Cycloidal Gearboxes

Cycloidal gearbox

cycloidal gearbox manufacturers, cycloidal gearbox for sale, cycloidal rotary drive

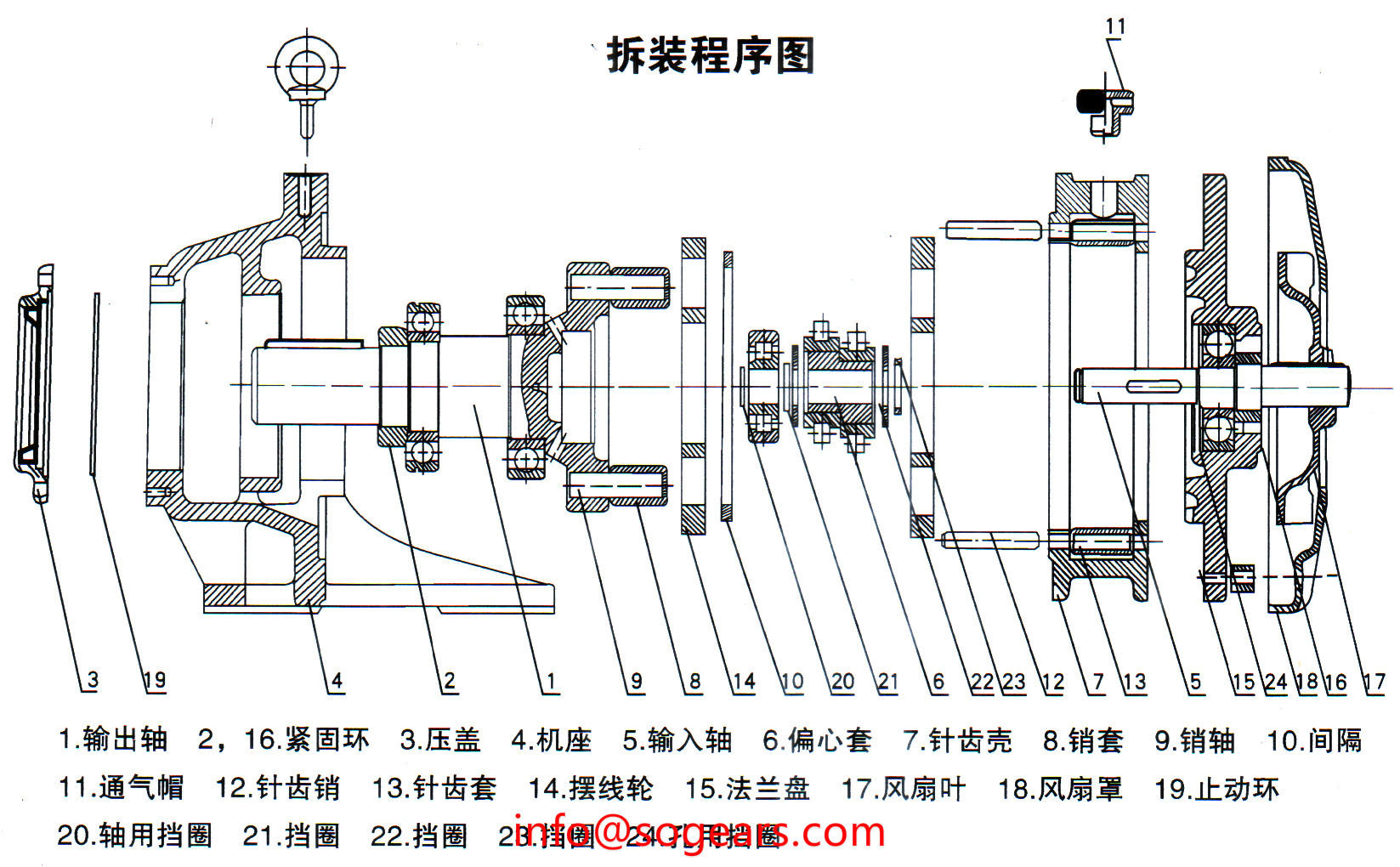

1.Dislocation on the input shaft is equipped with a 180°of the double eccentric sleeve of Cycloidal speed reduction gearbox , turn on the eccentric sleeve is equipped with two called arm of roller bearing, the formation of H, two cycloid gear center hole is the eccentric sleeve on the turning arm bearing raceway, and by a group of cycloid gear and pin gear mesh circular permutation needle, to form tooth difference, for the internal meshing gear gearbox is institutions (in order to reduce friction, in small ratio of speed gearbox, the needle with needle teeth on the gear set).

