Top 10 gearbox manufacturers in india

The gear reducer is an external meshing involute helical gear reducer manufactured by the national professional standard ZBJ19004. The gear reducer is a slewing mechanism widely used in the East China region for the tower-introduction crane machinery.Top 10 gearbox manufacturers in india. It is widely used in metallurgy. Mining, lifting, transportation, cement, construction, chemical, textile, printing and dyeing, pharmaceutical and other fields.

1 Introduction

Gear reducer is generally used for transmission equipment with low speed and high torque.Top 10 gearbox manufacturers in india The ordinary reducer of the motor will also have several pairs of identical gears to achieve the desired deceleration effect. The ratio of the number of teeth of the large and small gears is the transmission ratio. With the continuous development of the reducer industry, more and more enterprises have applied the reducer.

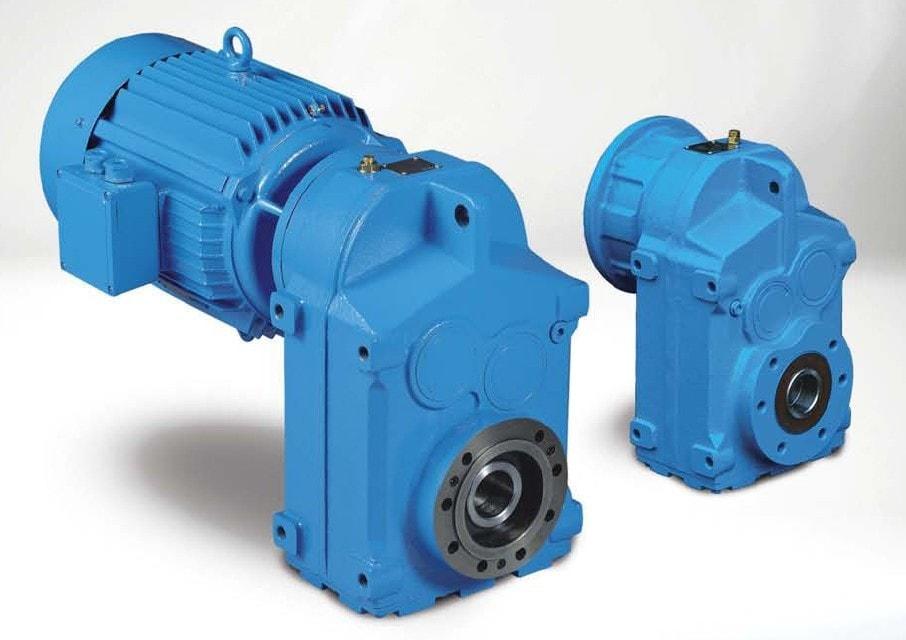

Gear reducer 1, R series coaxial helical gear reducer combined with international technical requirements, with high technology content 2, space saving, reliable and durable, with high overload capacity, power up to 132KW; 3, low energy consumption, Excellent performance, the speed reducer efficiency is up to 95%; 4, low vibration, low noise, high energy saving; 5, high-quality forged steel material, steel cast iron box, gear surface after high-frequency heat treatment; 6, after precision machining, ensure Shaft parallelism and positioning bearing requirements, the reducer that forms the helical gear transmission assembly is equipped with various types of motors, combined into mechatronics, which fully guarantees the quality characteristics of the products.

2. Scope of application

Reducer:Top 10 gearbox manufacturers in india

1. The high speed shaft rotation is not more than 1500 rpm.

2. The peripheral speed of the gear drive is not more than 20 m / s.

3. The working environment temperature is -40-45 °C. Top 10 gearbox manufacturers in india. If it is lower than 0 °C, the lubricating oil should be preheated to above 0 °C before starting.

4. The gear reducer can be used in both forward and reverse directions.

3. Machine features

1. The gear is made of high-strength low-carbon alloy steel by carburizing and quenching.Top 10 gearbox manufacturers in india. The hardness of the tooth surface is up to HRC58-62. The gears are all CNC grinding technology with high precision and good contact.

2. High transmission rate: single stage is greater than 96.5%, double level is greater than 93%, and third level is greater than 90%.

3. Smooth operation and low noise.

4. Small size, light weight, long service life and high carrying capacity.

5. Easy to disassemble and easy to install

4. Working principle

The gear reducer uses the gear transmission of all stages to achieve the purpose of speed reduction.Top 10 gearbox manufacturers in india. The reducer is composed of gear pairs of various stages. For example, the gear can be driven by a small gear to achieve a certain deceleration, and then a multi-stage structure is adopted. , you can greatly reduce the speed.

5. Model specifications

1. Models include: ZQ, ZQH, ZQSH gear reducer PM type cylindrical gear reducer JZQ series gear reducer.

PJ cylindrical gear reducer ZQA cylindrical gear reducer ZQ, ZQD large speed ratio cylindrical gear reducer.

ZD, ZDH, ZDSH type reducer ZL, ZLH, ZLSH type reducer ZS, ZSH, ZSSH type reducer.

ZSC, ZSC (A) reducer ZDY, ZDZ hard tooth surface medium hard surface cylindrical gear reducer JB/T8853-2001.

ZLY, ZLZ hard tooth surface medium hard surface cylindrical gear reducer JB/T8853-2001.

ZSY, ZSZ hard tooth surface medium hard surface cylindrical gear reducer JB/T8853-2001.

