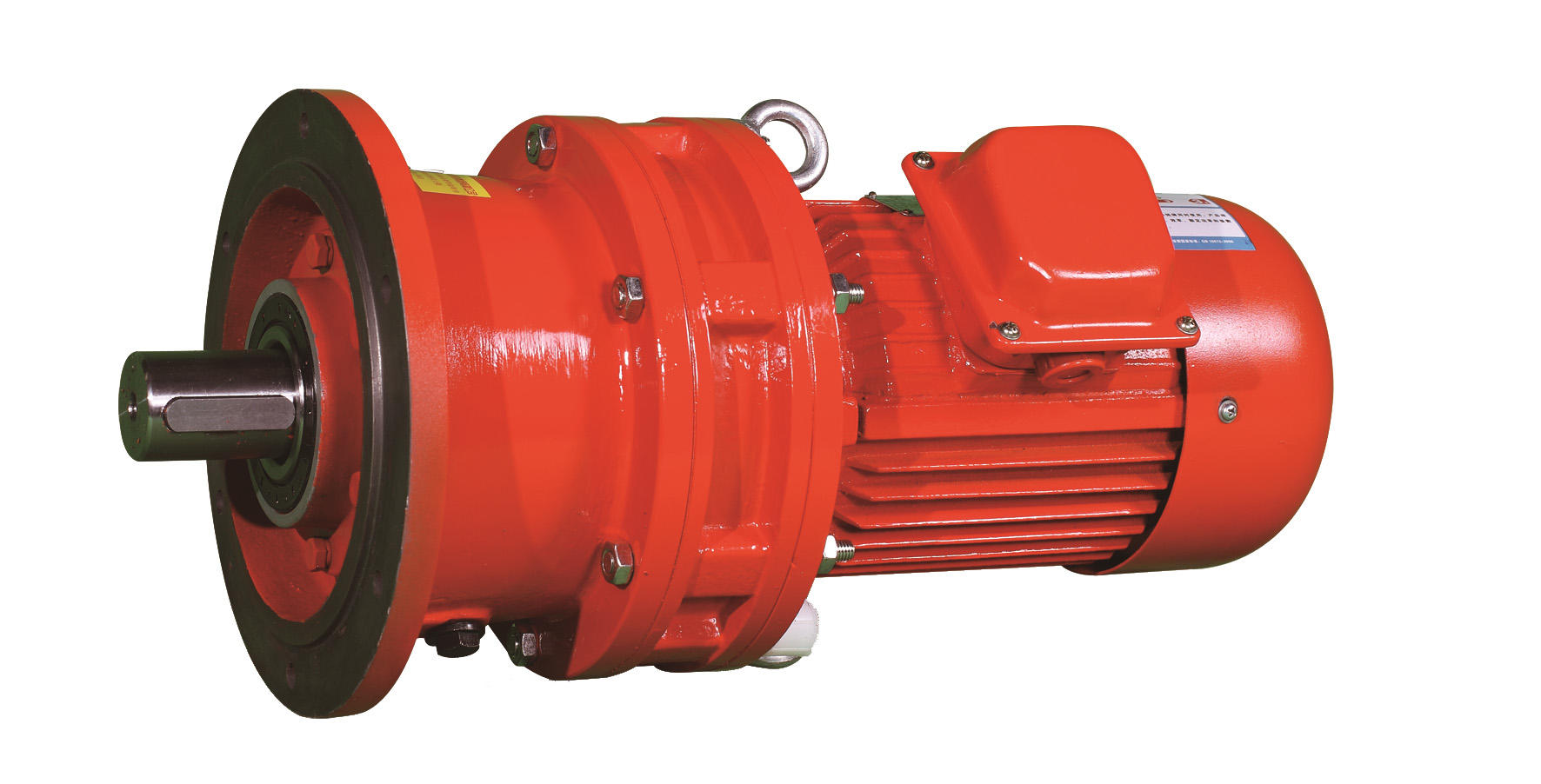

Eccentric cycloidal drive

The eccentric cycloidal drive is a new type of eccentric cycloidal drive with advanced design and novel structure, which is based on the principle of planetary transmission and adopts cycloid pin tooth meshing. The eccentric cycloidal drive can be widely used in various transmission machinery, such as: lifting, transportation, mining, metallurgy, petrochemical, textile, printing and dyeing, light industry, pharmaceutical, food machinery and so on.