2.Cycloidal speed reduction gearbox can achieve a high deceleration ratio of 1:87 and a high-efficiency single-stage transmission of more than 90%. If the multi-stage transmission is adopted, the deceleration ratio is larger.

3.The speed reduction ratio of the first-stage transmission is 9~87 of Cycloidal speed reduction gearbox , the speed reduction ratio of the two-stage transmission is 121 ~ 5133, and the multistage combination can reach tens of thousands, and the gear meshing system sleeve rolling friction, the meshing surface has no relative sliding, so the first stage speed reduction efficiency is up to 94%.

4.Cycloidal speed reduction gearbox compact size due to the planetary transmission principle, the input shaft output shaft is on the same axis line, so that its size as small as possible. Smooth running noise low cycloid needle tooth meshing number is more, the overlapping coefficient is big and has the mechanism of the balance of the machine parts, which makes the vibration and noise limited to the minimum extent.

5.Reasonable design of Cycloidal speed reduction gearbox, convenient maintenance, easy disassembly and installation, minimum number of parts and simple lubrication, so that cycloidal pin gear gearbox by the user's trust. Compared with cycloidal gearbox of the same power, the weight volume is more than one third smaller. Because of planetary transmission, the input shaft and output shaft are on the same axis to obtain the smallest size possible.

6.The number of teeth in contact at the same time during operation is large of Cycloidal speed reduction gearbox, the coincidence degree is large, the operation is stable, the overload ability is strong, the vibration and noise is low, the type of various specifications noise is small.

Find Variety Cycloid Gearbox from cycloidal reducer gear ,cycloid gear ,cycloidal reducer from China Cycloid Gearbox, Cycloid Gearbox from China Supplier

The cycloidal pinwheel gearbox is a novel transmission device that uses the planetary transmission

principle and uses cycloidal pin gear meshing. The transmission of the cycloidal pinwheel gearbox

can be divided into three parts: the input part, the deceleration part and the output part.

composition: A double eccentric sleeve with a 180° misalignment is mounted on the input shaft, and two roller

bearings called a jib are mounted on the eccentric sleeve. The central hole forming the H

mechanism and the two cycloidal wheels is an eccentric sleeved slewing bearing. a raceway, and

the cycloidal wheel and the needle gear are engaged with a set of annularly arranged pin teeth to

form an internal meshing speed reduction mechanism with a tooth difference of one tooth (in

order to reduce friction, in a speed gearbox with a small speed ratio) , the needle teeth have a

needle sleeve).

principle: When the input shaft rotates one year with the eccentric sleeve, the movement of the cycloidal

wheel becomes a plane motion with both revolution and rotation due to the characteristics of

the tooth profile curve on the cycloidal wheel and the restriction on the pin gear on the needle

gear. When the input shaft rotates positively, the eccentric sleeve also rotates once, and the

cycloidal wheel rotates one tooth in the opposite direction to obtain deceleration, and then the

W output mechanism is used to transmit the low speed rotation of the cycloidal wheel through

the pin shaft to the output shaft. This results in a lower output speed.

Features: 〇High-speed ratio and high-efficiency single-stage transmission can achieve a reduction ratio

of 1:87, and the efficiency is above 90%. If multi-stage transmission is adopted, the reduction

ratio is larger. 〇 Compact and small size Due to the planetary transmission principle, the input shaft output

shaft is on the same axis, making the model as small as possible. 〇 Smooth running noise Low Cycloidal pin teeth have a large number of meshing teeth, a large

overlap coefficient and a mechanism for balancing the components, so that vibration and hum

are limited to a minimum. 〇Reliable use and long service life Because the main parts are made of high-carbon chrome

steel, high strength is obtained by quenching treatment (HRC58~62), and some transmission

contact adopts rolling friction, so it has long durability and long service life.

Cycloid gearbox speed ratio: Single-stage transmission ratio: 9, 11, 17, 23, 29, 35, (39), 43, (47), 59, 71, 87 Two-stage

transmission ratio: 121 (11*11), 187 (17*11) , 289 (17 * 17), 493 (29 * 17) two-stage

transmission ratio that is the product of two single-stage transmission ratio, the above is

commonly used.

