Acvatix hydronics. Everything under control.

Acvatix™ is a versatile range of valves and actuators designed for ease of use, superior control accuracy, and energy efficiency. The Acvatix product range can help you to fulfill nearly any control and hydronic requirements associated with the generation, distribution and use of heating and cooling.

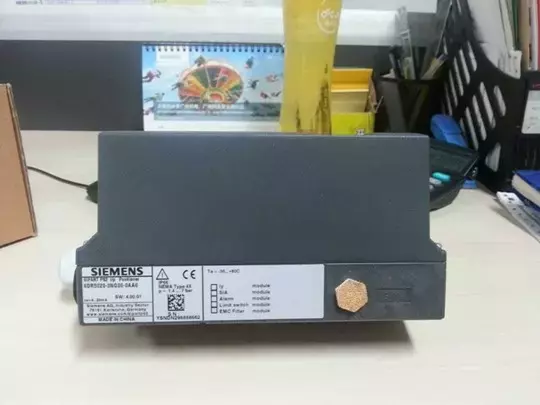

6DR5020-0NG00-0AA0, 6DR5010-0EN00-0AA0, 6DR5020-0NN00-0AA0, 6DR5020-0NN01-0AA0, 6DR5020-0NN01-0AA2, 6DR5220-0EG00-0AA0, 6DR5120-0NG00-0AA0, 6DR5020-0NN01-0AA2, 6DR5020-0EG00-0AA0, 6DR5010-0EN00-0AA0, 6DR5210-0EN00-0AA0, 6DR5010-0EN00-0AA0, 6DR5220-0EN00-0AA0, 6DR5220-0EN10-0AA0, 6DR5220-0EG00-0AA0, 6DR5110-0NG00-0AA0, 6DR5320-0NG00-0AA0, 6DR5320-0NG00-0AA0, 6DR5510-0NN00-0AA0

Selection of Siemens Valve Positioner

Installation accessories for NAMUR angular actuator

VDI / VDE3845, with plastic coupling wheel, without mounting bracket

VDI / VDE 3845, with stainless steel coupling wheel, without mounting bracket

SIPART PS100 NAMUR angular stroke actuator mounting bracket

• 80 x 30 x 20 mm

• 80 x 30 x 30 mm

• 130 x 30 x 30 mm

• 130 x 30 x 50 mm

6DR4004-8D

TGX: 16300-1556

6DR4004-1D

6DR4004-2D

6DR4004-3D

6DR4004-4D

Mounting components for other angular actuators

The following mounting brackets can be used to install components with NAMUR angular stroke actuators

6DR4004-8D supporting use

• SPX (DEZURIK) Power Rac, sizes R1, R1A, R2 and R2A

• Masoneilan Camflex II

• Fisher 1051/1052/1061, sizes 30, 40, 60 to 70

• Fisher 1051/1052, size 33

TGX: 16152-328

TGX: 16152-350

TGX: 16152-364

TGX: 16152-348

Mounting kit for NAMUR linear actuator

• NAMUR linear actuator mounting kit and short rod (2 ... 35mm

(0.08 ... 1.38 inch)

• 35 ... 130 mm (1.38 ... 5.12 inch) stroke feedback lever, without

NAMUR mounting bracket

• Simplified installation kit (same as 6DR4004-8V but without mounting bracket and U

Plug), with short rod, maximum stroke 35 mm (1.38 inches)

• Simplified installation components (same as 6DR4004-8V but without mounting brackets and U-shaped

Bolt), with long rod, stroke greater than 35 mm (1.38 inches)

• Stainless steel 316 cylinder and gasket, used to replace NAMUR straight travel executive

The assembly of 6DR4004-8V, -8VK and -8VL

PTFE cylinder and gasket.

• Two stainless steel 316 clamps to replace NAMUR straight travel

Actuator mounting components 6DR4004-8V, -8VK and -8VL

Aluminum clamping parts.

6DR4004-8V

6DR4004-8L

6DR4004-8VK

6DR4004-8VL

6DR4004-3N

6DR4004-3M

Other straight-stroke actuator mounting components

• Masoneilan model 37/38, size 6-51 mm (<2 inches)

• Masoneilan model 87/88

• Masoneilan model 37/38, size 51-254 mm (> 2 inches)

• Fisher models 657/667, sizes 30-80

• Samson actuator model 3277

Bracket size = 101 mm (integrated connection without trachea), not applicable Ex d

TGX: 16152-595

TGX: 16152-1210

TGX: 16152-1215

TGX: 16152-900

6DR4004-8S

OPOS interface conforms to VDI / VDE 3847

• VDI / VDE 3847 interface OPOS adapter assembly, sealed, not suitable for isolation

