DC Motors

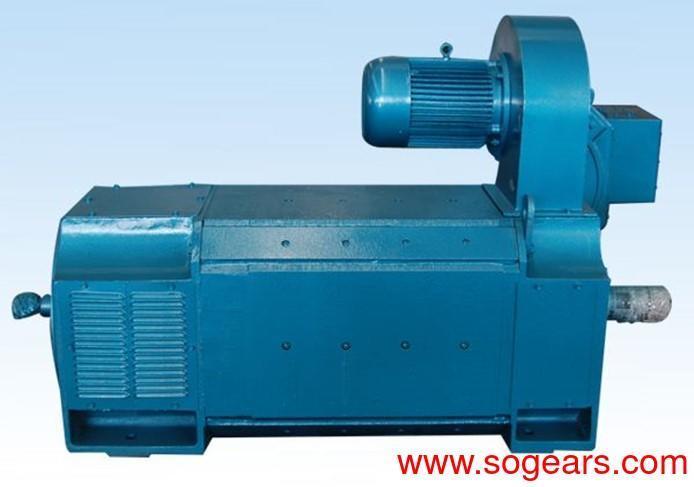

high torque dc motor z4 series

high torque dc motor

The Z4 series DC motor has greater advantages than the Z2 and Z3 series. It can be powered not only by the DC unit power supply, but also for the static rectification power supply. Moreover, the moment of inertia is small, has good dynamic performance, and can withstand high load change rate, and is especially suitable for a control system that requires smooth speed regulation, high efficiency, automatic steady speed, and responsiveness, and has the international advanced level.

Z4 series DC motor: The center height is 100-355mm, which is the standard series of small DC motors specified by the mechanical industry standard JB/T6316-92 "Z4 series DC motor technical conditions" of the People's Republic of China; the center height is 400-450mm, which is outside the standard series. Expand Z4 DC motor; center height is 500~710mm. Z4 series DC motors can be widely used in metallurgical industrial rolling mills, metal cutting machine tools, paper making, dyeing and weaving, printing, cement, plastic extrusion machinery and other industrial sectors.

The motor's rating is continuous continuous rating. In areas where the altitude does not exceed 1000m and the ambient air temperature does not exceed 40°C, the motor can be rated for operation according to the data in the technical data sheet. This series of motors uses Class F insulation.

The power range of Z4 series DC motors ranges from 1.5kW to 840kW. There are nine kinds of rated speeds of 3000, 1500, 1000, 750, 600, 500, 400, 300, 200r/min. The excitation mode is separately excited and the excitation voltage is 180V. A motor with a rated voltage of 160V is usually operated with a reactor in the case of a single-phase bridge rectifier. The inductance value of the external reactor is indicated on the motor nameplate. Motors with a rated voltage of 440V do not require an external reactor.

The performance of Z4 series DC motor not only meets the national standard GB/T755 "Basic Technical Requirements for Rotating Electric Machine", but also basically conforms to the German VDE0530 standard.

Model meaning: Z4-280-11B, Z means DC motor, 4 means 4 series, 280 means motor center height (mm), the first one indicates the core length serial number, the second one indicates the front end cover number, and the 1 is the short end. Cover, 2 is the long end cover, B indicates the compensation winding.

Note: For the Z4-112/2-1 model, the first digit after “/” represents the pole number, and the second digit represents the core length number.

Development:

In 1983, Jiangsu Kelong DC Motor Co., Ltd. (formerly Baoying Motor Factory) undertook the task of digesting and absorbing the introduction of DC motor technology from AEG Company of Germany, and trial-produced and developed the domestic Z4 series DC motor products, which made the domestic popular Z4 DC motor. An important contribution.

Structure Description:

(1) Basic structure

The Z4 series DC motor adopts an octagonal full laminated structure, which not only has high space utilization, but also can withstand pulsating current and rapid load current change when powered by a static rectifier.

Z4 series DC motors generally do not have series excitation windings, which are suitable for automatic control technology that requires forward and reverse rotation. It can also be made with series excitation winding according to user needs. The motor with a center height of 100 to 280 mm has no compensation winding, but the motor with a center height of 250 mm and 280 mm can be made with a compensation winding according to the specific conditions and needs. The motor with a center height of 315 to 450 mm has a compensation winding.

