Schneider DC contactors have a very compact installation range (45 mm to 38A), which is generally more convenient and simple, and also meets international standards. There has been a certain improvement in performance and product safety. The DC contactor has a wide range of product lines from 09A to 620A. The installation of surge suppressors does not require tools to be performed, as long as it is directly inserted into the contactor, so it does not occupy too much space.

What's more, the width of the reversible contactor is only 90 mm, so that the extra space is not taken up during the mechanical interlocking process, and the overall installation time efficiency has been greatly improved. Starter components provide pre-wired modules to make starter assembly easier. Schneider DC contactor 100A is an integrated 1 normally open / 1 normally closed auxiliary contact. The DC coil has a built-in bidirectional current suppressing diode. At the same time, the reversible contactor is also equipped with a bidirectional current suppressing diode. design.

Schneider DC contactors have a clear distinction between the main circuit and the control circuit in the control and protection components. The mirror contact design in accordance with safety standards is used. The service life can ensure 100 million reliable operations. The protective cover can prevent the contactor from accidentally turning on The phenomenon occurs, and a padlockable cover is configured on the circuit breaker and the thermal relay dial. Its role is to prevent accidental changes. The DC coil of the contactor has a wide range of control voltage (0.7 ~ 1.25Uc), and also has certain characteristics of shock resistance, noise reduction and high strength of the terminal.

The following is the product model and its introduction:

LC1-D09M7C, LC1-D115M7C, LC1-D12M7C, LC1-D18M7C, LC1-D25M7C, LC1-D32M7C, LC1-D38M7C, LC1-D40M7C, LC1-D50M7C, LC1-D65M7C, LC1-D80M7C, LC1-D95M7C, LC1-D150M7C, LC1-D170M7C, LC1-D205M7C, LC1-D245M7C, LC1-D300M7C, LC1D09M7C, LC1D12M7C, LC1D15M7C, LC1D18M7C, LC1D25M7C, LC1D32M7C, LC1D40M7C, LC1D50M7C, LC1D65M7C, LC1D80M7C, LC1D95M7C, LC1D11500M7C, LC1D15000M7C, LC1D17000M7C, LC1D205M7C, LC1D245M7C, LC1D300M7C, LC1D410M7C, LC1D475M7C, LC1D620M7C, LC1D09Q7C, LC1D12Q7C, LC1D15Q7C, LC1D18Q7C, LC1D25Q7C, LC1D32Q7C, LC1D40Q7C, LC1D50Q7C, LC1D65Q7C, LC1D80Q7C, LC1D95Q7C, LC1D11500Q7C, LC1D15000Q7C, LC1D205Q5C, LC1D245Q5C, LC1D300Q7C, LC1D410Q7C, LC1D475Q7C, LC1D620Q7C, LC1D09B7C, LC1D12B7C

Contactor,Coil voltage 230V AC,withAux contact LADN20-C LC1D18M7C

Contactor, coil voltage 230V AC,50HZ with aux contact LAEN11N LC1 E06 10

Ammeter ,Input 0-1/2A,SD-48,75/1A CP-T72-N

Voltmeter 0-137.5v CP-T72-N VOLT

Power meter, Power logic METSEPM5330 PM5300

contactor,coil volt 230V AC/50HZ,Ith 500A LC1D410C

Contactor, 2 pole, 1 set N/O and 1 set N/C , Coil Volt 48V LC1 D09-E7

Aux. contact block, 1 set N/C and 1 set N/O LADN11G

Contactor 1 set N/C and 1 set N/O, 48V LC1D12-E7

Contactor 4 set of N/O, 48V CA2KN40E7

Schneider DC contactor LC series model description is as follows:

1. The position of the number "1" represents a single contactor of the TeSys series;

2. The position of the letter "(T)" represents an AC 4-pole contactor;

3. The position of the number "09" represents the current specification A (including 09, 12, 18, 25, 32, 38, 40, 50, 65, 80, 95, 115, 150, 170, 205, 245, 300, 410, 475 , 620), 1NO + 1NC comes with below 95A, but no auxiliary contact above 95A;

4. The position of the letter "(A)" indicates that it has Everlink function;

5. The position of the number "(8)" represents a DC 4-pole contactor;

6. The position of the letter "M" represents the coil voltage code (including B24, CC36, D42, E48, F110, M220, P230, U240, Q380, V400, N415, R440, S500, Y660);

7. The position of the number “7” represents 7 50 / 60Hz coil (50 / 60Hz coil below 95A), D standard DC coil, L DC low power coil;

8. The position of the letter "C" represents SSIC manufacturing (9 ~ 620A).

Note: Schneider DC contactor TeSys series and thermal relay TeSys series can be directly inserted, but cannot be directly inserted with other series thermal relays.

