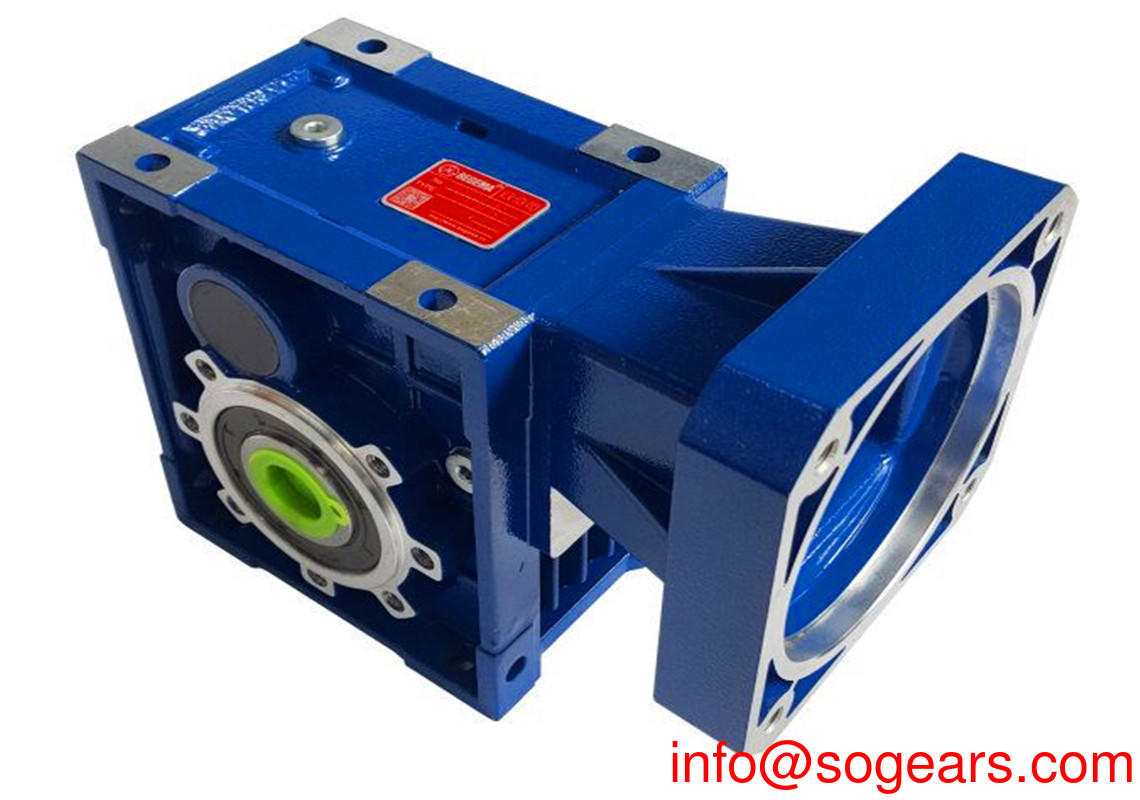

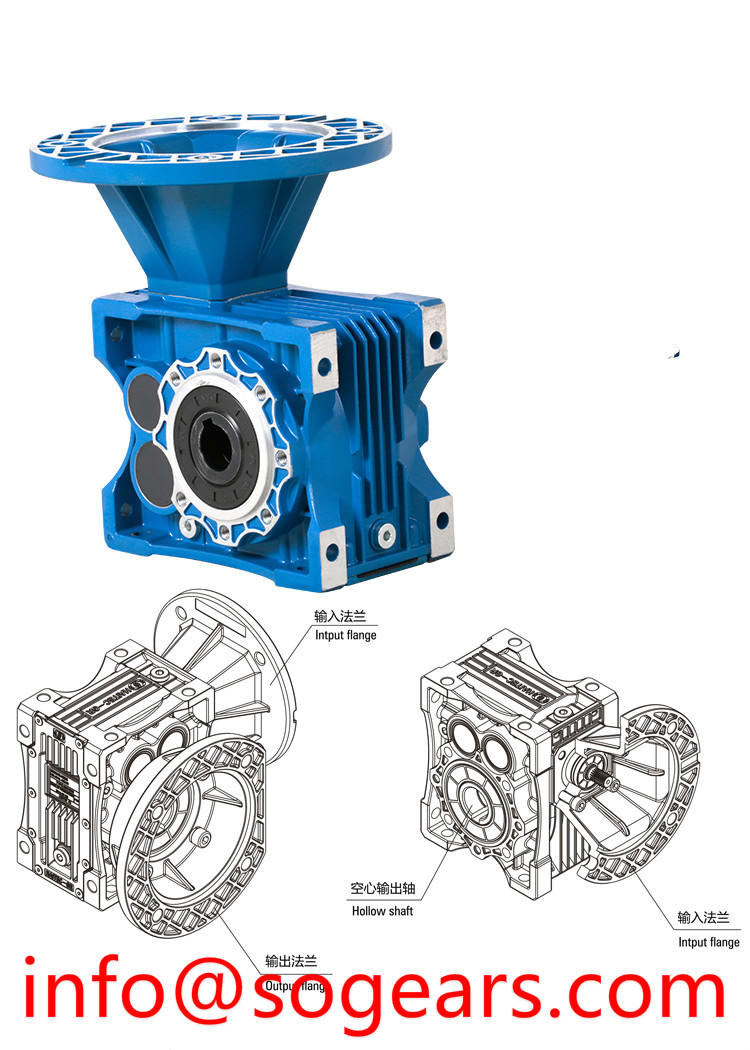

Skew Bevel Gear Box

skew bevel gear, skew bevel helical gearbox

Skew bevel helical gearboxes SM are suitable to the high power applications. The right gearbox to optimize the ratio between torque and costs. Bevel gears are gears where the axes of the two shafts intersect, Skew bevel gears are those for which the corresponding crown gear has teeth that are straight ,In a limiting case of making the "bevel" surface parallel with the axis of rotation。

Helical-quadrahys Skew Bevel Gear Box: SKM helical-quadrahys Skew Bevel Gear Box or SKM28C (IEC) hypoid Skew Bevel Gear Box, is a new generation of practical products independently developed by our company, which combines advanced technology at home and abroad, with the following Some main features:

1. Adopting quasi-double-sided gear transmission, the transmission ratio is large;

2. Large output torque, high transmission efficiency, energy saving and environmental protection;

3, high-quality aluminum alloy casting, light weight, no rust;

4, the transmission is stable, the noise is small, suitable for long-term continuous work in the superior and inferior environment;

5, beautiful and durable, small size;

6, can be applied to all-round installation, wide application, easy to apply;

7. The installation dimensions of SKM series Skew Bevel Gear Box are fully compatible with NMRV series worm Skew Bevel Gear Box (the difference between SKM28 and NMRV050 parts);

8, modular combination, can be combined in various forms to meet the needs of various transmission conditions.

Through the dual innovation of structural design and production process, SKM series Skew Bevel Gear Box has outstanding natural performance.

