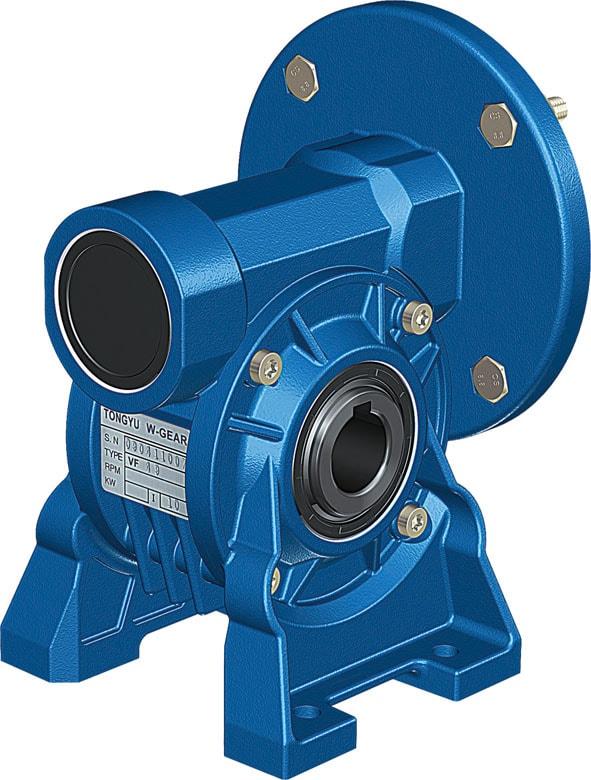

S series reducer sample - helical gear worm gear reducer drawings

The "Worm gear reducer definition" policy promulgated by the United Nations is to prevent the expansion of desert areas. Transporters are required to change and achieve this. Their operation is to let the transporter transport the steel for the construction of the railway, as well as the green barrier. Power Transmission worm gear reducer application is a sporting discipline that requires practitioners to consider tomorrow's challenges to worm gear reducer application today's latest innovations.

worm gear reducer application is natural With the development of technology and the development of industry, the style continues to develop and progress, and the standard solutions are changed and modernized. However, any good engineer will tell you that learning from the past is important; sometimes an old principle can be the latest answer to an industry. The roller table often constitutes a backbone factory for steel processing, which transports a large number of metal sheets and various stages of production through the factory. This work is a difficult job. The temperature of the work varies greatly, and the abrasive particles are more in the environment. During transportation, the steel itself will release a large amount of heat and physical weight as it passes. Each roller means they need to be able to withstand high regular impact loads. Until 1976, the most common solution, the steering roller was a solid coupling that was fitted with a built-in worm gear reducer mounted on a pedestal to connect the output shaft to the roller.

The worm gear reducer application's very rugged and mounting base support allows the specified reducer and motor to withstand any reaction forces when the roll is subjected to metal loads. Although the worm gear reducer application is for the purpose of fitness, it is undeniable that there are inherent defects. The worm gear reducer is easy to wear and cannot achieve transportation results. Factory engineers need a new solution that still provides the output needed for robustness and torque applications. This program was handed over to the engineers of the VEMTE Technology Center. The engineer added the module worm gear reducer application of the helical gear on the basis of the worm gear reducer. The gear materials are all superior, and the surface is hardened by carburizing and quenching. . After repeated experiments, the average speed is from about 2 m / s up to 8 m / s. Moreover, the transport aircraft is very sensitive and has no pauses.

We believe that we can cooperate with you on this business and please contact us if you are interested.

You are welcomed to visit our catalogue website for more information:

www.sogears.com

www.sogears.comMobile:+86-18563806647

www.guomaodrive.com

www.guomaodrive.com https://twitter.com/gearboxmotor

https://twitter.com/gearboxmotorViber/Line/Whatsapp/Wechat: 008618563806647

E-mail:

No.5 Wanshoushan Road, Yantai, Shandong,China