevel solid shaft L type solid shaft

K2 series air tightness improved type

Certification CCC CE ISO9001 CQC

YP/YPKK/YPKS series L-V &H-V Variable Frequency Adjusting Speed AC Motor

Product overview:

YPKS series AC Motor for Steel Rolling. The motor can be combined with the frequency converter to form an ideal, efficient and economical using system. It's also with a compact stricture and beautiful appearance, it's also easy to install and debug, easy to maintain, safe and reliable in operation.

Performance features:

Constant torque below base speed and constant power above base speed.

Good resistance to moisture and heat dissipation.

Shaft uses 35CrMo alloy steel own a excellent mechanical properties, able to withstand frequent overload and other impact loads.

Overload Capability: can be continuously operated with 115% overload,also can be 150% overload last 60 seconds.

The occasional using 250% overload with 15 seconds.

Standard Features:

Voltage:380v,400v ,690V or others 690V

Protection Class:F or H

Working Duty:S1 or S3-40%

Cooling Meathod:YPKS is IC86W,

Protection :IP55

Mounting size :IMB3

Connection:Δ/Y

Typical applications•Coal mill and rolling mill

•Compressor

•Rubber mixer

•Fans and Pumps

Furthermore, in order to distinguish us from competitors, to grow even further and gain more market share, we decided to invest most of its profits in specializing and acquired the quality certificate of ISO9001 , passed CE.At the same time we has dozens of Utility Model Patents. We also made a cooperation with Shanghai Electrical Apparatus Research Institute (Group) Co.,Ltd, as special motor production base for SEARI in 2005 . Now participates in many international tenders and exports to many countries around the world through everyone's efforts in Hengli