1. High efficiency, energy saving and environmental protection. The quasi-hypoid gears of this series have small meshing friction and the transmission efficiency is over 92%. Compared with the worm Skew Bevel Gear Box, the efficiency is increased by 10%~40%.

2. High strength and long life. The hypoid gear is made of high-quality alloy material. It is surface-hardened and processed by high-precision grinding machine. It is a hard-toothed gear with large output torque. The gear strength and life are much higher than that of worm Skew Bevel Gear Box.

3, the design is exquisite. The hypoid gears are compact, compact, small and take up less space.

4. Wide range of applications. The modular design of the product can be combined in a variety of forms to meet the needs of a variety of transmission conditions. Therefore, the user can freely exchange the Skew Bevel Gear Box products without changing the device configuration and without affecting the normal work, thereby strengthening the device function.

Main material:

1. Shell: aluminum alloy (frame: 28-58)

2. Gear: 20CrMnTi, carburized and quenched, the hardness of the tooth surface is 56-62HRC, and the thickness of the carburized layer is kept 0.3-0.5mm after fine grinding.

Surface coating:

Aluminum shell:

1. First shot blasting treatment, after special anti-corrosion treatment, maintain the corrosion of white metal, and resist the corrosion of organic solvents such as gasoline;

2. After phosphating, spray PAL5010 blue or silver-gray paint.

Structural features:

--From the power level range of 0.025KW-7.5KW, 9 kinds of frame specifications.

--The whole aluminum alloy die-casting structure of the terminal block and the whole body, good sealing performance, in line with IP54, IP55 enclosure protection level standard.--Enhanced The design of the heat dissipation ribs enables the unit to have strong cooling capacity. It maintains the good running performance of the motor in harsh environments.

