Gear motor for sale

Gear motor for sale,small gears for sale, gear dc motor, hydraulic gear motors, steel gears for sale, metal gears for sale

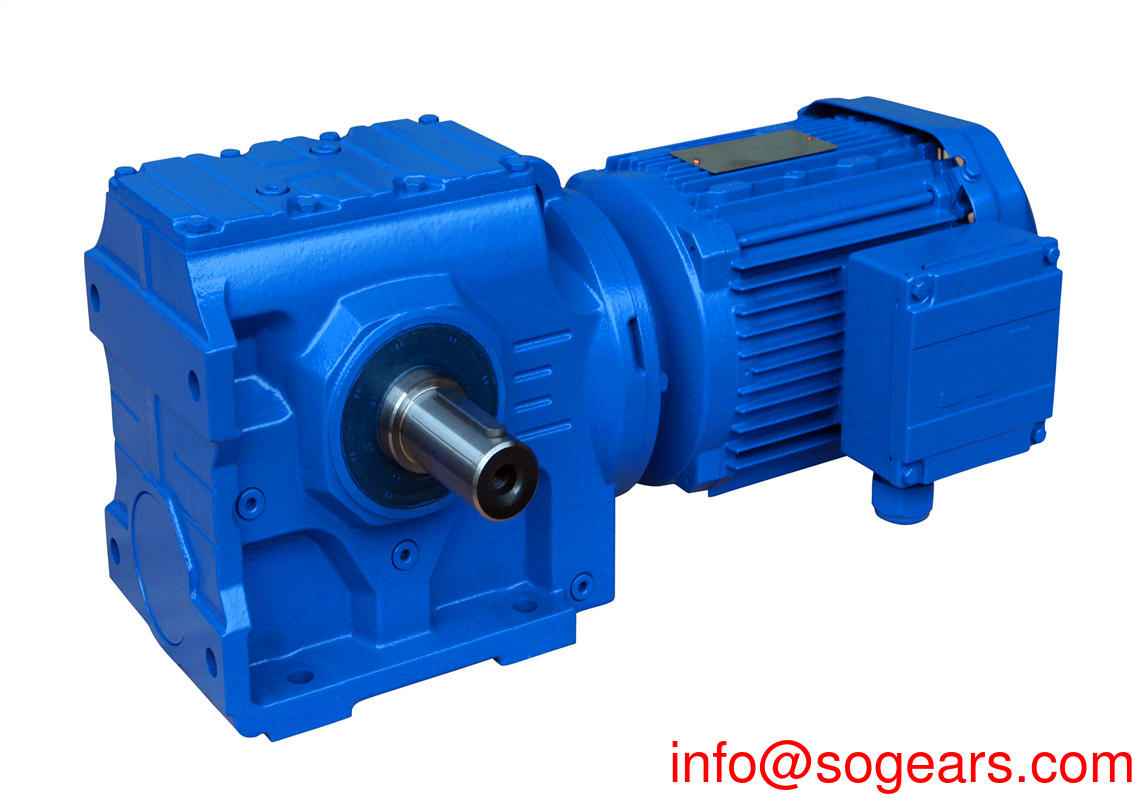

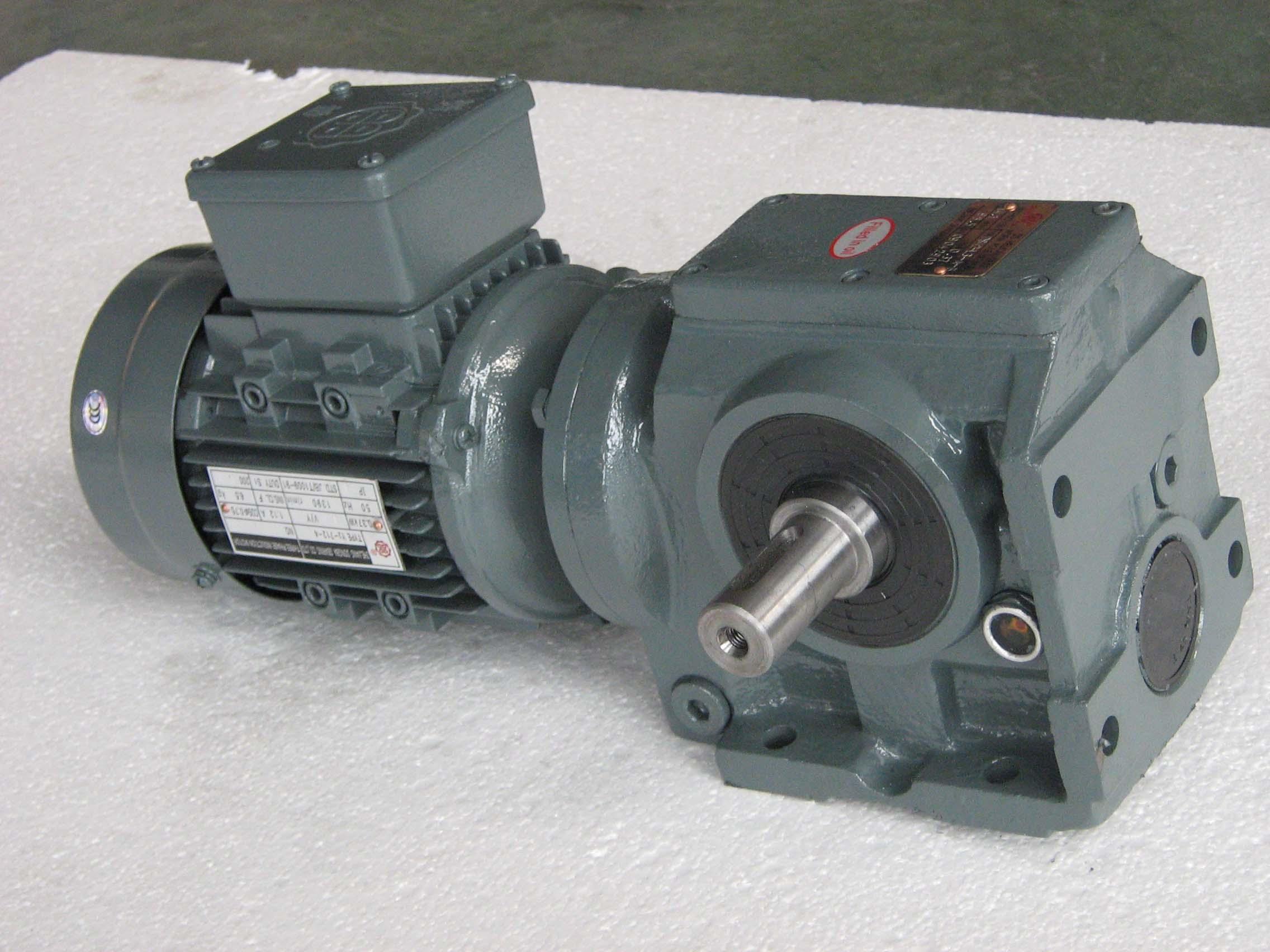

K series helical gear spiral bevel gear reducer (gear grinding, high transmission efficiency), Bevel gear motor is a type of helical gear reducer. It is a special gear motor for various reactors. Its gear adopts Gleason quasi-hyperbolic gear type, and the gear is hard tooth surface. It has large bearing capacity and low noise. The long life, high efficiency, stable operation, etc., the performance of the whole machine is much better than the cycloid reducer motor and the worm gear reducer motor, which has been widely recognized and applied by users. The geared motor is driven by a V-belt. The motor is driven by the belt to drive the input part. The factory is equipped with an ordinary V-belt. When using an explosion-proof motor, an anti-static V-belt (user-fitted) should be used.

1. K series gear motor is manufactured in accordance with international technical requirements and has high scientific and technological content.

2. This series of gear motor saves space, is reliable and durable, and has high overload capacity, and the power can reach more than 200KW.

3, low energy consumption, superior performance, gear motor efficiency of up to 95%.

4. K series spiral bevel gear motor has low vibration, low noise and high energy saving.

5, select excellent 20CrMnTi material, and after carburizing and quenching heat treatment, the surface hardness can reach 58-62HRC, the grinding tooth processing, the precision can reach 5-6, with high processing precision, stable transmission, small volume bearing capacity, Long life and other characteristics.