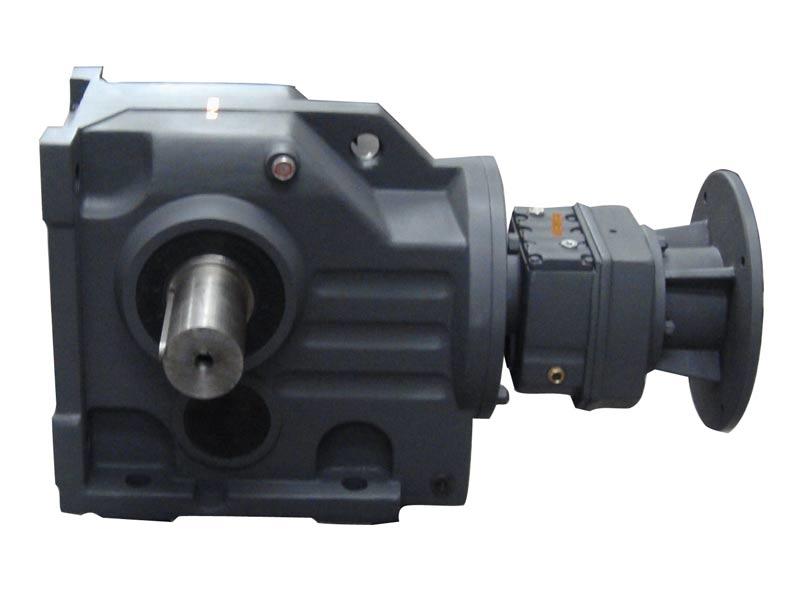

YK series conical-cylindrical gear reducer YB/T050-93K series conical-cylindrical gear reducer.

FZLY cylindrical gear reducer ZBJ19004-88FDBY conical cylindrical gear reducer ZBJ19026-90.

YN series gear reducer YB/T050-93.

HNK type circular gear reducer YB/T050-93QJY series hoist mechanical reducer.

QJ-L crane vertical reducer JB/T8905.3-1999.

QJ-T crane set reducer JB/T8905.4-1999QJ crane reducer JB/T89051-1999.

Top 10 gearbox manufacturers in india

QJ-D type crane base reducer JB/T8905.2-1999.

DBY, DCY, DBZ, DCZ cylindrical gear reducer JB/T9002-1999.

ZZL type conical cylindrical gear reducer S series gear reducer.

ZDS type gear reducer JB/T5560-1991.

GS type high speed involute cylindrical gearbox TJ315 cylindrical gear reducer.

JDX edge drive deceleration JC/T878.2-2001MHS, HS series gearbox.

ZJY type shaft mounted cylindrical gear reducer JB/T7007-1993.

PYZ series hard tooth surface mounted gear reducer C first stage helical gear reducer CE secondary helical gear reducer.

Top 10 gearbox manufacturers in india

CR helical gear reducer ZWS series spiral bevel gear reducer ZLZ series spiral bevel gear reducer.

ZLS, ZLSA spiral bevel gear reducer ZLD, ZLDA spiral bevel gear reducer JS series gear reducer.

R series gear reducer K series gear reducer F series gear reducer S series gear reducer.

2. Specifications are: single level: 80, 100, 125, 160, 200, 250, 280, 315, 355, 400, 450, 500, 560;

Two levels: 112, 125, 140, 160, 180, 200, 224, 250, 280, 315, 355, 400, 450, 500, 560, 630, 710; three levels: 160, 180, 200, 224, 250, 280, 315, 355, 400, 450, 500, 560, 630, 710;

6. Power ratio

Reduction ratio:

25~4000r/min (combined with RX, R, K series can achieve greater speed ratio)

Output torque:

Up to 2600000Nm

Motor Power:

0.4-12934kW

Troubleshooting

In the long-term operation of the reducer, there are often faults such as wear and leakage.Top 10 gearbox manufacturers in india The most important ones are:

1. The bearing chamber of the reducer is worn, which in turn includes the wear of the bearing housing of the housing, the bearing chamber of the housing, and the bearing chamber of the transmission.

2. The shaft diameter of the gear shaft of the reducer is worn, and the main wear parts are in the shaft head and keyway.

3. The bearing position of the reducer drive shaft is worn.

4. The reducer joint surface leaks.

For the wear problem, the traditional solution of the enterprise is repairing after repair welding or brush plating, but both have certain drawbacks: the thermal stress generated by the repair welding high temperature cannot be completely eliminated, which may cause damage to the material and cause the parts to bend or break; Top 10 gearbox manufacturers in india. Brush plating is limited by the thickness of the coating, and it is easy to peel off. The above two methods use metal to repair the metal, which can not change the "hard to hard" coordination relationship. Under the combined action of each force, it will still cause re-wear. For some large bearing enterprises, it is impossible to solve on-site, and it is necessary to rely on external repair. In the contemporary Western countries, the repair method of polymer composite materials is often used for the above problems, and the application has more comprehensive properties such as superior adhesion and excellent compressive strength. The application of polymer material repair can be free of disassembly and machining without the influence of repair welding thermal stress, and the thickness of repair can not be restricted. At the same time, the metal material of the product does not have the concession, which can absorb the shock vibration of the equipment and avoid the wear again. It is possible, and greatly extends the service life of equipment components, saving a lot of downtime for the enterprise and creating huge economic value.

For the leakage problem, the traditional method needs to disassemble and open the reducer, replace the sealing gasket or apply the sealant, which is not only time-consuming and laborious, but also difficult to ensure the sealing effect, and leakage will occur again during operation. Top 10 gearbox manufacturers in india. The polymer material can be used to treat leakage on site. The material has excellent adhesion, oil resistance and 350% elongation, which overcomes the impact caused by the vibration of the reducer, and solves the problem of leakage of the reducer for the enterprise.

With Best Regards,

www.sogears.com

Mobile:+86-18563806647

https://twitter.com/gearboxmotor

Whatsapp/Wechat: +8618563806647

E-mail:

No.5 Wanshoushan Road, Yantai, Shandong,China(264006)