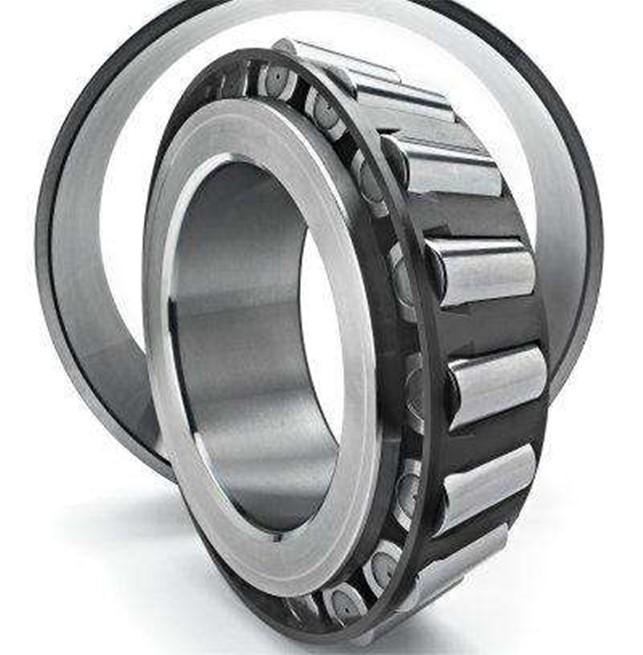

Tapered roller bearing

Tapered roller bearings are separable bearings. Both the inner and outer rings of the bearing have tapered raceways. This type of bearing is divided into single row, double row and four row tapered roller bearings according to the number of rows installed. Single row tapered roller bearings can bear radial load and single direction axial load. When the bearing bears radial load, it will produce an axial component force, so when it needs another bearing that can bear the axial force in the opposite direction to balance it.

Tapered roller bearings refer to radial thrust rolling bearings with tapered rollers. There are two types: small cone angle and large cone angle. The small cone angle mainly bears the combined radial and axial load, which is mainly the radial load. It is often used in double use and reverse installation. The inner and outer races can be installed separately. The radial and axial clearance can be adjusted during installation and use; The large taper angle mainly bears the combined axial and radial load based on the axial load. Generally, it is not used to bear pure axial load alone, but can be used to bear pure radial load when configured in pairs (the ends of the same name are installed relative to each other).

definition:

The ability of single-row tapered roller bearings to bear axial load depends on the contact angle, that is, the outer ring raceway angle. The greater the angle, the greater the axial load capacity. The most used tapered roller bearings are single row tapered roller bearings. In the front wheel hub of the car, a small-sized double-row tapered roller bearing is used. Four-row tapered roller bearings are used in heavy machines such as large cold and hot rolling mills.

Structural features:

The type code of tapered roller bearings is 30000, and tapered roller bearings are separate bearings. Under normal circumstances, especially in GB/T307.1-94 "Rolling Bearing Radial Bearing Tolerance", the tapered roller bearing outer ring and inner component can be used interchangeably in 100% of the size range.

The angle of the outer ring and the diameter of the outer raceway are the same as the outer dimensions and have been standardized. It is not allowed to change during design and manufacturing. As a result, the outer ring and inner components of the tapered roller bearing can be interchanged worldwide.

Tapered roller bearings are mainly used to bear combined radial and axial loads, mainly radial loads. Compared with angular contact ball bearings, the bearing capacity is large and the limit speed is low. Tapered roller bearings can withstand axial load in one direction and can limit axial displacement of the shaft or housing in one direction.

classification:

The single row tapered roller bearing has an outer ring, its inner ring and a set of tapered rollers are an inner ring assembly enclosed by a basket-shaped cage. The outer ring can be separated from the inner ring assembly. According to the ISO tapered roller bearing external dimension standard, any standard type of tapered roller bearing outer ring or inner ring assembly should be able to achieve internationality with the same type of outer ring or inner ring assembly exchange. That is to say, in addition to the external dimensions and tolerances of the outer ring of the same model, which must meet the requirements of ISO492 (GB307), the cone angle and component cone diameter of the inner ring components must also comply with the relevant provisions of interchange.

Generally, the tapered angle of the outer ring raceway of a single-row tapered roller bearing is between 10° and 19°, which can bear the combined action of axial load and radial load at the same time. The larger the cone angle, the greater the ability to withstand axial load. Bearings with large taper angle, add B to the rear code, and the taper angle is between 25°~29°, which can bear larger axial load. In addition, single-row tapered roller bearings can adjust the size of the clearance during installation.

The outer ring (or inner ring) of a double-row tapered roller bearing is a whole. The small end faces of the two inner rings (or outer rings) are similar, with a spacer in the middle. The clearance is adjusted by the thickness of the spacer. The thickness of the spacer can also be used to adjust the pre-interference of the double-row tapered roller bearing.

Four-row tapered roller bearings. The performance of this type of bearing is basically the same as that of double-row tapered roller bearings, but it bears greater radial load than double-row tapered roller bearings and has a slightly lower limit speed. It is mainly used for heavy machinery.

