Shandong Wanwei Transmission Technology Co., Ltd.

Shandong Wanwei Transmission Technology Co., Ltd. focuses on the R&D, production and sales of high-end core components of intelligent industrial robots, and provides customers with high-end hardware technology solutions. The company's independent R&D team adheres to continuous technological innovation in the fields of high-precision machinery such as professional machine tools and hardware equipment. Over the past decades, it has accumulated rich technological innovation achievements and successful practice cases, and has won good reputation from domestic and foreign customers. In recent years, the company has achieved world-leading technological breakthroughs in the research and development of the iRV reducer, the core component of industrial robots. The technological research and development achievements have obtained national invention patents. The inspection, evaluation, key technical indicators and comprehensive performance indicators of the competent department are at the international leading level. Wanwei transmission reducer has been applied and promoted in high-end professional machine tools and high-precision intelligent industrial robots. It broke the high dependence of Chinese robot manufacturers on imports of more than 50% of high-end reducers.

China World Speed Reducer Group

Guomao Gear Reducer Group is a comprehensive private enterprise focusing on gear reducer and other equipment manufacturing industries and diversified development of related industries. The main business of the group and its holding and shareholding subsidiaries involves equipment manufacturing, new materials, financial investment, and industrial parks. , Real estate development and many other industrial fields, the cooperative customers are distributed all over the world. In 2016, it was successfully selected into the top 500 private enterprises in China (ranking 487th). Jiangsu Guomao Reducer Co., Ltd. in the group industry sector It has been in the leading position in the national general reducer industry for many consecutive years.

Gearboxes have a wide range of applications, such as in wind turbines. Gearboxes are an important mechanical component that is widely used in wind turbines. Its main function is to transmit the power generated by the wind wheel under the action of the wind to the generator and make it get the corresponding speed.

Generally, the rotation speed of the wind wheel is very low, far less than the rotation speed required by the generator to generate electricity. It must be realized by the speed increasing effect of the gear pair of the gear box, so the gear box is also called the speed increasing box.

The gear box bears the force from the wind wheel and the reaction force generated during gear transmission, and must have sufficient rigidity to withstand the force and torque, prevent deformation, and ensure the transmission quality. The design of the gear box body should be carried out in accordance with the requirements of the layout of the wind turbine power transmission, processing and assembly conditions, and ease of inspection and maintenance. With the continuous rapid development of the gearbox industry, more and more industries and different companies have used gearboxes, and more and more companies have developed and grown in the gearbox industry.