Large transmission ratio: the transmission ratio is 1/6-1/87 at the first stage, 1/99-1/5133 at the second stage, 1/5841-17658503 at the second stage, and more stages can be adopted as required.

The transmission efficiency is high: because the machine meshing part uses rolling engagement, so the average efficiency can reach more than 90%.

Small volume and light weight: not only the planetary transmission principle is adopted, the input shaft and output shaft are on the same axis, but also have the uniqueness of being in direct connection with the eccentric cycloidal drive, so the machine has the characteristics of compact structure, small volume and light weight.

Few faults and long life: The main transmission meshing parts of the machine are made of bearing steel, so the mechanical properties are good, wear resistance is good, and the rolling friction is used, so the machine has fewer faults and longer life.

The ring gear is fixedly coupled to the housing, and oil entering from the port urges the rotor to revolve around a center point. This slow-rotating rotor drives the output through a splined shaft called a eccentric cycloidal drive. After the introduction of this initial eccentric cycloidal drives, after decades of evolution, another concept of the eccentric cycloidal drive began to form. In the late 1950s, the original low-speed, high-torque eccentric cycloidal drives was developed from a fixed-rotor component of the oil pump. This component consisted of an internal ring gear and a matching gear or rotor.

Introduction: The ring gear is fixedly coupled to the housing, and oil entering from the port urges the rotor to revolve around a center point. This slow-rotating rotor drives the output through a splined shaft called a eccentric cycloidal drive. After the introduction of this initial eccentric cycloidal drives, after decades of evolution, another concept of the eccentric cycloidal drive began to form. This eccentric cycloidal drive has a roller mounted in the built-in ring gear. The eccentric cycloidal drive with roller provides high starting and running torque, and the roller reduces friction, which increases efficiency even at very low speeds. Can produce a stable output. By changing the direction of the input and output flow, the eccentric cycloidal drive is quickly reversed and produces equivalent torque in both directions. Each series of eccentric cycloidal drives has a variety of displacement options to meet various speed and torque requirements.

advantage: The eccentric cycloidal drive is a small low-speed, high-torque eccentric cycloidal drives with one-axis

flow-setting insert and stator-rotor pair. The advantages are as follows: 1. Small in size and light in weight, its outer dimensions are much smaller than other types of

eccentric cycloidal drives of the same torque. 2. Wide range of speed, stepless speed regulation, minimum stable speed up to 15 rev / min,

convenient installation and installation, low investment cost. 3. It can be used in series in the hydraulic system or in parallel. 4. The rotation inertia is small, easy to start under load, both forward and reverse can be used,

and there is no downtime when commutating

Structure and performance characteristics: The eccentric cycloidal drive is an integral part of the output shaft and the valve, and the

geared stator and rotor auxiliary eccentric cycloidal drive. Main features: 1. Adopting end face distribution and axial flow distribution, the structure is simple and compact,

and the flow matching precision is high; 2. Adopting the stator and rotor pair, the mechanical efficiency is high, and the high-voltage

operation life is long; 3. Double-joint ball bearing can withstand large radial and axial loads, low friction and high

mechanical efficiency.

4. Advanced flow distribution mechanism design, featuring high flow distribution accuracy and

automatic wear compensation.

5. The eccentric cycloidal drive can be used in series and parallel, and should be connected to the external drain

when used in series.

6. Adopt tapered roller bearing support design, with large radial load capacity, so that the

eccentric cycloidal drive can directly drive the working mechanism.

7. A variety of flanges, output shafts, oil ports, etc. The eccentric cycloidal drives is a small, low-speed, high-torque eccentric cycloidal drives with an internal meshing

cycloidal gear. The utility model has the advantages of simple structure, good low-speed

performance and strong short-term overload capability. The eccentric cycloidal drives has a stator and a

movable blade therein, and the stator, the blade and the transmission shaft divide the eccentric cycloidal drive

into two chambers, each of which has a port and a port. When the oil enters, another oil is

released, and the oil pushes the blade to swing. The eccentric cycloidal drive is a small-sized

low-speed high-torque eccentric cycloidal drives with one-axis flow-setting insert and stator-rotor

Operating notes: 1. Check that all components of the hydraulic system are connected correctly before operation,

and add oil to the specified height through the filter. 2. Start running for 10 to 15 minutes without load, and exhaust, foam in the fuel tank, noise in

the system, and stagnant eccentric cycloidal drive cylinders prove that there is air in the system. 3. After removing the air, fill up the fuel tank, and then gradually increase the load to the

eccentric cycloidal drive until the maximum load, observe whether there are abnormal phenomena, such as noise

, oil rise and oil leakage. 4. Change the oil by running for 50 hours, and replace it according to the maintenance rules. 5. If it is not a eccentric cycloidal drive failure, please do not disassemble it easily.

