Helical Gearboxes

Helical gearbox

helical gearboxes, electric motor gear reduction box, helical helical gearbox, speed reduction gearbox, small reduction gear boxes, right angle gearbox, gear reduction box, helical gearboxs, gear boxes industrial

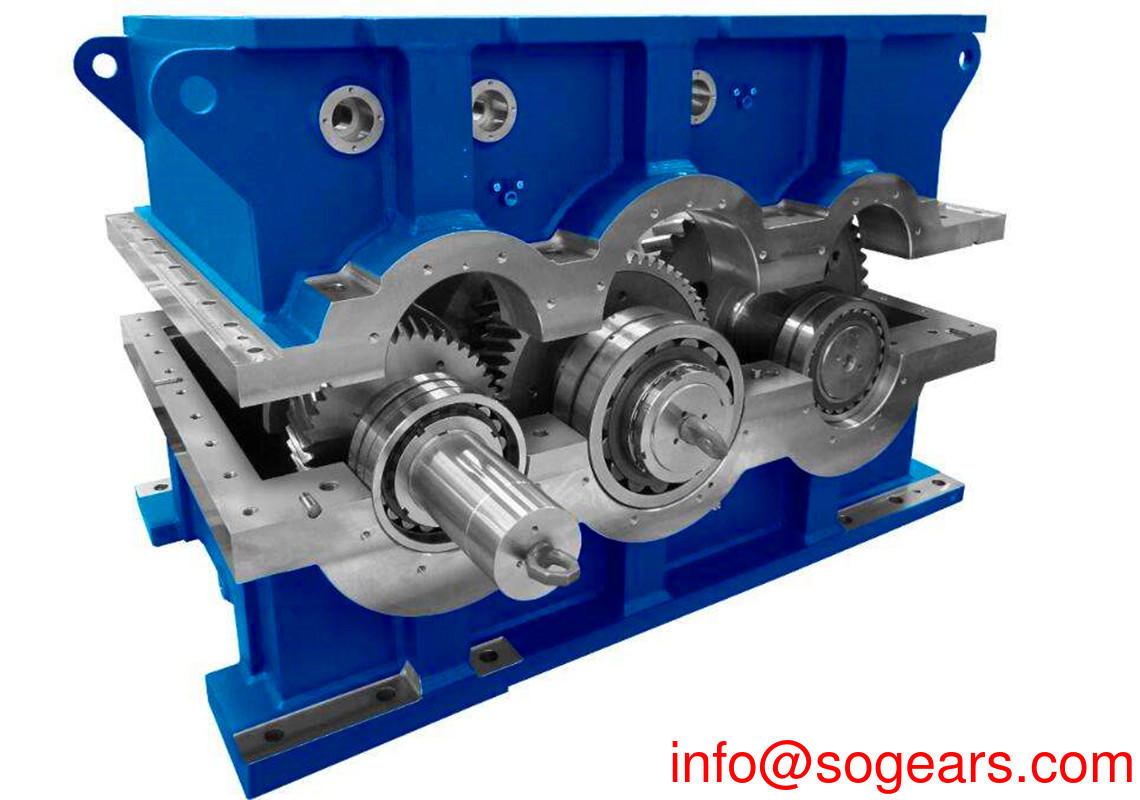