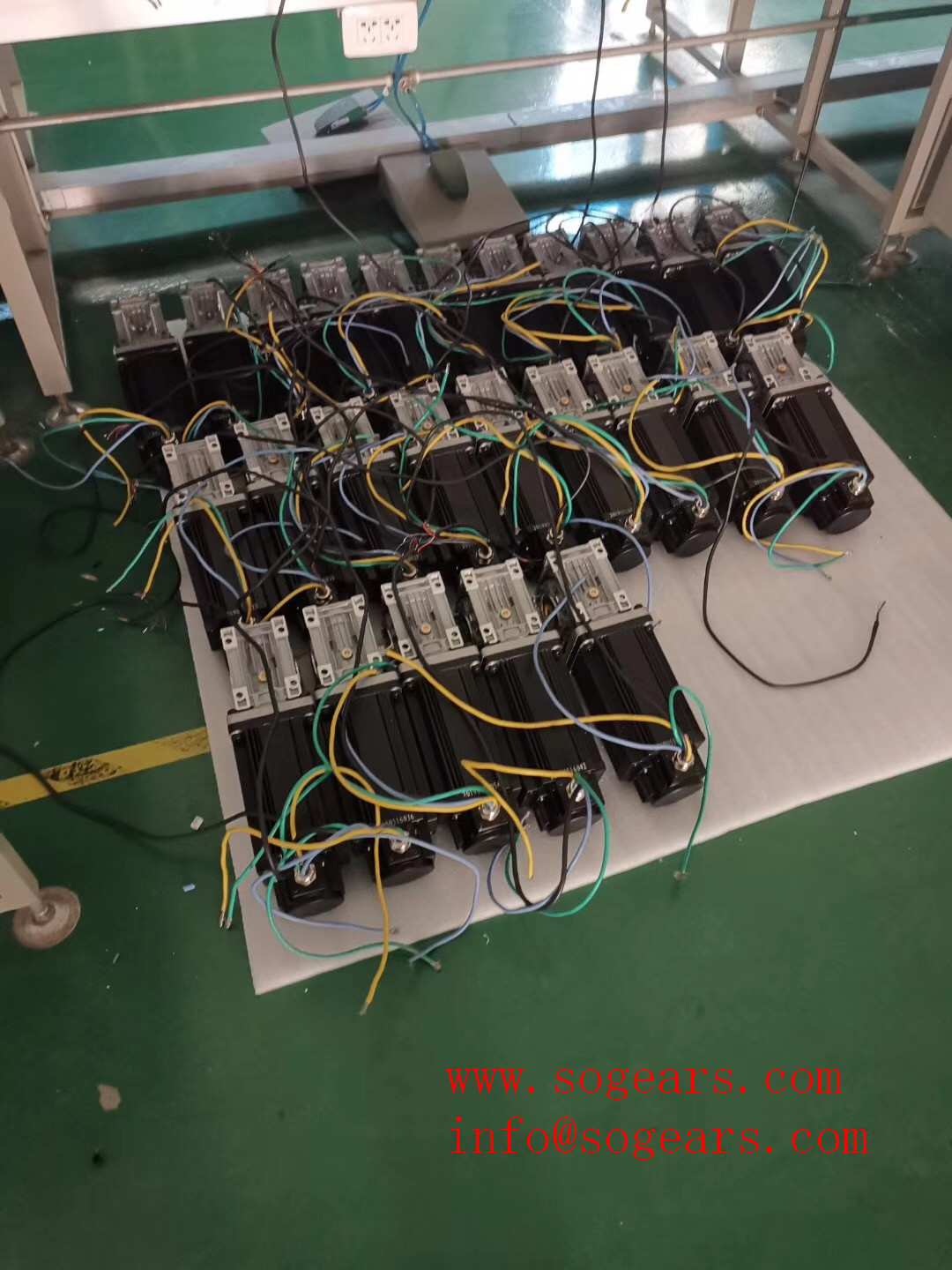

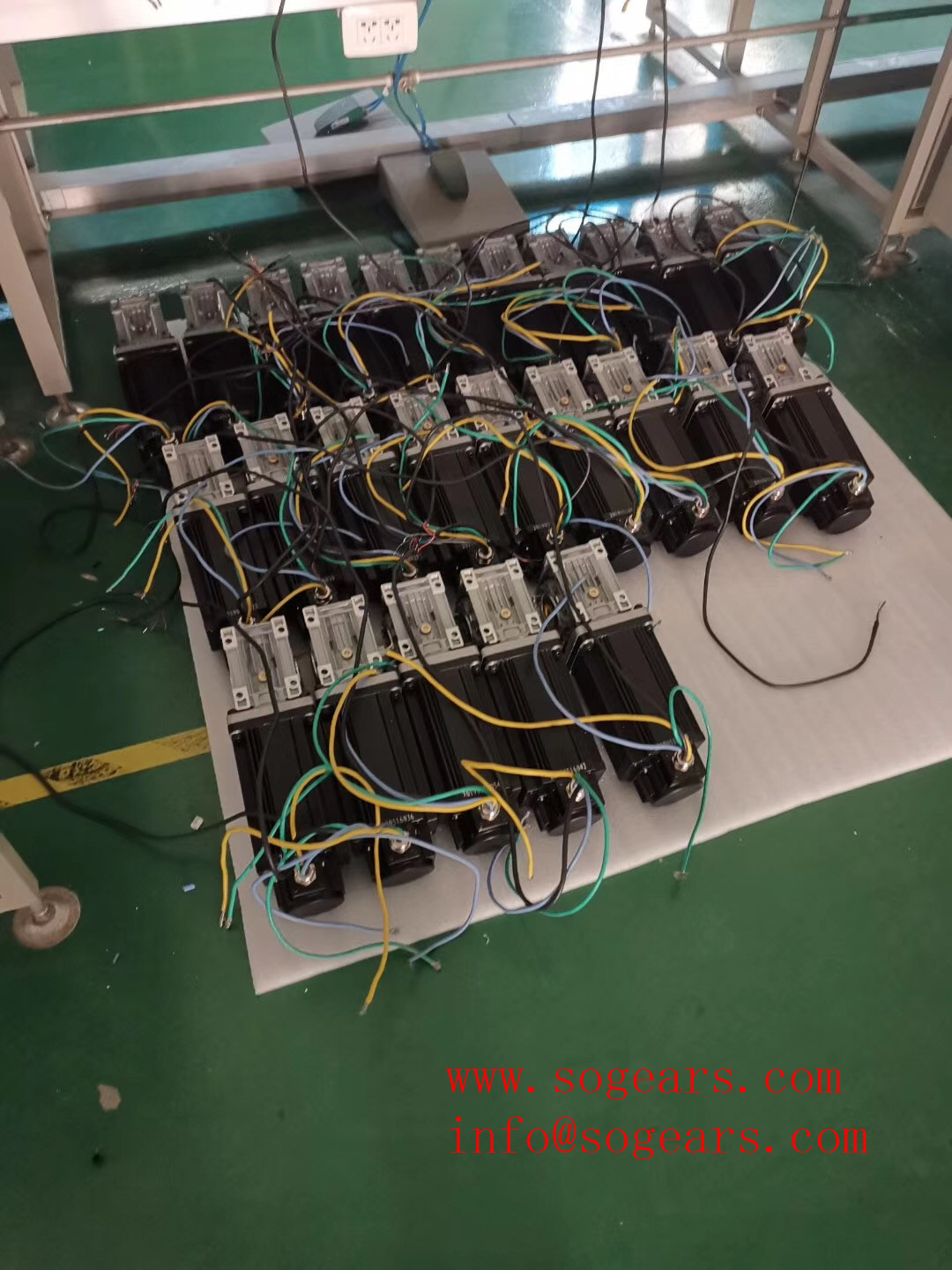

We strictly check on every step of the production chain to ensure links is good in quality, to satisfy customers' demand and ensure delivery at the same time. advanced equipment and complete internal supply chain, from punching, laminating, welding, machining, winding, embedded line, dipping, assembled to test, all the procedures are done in-house to ensure quality.Variable speed control of 3 phase induction motor manufacturers india.The motor could work well within one year's using period or no less than thirteen months from departure date of our company(subject to the first) if the user use and store the motor properly according to the instruction .

If the motor is damaged or can not work normally within the stipulated time due to the poor quality , our company will repair and replace the spare parts or motors free of charge ,while all entry and exit costs borne by the buyer.

Service after the Warranty Period :

Our company implements the lifelong paid service if malfunction occurs after the warranty period, we will supply the required easy-weared parts and spare parts at cost price. After sales- service personnel will call back the user irregularly.

MOTOR TYPE Induction Motor

OUTPUT POWER 100W / 200W / 400W / 750W / 1500W / 2200W / 3700W (Can Be Customized)

OUTPUT SHAFT 18mm / 22mm / 28mm / 32mm / 40mm / 50mm; Round Shaft, D-Cut Shaft, Key-Way Shaft (Can Be Customized)

Voltage type Single phase 110V50/60Hz, 220V/50/60Hz; Three phase 220-240/380-415V, 50/60Hz

Accessories Electric Brake / Fan / Terminal Box

Gear Ratio 3K-1800K

YE2 series high efficiency three phase induction motors are produced according to GB/T11707, the efficiency reaches CLASS III of GB18613, which is equally to IE2 of IEC60034-30.

It is high efficiency, energy saving of new technology and new materials, F class insulation of good safe reliability. And widely used for machines, fans, pumps, compressor, mine, construction etc.

The basic design of induction motors has not changed in the last years, with latest and good insulation materials, pre-simulation for design, computer optimization techniques in design and using automated manufacturing devices have resulted in motors of less cost per kW, heating reduction and smaller physical size. Due to standards by International of physical dimensions and frame sizes the motors from most manufacturers are physically interchangeable and they have similar performance characteristics, dimensions and electrical distribution of multiphase coils are affecting on magnetic field density, because of difficulty in measuring magnetic flux in each point of the machine computer simulations help in machine design to demonstrate and adjustments in magnetic flux distribution. Three-phase and six-phase induction motor electromagnetic models are developed in two-dimensions in the finite element method based software-tool Computer Solutions (COMSOL) Multiphysics.