Disassembly and assembly: When the Tylers eccentric cycloidal drives fails to be disassembled, please pay attention to the following: 1. Do not touch the joint surface when disassembling. If there is a bump, it needs to be

trimmed before assembly. 2. Wash all parts with gasoline or kerosene before assembly. Do not use cotton yarn or rag to

scrub the parts. Apply a brush or silk cloth. Do not immerse the rubber ring in gasoline. After

the eccentric cycloidal drive is installed, add 50~100ml of hydraulic oil to the two ports before installing the

machine, and rotate the output oil. If there is no abnormality, install the machine. 3. In order to ensure the correct rotation direction of the eccentric cycloidal drive, attention should be paid to the

positional relationship between the rotor and the output shaft. 4. The back cover bolts must be tightened diagonally, and the tightening torque is 4~5 kg

force·m

the structure and performance characteristics: The eccentric cycloidal drive is an integral part of the output shaft and the valve, and the gear

-type stator and rotor sub-eccentric cycloidal drive. The specific structure is shown in Figure 1.

Main features: 1 Adopting end face distribution and axial flow distribution, the structure is simple and compact

, and the flow matching precision is high; 2 Adopting the stator and rotor pair, the mechanical efficiency is high, and the high-voltage

operation life is long; 3 Double-joint ball bearing can withstand large radial and axial loads, low friction and high

mechanical efficiency. 4 Advanced flow distribution mechanism design, featuring high flow distribution accuracy and

automatic wear compensation. 5 The eccentric cycloidal drive can be used in series and in parallel, and should be connected to the external

drain when used in series. 6 The tapered roller bearing support design has a large radial load capacity, so that the eccentric cycloidal drive

can directly drive the working mechanism. 7 Various flanges, output shafts, oil ports, etc.

From the point of view of energy conversion, the eccentric cycloidal drives converts the input hydraulic

energy into mechanical energy, and the hydraulic pump is just the opposite, so the hydraulic

pump and the eccentric cycloidal drives are reversible hydraulic components, and the working fluid is

input to any hydraulic pump. It can be turned into a eccentric cycloidal drives operating condition;

conversely, when the main shaft of the eccentric cycloidal drives is driven to rotate by an external

torque, it can also be changed to a hydraulic pump operating condition. Because they have the

same basic structural elements - a closed and periodically variable volume and a corresponding

oil distribution mechanism.

However, due to the different working conditions of eccentric cycloidal drives and hydraulic pumps,

their performance requirements are different, so there are still many differences between

eccentric cycloidal drives and hydraulic pumps of the same type. First of all, the eccentric cycloidal drives should

be able to rotate in both the positive and negative directions, thus requiring the internal

structure to be symmetrical; the speed range of the eccentric cycloidal drives needs to be large enough,

especially for its minimum stable rotational speed. Therefore, it usually uses a rolling bearing or

a hydrostatic sliding bearing; secondly, the eccentric cycloidal drives does not have to have self-priming

capability because it operates under input pressure oil, but requires a certain initial sealing to

provide the necessary starting torque. Due to these differences, the eccentric cycloidal drives and the

hydraulic pump are similar in structure but cannot be reversible.

The eccentric cycloidal drive is an internal meshing cycloidal gear eccentric cycloidal drives made by a

principle similar to a planetary eccentric cycloidal drive (small tooth difference principle), referred to as a

eccentric cycloidal drives.

eccentric cycloidal drives can be divided into gear type, vane type, and plunger type according to their

structure types. According to the rated speed of the eccentric cycloidal drives, it is divided into two

categories: high speed and low speed. A high-speed eccentric cycloidal drives with a rated speed higher

than 500r/min is a low-speed eccentric cycloidal drives with a rated speed lower than 500r/min. It features a fixed rotor design for high efficiency. Reliable shaft end seal design that withstands high pressures and can be used in series and in

parallel The forward and reverse conversion is convenient and the rotation speed is stable. Efficiency and economic performance for medium loads.