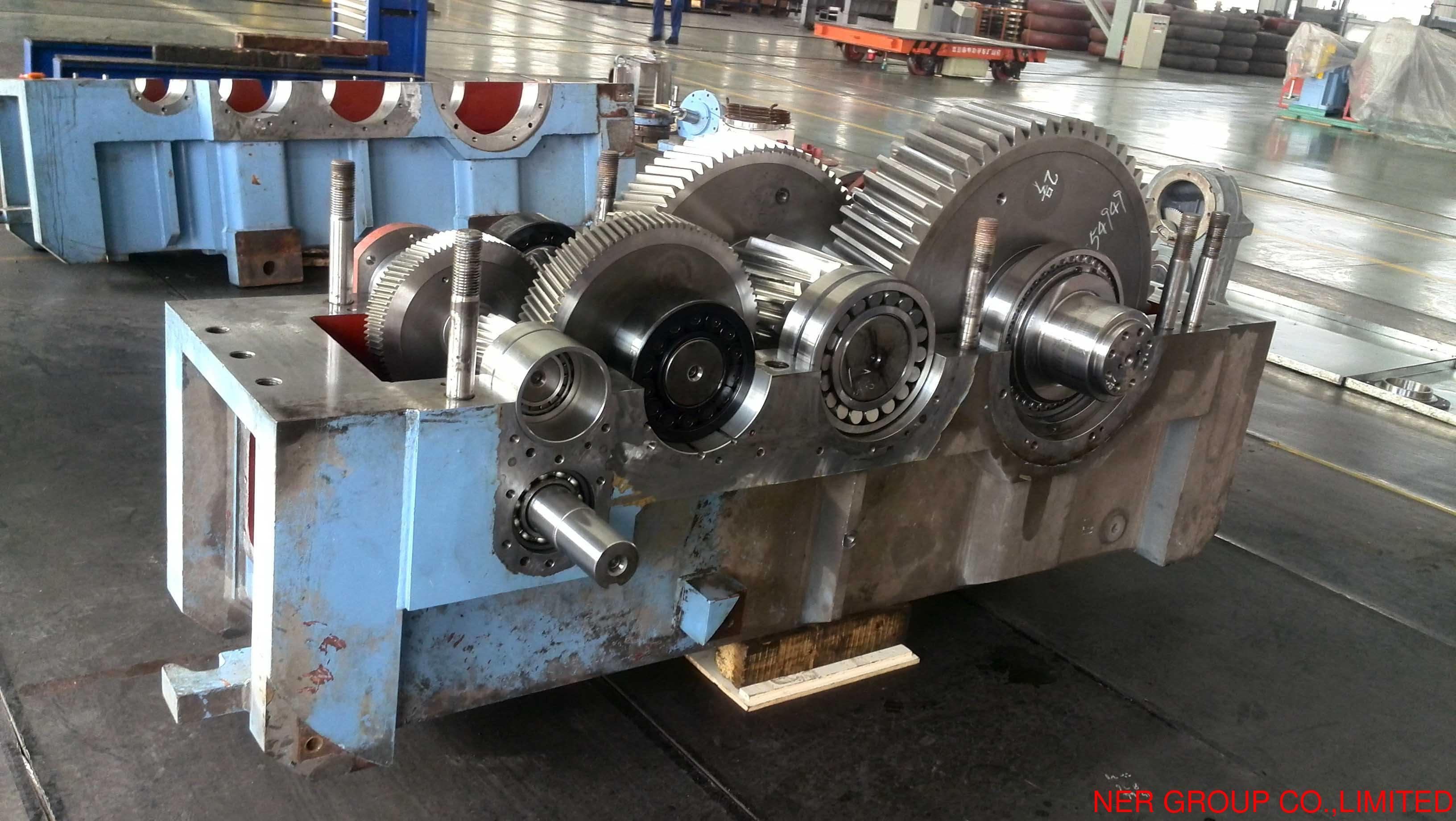

Helical helical gearboxes Product Description

1.Heavy duty gearbox Torque Range: Up to 470000N.m

2.Helical helical gearboxes Output speed:1.7~1200rpm

3.Heavy duty gearbox Input power:2.2~5366kw

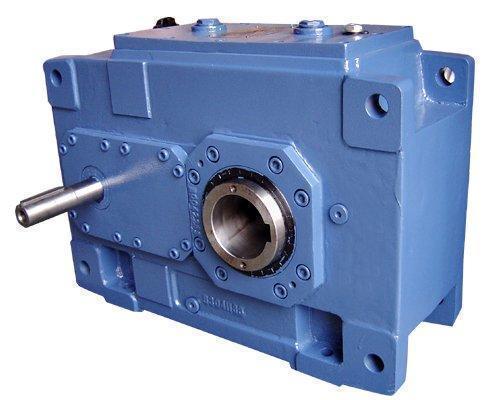