The paper deals with analysis of the situation in a six-phase induction machine. For this purpose, the method of space vectors is used. It is shown that higher space harmonic waves of current layer, flux density and flux in the stator yoke have to be considered especially when the stator is fed by unbalanced voltages. The equations of a six-phase induction machine are derived and relation between symmetrical components of instantaneous values and groups of spatial harmonics of the field in the air gap is shown. Also experimental verification of results from the mathematical analysis is presented in this paper. Values from measurements are compared with those of numerical simulations.

In this paper, two dual three-phase winding configurations are compared based on the Toyota Prius 2010 interior permanent magnet (IPM) machine. It is found that the winding configuration with single-layer full-pitched (SF) windings can improve average torque and reduce torque ripple in constant torque range. The winding configuration with double-layer short-pitched (DS) windings has better torque performance in a constant power range. Variable speed control of 3 phase induction motor manufacturers india.The electromagnetic performances of the two winding configurations when one winding set is excited and the other one is open-circuited are also compared. The DS winding configuration shows much better performance under this condition. Overall, the dual three-phase winding configuration with DS windings is preferred for dual three-phase IPM machines in electric vehicles. A Toyota Prius 2010 IPM machine equipped with DS windings was manufactured to verify the analyses presented in this paper.

Assuming that you checked the mechanical properties and the centrifugal force at the rotor at the higher speed from 50Hz to 60Hz, 50Hz 60Hz Converter and they are OK, then you have to consider that the flux in the machine will go down by the ratio of the increase of frequency to 60Hz. Also the inductances will increase, so locked amps will be down, Locked rotor torque will be down, power factor will change, and efficiency will change. No load amps will decrease. If you want to change the electrical design to make it like it was for 50Hz then you have to increase the number of turns of the motor, but you have to know what you are doing.Please note that except the change in the asynchronous speed of the motor machine, many other parameters will change. This will include the effective phase impedance of the motor, the current/voltage levels, etc. Also, please note that the torque-speed curve and the associated efficiencies will be affected by the change in frequency 60Hz to 50Hz.

Mentor Graphics and Lumerical are offering Photonic Integrated Circuit designers a integrated tool platform where Lumerical INTERCONNECT is integrated with Pyxis Schematic. INTERCONNECT is a photonic integrated circuit design software for designing, simulating and analysis of photonic integrated circuits.

Pyxis Schematic EDA tool helps VLSI engineers to design capture, simulation control, and results viewing for analog, RF, and mixed-signal designs.

Designers can now capture a photonic design and testbench, set up optical simulation parameters for transient and frequency analysis, perform simulation, and view results interactively from the Pyxis Schematic simulation cockpit. This also leverages the existing integration to high-capacity Ezwav waveform viewer which can be used for processing optical simulation results.

Another tool named Pyxis Implement with schematic-driven layout helps engineers to quickly place and assemble photonic PCells using connectivity-driven waveguide routing with radial and adiabatic bends, as well as S-bend support.

We offer the entire range of power semiconductors and ICs including discrete IGBTs and power MOSFETs as well as power modules and intelligent power modules (IPM), high-voltage gate drivers and powerful STM32 microcontrollers needed to implement high-efficiency variable-frequency drive (VFD) motor control.

To help reduce and simplify the design cycle, we offer a complete ecosystem of hardware, evaluation boards and reference designs, as well as firmware and software libraries.