The BM series eccentric cycloidal drive is a small, low-speed, high-torque eccentric cycloidal drives with an internal

meshing cycloidal gear that can be used for long-term operation under high pressure. The

overall structure design of the output shaft and the flow distribution mechanism, the indented

stator and rotor, the rolling shaft support at both ends, and the special inlet return rotary seal

ring enable the eccentric cycloidal drive to work under a high back pressure.

Bm eccentric cycloidal drives has six series, which can completely replace imported Eaton J2K, J6K;

Danfoss DANFOSS, OMP, OMR, OMS, OMV, OMT, etc., and can also replace domestic BM1,

BM2, BM3, BM4, BM5/2X, BM6/6X and other products

Specifications and features: 1. The flow distribution mechanism and the output shaft are integrally formed, which has

higher oil distribution precision and high volumetric efficiency. Advanced shaft seal design with

high back pressure bearing capacity. 2. The geared stator and rotor and advanced spline parameters are designed with high

mechanical efficiency and long service life. The double-rolling bearing design at both ends has

a larger lateral load capacity and is suitable for various working conditions. 3, simple structure, low speed performance, short-term overload capacity, compared with other

types of eccentric cycloidal drives of the same displacement, has the advantages of small size, light

weight, large output torque, etc., the oil pipe only needs to be directly connected to the eccentric cycloidal drive

inlet and outlet ports. , you can work, change the direction of oil flow, you can get different

directions of rotation

The eccentric cycloidal drive can be widely used in engineering machinery, agricultural machinery, transportation,

oil mining, machine manufacturing and other departments, such as hydraulic presses,

conveyors, operating machines, injection molding machines, tubing pliers, robots, road sweeper

s, lifting cranes, etc. Mechanical equipment and other places where speed and direction need

to be changed

The eccentric cycloidal drive is a small low-speed, high-torque eccentric cycloidal drives with one-axis

flow-setting insert and stator-rotor pair. The advantages are as follows:

1. Small in size and light in weight, its outer dimensions are much smaller than other types of

eccentric cycloidal drives of the same torque.

2, wide range of speed, stepless speed regulation, the lowest stable speed up to 15 rev / min,

easy installation and installation, low investment costs.

3. It can be used in series in the hydraulic system, or it can be used in parallel.

4, the rotation inertia is small, easy to start under load, both forward and reverse can be used,

and there is no need to stop when commuting. eccentric cycloidal drives are widely used in

agricultural, fishing, light industry, lifting and transportation, mining, engineering machinery

and other mechanical slewing mechanisms.

Examples of foreign applications of eccentric cycloidal drives: 1 Agricultural: various combine harvesters, seeders, rotary tillers, lawn mowers, sprayers, feed

mixers, surface drilling machines. 2 Fishing: use the net machine. 3 Light industry: winder, textile machine, printing machine, business washing machine. 4 Construction industry: road roller, cement mixer, sweeper.

The GT eccentric cycloidal drive is a disc distribution eccentric cycloidal drive. 1. Advanced disc distribution structure design, low speed performance. 2. High volumetric efficiency and automatic wear compensation. 3. Double row tapered needle roller bearings can withstand large radial forces and are used in

heavy load driving applications.

The GGM series eccentric cycloidal drives is an ultra-high speed eccentric cycloidal drives. Can be used on seeder fans as well as on mining machinery coolers. technical parameter: 1. Displacement: 3.6ml / r; 6.1ml / r; 7.4ml / r; 9.5ml / r; 11.5ml / r; 2. Rated speed: 3000r/min, maximum speed: 5000r/min; 3. Rated flow rate: 3.6l/min; 4. Continuous working pressure. pressure: 13.8Mpa, maximum: 17.25Mpa; 5. Output torque (6.9Mpa): 3.92Nm; 6. Housing material: cast aluminum 9-tooth splines are also available.

technical parameter: 1. Displacement: 3.6ml / r; 6.1ml / r; 7.4ml / r; 9.5ml / r; 11.5ml / r; 2. Rated speed: 3000r/min, maximum speed: 5000r/min; 3. Rated flow rate: 3.6l/min; 4. Continuous working pressure. pressure: 13.8Mpa, maximum: 17.25Mpa; 5. Output torque (6.9Mpa): 3.92Nm; 6. Housing material: cast aluminum 9-tooth splines are also available.