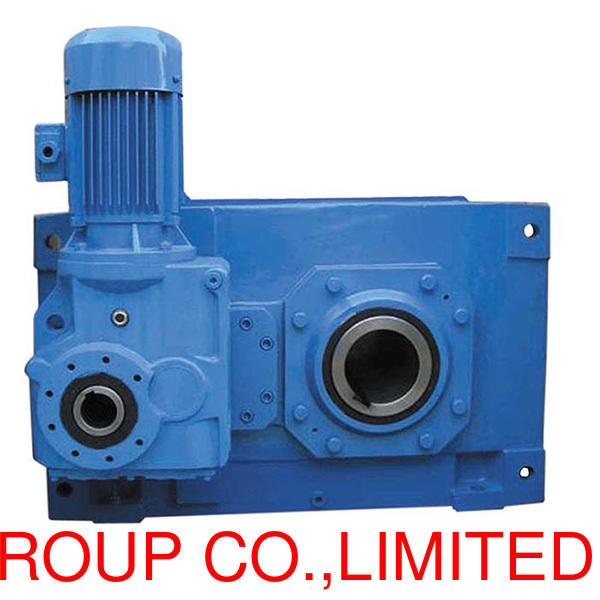

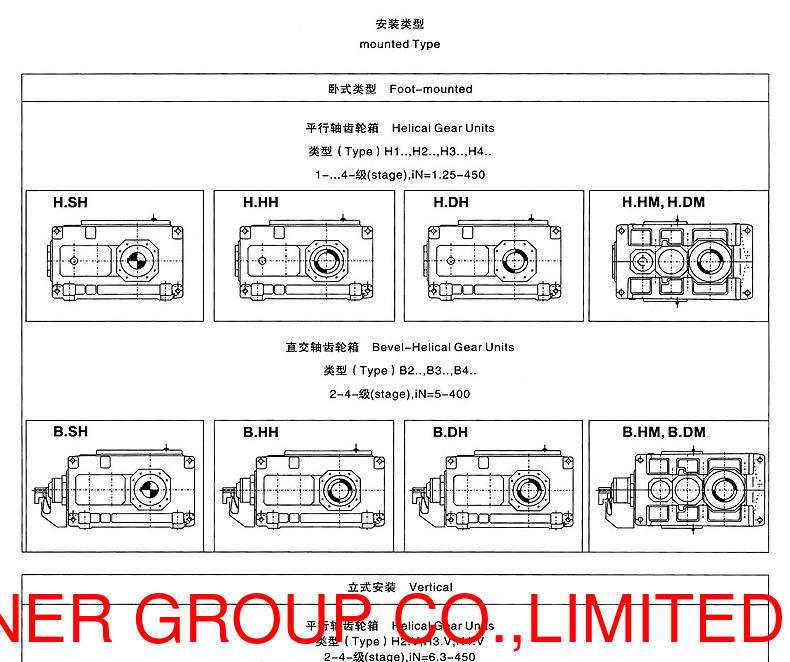

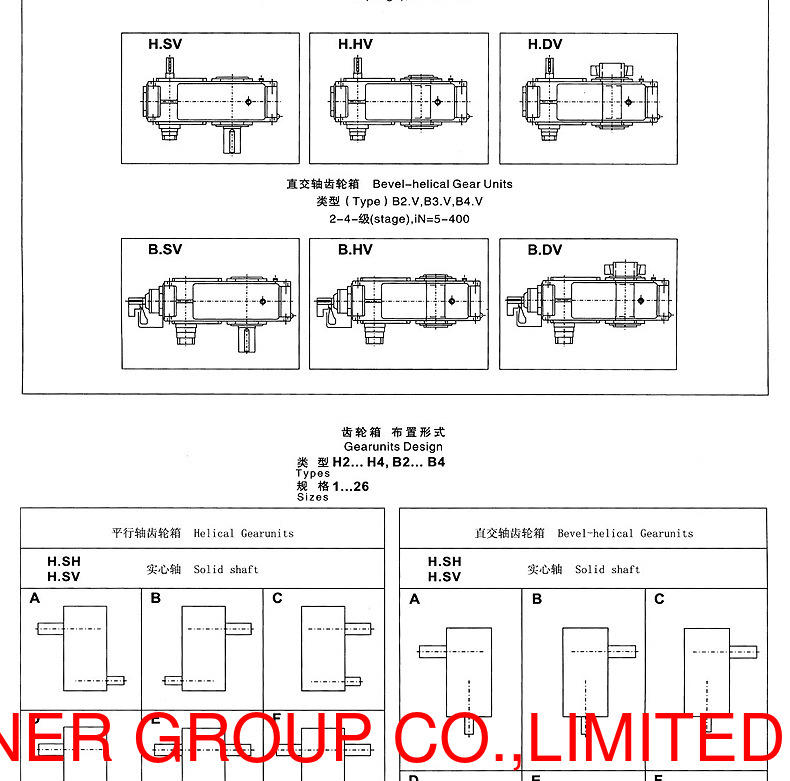

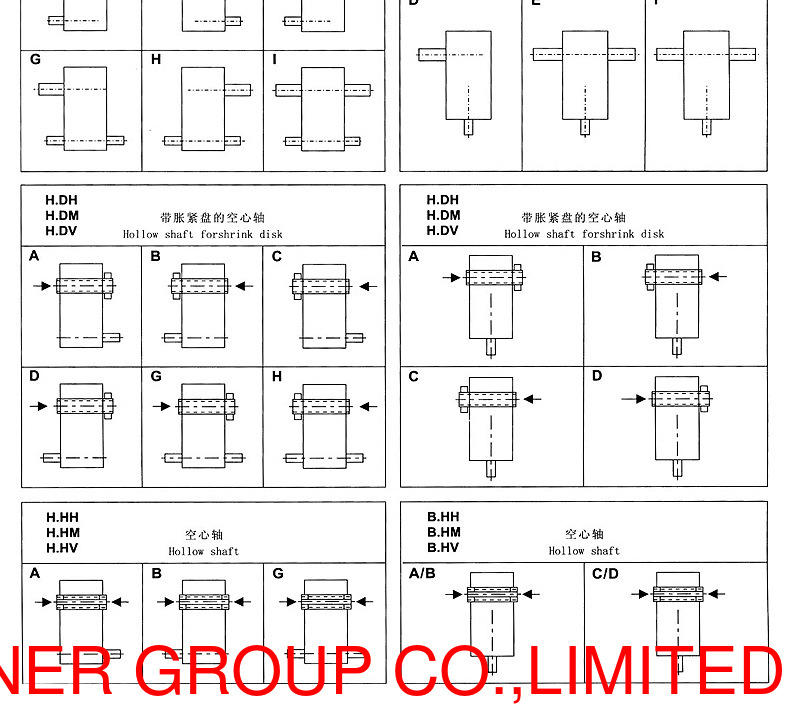

4.Helical helical gearboxes Mounting solution: foot mounted,shaft mounted,shrink disk mounted.

