Which of the following is not an advantage of helical gears

Gears are a common part often used in mechanical transmission. The gears are made of high-quality high-strength alloy steel, surface carburized and hardened, with strong carrying capacity and durability. In practical applications, the helical gear is widely used in high-speed heavy-duty applications due to its smooth transmission, small impact, vibration and noise.

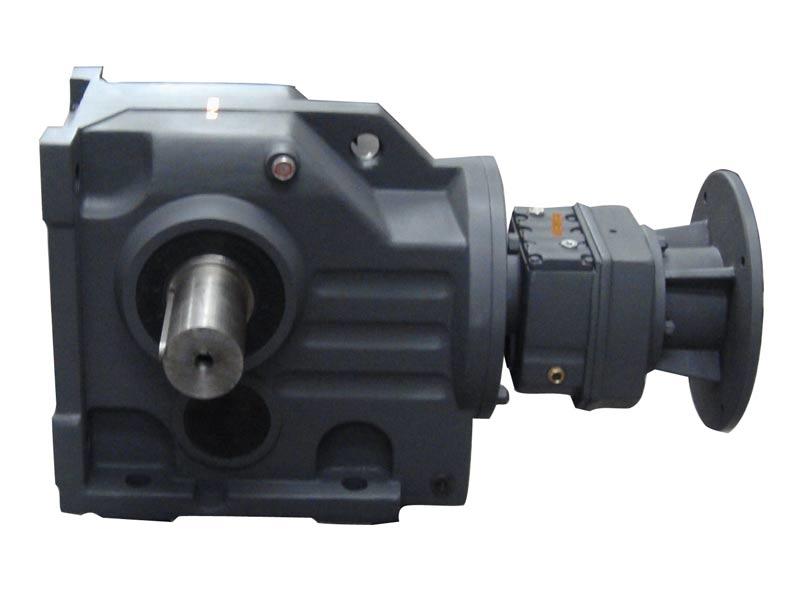

Which of the following is not an advantage of helical gears. The helical gear is not exactly a helical gear. It should be said that the helical gear is the meshing mode of the two helical gears, which are distinguished by the difference in the direction in which the force is transmitted in space. Ordinary spur gears enter the mesh at the same time along the tooth width, thus generating impact vibration noise and the transmission is not stable. The helical gear drive is superior to the straight tooth and can be used for high speed and heavy load. The helical gear reducer is a novel reduction gearing. Adopting the optimization, the advanced design concept of the module combination system has the advantages of small size, light weight, large transmission torque, stable starting, fine classification of transmission ratio, and can be connected according to user requirements and a variety of installation positions.

1 content introduction

There are many types of gear transmissions, among which helical helical gears are highly efficient, for example, the efficiency of a spur gear is lower than that of a helical gear. Which of the following is not an advantage of helical gears.The helical spur gear is the same as the spur gear mechanism. The helical spur gear can utilize the method of reducing the center distance a in order to improve the load carrying capacity of the transmission for high speed operation. The helical gear reducer is a novel reduction gearing. The helical gear reducer is small in size, light in weight and economical.

2 basic parameters Which of the following is not an advantage of helical gears

1. Helix angle: It refers to the angle between the teeth of the helical gear and the axis.

The helix angle is a characteristic characteristic of a helical gear and does not exist in a spur gear, that is, a spur gear. In general, the helix angle of the helical gear we usually refer to refers to the helix angle on the indexing cylinder. The larger the helix angle, the greater the overlap, the more stable the motion and the lower the noise. Everything is two-sided. Although increasing the helix angle brings many advantages, the axial force generated during operation also increases. The size should depend on the quality requirements of the work and the processing accuracy. Generally, if it has special requirements for noise, it can take a larger value according to the situation.

Which of the following is not an advantage of helical gears.Spiral rotation direction discrimination: First, we will make the gear axis vertical, if the right side of the spiral line is right-handed; otherwise, the left side of the spiral line is left-handed.

2. End face and normal parameters:

End face: a plane perpendicular to the axis of the gear, the parameters on the end face are generally subscripted t;

Normal: The plane perpendicular to the spiral, the parameters on the normal surface are generally subscript n.

(1) Pitch and modulus: =t=π

(2) Pressure angle: Generally, the parameters in the normal surface are standard parameters.

a. Correct meshing conditions: The helix angles must be equal in magnitude and opposite in direction. Which of the following is not an advantage of helical gears.The normal modulus m and the normal pressure angle requirements are equal.

b. Geometric dimension calculation: The calculation formula of the spur gear can be directly used for the end face of the helical gear in the calculation because a pair of helical gear transmissions are equivalent to a pair of spur gear transmissions on the end plane.