Technical Parameters:

1. LC1D09 to D38: Clamp and install on 35MM rail AM1DP or fix with screws;

2. LC1D40A to D65A: clamp and install on 35MM guide rail AM1DP or fix with screws;

3. LC1D40 to D90: Clamped on 35mm or 75MM rail AM1DL or fixed by screws;

4. LC1D115 and D150: clamped and mounted on 2X35MM rail AM1DP or fixed by screws;

5, LC: low power consumption;

6. The weight is a contactor using an AC control circuit. For DC or bottom function number control circuits, Schneider DC contactors LC1D09 to D32 increase by 0.160KG;

7. In the lifting industry, 50HZ can continue to use "5C" coil contactor, 50 / 60HZ recommends using 7CS003 coil contactor.

Speaking of contactors, many friends are not very familiar with them. Contactors are divided into DC contactors and AC contactors. There are many types of contactors. Contactors are actually very common in industry and are similar to temperature switches. When the power is turned on, the contactor becomes an electromagnet, and the electromagnetic attraction force disappears when the power is turned off. This is the simple principle of the contactor. When talking about the contactor, you have to say a brand. Contactors produced by Schneider are in the country. All are benchmarks. Today we will introduce several series of Schneider contactors.

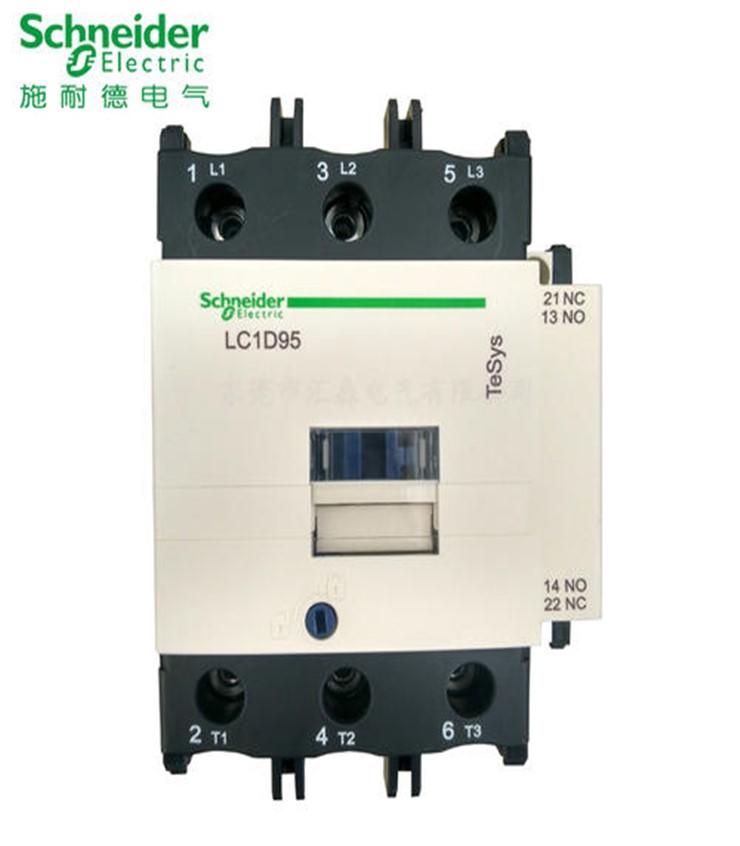

LC1-D contactor

The LC1-D contactor is mainly used in AC 50Hz or 60Hz, AC voltage to 660V (690V), when the working voltage is 380V under the AC-3 use category, the rated operating current is 170A, for long-distance switching on and off The circuit can be combined with a thermal relay of corresponding specifications to form a magnetic starter to protect the circuit that may be overloaded. The contactor is suitable for frequently starting and controlling AC motors. AC, DC and DC low power control loops. AC, DC and DC low power control loops.

Can be composed of a variety of starters, non-reversible or reversible contactors, star delta starters, autotransformer starters. Connection method: spring terminal, Everlink terminal, screw connection, ring terminal and quick wiring method. The new 40 ~ 65A contactor uses Everlink connection technology, and the connection to the circuit breaker is simple and reliable. Complete certifications: CE, CCC, CSA, UL, DNV, BV, LROS, etc. Covers 9 ~ 150A rated current range. Mechanical life is up to 20 million times and electrical life is up to 2 million times. With 50Hz-60Hz universal coil, it can be used worldwide. Modular accessories for all contactor sizes. Provide 4 different terminal blocks. More specifications and more selectivity.