Burst shell

6DR4004-5PB

Connector

For safety solenoid valve with extended mounting flange (according to NAMUR standard)

• Actuators for installation to IEC 534-6

• For SAMSON actuator (integrated installation) see above 1)

6DR4004-1B

6DR4004-1C

documentation

SITRANS I100 isolated power supply HART

(See "SITRANS I power supply unit and isolation amplifier")

• 24 V DC auxiliary power supply

7NG4124-0AA00

SITRANS I200 output isolated HART

(See "SITRANS I power supply unit and isolation amplifier")

• 24 V DC auxiliary power supply 7NG4131-0AA00

1. Intelligent valves

Makes it a snap

Intelligent Valves are self-optimizing dynamic valves with cloud connection used in heating groups and air handling units. They balance and control flow, measure energy, and provide data for energy monitoring and system optimization.

Intelligent Valves offer benefits: Facilitate work

Save time

Ensure comfort in buildings

Increase energy efficiency

2. Dynamic hydronic balancing

We have a responsibility to create buildings that are better for people and that are sustainable for the environment – and that means transforming buildings into environments that care.

3. PICVs

Hydronics made easy

PICVs (pressure-independent combi valves) prevent oversupply and reciprocal hydronic interference, reducing energy consumption and operational costs. Additionally, PICV enabled precise temperature control improves the comfort and wellbeing of building users. Siemens recommends PICVs especially for radiators, chilled ceilings, VAV and fan coil units.

Acvatix product benefits

Simple planning and implementation of energy-efficient HVAC systems

Flexible planning thanks to continuous volumetric flow ranges and large differential pressure ranges

Simplified dimensioning, presetting, hydronic balancing, and commissioning

Easier system extension with independent pressure control.

4. Globe Valce

An excellent choice for your business

Designed for efficiency, with precise control and leak-free operations, control ball valves are used for continuous and precise control in closed circuits. Siemens recommends control ball valves especially for air handling units and the 6-port control ball valves for heated and chilled ceilings.

Acvatix benefits:

Simple handling for quick, error-free installation

Highly efficient, with low torque and friction, and fine kvs graduation

Broad range of actuators and customer-specific adaptations

Flexible connection with internal and external thread screw fittings for the 6-port control ball valves

5. Solid conditions with accurate control

Magnetic valves are valves with a pre-installed magnetic actuator. They are used for the shutoff and mixing of fluids (water, water with antifreeze, heat transfer fluid etc.) and steam in nearly all HVAC applications. Magnetic valves are also ideal for applications with even the most stringent requirements, including industry-related areas such as engine test benches. Siemens recommends magnetic valves especially for domestic hot water and chiller plants.

Your benefits with Acvatix:

Energy efficiency

Rapid, magnetic valve control in under two seconds

Precise drop-by-drop control, for high efficiency and stable control conditions

6. Rotary valves

Close off and mix reliably

Rotary valves – ball valves, slipper valves, butterfly valves – are primarily used in energy generation and distribution. Typical applications are if an additional boiler needs to be connected, or for the switching over of storage tank charging. Siemens recommends rotary valves especially for cooling towers.

Acvatix benefits:

Fast and simple valve-actuator coupling

Large dimensions for the highest volumetric flows

Visibility of operating status and position displays for easy service troubleshooting

7. Refrigerant valves

Hermetically sealed for highest safety

The Acvatix range offers hermetically sealed mixing, diverting, and 2-port valves for refrigeration plants. They also include refrigerant valves for expansion, hot gas and suction throttle applications. All Acvatix refrigerant valves save energy in the refrigeration plant, for example through their accurate superheat control also in part load situations.

Your benefits with Acvatix:

Hermetically sealed refrigerant valves – also in IP65 design

Energy savings with accurate superheat control, fine stroke resolution and <1 second positioning time

Vibration-free operation

Safety feature for power failure

Control of dynamic processes

Easy to install and service

High degree of environmental compatibility

8. Actuators for globe valves and PICV

Efficiency, reliability and longevity

Acvatix actuators for globe valves and PICVs consist of a comprehensive range of electrohydraulic, electromotoric, thermostatic and thermal actuators that can perform in a broad range of applications. For every type of actuator the suitable Acvatix valves are available.

9. Actuators for rotary valve

Rotary actuators for accurate control

The Acvatix range offers actuators for butterfly, mixing and slipper valves as well as damper actuators for ball valves. They cover a wide application area, and for every type of actuator the suitable Acvatix valves are available.