Stoper Robotic FL-04 DNCB-40-200-PPV-A 532744 W236 1 Ea FESTO

Electric motor 0.37 Kw, 380V, 50Hz, 1500 Rpm, 2 Pole, Flange mounted 1LA7073-4AB11 4 Pcs Siemens

Electric motor 0.18 Kw, 380V, 50Hz, 1500 Rpm, 2 Pole, Flange mounted 1LA7063-4AB11 4 Pcs Siemens

Electric motor 0.75 Kw, 380V, 50Hz, 1500 Rpm, 2 Pole, Flange mounted 1LA7083-4AA11 4 Pcs Siemens

Electric motor 1.1 Kw, 380V, 50Hz, 1500 Rpm, 2 Pole, Flange mounted 1LA7090-4AA11 4 Pcs Siemens

Electric motor 1.5 Kw, 380V, 50Hz, 1500 Rpm, 2 Pole, Flange mounted 1 Pcs Siemens

Electric motor 3 Kw, 380V, 50Hz, 1500 Rpm, 2 Pole, Flange mounted EM100LB-4 3 Pcs Elektrim

Motor 90W 3Ø 4 Pole Botle Sticker M-51K90U-SF 3 Pcs Peeimoger

Motor 150W 3Ø 4 Pole Botle Sticker M-51K150U-SF 3 Pcs Peeimoger

Motor 1 Phase 4P 60watt, 220V M-51K60U-CFV 3 Pcs Peeimoger

Motor 1,5 Kw 1420RPM 380V 3Ø 7983 1 Pcs ABB

I/O IP65R424E11493/24 VDC 1 Pcs Rexroth

Selenoid 43004541,24VDC 10 Pcs MPM

Selenoid 43004166,24VDC 10 Pcs MPM

Limit Switch HL-5300, 250 VAC 5A, 125 VDC 0.4 A, 250 VDC 0.2 A 5 Pcs Omron

Limit Switch WLNJ 2A/250VAC 5 Pcs Omron

Power Supply S8FS-C10024J input 200-240 VAC, output 24 VDC 4.5A 5 Pcs Omron

Power Supply S8JX-05024CD input 200-240 VAC, output 24 VDC 2.1A 5 Pcs Omron

Power Supply SPB-240-24, input 100-240 VAC 3.8 A, output 24 VDC 10A 5 Pcs Autonics

Power Supply S8VS-06024 input 100-240 VAC 1.7A, output 24 VDC 2.5A 5 Pcs Omron

Pressure indicator/switch Ettore Cella Spa SN: 712159 15 Pcs Cella

Pressure switch PCS2MG, elec rating 5A-220V 15 Pcs Cella

Pressure switch PCS2MG, elec rating 5A-220V 15 Pcs Cella

Profi Bus RMV04-DP 32, 24 VDC 5 Pcs Rexroth

RCCB ACTi9 16A, 2P, 30mA 3 Pcs Schneider

RCCB ACTi9 20A, 2P, 30mA 3 Pcs Schneider

Relay MY2 24 VDC 5A, 8 pin 3 Pack Omron

Relay MY4N 24 VDC 5A, 14 pin 3 Pack Omron

Relay MY4N 220 VAC 5A, 14 pin 3 Pack Omron

Relay MY2 220 VAC 5A, 8 pin 3 Pack Omron

Selenoid MSFW-230-50/60, 220/230VAC, 9/7VA IP00/65 10 Pcs Festo

Selenoid Id no. 9710000 10 Pcs Norgren

Selenoid Joucomatic type 551A001MS 10 Pcs Asco

Selenoid M281547 10 Pcs Asco

Selenoid Id no. 2623077 10 Pcs Norgren

Selenoid Id no. 3036,24 VDC, 1.6 watt 10 Pcs Norgren

Selenoid 2623077-3032-02400, 5/2 way, 24VDC 10 Pcs Herion

Selenoid 24VDC 10 Pcs Asco

Selenoid MPM 43004541 20 Pcs Asco

Selenoid MPM 43004166 20 Pcs Asco

Selenoid 0820055051, 24VDC, C 1.2 (0.35 W) 20 Pcs Rexroth

Selenoid 2623077-3032-02400,24VDC 5 Pcs Herion

Sensor Capasitif CR30-15DN 24 VDC 5 Pcs Autonics

In a 3-phase AC induction motor, there are three stator windings, each usually in two halves, with the rotor winding short-circuited by end rings. As the current passes through the coils on opposite sides of the stator, a two-pole electromagnet is established, creating a two-pole motor. Applying a phase to each of the electromagnets in turn creates the rotating magnetic field that is strong enough to start moving the rotor.