The cycloidal pinwheel gearbox is a novel transmission device that uses the planetary transmission

principle and uses cycloidal pin gear meshing. The cycloidal pinwheel gearbox is a novel transmission device that uses the planetary transmission

principle and uses cycloidal pin gear meshing. The transmission of the cycloidal pinwheel gearbox

can be divided into three parts: the input part, the deceleration part and the output part. A double

eccentric sleeve with a 180° misalignment is mounted on the input shaft, and two roller bearings

called a jib are mounted on the eccentric sleeve. The central hole forming the H mechanism and

the two cycloidal wheels is an eccentric sleeved slewing bearing. a raceway, and the cycloidal wheel

and the needle gear are engaged with a set of annularly arranged pin teeth to form an internal

meshing speed reduction mechanism with a tooth difference of one tooth (in order to reduce friction,

in a speed gearbox with a small speed ratio) , the needle teeth have a needle sleeve).

use: The cycloidal pinwheel gearbox adopts the cycloidal pin gear meshing and planetary transmission

principle, so it is also called the planetary cycloidal gearbox. The planetary cycloid gearbox can be

widely used in petroleum, environmental protection, chemical industry, cement, transportation, Textile

, pharmaceutical, food, printing, lifting, mining, metallurgy, construction, power generation and other

industries, as a drive or gearbox, the machine is divided into horizontal, vertical, double-axis and

direct-coupled assembly. Its unique smooth structure can replace ordinary cylindrical gear gearbox

and worm gear gearbox in many cases. Therefore, planetary cycloidal gearbox is widely used in

various industries and fields, and is widely welcomed by users.

Conditions of Use: 1. The cycloidal pinwheel gearbox is allowed to be used in the continuous working system, while

allowing both forward and reverse directions. Some models of cycloidal gearboxes allow only one

direction of rotation. 2. The rated speed of the input shaft is 1500 rpm. When the input power is greater than 18.5

kW, it is recommended to use a 6-pole motor with 960 rpm. 3. The working position of the horizontally mounted cycloid gearbox is horizontal. The maximum

horizontal tilt angle during installation is typically less than 15°. Other measures should be take

n to ensure adequate lubrication and prevent oil leakage when it exceeds 15°. 4. The output shaft of the cycloid gearbox cannot be subjected to large axial and radial forces.

Other measures must be taken when there are large axial and radial forces.

performance: 1. Reasonable design, convenient maintenance, easy to disassemble and install, minimum

number of parts and simple lubrication, so that the cycloidal pinwheel gearbox is deeply trusted

by users. 2. Model of cycloidal pinwheel gearbox: 1) B series cycloidal pinwheel gearbox BW foot plate type horizontal double shaft cycloidal pin

wheel gearbox BL flange type vertical double shaft cycloidal pin wheel speed machine BWY foot

plate horizontal special motor direct connection type cycloidal pin wheel gearbox BLY flange

type vertical special motor direct connection type cycloid gearbox BWD foot plate type ordinary

motor direct connection type cycloidal pin gearbox BLD flange type vertical ordinary motor

direct connection type cycloidal pin wheel gearbox 2) X series cycloid gearbox XW foot plate type double axis cycloid gearbox

kind: XL flange type vertical double shaft cycloid gearbox XWD foot plate type horizontal

ordinary motor direct connection type cycloid gearbox XLD flange type vertical motor direct

connection type cycloid gearbox XWD foot plate type Horizontal ordinary motor direct-coupled

cycloid gearbox XLY flange-type vertical motor-connected cycloid gearbox 3) 8000 series planetary

cycloid gearbox 8000 series XW, XWD cycloidal needle Wheel gearbox 8000 series XL, XLD cycloid

gearbox 8000 series XWE, XWED cycloid gearbox 8000 series XLE, XLED cycloidal gearbox 4) F8000

series planetary cycloid gearbox FWD, FLD, FL, FW, FWED, FLED, FWE, FLE 5) Z series planetary

cycloid gearbox JB/T2982-1994 ZW, ZWD, ZL, ZLD, ZWE, ZWED, ZLE, ZLED, ZWS, ZWSD , ZLS, ZLSD