5.right angle gearbox Heavy duty gearbox Input:shaft with key-way,IEC flange;

6.Helical helical gearboxes Output:hollow shaft with key-way,hollow shaft with shrink disk;

7.Heavy duty electric motor gear reduction box gearbox Shaft arrangment: A,B,C,D (detailed please see catalogue)

we have experience in comprehensive and effective helical gearboxes repair dating back to 1992 and we know what it takes to save you time and money over a new replacement. Not to mention helical gearboxes Repair Service provides a value add for customers that cannot afford equipment breakdowns or operation downtime.

gear reduction box Vertical Downward helical gearboxes (Flange Mounted), Vertical Upward helical Gearbox, Double Reduction helical Gearbox and helical gearboxes offered that Sogears provide an effective low cost solution to speed reduction and increased torque, with higher tolerances for shock loading than helical helical gearboxes. In order to select a helical gearboxes, you will need to determine the required torque and service factor for the application.

Application shows:

* Belt conveyor drives

* Bucket elevator drives

* Agitator drives

* Hoisting gear drives

* Travelling gear drives

* Paper machine drives

* Dryer drives

* Water screw drives

helical helical gearbox REDUCTION GEARBOXES have been designed to allow the OEM or end-user more flexibility inengine choices. Gone are the long lead times, higher prices and reliance o one engine company tosupply your gear reduction needs.

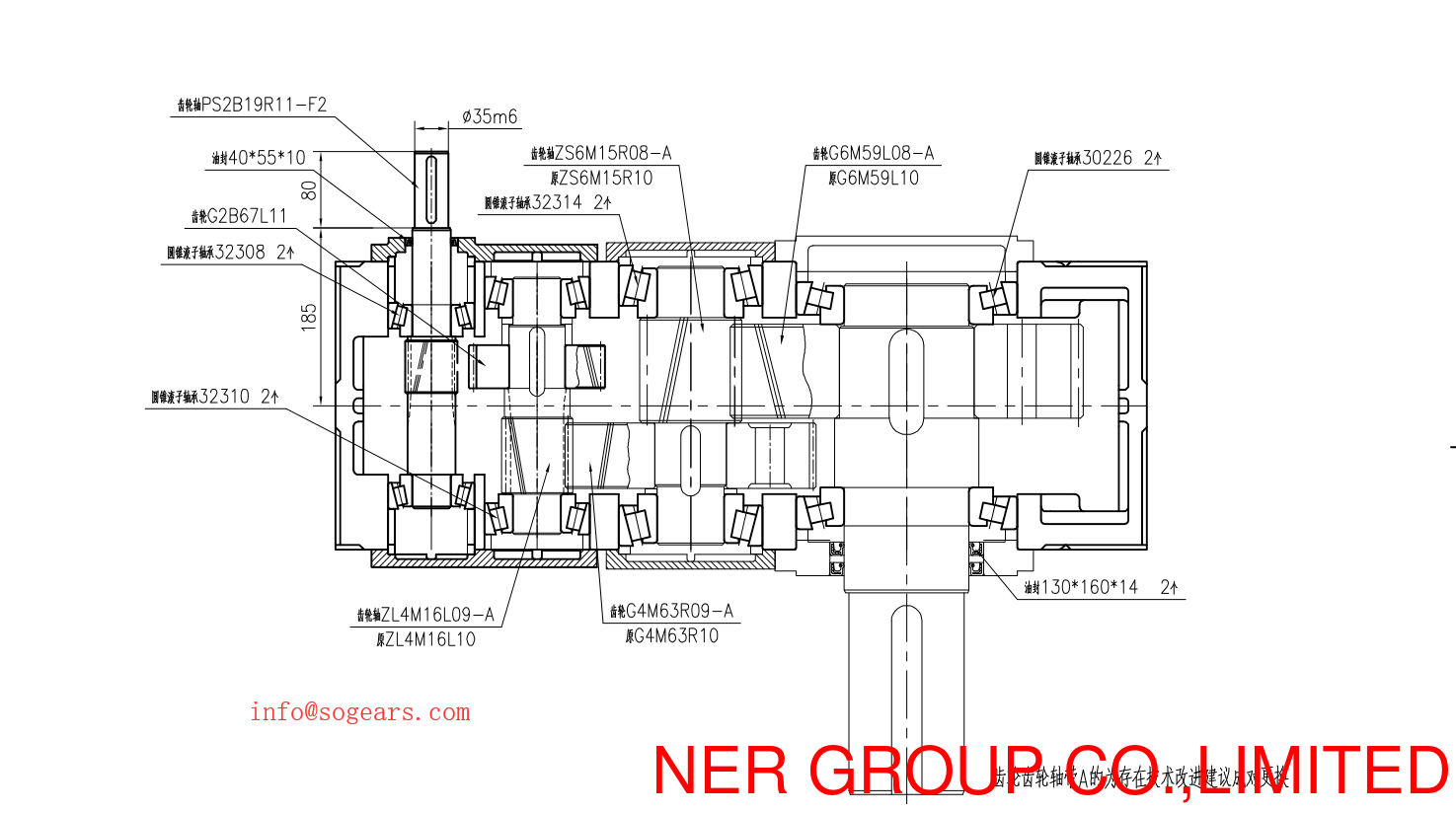

1.Helical helical gearboxes Housing material:HT250 high-strength cast iron ;