6. After precision machining, the gear motor that constitutes the helical gear, bevel gear and bevel gear transmission assembly is equipped with various types of motors to form electromechanical integration, which fully guarantees the quality characteristics of the geared motor products.

Sogears Motors and Generators offers a comprehensive range of reliable and high quality and coupled with the electric motors and generators are designed to operate reliably no matter what kind of envirement. Sogears Value Providers deliver the authorized offering of sales, support, service.

Technical parameter:

Speed ratio range: basic 5.36 ~ 197.37, K series / R series combination can reach 32625

Torque range: 200~50000 Nm

Power range: 0.18 ~ 200 kW

structure type:

K-shaft extension, foot mounting KA-shaft mounting

KF-shaft extension, flange mounting KAF-shaft mounted, flange mounting

S- indicates axis input. This series is identical to the S series gear motor and can be used interchangeably. However, under the premise of the same speed ratio, the same power and the same frame number, the output torque of the K series is greater than the output torque of the S series gear motor.

The main models of K series gear motors are: K/KA/KAF37, K/KA/KAF47, K/KA/KAF57, K/KA/KAF67, K/KA/KAF77, K/KA/KAF87, K/KA/KAF97 , K/KA/KAF107, K/KA/KAF127, K/KA/KAF157, K/KA/KAF167, K/KA/KAF187

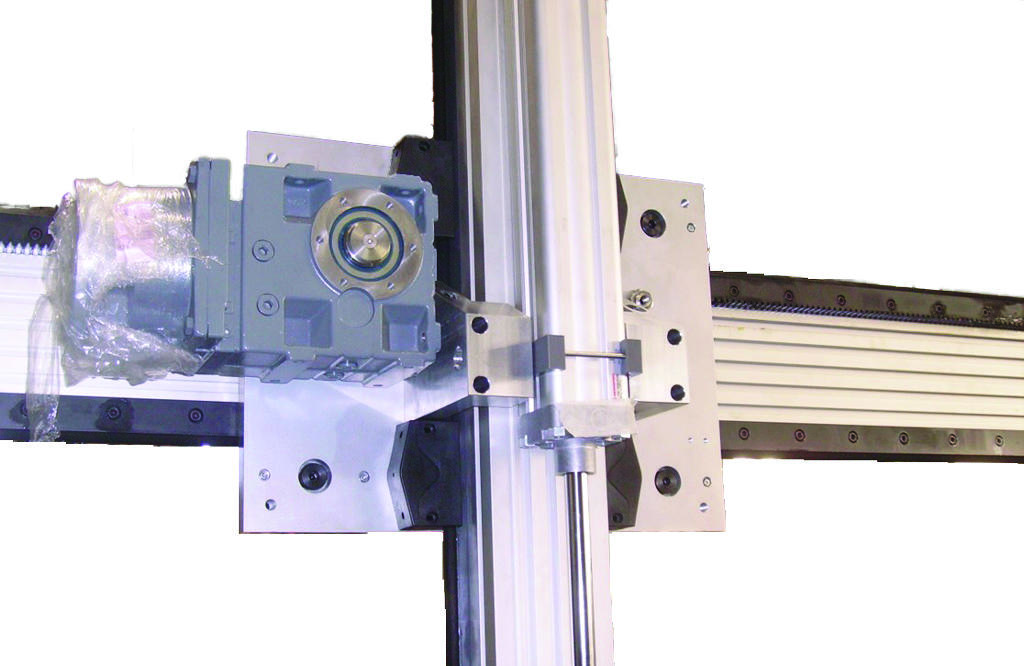

1.Harbor and shipping

2.Hoist and transport

3.Electric power

4.Coal mining

5.Cement and construction

6.Paper and light industry

7.Chemical industry and environmental protection.Etc.

- Classification of bevel gear motor

The bevel gear reduction motor can be divided into straight teeth, helical teeth and curved teeth according to the shape of the tooth line; the curved teeth are divided into arc teeth, long outer cycloidal teeth (referred to as cycloidal teeth) and quasi-involute teeth. Although the helical tooth is slightly larger than the straight tooth, it is very sensitive to the error, so it is gradually replaced by the curved tooth. Quasi-involute bevel gears with tapered hobs are inferior in competition with arc teeth and cycloidal bevel gears due to complex tools and difficult to control the contact area of the tooth surface. They have been eliminated and have not been introduced in China. This type of gear milling machine.