--Accurate dynamic balance correction and special low-noise bearings make the motor run balanced and silent.--B class , F-class insulation grade manufacturing.--Pre-set shaft sealing device, when connected with gearbox and reducer, the sealing performance is reliable and safe.--According to IEC size standard and IM safety structure, with excellent interchangeability Uniform standard: Production standards for all general-purpose motors:

--Motor power class and size: GB4826-84; GB4772.2-84; IEC72--Electrical specification: GB755-87; IEC34-1--Structure and installation type: GB997-81; IEC34-7--shell protection grade: GB4942.1-85; IEC34-5

--cooling method: GB/T1993-93; IEC34-6 Enclosure protection level: The enclosure protection level of the motor indicates the protection capability of the motor in the following two aspects: (1) The ability to prevent the human body from coming into contact with the internal electrified or rotating part of the motor and to prevent solid foreign matter from entering the motor interior. (2) Prevent water from entering the motor. The motor manufactured by our company adopts the junction box and the whole body to die-cast, and has a sealing device at all the shafts and joints of the outer casing to achieve the protection level of IP54 and IP55. Product labeling: The motor product labeling is marked according to the following rules: series code + frame number + core length specification number + motor pole number + installation form.

Pay attention to the following items when installing the gear unit:

1. Before assembling the Skew Bevel Gear Box and mechanical equipment, check whether the rotation direction of the output shaft of the Skew Bevel Gear Box is correct;

2. Before assembling the Skew Bevel Gear Box and prime mover and equipment, check the deviation dimensions of each shaft diameter, aperture, key and keyway to avoid the performance of the Skew Bevel Gear Box;

3. The Skew Bevel Gear Box must be installed on the mechanical equipment to avoid looseness and vibration;

4. Avoid exposing the Skew Bevel Gear Box to the sun and the harsh environment as much as possible;

5. If the storage time of the Skew Bevel Gear Box is 4-6 months, check whether the sealing glaze is completely infiltrated in the lubricating oil. The oil sealing lip may lose its elasticity. Since the suitable elasticity is a necessary condition for the oil seal work, it is recommended to replace the oil seal. ;

6. All rubber parts and venting holes cannot occupy paint;

7. When the hollow shaft and the solid shaft of the Skew Bevel Gear Box are linked with each other, the lubricating part of the shaft should be coated with lubricating oil to avoid jamming;

8. The oil level must be checked during use (such as oil level mirror hole or open oil plug, small model is not available);

9. When using the new Skew Bevel Gear Box, it cannot start at full load, and should not increase the load;

10. When using various types of motor direct-connected Skew Bevel Gear Boxs, if the weight of the motor is too large, support devices should be provided;

11. Ensure that there is a good ventilation environment near the motor fan to avoid affecting the heat dissipation effect;

12. The standard working environment temperature of the Skew Bevel Gear Box is -5 °C to 40 °C. If it is not within this range, please contact our technical staff.

The series of motors are equipped with heat sinks, and the whole machine is made of aluminum alloy or cast aluminum.

The insulation grade is F grade and the protection grade is IP55.

The frame number is from 56 to 132, and the power is from 0.09KW to 11KW.

Model Description: T Series-----Three-phase AC Motor

D series-----two-speed three-phase AC motor

S series-----single phase motor

TB series----brake three-phase AC motor

DB series----killing two-speed three-phase AC motor

SB series----brake single-phase motor

HS series----single-phase high starting torque motor plus centrifugal switch

Detailed introduction:

Power: 0.09KW ~ 7.5KW (56 ~ 132 frame number) aluminum alloy die-cast housing

*Number of revolutions: 3000/1500/1000/750rpm, etc.

*Installation method: B5 (standard flange, vertical) B14 (small flange, vertical) B3 (horizontal)

*ICE certification: wide voltage: (220/380V, 240/415V, 260/440V, 280/480V)

Wide frequency: 50/60HZ

*Motor bearing: Sweden SKF or Japan NSK, low noise, low vibration

* Class F insulation, 155 ° C high temperature * Protection class IP55

M.T. brake motor (DC)

1. Brake motor, when the power is cut off, the brake can be manually released and the motor output can be turned.

2, the brakes come to this film is made of high friction coefficient and long life materials, the brakes can be adjusted up to 1,00,000 times, can withstand higher temperature rise, can still load when the temperature is 75 °C use.

3. The brake motor uses AC power and is supplied after being converted via a rectifier. The characteristics of the DC brake coil are low noise and low impact. Both forward and reverse can effectively achieve the braking action.

4, the brake parts and components are sufficient, does not affect the after-sales service problem

5, can bring a release device

See More Products:

The best service from our transmission drive expert to your inbox directly.

Our Service

Get in Touch

Yantai Bonway Manufacturer Co.ltd

ANo.160 Changjiang Road, Yantai, Shandong, China(264006)

T+86 535 6330966

W+86 185 63806647