2.Heavy duty speed reduction gearbox Housing hardness:HBS190-240;

3.Helical helical gearboxes Gear material:20CrMnTi alloy steel,other materials requested:17CrNi2Mo,20CrNi4A

4.Heavy duty gearbox Surface hardness of gears:HRC58-62;

5.Helical helical gearboxes Gear core hardness:HRC33-40;

6.Heavy duty gearbox Input / Output shaft material:42CrMo alloy steel;

7.Helical helical gearboxes Input / Output shaft hardness:HRC25-30;

8.From small reduction gear boxes to Heavy duty gearbox Heat treatment:tempering,cementiting,quenching.etc.;

We manufacturing high quality helical gearboxes for power transmission systems since 1975. Our helical gearboxes include right angle, bevel, helical gear and spindle for various types of on and off-road applications. Sogears offers the industry’s most comprehensive product array featuring more than 30,000 standard products combined with the ability to custom engineer unique solutions when required. Product lines include standard enclosed helical gearboxes, custom helical gearboxes, AC/DC motors, DC drives and Centric.

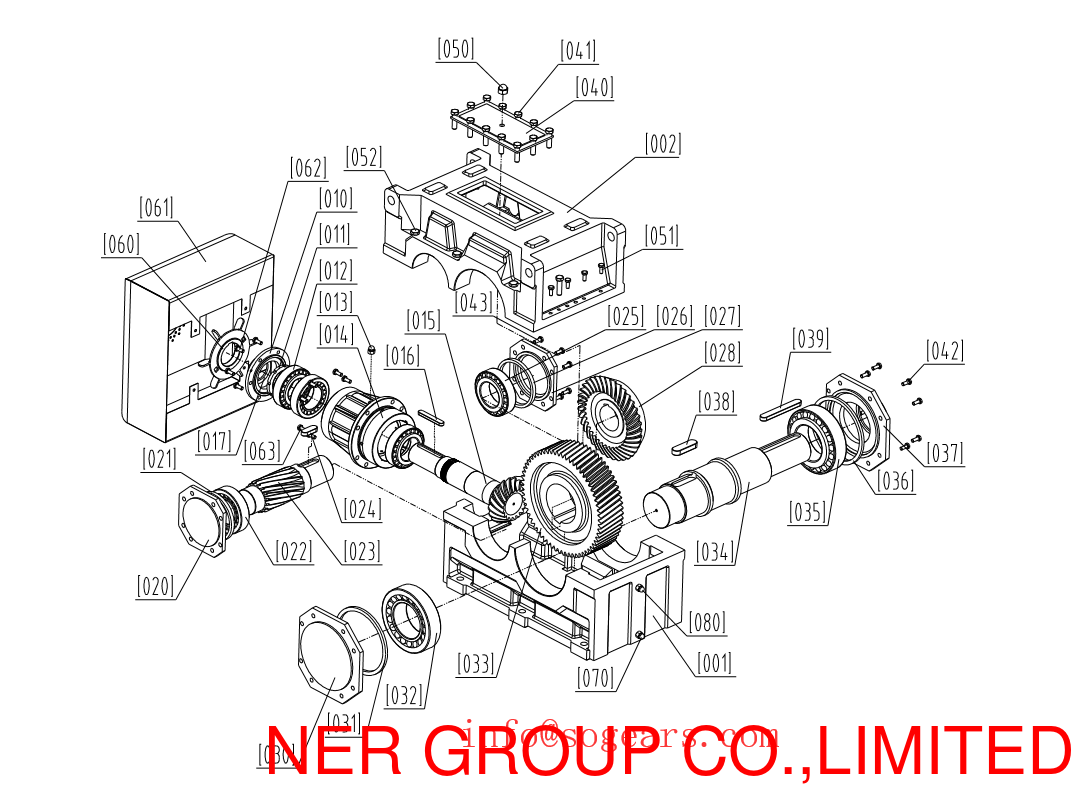

Additional shafts and gears are used in these systems. For example, a smallgear is added to the output shaft of the first set of gears to serve as the input driver.

The gearbox is subjected to the force from the wind wheel and the reaction force generated during the gear transmission. It must have sufficient rigidity to withstand the force and torque to prevent deformation and ensure the transmission quality. The design of the gearbox housing should be in accordance with the layout, processing and assembly conditions of the wind turbine power transmission, and easy inspection and maintenance. With the rapid development of the gearbox industry, more and more industries and different enterprises have applied gearboxes, and more and more enterprises have grown stronger in the gearbox industry.