Find helical bevel gear motor surplus 1/2 HP, 3/4 HP, 2 HP electric gear motors for sale from china famous brand manufacturer sogears and with 1/3HP Reliance Duty-Master Motor with Gear Reducer ratio of 40:1. This small-sized gear motor series has a motor capacity of 4kW-250kW Notice regarding product discontinuation: We are discontinuing sales of some models K series for sale. In combination with the directly mounted AC motors the sogears Modular geared motor system makes a compact drive for a wide range of applications.

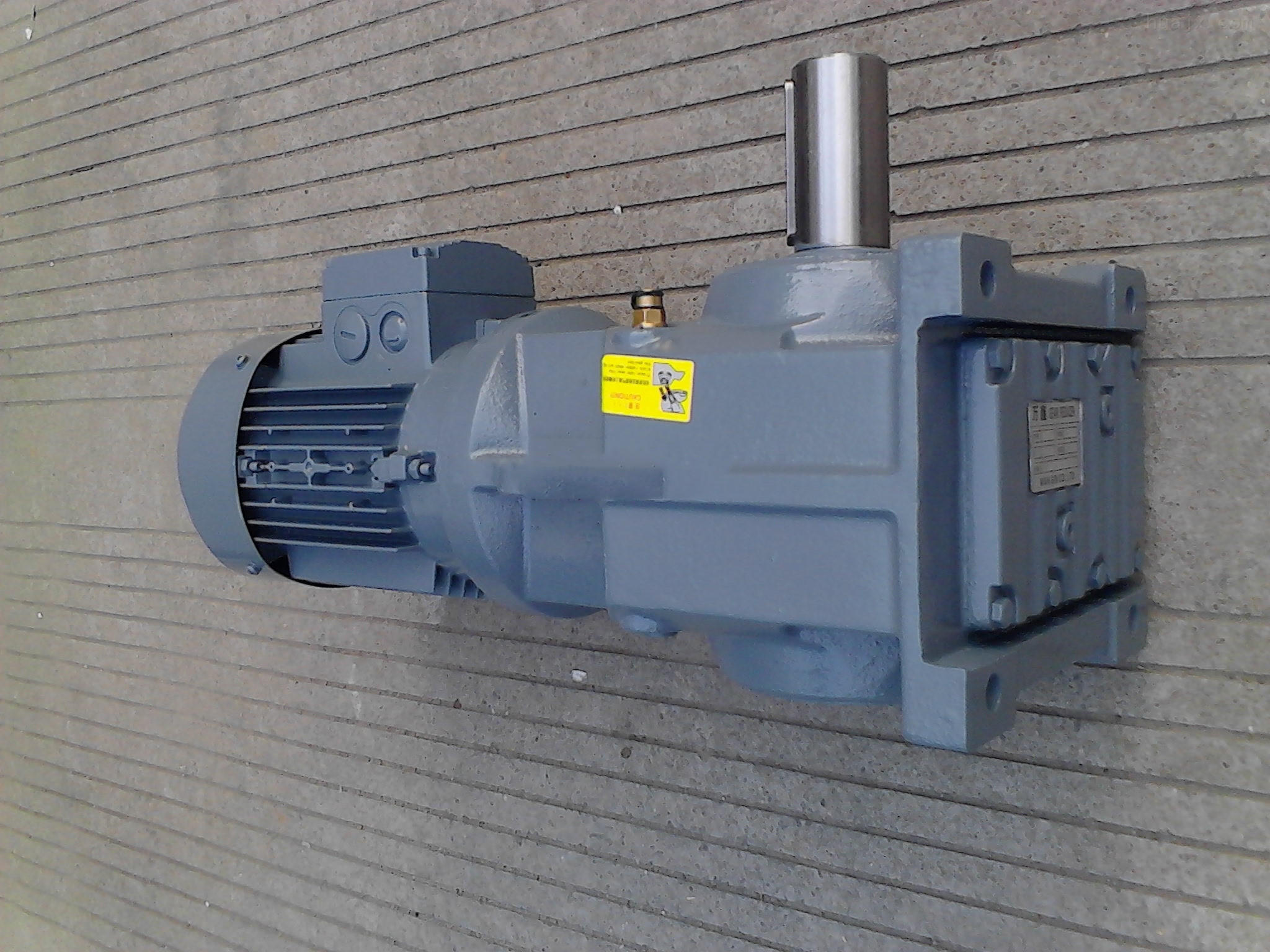

The structure of the bevel gear motor is K-shaft extension, foot mounting, KA-shaft mounting, KF-shaft extension, flange mounting, KAF-shaft mounting, flange mounting, KS- indicates shaft input Wait,

Its technical parameters are generally:

Power: 0.12KW ~ 200KW

Torque: 10N·m to 58500N·m

Output speed: 0.08 ~ 263r / min

This 10-120:1 gearbox with electric motor has a low-current motor and provides power and speed that is comparable to an RC servo at a fraction of the cost.

K series helical-bevel gear motor, Lower cost AC gear motor & torque motor with gearbox, 3, 5, 6, 200 21 different kinds of gear ratio for you to choose. It has 20 KW power and 1350 rpm rated torque. We have explained how motor speeds differ between AC and DC motors and the ways they make torue. With A gearbox—otherwise known as a gear reducer or speed reducers, consist of a electric motor, gears, and bearings in a housing and are commonly used in applications that require a high amount of force (torque).

The helical-bevel gear motor, also known as the K-series reducer, is in the form of a three-stage transmission consisting of two sets of helical gears and a set of bevel gears. This type of transmission has high efficiency, high rigidity, high torque, strong bearing capacity and low noise. It can be matched with servo motor and work with three-phase asynchronous motor. The servo reducer helical gear reducer produced by the company has long service life and large torque.

Gear Motors are made in three series of models with displacements ranging for the shaft and Our unique gear tooth design and trapping reliefs provide quiet, smooth operation at any power and ratio. Assistance is always available from either our customer service, sales.