The valve is often used in important industrial production and people's livelihood, and its safe and reasonable use is very important. In terms of safety, it is easy to cause safety problems and environmental pollution problems after a leak, causing great losses to investors and society. Reasonably speaking, there is a big gap between the size of the valve configuration and the cost, and the valve switching characteristics have a great influence on the process production. Most of our original model selection is based on empirical data. It is difficult to adjust and it is difficult to judge whether your valve selection has problems .

Conventional valves have difficulties in leak detection, and it is often necessary to have special equipment to judge the failure of the valve. Generally, the factory is rarely equipped, even if it is equipped, it is difficult to check in time. There is a large investment. Disadvantages.

Moreover, many industrial valves are expensive, and the conditions of use vary greatly. How to track the use of the valve and develop the corresponding products according to the use of the situation can only rely on human response, there is no unified data basis.

Valves are often used in important industrial production and people's livelihood occasions. After a leak, it is easy to cause safety problems and environmental pollution problems, causing great losses to investors and society.

The working principle of the pneumatic valve positioner is that it and the pneumatic actuator constitute an automatic control unit and various regulating valves are connected to each other after debugging and installation, and then combined into a pneumatic regulating valve. It is used in various industrial automation process control fields.

Pneumatic valve positioner receives a weak current signal from the controller or control system of 4 ~ 20mA, and sends an air signal to the pneumatic actuator to control the valve position.

It is used in conjunction with pneumatic control valves to form a closed-loop control loop. Convert the DC current signal given by the control system to the gas signal that drives the regulator valve to control the action of the regulator valve. At the same time, it feedbacks according to the opening of the regulating valve, so that the valve position can be correctly positioned according to the control signal output by the system.

The pneumatic valve positioner works according to the principle of torque balance. When the signal pressure P1 into the bellows 2 increases, the main lever 3 rotates around the fulcrum, so that the nozzle baffle 9 approaches the nozzle. The nozzle back pressure is amplified by the unidirectional amplifier 8 After that, the pressure into the membrane chamber of the actuator increases, causing the valve stem to move downward. And drive the feedback lever to rotate around the fulcrum, and the feedback cam also rotates counterclockwise. The auxiliary lever 4 rotates around the fulcrum through the roller, and the feedback spring is stretched. The tension and signal pressure of the spring on the main lever 3 are used in the bellow When the force on reaches the moment balance, the instrument reaches the balance state. The valve position of the actuator is maintained at a certain opening degree, and a certain signal pressure corresponds to a certain valve position opening degree. The above action mode is positive action, if you want to change the action mode, as long as the cam is flipped, A direction becomes B direction, etc. The so-called positive acting positioner means that the signal pressure increases and the output pressure also increases; the so-called negative acting positioner means that the signal pressure increases and the output pressure decreases. As long as a positive acting actuator is equipped with a reaction positioner, it can realize the action of the reaction actuator; on the contrary, as long as a reaction actuator is equipped with a reaction positioner, it can realize the action of the positive action actuator.

Advantages of Siemens SIPART PS2 positioner:

What are the advantages of SIPART PS2 positioner? It provides decisive advantages:

• Simple installation and automatic initialization (automatic adjustment of zero position and travel range i)

• Easy operation

-Use three buttons and user-friendly two-line display for local operation (manual operation) and configuration

-Configuration via SIMATIC PDM

• High-quality control stems from online adaptive program

• Negligible air consumption during steady-state operation

• "tight shut-off" function (ensure maximum positioning pressure on the valve seat)

• "Positioning" function: keep current position when power off or signal off

• Various functions can be realized through simple configuration (such as setting characteristic curve and limit value)

• Extended diagnostic functions for valves and actuators

• The linear and angular stroke actuators use the same type of positioner

• Fewer moving parts and therefore less sensitive to vibration

• Under extreme environmental conditions, external non-contact sensors can be selected

• "Intelligent solenoid valve": part of the stroke test and solenoid valve function are integrated in one device

• Partial stroke test, for example for safety valves

• Full stroke test, multi-step response test, valve performance test, used for valve performance and maintenance evaluation

• You can also use pure natural gas, carbon dioxide nitrogen or inert gas as the gas source

• SIL (Safety Integrity Level) 2

The difference between ordinary electric valve positioner and intelligent electric valve positioner

Do you know the difference between ordinary electric valve positioner and intelligent electric valve positioner? What are the advantages of intelligent electrical valves, let's take a look at it together.

Valve locator, divided into pneumatic valve locator, electro-pneumatic valve locator and intelligent valve locator according to the structure, is the main accessory of the control valve, usually used in conjunction with the pneumatic control valve, it accepts the output signal of the regulator, and then The output signal is used to control the pneumatic regulating valve. When the regulating valve is activated, the displacement of the valve stem is fed back to the valve positioner through the mechanical device, and the valve position status is transmitted to the upper system through the electrical signal.