According to the modular design principle of the unit structure, the gear box greatly reduces the types of parts and is suitable for large-scale production and flexible and variable selection. The spiral bevel gear and the helical gear of the helical gearbox are all carburized and quenched with high-quality alloy steel. The hardness of the tooth surface is up to 60±2HRC, and the precision of the tooth surface grinding is up to 5-6.

The bearings of the transmission parts are all domestic famous brand bearings or imported bearings, and the seals are made of skeleton oil seals; the structure of the speaker body, the larger surface area of the cabinet and the large fan; the temperature rise and noise of the whole machine are reduced, and the reliability of operation is improved. The transmission power is increased. Parallel axis, orthogonal axis, vertical and horizontal universal box can be realized. The input mode includes motor coupling flange and shaft input; the output shaft can be output at right angle or horizontal, and solid shaft and hollow shaft and flange are available.

Carburizing and quenching

Output shaft. The gearbox can meet the installation requirements of a small space, and can also be supplied according to customer requirements. Its volume is 1/2 smaller than the soft tooth helical gearbox, the weight is reduced by half, the service life is increased by 3~4 times, and the carrying capacity is increased by 8~10 times. Widely used in printing and packaging machinery, three-dimensional garage equipment, environmental protection machinery, transportation equipment, chemical equipment, metallurgical mining equipment, steel power equipment, mixing equipment, road construction machinery, sugar industry, wind power generation, escalator elevator drive, ship field, light High-power, high-speed ratio, high-torque applications such as industrial fields, papermaking, metallurgical industry, sewage treatment, building materials industry, lifting machinery, conveyor lines, and assembly lines. It has a good cost performance and is conducive to the domestic equipment.

Function editing

The gearbox has the following functions:

1. Accelerated deceleration is the variable speed gearbox that is often said.

2. Change the direction of the drive. For example, we use two sector gears to transmit the force vertically to the other.

3. Change the turning moment. Under the same power conditions, the faster the gear rotates, the smaller the torque the shaft receives, and vice versa.

4. Clutch function: We can separate the engine from the load by separating the two originally meshed gears. Such as brake clutches.

5. Distribute power. For example, we can use one engine to drive multiple slave shafts through the gearbox main shaft, thus realizing the function of one engine to drive multiple loads.

Design editor

Compared with other industrial gearboxes, because the wind turbine gearbox is installed in a small cabin that is several tens of meters or even more than one hundred meters high from the ground, its own volume and weight for the cabin, tower, foundation, unit wind load, installation and maintenance Costs and the like have an important impact, so it is important to reduce the size and weight. At the same time, due to inconvenient maintenance and high maintenance costs, the design life of the gearbox is usually required to be 20 years, and the reliability requirements are extremely demanding. Because size and weight and reliability are often a pair of irreconcilable contradictions, the design and manufacture of wind turbine gearboxes often fall into a dilemma. The overall design stage should meet the requirements of reliability and working life, and compare and optimize the transmission scheme with the minimum volume and minimum weight as the target; the structural design should meet the transmission power and space constraints, and consider the structure as simple as possible. Reliable operation and convenient maintenance; product quality should be ensured at every stage of the manufacturing process; gearbox operating conditions (bearing temperature, vibration, oil temperature and quality change) should be handled during operation

Inner ring gear

Real-time monitoring and routine maintenance according to specifications.

Since the tip line speed cannot be too high, the rated input speed of the gearbox gradually decreases with the increase of the single unit capacity, and the rated speed of the unit above MW is generally not more than 20r/min. On the other hand, the rated speed of the generator is generally 1500 or 1800r/min, so the speed ratio of the large wind power increasing gearbox is generally around 75~100. In order to reduce the volume of the gearbox, the wind power transmission box above 500kw usually adopts the power split planetary transmission; the common structure of 500kw~1000kw has two levels of parallel axis + 1 planet and 1 parallel shaft + 2 planetary transmission. The megawatt gearbox adopts a 2-stage parallel shaft +1 planetary transmission structure. Due to the relatively complicated planetary transmission structure and the difficulty in processing large internal ring gears, the cost is high. Even with the 2-stage planetary transmission, the NW transmission is the most common [1].

Manufacturing technology editor

The external gear of the wind power gear box generally adopts a carburizing and quenching grinding process. The introduction of high-efficiency and high-precision CNC forming gear grinding machines.

High precision CNC forming gear grinding machine

There is not much difference between China's external gear finishing level and foreign countries. There is no difficulty in achieving the 5-level precision specified by the 19073 standard and the 6006 standard. However, there are still gaps between China's advanced technology in heat treatment deformation control, effective layer depth control, tooth surface grinding tempering control, and gear tooth shaping technology.

Due to the large size of the ring gear of the wind turbine gearbox and the high processing precision, the manufacturing technology of the inner ring gear in China is quite different from the international advanced level, which is mainly reflected in the gear processing and heat treatment deformation control of the helical internal gear.