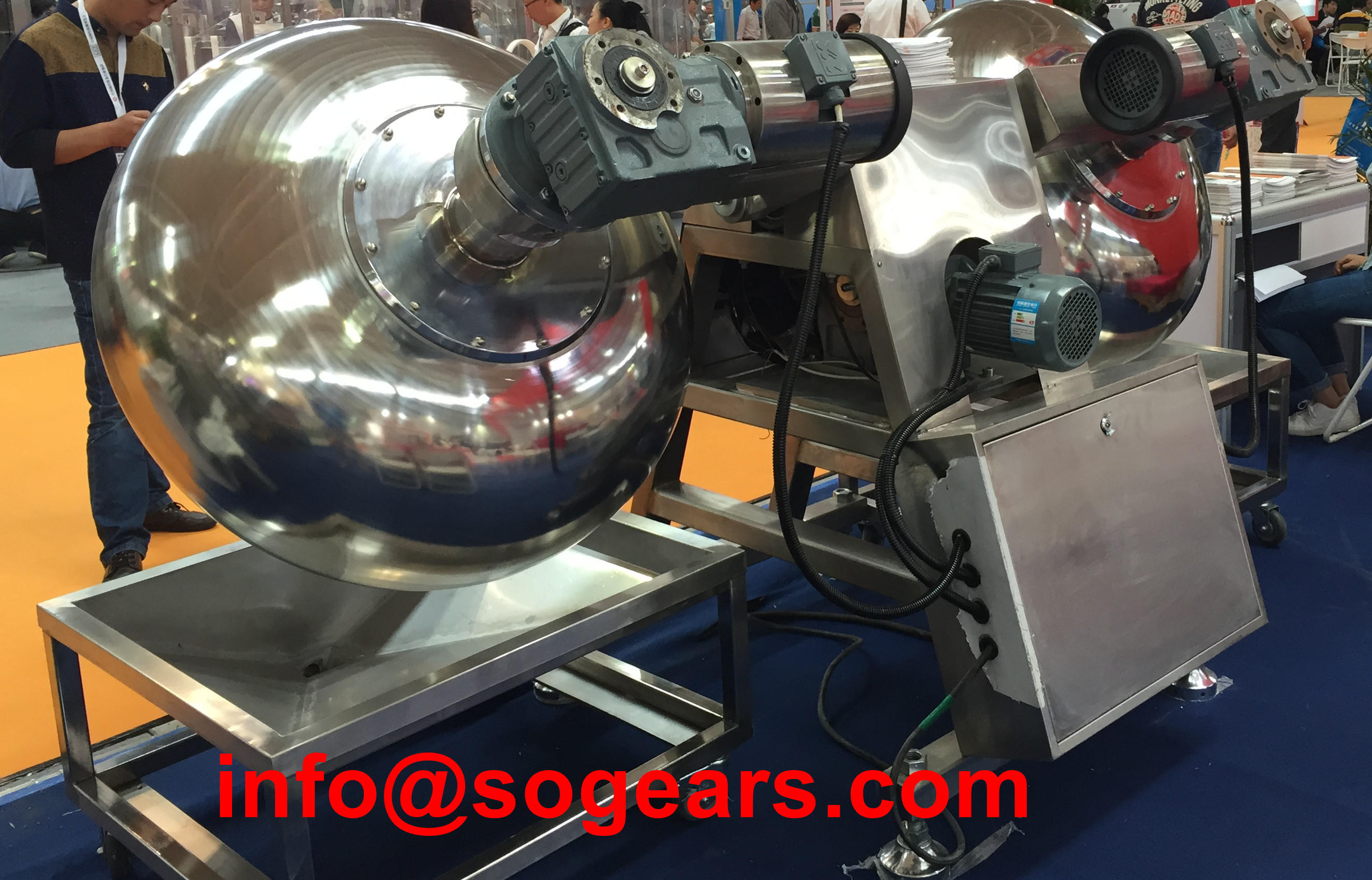

Widely used in food machinery, printing machinery, metallurgical machinery, wire and cable machinery, conveyor machinery, chemical machinery, textile machinery, printing and dyeing machinery and pharmaceutical machinery.

Our sogears brand Gear Motors from Surplus Sales of manufacturer directly. AC and DC gear motors, synchronous, reversible, gear motor mounting plate. 1.9 RPM 115 Volt AC 100 in-lb Sogears Gearmotor. Item Number: 5-1820-2 5 In Stock. Buy Gear Motor at best price in China or India from Sogears. Huge range of Geared Motors in our warehouse , Wholesale Price and Free Shipping.

For Sogears' Sub-Fractional Gearmotors. our new VFDs allows for the gearmotors included in machines typically found in a wide range of various speed. Motor & Gear Engineering, we have been the world class leader in design, engineering and manufacturing of gears and shafts. Sales and Repair of Electric Motors and Drives.

The cycloidal bevel gear reducer adopts contour teeth, and the tooth height at each point along the indexing cone is constant; the spur, helical and spiral bevel gear reducers adopt contraction teeth, from the big end (outer end) of the teeth. Along the indexing cone busbar to the small end (inner end) of the tooth, the tooth height gradually decreases.

Sogears AC Gearmotors are available in a wide variety of torques ranging from 15 to 1827 in-lbs in both right angle and parallel shaft designs with industry. oUR Gearmotors & Speed Reducers for Sale to world wide, NEW Oriental Motor 1/19 HP Single Phase Gearmotor. Inventory:GEA2049. Ratio to 1:0. Manufacturer:sogears.

The straight bevel gear reduction motor has a small axial force and a simple support system; however, the coincidence degree is small, the error is sensitive, and the noise is large. Generally used for peripheral speed transmissions such as automotive differentials and heavy mechanical gears.