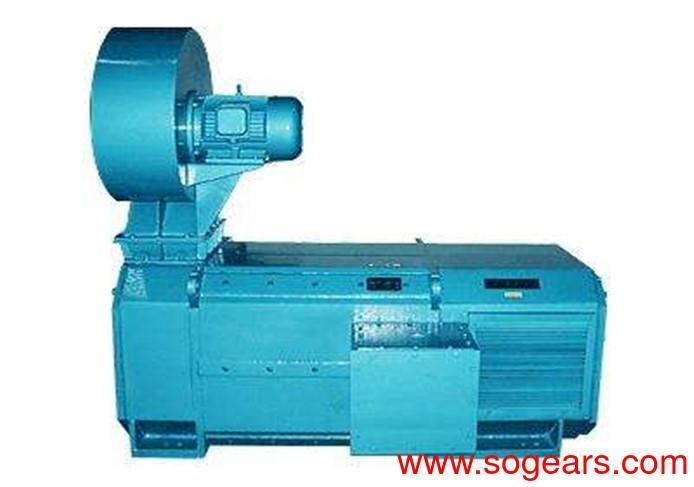

(2) Cooling method and structure, installation form

IC06: External ventilation with blower;

ICl7: the cooling air inlet is a pipe, and the outlet is a blind window exhausting;

IC37: that is, the cooling air inlet and outlet are pipelines;

IC611: fully enclosed air/air cooler;

ICW37A86: Fully enclosed air/water cooler.

And there are a variety of derivative forms, such as self-venting type, with axial fan type, closed type, air/air cooler type. See Table 1 for the cooling air volume, wind pressure, and fan motor power required for each frame motor. The basic protection of the entire series of motors is IP21S.

This series of sima motors can be powered not only by the DC unit power supply, but also by the static rectification power supply. Can be widely used in metallurgical industry rolling mills, metal cutting machine tools, paper, dyeing, printing, cement, plastic extrusion machinery and other industrial sectors.

The Z4 series DC motor has greater advantages than the Z2 and Z3 series. It can be powered not only by the DC unit power supply, but also for the static rectification power supply. Moreover, the moment of inertia is small, has good dynamic performance, and can withstand high load change rate, and is especially suitable for a control system that requires smooth speed regulation, high efficiency, automatic steady speed, and responsiveness, and has the international advanced level.

The rating of the motor is continuous continuous rating. In areas where the altitude does not exceed 1000 m and the ambient air temperature does not exceed 40 °C, the motor can be rated for operation according to the data in the technical data sheet. This series of sima motors uses Class F insulation.

The power range of the 4 series DC motors ranges from 1.5kW to 840kW, and the rated speeds are nine, 3000, 1500, 1000, 750, 600, 500, 400, 300, 200r/min. The excitation mode is separately excited and the excitation voltage is 180V. In addition to the above specified levels, other power, armature voltage, speed and excitation voltage values can be derived depending on the specific situation and the needs of the user.

A motor with a rated voltage of 160V is usually operated with a reactor in the case of a single-phase bridge rectifier. The inductance of the external reactor is indicated on the motor nameplate. Motors with a rated voltage of 440V do not require an external reactor.

The position of the motor outlet box is viewed from the drive end (non-commutator end) on the right side of the base (ie, the positive box). If the user requests the outlet box to be placed on the other side of the base, the reverse box is indicated when ordering. The basic output shaft of the motor is a single shaft extension, and the direction of the exit axis of the outlet box (the positive box) is the left exit shaft. Double shaft extension can also be made if required by the user. The basic direction of rotation of the shaft is viewed counterclockwise from the end of the commutator. The transmission mode of the motor is the coupling of the elastic coupling, and it can also be used for the transmission mode of a certain radial force (belt or gear transmission).

The series motor adopts advanced design, and the stator base adopts a polygonal lamination structure, which effectively utilizes the space and has the advantages of small size, light weight and good performance. The stator yoke, magnetic pole and armature core are laminated by high-quality cold-rolled silicon steel sheets, which have good magnetic permeability. The overall thermal conductivity is excellent. This series of motors adopts rolling bearings, non-stop refueling structure, and the insulation grade is F grade.