The machining accuracy of the structural parts such as the box body, the planet carrier and the input shaft has a very important influence on the meshing quality of the gear transmission and the bearing life. The quality of the assembly also determines the length of the wind turbine gearbox and the reliability. . China has realized from the importance of the processing and assembly precision of structural parts that there is a certain gap between the level of equipment and the advanced level of foreign countries. The acquisition of high-quality, high-reliability wind turbine gearboxes, in addition to advanced design techniques and necessary manufacturing equipment support, is inseparable from the strict quality control of every step of the manufacturing process. The 6006 standard provides strict and detailed requirements for the quality assurance of the gearbox [1].

Lubrication editing

Commonly used gearbox lubrication methods include gear oil lubrication, semi-fluid grease lubrication, and solid lubricant lubrication.

Molybdenum disulfide

Slide several ways. For better sealing, high speed, high load, good sealing performance can be lubricated with gear oil; for poor sealing, low-speed can be lubricated with semi-fluid grease; for oil-free or high-temperature applications Molybdenum sulfide superfine powder lubrication.

The lubrication system of the gearbox is very important for the normal operation of the gearbox. The large wind turbine gearbox must be equipped with a reliable forced lubrication system to inject the oil to the gear meshing area and bearings. In the cause of the failure of the gearbox, the lack of lubrication accounted for more than half. Lubricating oil temperature is related to component fatigue and overall system life. Generally speaking, the maximum oil temperature of the gearbox should not exceed 80 °C during normal operation, and the temperature difference between different bearings should not exceed 15 °C. When the oil temperature is higher than 65 °C, the cooling system starts to work; when the oil temperature is lower than 10 °C, the oil should be heated to the predetermined temperature and then turned on.

In the summer, due to the long-term full state of the wind turbine, plus direct sunlight, the operating temperature of the oil rises above the set value; while in the cold winter in the northeast, the minimum temperature often reaches below 30 °C, lubrication. Lubricating oil in the pipeline is not smooth, gears and bearings are not well lubricated, causing the gearbox to stop at high temperature, the tooth surface and bearing are worn out, and the low temperature will also increase the viscosity of the gearbox oil. When the oil pump starts, the load is heavy, and the oil pump motor

lubricating oil

overload.

Gearbox lubricants have an optimum temperature range for operation. It is recommended to design a lubricant thermal management system for the gearbox lubrication system: when the temperature exceeds a certain value, the cooling system starts to work. When the temperature is lower than a certain value, the heating system starts to work. Always keep the temperature within the optimal range. In addition, improving the quality of lubricating oil is also an important aspect that must be considered in the lubrication system. Lubricant products must have excellent low temperature fluidity and high temperature stability, and research on high performance lubricating oil should be strengthened.

Bearing life editor

Statistics show that about 50% of faults in wind turbine gearbox failures are related to bearing selection, manufacturing, lubrication or use. At present, due to the backward technical conditions, etc., many of the core components of domestic megawatt-class units, such as motors, gearboxes, blades, electronic control equipment and yaw systems, rely on imports and are used in these large wind turbines. Box bearings, yaw bearings, pitch bearings and spindle bearings are completely dependent on imports. Therefore, the more accurate calculation method of bearing life is particularly important for the design of wind turbine gearboxes.

Wind power gearbox

Due to the high reliability required for bearings, the service life of bearings is usually not less than 130,000 hours. However, due to too many factors affecting the bearing fatigue life, the bearing fatigue life theory still needs to be improved continuously. There is no uniform bearing life theory at home and abroad, which is a calculation method accepted by all industries.

The operating temperature of the bearing, the viscosity of the lubricating oil, the cleanliness and the rotational speed have a great influence on the bearing life. When the operating state is deteriorated (temperature rise, speed decrease, pollutant increase), the bearing life may be greatly reduced. In-depth analysis of various factors affecting the life of wind turbine gearbox bearings, researching a more accurate calculation of bearing life is the top priority of the domestic bearing industry and even the wind power industry.

Use editing

1. Accelerated deceleration, which is often referred to as the variable speed gearbox.

2. Change the direction of the drive. For example, we can use two sector gears to transmit the force vertically to the other.

3. Change the turning moment. Under the same power condition, the faster the speed turns, the smaller the torque the shaft receives, and vice versa.

4. Clutch function: We can separate the engine from the load by separating the two originally engaged gears, such as brake clutch.

5. Distributing power. For example, we can use an engine to drive multiple slave shafts through the gearbox main shaft, thus realizing the function of one engine to drive multiple loads.

Noise processing editor

The gear box is an important part of the wide application in mechanical transmission. When a pair of gears mesh, there is inevitably a tooth pitch, tooth shape and other errors. During the operation, an meshing impact will occur and a noise corresponding to the gear mesh frequency will occur. Frictional noise occurs between the tooth faces due to relative sliding. Since gears are the basic part of the gearbox drive, reducing gear noise is necessary to control gearbox noise. In general, the causes of gear system noise mainly have the following aspects:

1. Gear design. Improper parameter selection, too small coincidence, improper or no shape modification, and unreasonable gearbox structure. In the gear processing, the base section error and the tooth profile error are too large, the flank clearance is too large, and the surface roughness is too large.