More winding can create more poles in the motor, with more complex control required but more accuracy in positioning the rotor. A four-pole motor is regarded as optimum for the torque and responsiveness needed to for the motor drives of electric cars, for example. But higher pole counts are only possible with more sophisticated control schemes.

The typical drive has three half-bridges, each delivering a sine-wave voltage to the stator. This uses power MOSFETs or IGBTs with high-voltage gate drivers, or power modules that combine the three half-bridges and related gate drives. These can use scalar algorithms that vary the voltage to determine the frequency of the phases, or volts/hertz. More sophisticated algorithms such as vector control or Field-Oriented Control(FOC) are used to control the frequency of multiple phases in high-end motors are now increasingly popular across the range of three-phase induction motors.

Polyphase motors generally cover three-phase motors using multiple poles.

A soft-start controller is used in three-phase AC induction motors to reduce the load on the self-starting motor and the current surge of the motor during start-up. This reduces the mechanical stress on the motor and shaft, as well as the electrodynamic stresses on the attached power cables and electrical distribution network, extending the lifespan of the system.

Induction motors can have inrush currents seven to ten times that of the operational current. Starting torques can be 3 times higher to overcome the starting conditions, causing mechanical stress on the components in the motor. So electronic soft starters use a control system to reduce the torque by temporarily reducing the voltage or current input until the induction motor reaches its synchronous speed.

A digital soft-starter controller continuously monitors the voltage during start-up, adjusting to the load of the motor to provide a smooth acceleration and the speed control. This is often done with connected silicon-controlled rectifiers (thyristors) controlling each phase separately to give the optimum control.Variable speed control of 3 phase induction motor manufacturers india.The torque generated in the rotor of a 3-phase induction motor is proportional to the flux generated by each stator pole, the rotor current and the power factor of the rotor. Direct torque control (DTC) is a technique used in variable frequency drives. It comes from estimating the magnetic flux from the voltage and current of the motor. This is compared to a reference value to control the torque.

This allows the flux and the torque to be changed quickly by changing the references, making the motor more efficient and reducing power losses as only the exact current is used. This also avoids the rotor overshooting, allowing more accurate control over the motor.

The torque generated in the rotor of a 3-phase induction motor is proportional to the flux generated by each stator pole, the rotor current and the power factor of the rotor. Direct torque control (DTC) is a technique used in variable frequency drives. It comes from estimating the magnetic flux from the voltage and current of the motor. This is compared to a reference value to control the torque.

This allows the flux and the torque to be changed quickly by changing the references, making the motor more efficient and reducing power losses as only the exact current is used. This also avoids the rotor overshooting, allowing more accurate control over the motor.

This project will focus on developing a simulation model of variable speed, variable voltage for an induction motor drive. The main component of this system consists of a 3-phase induction motor (DL 1021) and a 3-phase ABB inverter (ACS 550-01-08A8-4). Based on the actual 3-phase induction motor (DL 1021), the parameters such as R1, X1, R2, X2 and Xm is defined using certain tests which are open and short circuit test. Using mathematical equations and MATLAB simulation, others parameter such as starting current, maximum torque and rated torque will also are defined. For variable voltage variable frequency (VVVF), the ABB inverter will play a major role. Inverter section determines the voltage level, frequency level and the current level that a motor receives in order to control the motor speed. So, the inverter section will focus on the concepts study and parameter setting of an ABB inverter. Finally, this project will develop a simple manual of variable speed control system.

quality of the rotor and aesthetic appearance.