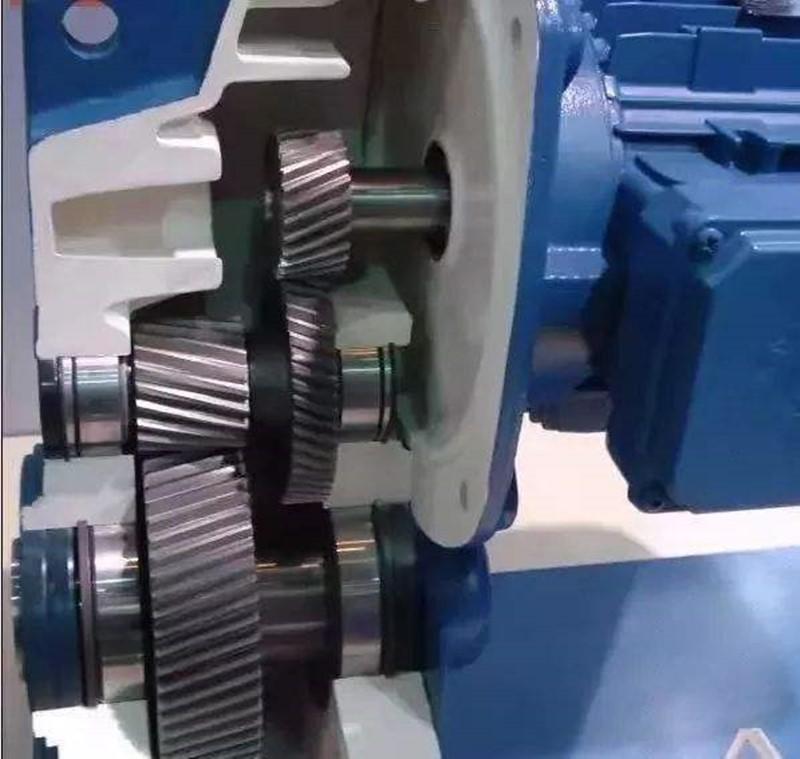

The gearbox is based on the modular design principle of the unit structure, which greatly reduces the types of parts and components, and is suitable for large-scale production and flexible selection. The spiral bevel gears and helical gears of the reducer are all carburized and quenched with high-quality alloy steel. The tooth surface hardness is as high as 60±2HRC, and the tooth surface grinding accuracy is as high as 5-6.

The bearings of the transmission parts are all domestic well-known brand bearings or imported bearings, and the seals are skeleton oil seals; the structure of the suction box, the larger surface area of the cabinet and the large fan; reduce the temperature rise and noise of the whole machine, and improve the reliability of operation , The transmission power increases. It can realize parallel shaft, right-angle shaft, vertical and horizontal general box. The input methods include motor connection flange and shaft input; the output shaft can be output at right angles or horizontally, and solid shaft and hollow shaft, flange type output shaft are available . The gearbox can meet the installation requirements of small spaces, and can also be supplied according to customer needs. Its volume is 1/2 smaller than that of the soft gear reducer, the weight is reduced by half, the service life is increased by 3 to 4 times, and the carrying capacity is increased by 8 to 10 times. Widely used in printing and packaging machinery, three-dimensional garage equipment, environmental protection machinery, conveying equipment, chemical equipment, metallurgical mining equipment, iron and steel power equipment, mixing equipment, road construction machinery, sugar industry, wind power generation, escalator and elevator drives, shipbuilding, light High-power, high-speed ratio, high-torque occasions such as industrial field, papermaking field, metallurgical industry, sewage treatment, building material industry, lifting machinery, conveyor line, assembly line, etc. It has a good cost performance and is conducive to the matching of localized equipment.

The gearbox has the following functions:

1. Accelerating and decelerating is the so-called variable speed gearbox.

2. Change the transmission direction. For example, we can use two sector gears to transmit the force vertically to the other rotating shaft.

3. Change the rotating torque. Under the same power condition, the faster the gear rotates, the smaller the torque on the shaft, and vice versa.

4. Clutch function: We can achieve the purpose of separating the engine from the load by separating the two originally meshed gears. Such as brake clutch and so on.

5. Distribution of power. For example, we can use an engine to drive multiple slave shafts through a gearbox main shaft, so as to realize the function of one engine driving multiple loads.

The reducer is an independent component composed of gear transmission, worm transmission, and gear-worm transmission enclosed in a rigid shell. It is often used as a reduction transmission device between the original moving part and the working machine. It plays the role of matching the speed and transmitting torque between the prime mover and the working machine or the actuator. It is widely used in modern machinery.

The reducer is generally used for low-speed and high-torque transmission equipment. The motor, internal combustion engine or other high-speed running power is used to achieve the purpose of deceleration by meshing with the large gear on the output shaft through a gear with a small number of teeth on the input shaft of the reducer. The reducer will also have several pairs of gears with the same principle to achieve the ideal reduction effect. The ratio of the number of teeth of the large and small gears is the transmission ratio.

The reducer plays the role of matching the speed and transmitting torque between the prime mover and the working machine or the actuator. It is a relatively precise machine. The purpose of using it is to reduce the speed and increase the torque. There are many types, different models, and different types have different uses. There are many types of reducers, which can be divided into gear reducers, worm reducers and planetary gear reducers according to the transmission type; according to the transmission stages, they can be divided into single-stage and multi-stage reducers; according to the gear shape, they can be divided into cylindrical gear reducers According to the arrangement of transmission, it can be divided into expansion type reducer, shunt type reducer and coaxial type reducer.