This series of motors can be powered not only by the DC unit power supply, but also by the static rectification power supply. Moreover, the moment of inertia is small, has good dynamic performance, and can withstand a high load change rate, and is particularly suitable for a control system that requires smooth speed regulation, high efficiency, automatic steady speed, and responsiveness.

Conditions of Use

1. The rated power of the motor refers to the condition that the altitude does not exceed 1000 meters and the ambient air temperature does not exceed 40 °C.

2. The armature circuit and the excitation circuit of this series of motors can be adapted to the power supply of the controllable power supply, and also to the power supply by the DC generator set.

3. The working environment of this series of motors should not contain acid, alkaline or other gases that are corrosive to insulation.

4. The motor can be installed in a place with harsh environmental conditions, but the correct cooling method and protection level must be selected to protect the motor from normal operation.

5. If the motor is used in ships and wet tropics and the working environment is salty, humid, etc., it should be agreed separately.

6. When the motor is powered by static rectification power supply, the pulse wave of the rectifier is not less than 6. At the rated base speed, rated voltage and rated load current, the peak ripple factor of the power supply does not exceed 10%.

Product performance

1. The basic working mode of this series of Sima motor is continuous load. If other working methods are required, it should be agreed separately;

2. The standard rated voltage of this series of Sima motors is 220V, 330V, 440V, 550V, 660V, 750V. It can also be used to derive other grades of voltage, which must be agreed upon when ordering.

3. The basic mode of this series of Sima motor is the other excitation, the basic excitation voltage is 220V. Other excitation voltages can also be derived. This series of motors allows for forced excitation, and the excitation voltage does not exceed 500V. When the excitation is strong, the excitation current can slightly exceed the rated excitation current, but after the excitation current is stable, the rated excitation current value must not be exceeded.

4. Short-term overload capability of this series of electric persuasion machines:

The first type of motor (Class A) can withstand the short-term (one-minute) overload specified in Table 2;

The second type of motor (Class B) can withstand the short-term (one-minute) overload specified in Table 3;

Occasionally, the short-term overload capability refers to the ability of the motor to withstand the rated load of the frontier in less than one minute or in an emergency. It is recommended that the instantaneous breaking device of the open circuit be set according to the short-term overload capability of the occasional use.

The often used short-term overload capability refers to the ability of the motor to repeatedly withstand the rated load as part of the normal duty cycle. After a short-time overload operation, it must be operated at light load so that the load rms value of the motor during the entire load cycle does not exceed its frontier quota.

The second type of motor (Class B) shall withstand the following continuous loads:

Continuous operation with a 115% rated power load within the rated armature voltage and rated speed range. Under this load, the temperature rise will be higher and other characteristics may differ from the operating conditions under rated conditions.

Within the rated armature voltage and rated speed range, after continuous operation of the rated load, followed by 125% rated power load for two hours, the temperature rise does not exceed the specified value, other characteristics may be different from the operating conditions under rated conditions.

The motor allows for a longer overload time at lower overload multiples. For the second type of DC motor (Class B), the overload factor is allowed to reach 2.5 times (at the rated base speed) for occasional use, and the time is not more than 15 seconds (but necessitate consultation with the manufacturer).

The outline mounting dimensions of this series of motors comply with the IEC72 international standard except for the axial dimension 'B' of the two foot spaces.

The performance and technical requirements of this series of motors can be assessed in accordance with the requirements of the International Electrotechnical Commission standard IEC34-1 or the West German national standard DIN7530.

This series of motors adopts a polygonal structure and has high space utilization. The stator yoke is laminated, suitable for power supply to the rectifier, and can withstand the pulsating current and the sudden change of current (load change). The magnetic pole is mounted with precise positioning, so the commutation is good.

The motor insulation is Class F. It adopts reliable insulation structure and impregnation process to ensure stable insulation performance and good heat dissipation.

This series of motors has the characteristics of small size, good performance, light weight, high output power, high efficiency and high reliability, which can compete with the current international advanced level motor.

The motor can work for a long time with a three-phase fully-controlled rectifier power supply and no external smoothing reactor. The motor with a rated voltage of 160V is powered by a single-phase bridge power supply. At this time, the armature circuit must be connected to the reactor to suppress the pulse current.

Precautions:

1. The standard rated voltage of the motor is 160V, 440V. Also according to

The body condition derives 220V, 400V and 660V or other voltages.