Multi-sealed double and four-row tapered roller bearings, ZWZ provides long-life, multi-sealed double and four-row tapered roller bearings. Carry out a new and personalized design of the bearing, change the traditional design method of the fully sealed bearing, and adopt a new type of sealing structure that combines sealing and dust prevention to improve the sealing effect and improve the sealing performance. Compared with open structure bearings, multi-sealed double and four-row tapered roller bearings can increase their life by 20% to 40%, and reduce lubricant consumption by 80%.

use:

Tapered roller bearings are mainly subjected to combined radial and axial loads based on the radial direction. The bearing capacity depends on the raceway angle of the outer ring, the larger the angle, the greater the bearing capacity. This type of bearing is a separable bearing and is divided into single row, double row and four row tapered roller bearings according to the number of rows of rolling elements in the bearing. The clearance of single-row tapered roller bearings needs to be adjusted by the user during installation; the clearances of double-row and four-row tapered roller bearings have been set at the factory according to user requirements and do not require user adjustment.

Tapered roller bearings have tapered inner ring and outer ring raceways, with tapered rollers arranged between the two. The projection lines of all cone surfaces converge at the same point on the bearing axis. This design makes tapered roller bearings particularly suitable for bearing compound (radial and axial) loads. The axial load capacity of the bearing is mostly determined by the contact angle α; the larger the angle α, the higher the axial load capacity. The size of the angle is expressed by the calculation coefficient e; the greater the value of e, the greater the contact angle, and the greater the applicability of the bearing to bear the axial load.

Tapered roller bearings are usually separated, that is, the tapered inner ring assembly composed of the inner ring with roller and cage assembly can be installed separately from the tapered outer ring (outer ring).

Tapered roller bearings are widely used in industries such as automobiles, rolling mills, mining, metallurgy, and plastic machinery. Mainly used for large and medium-sized motors, locomotives, machine tool spindles, internal combustion engines, generators, gas turbines, reduction gear boxes, rolling mills, vibrating screens, and lifting and transporting machinery.

installation:

Adjusting the axial clearance For the installation axial clearance of tapered roller bearings, you can use the adjustment nut on the journal, the adjustment washer and the thread in the bearing seat hole, or use the pretension spring to adjust. The size of the axial clearance is related to the arrangement of the bearing, the distance between the bearings, and the material of the shaft and the bearing seat, and can be determined according to the working conditions.

For tapered roller bearings with high loads and high speeds, when adjusting the clearance, the effect of temperature rise on the axial clearance must be considered, and the reduction in clearance caused by the temperature rise shall be estimated, that is, the axial clearance It should be appropriately adjusted to be larger.

For low-speed and vibration-bearing bearings, clearance-free installation or pre-load installation should be adopted. Its purpose is to make the rollers and raceways of tapered roller bearings make good contact, evenly distribute the load, and prevent the rollers and raceways from being damaged by vibration and impact. After adjustment, the size of the axial clearance is checked with a dial indicator.

Installation of four-row tapered roller bearings (installation of roller bearings):

1. The fit between the inner ring of the four-row tapered roller bearing and the roll neck is generally with gaps. When installing, first put the bearing into the bearing box, and then put the bearing box into the journal.

The outer ring of the two- and four-row tapered roller bearing also adopts a dynamic fit with the bearing box hole. First, install the outer ring A into the bearing box. The word {HotTag} is printed on the outer ring, inner ring, and inner and outer spacers when leaving the factory, and must be installed in the bearing box in the order of the characters and symbols during installation. Can not be interchanged arbitrarily to prevent the change of bearing clearance.

3. After all the parts are installed in the bearing box, the inner ring and the inner spacer, and the outer ring and the outer spacer are axially abutted.

4. Measure the gap width between the end face of the outer ring and the bearing box cover to determine the thickness of the corresponding gasket.

Multi-sealed bearings use the post code XRS mark.

al rollers and raceways are linear contact bearings. Load capacity, mainly bear radial load. The friction between the rolling element and the retaining edge of the ring is small, which is suitable for high-speed rotation. According to whether the ring has ribs, it can be divided into single row cylindrical roller bearings such as NU, NJ, NUP, N, NF, and double row cylindrical roller bearings such as NNU and NN. The bearing has a separable structure with inner ring and outer ring.

Cylindrical roller bearings with no ribs on the inner or outer ring, the inner ring and outer ring can move relative to the axial direction, so it can be used as a free end bearing. Cylindrical roller bearings with double ribs on one side of the inner ring and outer ring and a single rib on the other side of the ring can bear a certain degree of axial load in one direction. Generally use steel stamping cage or copper alloy car solid cage. But some use polyamide forming cage.

Bearing features:

1. The roller and raceway are in line contact or repaired offline contact, with large radial bearing capacity, suitable for bearing heavy loads and impact loads.

2. The friction coefficient is small, suitable for high speed, and the limit speed is close to the deep groove ball bearing.

3. The N type and NU type can move axially, can adapt to the change of the relative position of the shaft and the housing caused by thermal expansion or installation error, and can be used as a free end support.

4. The processing requirements for the shaft or the seat hole are high, and the relative deviation of the outer ring axis after the bearing is installed must be strictly controlled to avoid contact stress concentration.

5. The inner ring or outer ring can be separated for easy installation and disassembly.

product features:

The cylindrical roller is in line contact with the raceway, and the radial load capacity is large. It is not only suitable for bearing heavy load and impact load, but also suitable for high-speed rotation.

The raceways and rolling elements of cylindrical roller bearings are geometrically shaped. After the improved design, it has a higher load-carrying capacity. The new structural design of ribs and roller end faces not only improves the axial load-bearing capacity of the bearing, but also improves the lubrication conditions of the contact area between the roller end face and the rib. The performance of the bearing.

The best service from our transmission drive expert to your inbox directly.

Our Service

Get in Touch

Yantai Bonway Manufacturer Co.ltd

ANo.160 Changjiang Road, Yantai, Shandong, China(264006)

T+86 535 6330966

W+86 185 63806647