LC1-K contactor

LC1-K contactor can remotely switch on and off the circuit and frequently start and control the AC motor. It can also form a magnetic starter with an appropriate thermal relay to protect the circuit that may be overloaded.

Scope of application: LC1-K series AC contactors (hereinafter referred to as contactors) are mainly used for AC 50Hz, rated insulation voltage (Ui) and rated operating voltage (Ue) of 600V, and rated operating voltage of 380V under AC-3 use In the circuit with a rated working current of 95A, it is used for remotely connecting and breaking the circuit and frequently starting and controlling the AC motor, and it can be combined with a suitable thermal relay to form a magnetic starter to protect the circuit that may be overloaded.

Schneider AC contactor

1. Basic composition

(1) Electromagnetic system, including attraction coil, moving iron core and static iron core;

(2) Contact system, including three sets of main contacts and one to two sets of normally open and normally closed auxiliary contacts, which are linked to each other with the moving iron core;

(3) Arc extinguishing device, generally large-capacity AC contactors are equipped with arc extinguishing device in order to cut off the arc quickly and avoid burning the main contact;

(4) Insulated housings and accessories, various springs, transmission mechanisms, short-circuit rings, terminals, etc.

working principle:

When the coil is energized, the static iron core generates electromagnetic attraction and pulls the moving iron core. Since the contact system is linked with the moving iron core, the moving iron core drives the three moving contacts to run simultaneously, and the contacts are closed, thereby turning on power supply. When the coil is powered off, the suction force disappears, and the moving iron core linkage part is separated by the reaction force of the spring, so that the main contact is disconnected and the power is cut off.

Instructions:

(1) Generally, there are 8 points for three-phase contactors, three inputs, three outputs, and two control points. The output and input are corresponding and can be easily seen. If you want to add self-locking, you also need to connect the line to the control point from one terminal of the output point.

(2) The principle of AC contactor should be known first. He uses external power to add to the coil to generate an electromagnetic field. When the power is turned on, the contact point will be opened after the power is turned off. After knowing the principle, you should find out the contacts of the external power supply, that is, the two contacts of the coil, which are generally located on the lower part of the contactor and on each side. The other several inputs and outputs are generally on the upper part, you can see at a glance. Also pay attention to the voltage of the external power supply (220V or 380V), which is usually marked with. And pay attention to whether the contact point is normally closed or normally open. If there is self-locking control, it is enough to sort out the line according to the principle.

Second, Schneider DC contactor

1.Working principle

When the contactor coil is energized, the coil current generates a magnetic field, which causes the static iron core to generate electromagnetic attraction to attract the moving iron core and drive AC.

Contactor contact action: normally closed contact is open, normally open contact is closed, the two are linked. When the coil is de-energized, the electromagnetic attraction force disappears, and the armature is released under the action of the release spring, so that the contact is restored: the normally open contact is opened, and the normally closed contact is closed.

2. Selection method

(1) Selecting the type of DC contactor The type of DC contactor should be selected according to the type of load current and the weight of the load, that is, AC load or DC load, whether it is light load, general load or heavy load.

(2) Rated current of the main contact of the DC contactor The rated current of the main contact of the DC contactor can be calculated according to an empirical formula. IN main contact ≥ PN motor / (1 ~ 1.4) UN motor, if the motor controlled by the DC contactor starts 2. Frequent braking or reversing. Generally, the rated current of the main contactor of the contactor is degraded.

(3) Rated voltage of the main contact The voltage marked on the nameplate of the contactor refers to the rated voltage that the main contact can withstand, not the voltage attracting the coil. The rated voltage of the main contact of the contactor should not be less than the rated voltage of the load during use. .

(4) Selection of operating frequency The operating frequency refers to the number of times the contactor is switched on and off per hour. When the on-off current is large and the on-off frequency is too high, it will cause the contacts to overheat severely or even be welded. If the operating frequency exceeds the specified value, a DC contactor with a large rated current should be selected.

(5) Selection of rated coil voltage The rated voltage of the coil may not necessarily be equal to the rated voltage of the main contact. When the wiring is simple and there are few electrical appliances, a voltage of 380V or 220V can be directly selected. If the wiring is complicated and the electrical appliances are used for more than 5 hours, 24V, 48V or 110V (36V, 110V, or 127V international regulations in 1964) coils.