Compared with spur gears and helical bevel gears, the curve bevel gears have a large degree of coincidence, and the tooth surface contact points have a relatively large radius of curvature; the tooth surface contact areas are easy to control; they are less sensitive to errors. Because of the high carrying capacity, the transmission is stable and the noise is low. Typically used in transmissions such as the central drive of various vehicles, tractors and helicopters.

|

SIZE

|

Shaft Dia.(mm)

Solid Hallow

|

Center Height

|

Output Flange Dia.(mm)

|

Power(kw)

|

Ratio

|

Permissible Torque(N.m)

|

Weight

(KGS) |

|

|

37

|

φ25k6

|

φ30h7

|

100

|

φ110/160

|

0.18-3.0

|

5.36-106.38

|

200

|

11

|

|

47

|

φ30k6

|

φ35h7

|

112

|

φ120/200

|

0.18-3.0

|

5.81-131.87

|

400

|

20

|

|

57

|

φ35k6

|

φ40h7

|

132

|

φ155/250

|

0.18-5.5

|

6.57-145.14

|

600

|

27

|

|

67

|

φ40k6

|

φ40h7

|

140

|

φ155/250

|

0.18-5.5

|

7.14-144.79

|

820

|

33

|

|

77

|

φ50k6

|

φ170

|

180

|

φ170/300

|

0.37-11.0

|

7.24-292.18

|

1550

|

57

|

|

87

|

φ60m6

|

φ60h7

|

212

|

φ215/350

|

0.75-22.0

|

7.19-197.18

|

2700

|

85

|

|

97

|

φ70m6

|

φ70h7

|

265

|

φ260/450

|

1.1-30.0

|

8.95-176.05

|

4300

|

130

|

|

107

|

φ90m6

|

φ90h7

|

315

|

φ304/450

|

3.0-45.0

|

8.74-141.46

|

8000

|

250

|

|

127

|

φ110m6

|

φ100h7

|

375

|

φ350/550

|

7.5-90.0

|

8.68-146.07

|

13000

|

380

|

|

157

|

φ120m6

|

120h7

|

450

|

φ400/660

|

11.0-160.0

|

12.65-150.41

|

18000

|

610

|

|

167

|

φ160m6

|

140h7

|

500

|

φ800

|

11.0-200.0

|

17.28-163.91

|

32000

|

1015

|

|

187

|

φ190m6

|

160h7

|

600

|

φ800

|

18.5-200.0

|

17.27-180.78

|

50000

|

1700

|

Performance characteristics:

1. Vertical output, compact structure, high torque transmission on the hard tooth surface, high precision gear ensures stable operation, low noise and long service life.

2, installation method: foot installation, hollow shaft installation, flange installation, torque arm installation, small flange installation.

3. Input mode: motor direct connection, motor belt connection or input shaft, coupling flange input.

4. Output mode: hollow shaft output or solid shaft output, the average efficiency is 94%.

5, and the R series combination can get a larger speed ratio.

In a larger horsepower gearmotors, motors, parallel shaft gearmotors, and motor speed reducers, we can replace 90V or 180VDC gearmotors sold by sogears, When you call on a sogears Electric regional sales manager to answer your, we will reply.

Sogears Electric Motor specializes in the sale and repair of electric motors, pumps, power transmission, and related industrial equipment.

Application of bevel gear motor:

It is now widely visible in the transmission systems of various types of machinery, from ships, automobiles, locomotives, heavy machinery for construction, processing equipment and automated production equipment used in the machinery industry, to the most common in our daily life. Home appliances, clocks, etc. Its applications range from high-power transmission to small loads, precise angular transmission, and in industrial applications, geared motors have deceleration and increased torque. Therefore, it is widely used in speed and torque conversion equipment. Bevel gear motor is an external meshing involute helical gear motor produced by national professional standard ZBJ19004. It is widely used in metallurgy, mining, lifting, transportation, cement, construction, chemical, textile, printing and dyeing, pharmaceutical and so on. field.

Even a 250 HP Electric Motors we can coupled with our gear motors and it's for sale. As a global supplier of motors, we offer different types of AC Motors and DC Motors including Traction Motors, Horizontal and vertical type. Delivering anywhere to the world from China, Sogears Direct provides the best selection and knowledge of electric motors, spare parts, geard motors and accessories to get them what they need.

The best service from our transmission drive expert to your inbox directly.

Our Service

Get in Touch

Yantai Bonway Manufacturer Co.ltd

ANo.160 Changjiang Road, Yantai, Shandong, China(264006)

T+86 535 6330966

W+86 185 63806647