Intelligent electrical valve positioners are widely used for positioning control of pneumatic linear or angular actuators. It converts the current signal output from the control room into the gas signal that drives the control valve. According to the friction force of the valve stem when the control valve is working, the unbalanced force generated by the pressure fluctuation of the medium is offset, and the valve opening corresponds to the control room output.

According to whether the valve positioner is equipped with CPU, it can be divided into ordinary electric valve positioner and intelligent electric valve positioner. Ordinary electrical valve positioners do not have a CPU, so they do not have intelligence and cannot handle related intelligent operations. The intelligent electric valve positioner has a CPU, which can handle related intelligent operations, for example, non-linear compensation of the forward channel, etc., and the fieldbus electric valve positioner can also have PID and other functional modules to realize the corresponding operation.

The above is about the difference between ordinary electrical valve positioners and intelligent electrical valve positioners. Siemens Industrial Automation sells well in the consumer market and enjoys a high position among consumers. Delsmann is a partner of Siemens Industrial Automation and Drive Group and comprehensive competition Strength is constantly increasing.

Explain the working principle of Siemens electric valve positioner

With the development of smart instrument technology, microelectronic technology is widely used in traditional instruments, which greatly improves the function and performance of the instrument. Siemens electric valve positioner is the main accessory of the regulating valve, usually used with pneumatic regulating valve. It accepts the output signal of the regulator, and then uses its output signal to control the pneumatic regulating valve. When the regulating valve acts, the displacement of the valve stem It is fed back to the valve positioner through a mechanical device, and the valve position status is transmitted to the upper system through an electrical signal.

According to the working principle, the positioner can be divided into: pneumatic positioner, electric positioner, intelligent positioner

The working principle of electric valve positioner. The electric valve positioner is the main accessory of the control valve. It uses the valve stem displacement signal as the input feedback measurement signal, and the controller output signal as the set signal for comparison. The output signal causes the actuator to move, establishing a one-to-one correspondence between the displacement of the valve stem and the output signal of the controller. Therefore, the valve positioner constitutes a feedback control system that uses the displacement of the valve stem as the measurement signal and the output of the controller as the set signal. The manipulated variable of this control system is the output signal from the valve positioner to the actuator.

SIPART PS2 Intelligent Electric Valve Positioner

---- Overview

---- The most widely used intelligent electrical valve positioner can be used for straight stroke and angular stroke valves.

---- SIPART PS2 is the absolute leading product in the world valve positioner market. We have many years of field application experience, which will bring safety to your field application in the past, present and future.

---- Its operation is very simple, it can be operated on the spot through the buttons and LCD, or it can be operated through the HART interface or PROHBUS PA protocol using SIMATIC PDM process device management software.

Automatic initialization setting saves a lot of time

Low gas consumption greatly reduces operating costs

---- SIPART PS2 adds a variety of diagnostic functions, which can provide various information such as the status and operating conditions of the positioner and valve.

---- Important features

---- Simple operation-no special programming training is needed at all

---- The positioner can be operated on-site through the built-in LCD display and three control keys.

---- You can use the buttons to switch between automatic, manual and configuration status.

---- Install SIMATIC PDM software in PC / laptop computer to control and monitor it remotely.

---- Automatic initialization-fast automatic initialization

---- SIPART PS2 can be initialized automatically through a simple menu in a few minutes.

---- In this process, the microprocessor can determine the zero point, end position, movement direction and speed. From these items, the minimum pulse time and dead zone can be determined and optimized.

---- Low gas consumption-low cost operation brought by low gas consumption

---- Another significant feature of SIPART PS2 is its extremely low gas consumption. The traditional valve positioner will have a lot of instrument air discharge or leakage during work, resulting in a large demand for instrument air and high operating costs. Due to the new piezoelectric valve technology, SIPART PS2 will not emit any instrument air when the valve is not actuated, and it will use gas when the valve is most needed-the valve actuation.

---- Abundant diagnostic functions-make every event under control

---- The new SIPART PS2 can provide more parameters and additional diagnostic information.

---- Basic diagnostic functions

---- · Working hours recording

---- · Temperature measurement

------ Current Temperature

------ Min / Max temperature (memory)

------ Working time of each temperature section

---- Set point alarm detection

Extended diagnostic functions

---- · Online control valve seat (up and down stroke position)

---- · Monitor or display adjustable threshold

------ Cumulative travel

------ Number of actions

------ 100% valve position

------ Dead zone compensation

---- · Number of alarms 1 and 2 (position alarm)