3 advantages and disadvantages

advantage:

(1) Good meshing performance: the meshing process between the helical gear teeth is an excessive process, the force on the gear teeth is gradually reduced from small to large, and then from large to small; the helical gear is suitable for high speed. Overload situation.

(2) Large degree of coincidence: an increase in the degree of coincidence increases the load carrying capacity of the gear. This extends the life of the gear. The degree of coincidence mainly depends on the engagement time, while the helical gear has a long engagement time and a large contact area, which reduces the stress. It also smoothes the drive and increases its economy.

(3) Compact structure: the smaller the minimum number of teeth, the more compact the structure.

Which of the following is not an advantage of helical gears,Disadvantages and corrections:

Herringbone gear manufacturing is more troublesome.

The axial component force is detrimental to the gearing, which increases the friction between the devices, making the device susceptible to wear or damage. As long as the helical gear has the disadvantage that the axial component will be generated when the gear meshes. The axial force is caused by the helix angle, and the larger the helix angle, the greater the axial force generated. In order not to cause excessive axial force on the helical gear, the design is generally taken as 8 to 15.

Which of the following is not an advantage of helical gears.The herringbone gear can reduce the influence of the axial component, but the herringbone gear is more troublesome to manufacture. Uneconomical.

The helical gear drive is composed of two helical gears meshing.

Use: Transfer the movement between the two axes of the space.

Which of the following is not an advantage of helical gears. Features:

(1) The spiral direction can change the center distance and the transmission ratio;

(2) The steering can be changed by the spiral turn;

(3) fast wear;

(4) point contact;

(5) The axial force is small.

4 classification introduction

The helical gear reducer is a novel reduction gearing.Which of the following is not an advantage of helical gears. It has many advantages, such as small size and light weight. Thanks to the optimized cash design concept, the weighted average of the performance makes the advantages complement each other. The transmitted torque is increased, the transmission ratio is finely graded, the load carrying capacity is enhanced, the use is durable, and the economy is good.

1. Involute helical gear reducer

The involute helical gear reducer has the characteristics of small size, light weight, high bearing capacity, high efficiency, long service life, convenient installation, wide motor power range and fine classification of transmission ratio. Can be widely used in equipment that needs to be decelerated in various industries.

2, helical gear worm gear reducer

The helical gear worm reducer adopts the direct connection mode of the motor, and the structure is a first stage helical gear plus a first stage worm gear transmission. The output is shaft mounted and comes in six basic mounting styles. It can be reversed and reversed. The helical gear adopts hard tooth surface, stable operation, large carrying capacity, working environment temperature -10 °C ~ 40 °C. This product has the characteristics of large speed variation range, compact structure and convenient installation compared with similar products. Can be widely used in metallurgy, mining, lifting, light industry, chemical, transportation, construction and other mechanical equipment speed reduction mechanism.

5 parts comparison

The meshing line of the spur gear is a parallel line. It is easy to process and has no axial component. However, it has poor stability and vibration. The meshing line of the helical gear is oblique, difficult to process and has axial force, but smooth. Good sex and low vibration.

7 frequently asked questions

1. Common problems and causes of helical gear reducer:

a. The reducer generates heat and oil leakage;

b. Worm gear wear;

c. Drive small helical gear wear;

d. The worm bearing is damaged.

2, the helical gear reducer common problem solving method

(1) Guarantee assembly quality

Which of the following is not an advantage of helical gears. Professional tools are essential to ensure assembly quality. Original parts are generally the best choice for disassembly and replacement of parts. When one of the paired parts is damaged, the principle of replacement in pairs is generally adhered to. When assembling the output shaft, pay attention to the tolerance fit: the hollow shaft is also the key object to be protected. If there is wear and rust or surface area scale, it will affect the disassembly in the future maintenance.

(2) Selection of lubricants and additives

Lubricating oils and additives are used to ensure that the speed reducer has an oil film attached to the surface to protect the gear when the gear unit stops moving. Oil film protection for frequent start-ups extends machine life while protecting the machine from high speed and heavy loads. The use of additives can also effectively prevent oil leakage, making the seal mission longer, keeping soft and elastic. helical gear. The lubricating oil of the worm gear reducer is generally selected as 220# gear oil. The use of the additive is generally used when the use environment is poor, such as a large load and unstable instability caused by frequent startup.

NER GROUP CO.,LIMITED

Mobile:+86-13053534623

.png) http://www.bonwaygroup.com/

http://www.bonwaygroup.com/.png) https://twitter.com/gearboxmotor

https://twitter.com/gearboxmotor.png) https://www.facebook.com/sogears1993

https://www.facebook.com/sogears1993Viber/Line/Whatsapp/Wechat: 008613053534623

E-mail:

Address: No.5 Wanshoushan Road, Yantai, Shandong Province, China (264006)