2. Gear train and gearbox. The assembly is eccentric, the contact precision is low, the parallelism of the shaft is poor, the rigidity of the shaft, the bearing and the support is insufficient, the rotation precision of the bearing is not high, and the gap is not appropriate.

3. Input torque in other aspects. Fluctuation of load torque, torsional vibration of the shafting, balance of the motor and other transmission pairs, etc.

Entry Atlas More Atlas

9.Helical helical gearboxes Machining precision of gears:accurate grinding, 6-5 Grade;

10.Heavy duty gearbox Noise (MAX):60~68dB;

11.Helical helical gearboxes Lubricating oil:GB L-CKC220-460, Shell Omala220-460;

12.Heavy duty helical gearboxs Temp. rise (MAX):40°C ;

13.Helical helical gearboxes Efficiency:94%~96% (depends on the transmission stage) ;

14.Heavy duty gearbox Temp. rise (Oil)(MAX):50°C;

15.Helical helical gearboxes Backlash:≤20Arcmin;

16.Heavy duty gear boxes industrial Vibration:≤20µm;

We design, engineer, and manufacture our PP series double reduction helical helical gearboxes to provide high reduction ratios in a compact housing. With three frame sizes, ratios from 25:1 to 900:1, and torque values from 2.2Nm to 34Nm, these high reduction gearboxes are useful in a broad range of applications.

Our gear manufacturing makes skew-axis, high torque gears enable world-class power density custom helical gearboxes for robotics, aerospace and military. Our gear manufacturing makes skew-axis, high torquehelical gearboxes enable world-class power density custom reduction helical gearboxes for robotics, aerospace and military.

helical gearboxes, Gear box, gearbox, reduction drive, belt drive, beltdrive, Airboat reduction drive, airboat gearbox, airboat gear box, airboat gear reduction drive, Experimental airplane, experimental airplane drive, experimental airplane gearbox, experimental airplane gear box, Stinger Drives, Stingerdrives, stinger gearbox, stinger gear.

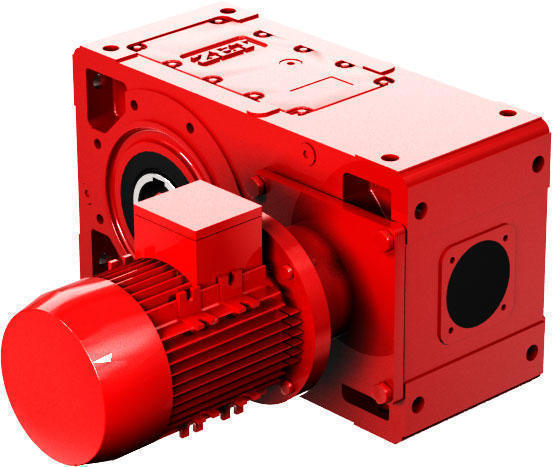

With a wide range of reduction gearboxes for actuator system building whether it be a single motorised actuator or several actuators mechanically linked. The gearboxes available are available as motorised units as standard, however the helical gearboxes itself can be supplied. The most popular types of gearboxes are Helical helical Gearboxes, In-line Helical and Parallel Shaft, others.

With a combination of gears used to reduce the input speed (as of a marine turbine) to a lower output speed (as of a ship's propeller). a large selection of helical gearboxes and helical gearboxs for a wide variety of applications which require high torque and slow speed. Check out our everyday low prices

SAFETY INSTRUCTION During running progress or after, for gearbox, motor and electrical parts and high temperature surface ,only allow professional to do work such as transport, warehouse, amount, installation, running and maintance. Please must pay attention to: a. Relevant manual and circuit diagram b. Worm and safe sign c. All request and special provision d. Regular provision for safety& prevent from accident from country/local government/special field Launch into running Please check if turning is right without connection (note singular frictional noise in the progress of turning), if transmission parts hadn’t be connected on trial. Please pay attention to if keyway is fix, note insure exam and protector even if for trail running. IF there are notice, temperature is rising, libration and other deviant running state. Should turn off motor, clear the reason. If it is need, please contact us

With Best Regards,

Cherry Zhang ( Sales Department; Miss. )

NER GROUP CO.,LIMITED

Yantai Bonway Manufacturer Co., Ltd

Tel:+86-535-6330966

Mobile:+86-18865558975

www.planetary-gearbox.com

https://twitter.com/gearboxmotor

https://www.facebook.com/sogears1993

Viber/Line/Whatsapp/Wechat: 008618865558975

E-mail:

Add:No.5 Wanshoushan Road Yantai city Shandong Province, China

The best service from our transmission drive expert to your inbox directly.

Our Service

Get in Touch

Yantai Bonway Manufacturer Co.ltd

ANo.160 Changjiang Road, Yantai, Shandong, China(264006)

T+86 535 6330966

W+86 185 63806647