The GS eccentric cycloidal drive is a disc distribution eccentric cycloidal drive. 1. Advanced disc distribution structure design, low speed performance. 2. High volumetric efficiency and automatic wear compensation. 3. Double row tapered needle roller bearings can withstand large radial forces and are used in

heavy load driving applications.

The GR eccentric cycloidal drive is a shaft distribution eccentric cycloidal drive. 1. It adopts the design of the inserting pin and the rotor, which is superior to the BMP eccentric cycloidal drive. 2. Reliable shaft seal design, withstand high back pressure, can be used in series and parallel. 3. Forward and reverse conversion is convenient and the speed is stable. 4. High efficiency and economical, suitable for medium load applications.

The GP eccentric cycloidal drive is a shaft distribution eccentric cycloidal drive: 1. It adopts high-pressure shaft sealing ring and can withstand high back pressure operation. 2. There are a variety of flange, output shaft, oil port connection options to choose from. 3. The commutation is convenient and the speed can be adjusted freely. 4. High efficiency and economical, widely used in medium load applications.

working principle: A typical structure of a eccentric cycloidal drives, a cycloidal rotor having Z1 teeth (ie, an externally toothed pinion) 14, and an eccentricity e between a stator having z2 arc-shaped teeth (ie, an internal ring gear) 13, When the difference in the number of teeth of the two wheels is 1, that is, z2–z1=1, all the teeth of the two wheels can mesh and form z2 as shown in the XX section of Fig. 1 (22=7, Zl=6). Number of needle teeth) A separate volumetrically sealed chamber. The transverse grooves A and B on the distribution shaft (ie, the output shaft) 7 communicate with the inlet and outlet ports. There are 22i groups of longitudinal oil grooves uniformly distributed on the surface of the distribution shaft, and one group (Zl) communicates with A, and the other Group (Zl) communicates with B (see Figure 2). There are 22 holes C in the housing 6 of the eccentric cycloidal drive, and the holes pass through the corresponding 22 holes D of the auxiliary distribution plate 10 to communicate with the tooth bottoms of the stator respectively (ie, communicate with 22 sealed cavities respectively)

When the Tylers eccentric cycloidal drives fails to be disassembled, please pay attention to the following: (1) Do not touch the joint surface when disassembling. If there is a bump, it needs to be

trimmed before assembly. (2) Wash all parts with gasoline or kerosene before assembly. Do not use cotton yarn or rag to

scrub parts. Apply brush or silk cloth. Do not immerse the rubber ring in gasoline. After the

eccentric cycloidal drive is installed, add 50~100ml of hydraulic oil to the two ports before installing the machine,

and rotate the output oil. If there is no abnormality, install the machine. (3) In order to ensure the correct rotation direction of the eccentric cycloidal drive, attention should be paid to

the positional relationship between the rotor and the output shaft. (4) The back cover bolts must be tightened diagonally, and the tightening torque is 4~5 kg

force·meter.

The longitudinal oil groove on the distribution shaft plays a distribution function, so that nearly

half of the 22 closed chambers communicate with the pressure oil, and the rest communicate

with the low pressure oil return. When the pressure oil is input through the A port, the 5, 6,

and 7 chambers enter the high pressure oil (see Fig. 3), and the rotor (pinion gear) rotates in

the direction of increasing the volume between the teeth of the high pressure chamber under

the action of the oil pressure. Since the stator is stationary, the rotor rotates around the axis

O1 at a low speed, and the rotor center Ol also revolves around the center 02 of the stator.

When the rotor revolves, that is, when the rotor rolls along the stator, it sucks. The pressure

oil chamber is constantly changing, but it is always divided into two chambers by the center

line 0102. The volume between the teeth on one side is the high pressure chamber, and the

volume between the other side is the oil discharge chamber. . The revolution and the rotation

of each tooth chamber complete one cycle of oil inlet and return.

The best service from our transmission drive expert to your inbox directly.

Our Service

Get in Touch

Yantai Bonway Manufacturer Co.ltd

ANo.160 Changjiang Road, Yantai, Shandong, China(264006)

T+86 535 6330966

W+86 185 63806647