6 ) 9000 series planetary cycloidal pinwheel gearbox 9000 series XW, XWD cycloidal pinwheel gearbox

9000 series XL, XLD cycloidal pinwheel gearbox 9000 series XWE, XWED cycloidal pin wheel

deceleration Machine 9000 series XLE, XLED type cycloidal pinwheel gearbox Note: The above

various forms of gearbox, its essence The same, but each cycloid gearbox manufacturers introduced

their own models, different only 7) identifies the way Taiwan Chuan Shi 600 series cycloid gearbox

THM, THHM, THHHM cycloid gearbox use instructions Notes

lubricating:

1. The horizontal cycloid gearbox is lubricated under normal conditions by oil pool. The height of the

oil surface can be kept in the middle of the oil window. When the working conditions are bad, the

ambient temperature is high temperature.

2. The cycloidal pinwheel gearbox is generally lubricated with 40# or 50# mechanical oil at normal

temperature. In order to improve the performance of the gearbox and extend the service life of the

cycloid gearbox, it is recommended to use 70# or 90# extreme pressure gears. Oil, oil should also

be reconsidered when working under high and low temperature conditions.

3. The vertical installation of the planetary cycloid gearbox should strictly prevent the oil pump

from breaking oil to avoid damage to the components of the gearbox.

4. When refueling, you can rotate the vent cap on the upper part of the base to refuel. When

draining oil, screw the oil drain plug on the lower part of the base to release the oil. The gearbox

is internally oil-free.

5, the first refueling operation for 100 hours should be replaced with new oil, (and the internal

sewage is washed clean) and then continue to work, change every six months (8-hour work

system), if the working conditions are bad, the oil change time can be shortened appropriately,

Practice has proved that the frequent cleaning and oil change of the gearbox (such as 3-6 months)

plays an important role in extending the service life of the gearbox. Lubricating oil should always be

replenished during use.

6. The new speed gearbox issued by our factory has been greased and replaced every six months.

The grease is made of aluminum disulfide-2# or 2L-2# lithium base grease.

use: The cycloidal pinwheel gearbox adopts the cycloidal pin gear meshing and planetary transmission

principle, so it is also called the planetary cycloidal gearbox. The planetary cycloid gearbox can be

widely used in petroleum, environmental protection, chemical industry, cement, transportation,

Textile, pharmaceutical, food, printing, lifting, mining, metallurgy, construction, power generation

and other industries, as a drive or gearbox. Its unique smooth structure can replace ordinary

cylindrical gear gearbox and worm gear gearbox in many cases. Therefore, planetary cycloidal

gearbox is widely used in various industries and fields, and is widely welcomed by users.

Conditions of Use: 1. The cycloidal pinwheel gearbox is allowed to be used in the continuous working system, while

allowing both forward and reverse directions.

2. The rated speed of the input shaft is 1500 rpm. When the input power is greater than 18.5 kW,

it is recommended to use a 6-pole motor with 960 rpm.

3. The working position of the horizontally mounted cycloid gearbox is horizontal. The maximum

horizontal tilt angle during installation is typically less than 15°. Other measures should be taken to

ensure adequate lubrication and prevent oil leakage when it exceeds 15°.

4. The output shaft of the cycloid gearbox cannot be subjected to large axial and radial forces. Other

measures must be taken when there are large axial and radial forces.

noise: Unit decibel dB (A), this value is the input speed of 3000 rev / min, without load, measured at a

distance of 1 m from the gearbox. Hysteresis: The input end is fixed, the output end rotates

clockwise and counterclockwise. When the output end is subjected to positive and negative 2%

rated torque, the output end of the gearbox is displaced by a slight angular displacement, which is

the return gap. The unit is "minute", which is 1/60 of the first degree. The following are some of

the gear ratios listed: Cycloidal pinwheel gearbox single-stage cycloid (BW.BWY.BWD, BL.BLY, BLD)

Machine models are: 12, 15, 18, 22, 27, 33, 39 , 45, 55, 65 Installation: 1. When the coupling of the coupling, pulley, sprocket, etc. is added to the output shaft of the

cycloid gearbox, the direct slamming method is not allowed, because the output shaft structure of

the gearbox cannot withstand the axial slamming force. The shaft end screw hole can be screwed

into the coupling member. 2. The shaft diameter of the output shaft and the input shaft is matched with GB1568-79. 3. The lifting eye screw on the gearbox is only used for lifting the gearbox.