Features:

The main feature of the worm gear reducer is that it has a reverse self-locking function and can have a larger reduction ratio. The input shaft and the output shaft are not on the same axis or on the same plane. But generally the volume is large, the transmission efficiency is not high, and the accuracy is not high. The harmonic drive of the harmonic reducer uses the controllable elastic deformation of the flexible element to transmit motion and power. The volume is small and the accuracy is high. However, the disadvantage is that the flexible wheel has limited life and is not resistant to impact. The rigidity is compared with metal parts. difference. The input speed cannot be too high. The advantages of planetary reducer are compact structure, small return clearance, high precision, long service life, and large rated output torque. But the price is slightly more expensive. The gear reducer has the characteristics of small size and large transmission torque. The gear reducer is designed and manufactured on the basis of a modular combination system. There are a lot of motor combinations, installation forms and structural schemes, and the transmission ratio is finely graded to meet different operating conditions and realize electromechanical integration. The gear reducer has high transmission efficiency, low energy consumption and superior performance. The cycloidal pinwheel reducer is a transmission model that adopts the principle of cycloidal pin tooth meshing planetary transmission. It is an ideal transmission device with many advantages, a wide range of uses, and can run forward and backward.

effect:

1. Reduce the speed and increase the output torque at the same time. The torque output ratio is the motor output multiplied by the reduction ratio, but be careful not to exceed the rated torque of the reducer;

2. Deceleration reduces the inertia of the load at the same time, and the reduction in inertia is the square of the reduction ratio.

Application areas:

The reducer is a mechanical transmission device in many fields of the national economy. The product categories involved in the industry include various gear reducers, planetary gear reducers and worm reducers, as well as various special transmission devices, such as speed increasing devices and speed regulation Devices, and various composite transmission devices including flexible transmission devices. The product service area involves metallurgy, nonferrous metals, coal, building materials, shipbuilding, water conservancy, electric power, engineering machinery and petrochemical industries.

The development history of the reducer industry in my country has been nearly 40 years, and the reducer products have been widely used in various fields of the national economy and national defense industry. Food and light industry, electric machinery, construction machinery, metallurgical machinery, cement machinery, environmental protection machinery, electronic appliances, road construction machinery, water conservancy machinery, chemical machinery, mining machinery, transportation machinery, building materials machinery, rubber machinery, petroleum machinery and other industries Reducer products have strong demand.

The huge potential market has spawned fierce industry competition. In the cruel market competition, enterprises in the reducer industry must accelerate the elimination of outdated production capacity, vigorously develop high-efficiency energy-saving products, make full use of the national energy-saving product benefiting project policy opportunities, and increase product renewal efforts , Adjust the product structure, pay attention to the national industrial policy, to cope with the complex and changeable economic environment, and maintain a good momentum of development.

Instructions

skill

1. After 200~300 hours of operation, the oil should be changed for the first time, and the quality of the oil should be checked regularly in the future use, and the oil mixed with impurities or deteriorated should be replaced in time. Under normal circumstances, for a long-term continuous working reducer, the new oil should be replaced by 5000 hours of operation or once a year, and the long-term deactivated reducer should also be replaced with new oil before restarting. The reducer should be filled with oil of the same grade as the original, and should not be mixed with oils of different grades. Oils with the same grade but different viscosity are allowed to be mixed;

2. When changing the oil, wait for the reducer to cool down and there is no danger of burning, but it should still be kept warm, because after the complete cooling, the viscosity of the oil increases and it is difficult to drain the oil. Note: Cut off the power supply of the transmission device to prevent accidental power on;

3. During work, when the oil temperature rises above 80°C or the oil pool temperature exceeds 100°C and abnormal noise is found, stop using it, check the cause, remove the fault, and replace the lubricating oil before continuing to run ;

4. The user should have reasonable use and maintenance rules and regulations, and carefully record the operation of the reducer and the problems found during the inspection. The above regulations should be strictly implemented.