2. The rated motor speed is 3000, 1500, 1000, 750, 600

, 500, 400, 300, 200 r / min a total of nine files. Reduce the armature voltage to

Constant torque speed regulation, reduce the excitation voltage to constant power speed regulation, see the speed regulation range

Technical data sheet (Table 2). Constant voltage regulation below the rated voltage

Torque. The minimum speed is specified to be no less than 20 r/min, and still

Maintain rated torque and stable speed.

3. The basic excitation mode of the motor is separately excited, and the standard excitation voltage is

180V, other excitation voltages can also be negotiated. The motor is allowed to force, strong

The excitation voltage must not exceed 500V. Excitation current must not be allowed when the motor is running normally

Exceeded the rated excitation current. To ensure the reliability of the excitation system insulation,

When disconnecting the excitation circuit, a release resistor must be connected in parallel across the excitation winding.

To prevent self-induced potential. The value is approximately seven times excitation at the standard excitation voltage

Winding resistance (cold). When the excitation voltage is higher than the standard voltage, and the release is released

The discharge resistance value can be less than seven times, and vice versa.

4. Z4-315, Z4-355, Z4-400, and Z4-450 four base belts

There are compensation windings. Derived in the two frame numbers Z4-250 and Z4-280

A motor that compensates for the winding is also possible.

5. The motor is supplied with a terminal marked with a grounding.

6. The power values in the technical data sheet are rated power, rated voltage and

Efficiency at speed, which includes excitation losses, excluding blower losses.

Z4 series DC motors are widely used as transmission sources for various types of machinery, such as metallurgical industry rolling mill drives, metal cutting machine tools, paper, printing, textile, printing and dyeing, cement, plastic extrusion machinery and so on.

The outline mounting dimensions of this series of motors comply with the IEC72 international standard except for the axial dimension 'B' between the two foot holes.

The performance and technical requirements of this series of motors can be evaluated in accordance with the requirements of the International Electrotechnical Commission standard, IEC34-1 or the West German national standard DIN57530.

This series of motors adopts a polygonal structure and has high space utilization. The stator yoke is a laminated type, which is suitable for power supply by a rectifier and can withstand the pulsating current and the sudden change of current (load change). The magnetic pole is mounted with *** positioning, so the commutation is good.

The motor insulation grade is F grade, and it adopts reliable insulation structure and impregnation process to ensure stable insulation performance and good heat dissipation.

This series of motors has the characteristics of small size, good performance, light weight, high output power, high efficiency and high reliability, which can compete with the current international advanced level motor.

The motor can be operated for a long time with a three-phase fully controlled bridge rectifier power supply and without an external smoothing reactor. The motor with rated voltage of 160V is powered by single-phase bridge power supply. At this time, the armature circuit must be connected to the reactor to suppress the ripple current. The inductance value is shown in the table.

The basic cooling mode of the motor is IC06, that is, the external ventilation of the self-contained blower; or the IC17, that is, the cooling air inlet is the pipe, the outlet is the louver exhaust, or the IC37, that is, the cooling air inlet and outlet are all pipes. And there are a variety of derivative forms, such as self-venting type, with axial fan type, closed type, air/air cooler type. The data of cooling air volume, wind pressure and fan motor power of each frame motor are shown in Table 1. The basic protection of the entire series of motors is IP21S.

The position of the motor outlet box is viewed from the drive end (non-commutator end) on the right side of the base (ie, the positive box). If the user requests the outlet box to be placed on the other side of the base, the reverse box is indicated when ordering. The basic output shaft of the motor is a single shaft extension, and the direction of the exit axis of the outlet box (the positive box) is the left exit shaft. Double shaft extension can also be made if required by the user. The basic direction of rotation of the shaft is viewed counterclockwise from the end of the commutator. The transmission mode of the electric motor is an elastic coupling. It can also be used in transmissions with a certain radial force (belt or gear drive), which are allowed to withstand radial forces not greater than the values on the curve in Appendix B.

The best service from our transmission drive expert to your inbox directly.

Our Service

Get in Touch

Yantai Bonway Manufacturer Co.ltd

ANo.160 Changjiang Road, Yantai, Shandong, China(264006)

T+86 535 6330966

W+86 185 63806647