4. When installing the gearbox on the basis, calibrate the installation centerline elevation of the

gearbox, the level and the relevant dimensions of the connected parts. The concentricity of the

calibration drive shaft should not exceed the range allowed by the coupling.

5. When the speed gearbox is calibrated, it can be carried out with steel blocks or cast iron blocks.

The height of the blocks should not exceed three, and it can also be carried out with the iron.

However, the gears should be replaced with flat blocks after calibration.

6. The arrangement of the blocks should avoid the deformation of the body. The two sides of the

foundation bolts should be arranged symmetrically. The mutual distance can be enough to allow the

water slurry to circulate freely during irrigation.

7. The irrigation of cement slurry should be dense, and there should be no air bubbles, voids and

other defects.

Oil spill treatment: Cycloidal pinwheel gearbox gearbox, bearing housing, thread seal, mechanical

seal, etc., due to long-term high-torque mechanical movement, the gearbox meshing gap becomes

larger, resulting in greater noise and equipment vibration. In addition, the sealing part is operated

under high speed and high temperature for a long time, and oil leakage occurs at the sealing part.

Due to the serious oil leakage during the operation of the equipment, many disadvantages are broug

ht to the safety production. The traditional method requires long-term shutdown to disassemble and

replace the gasket and handle the joint surface, and it is impossible to achieve effective treatment

in the operation of the equipment. In the 21st century, a new type of lubricant can be used to solve

this problem. Among the many materials, there is a Mettler Super Sealant & Lubricant, which has

superior self-lubricating properties and reduces the gap between the meshing parts. It effectively

alleviates equipment noise and leakage oil in the dynamic sealing part. Super Lubricant is an oil

additive that does not pollute the oil or degrade the oil. It solves the safety hazards in the production

without stopping the machine, saving the company a high cost of repair or replacement. In the long-term operation of the gearbox, there are often faults such as wear and leakage. The

most important ones are: 1. The bearing chamber of the gearbox is worn, and the wear gearbox including the bearing housing

box, the inner bore bearing chamber and the gearbox bearing chamber is one of the main equipments

of the enterprise. Once the running clearance occurs, the transmission shaft will be given to the drive

shaft. And the transmission gear caused serious damage, causing major downtime and production

accidents, and enterprises will suffer huge economic losses.

2. The shaft diameter of the gear shaft of the gearbox is worn, and the main wear parts are in the

shaft head, keyway, etc.

3. Bearing wear of the drive shaft of the gearbox

4, the gearbox joint surface leakage for wear problems

Transmission ratio: 9, 11, 17, 23, 29, 35, 43, 59, 71, 87 two-stage cycloid (BWE.BWEY.BWED, BLE.BLEY, BLED) Machine

models are: 1510, 1512, 1812, 1815, 2212 , 2215, 2218, 2715, 2718, 3318, 3322, 3922, 4527, 5527,

5533, 6533 gear ratio: 121 (11 × 11), 187 (17 × 11), 253 (23 × 11), 289 (17 × 17), 385 (35 × 11),

391 (23 × 17), 473 (43 × 11), 493 (29 × 17), 595 (35 × 17), 731 (43 × 17), 841 (29 × 29 ) Cycloidal

pinwheel gearbox torque calculation cycloidal pinwheel gearbox torque = 9550 × motor power ÷ motor

power input revolution number × speed ratio × use efficiency (65% - 75%)

Reduction ratio: The ratio of input speed to output speed. Series: Number of sets of planetary gears. Generally, the maximum level can reach three, and the

efficiency will be reduced. Full load efficiency: The transmission efficiency of the gearbox under the maximum load condition

(fault stop output torque). Working life: The cumulative working time of the gearbox under rated load

and rated input speed. Rated torque: It is the long-running torque allowed for the rated life. When the

output speed is 100 rpm, the life of the gearbox is the average life. When this value is exceeded, the

average life of the gearbox will decrease. The gear unit fails when the output torque exceeds twice.

The best service from our transmission drive expert to your inbox directly.

Our Service

Get in Touch

Yantai Bonway Manufacturer Co.ltd

ANo.160 Changjiang Road, Yantai, Shandong, China(264006)

T+86 535 6330966

W+86 185 63806647