Helical worm gear motor sew

Helical worm gear motor sew, helical gear vs worm gear, helical worm gearbox, helical gears for sale, helical drive gear, helical gear pump, sew gear motor, helical gear cutter, helical gears pdf

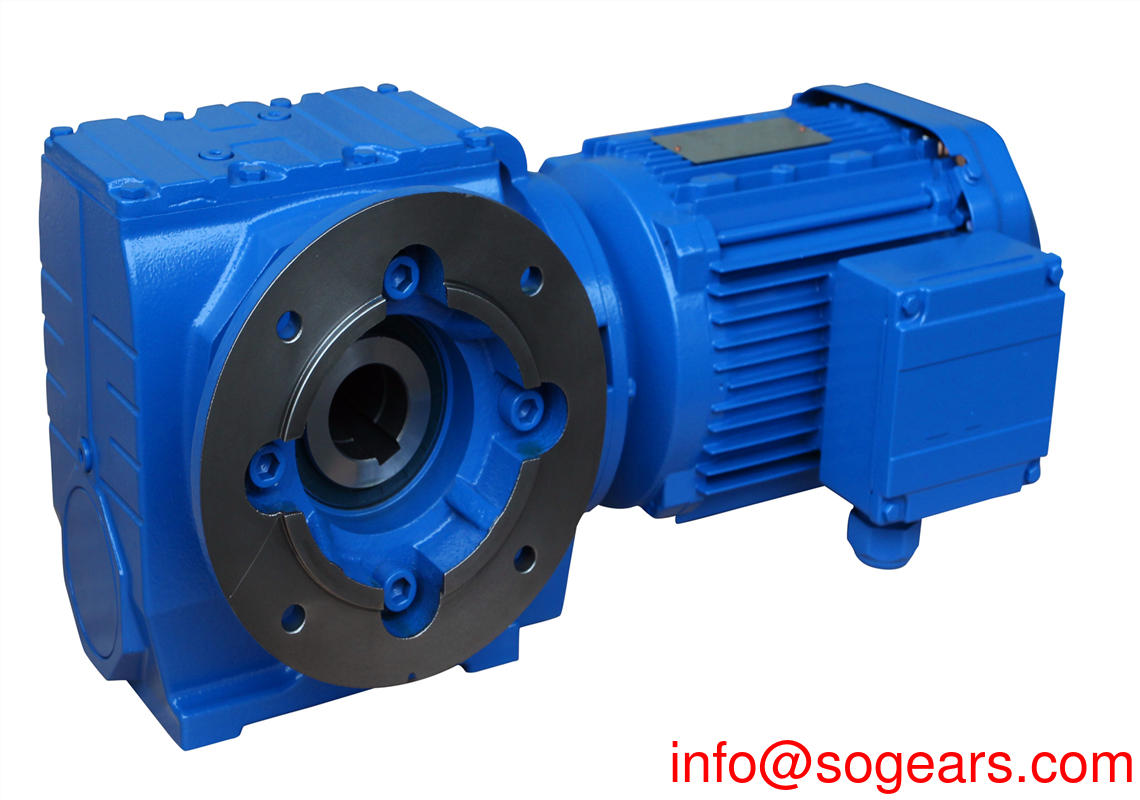

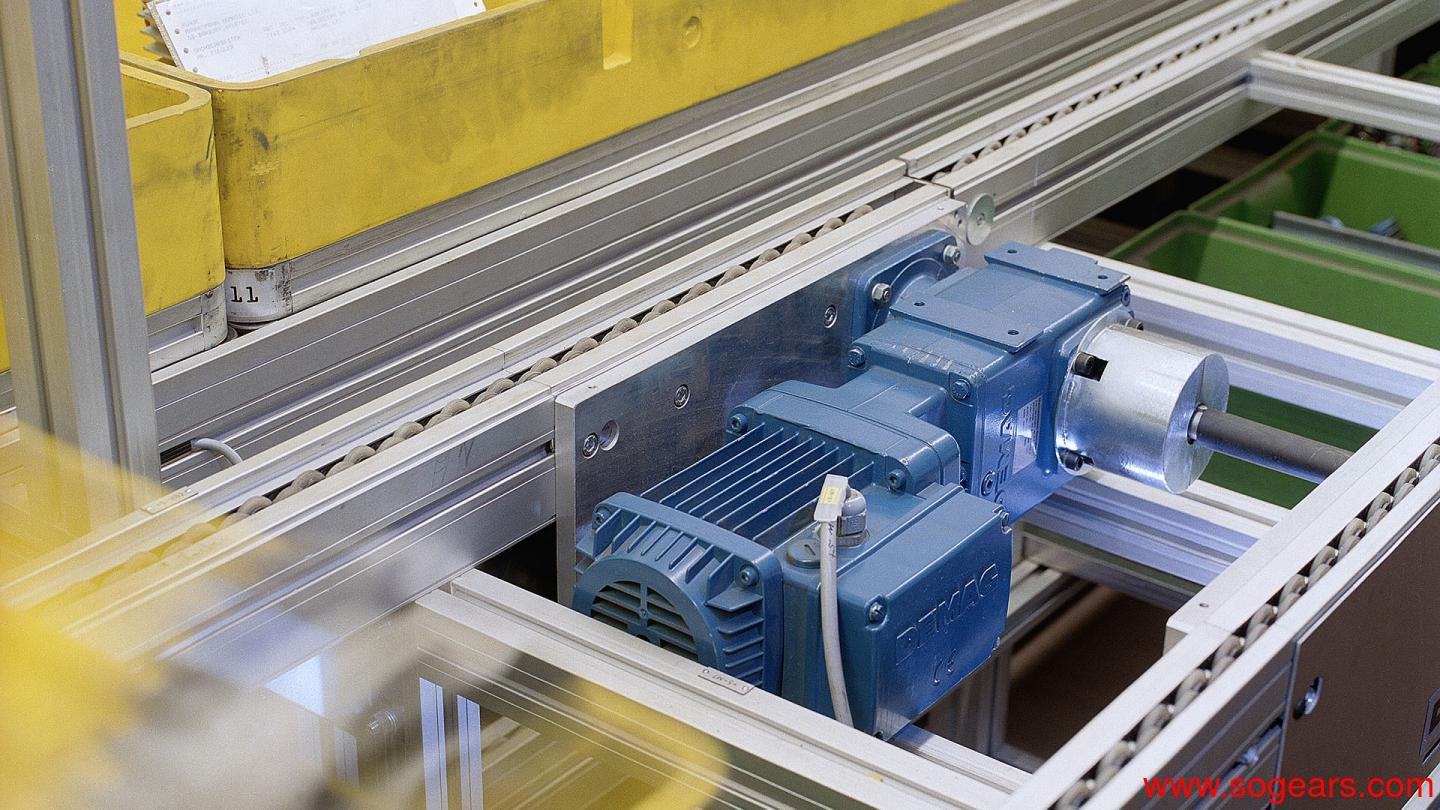

S series helical worm gear motor sew type. The worm reduction gears come in two series, in versions XA with shaft and XF-XC with mounting provisions for motor.

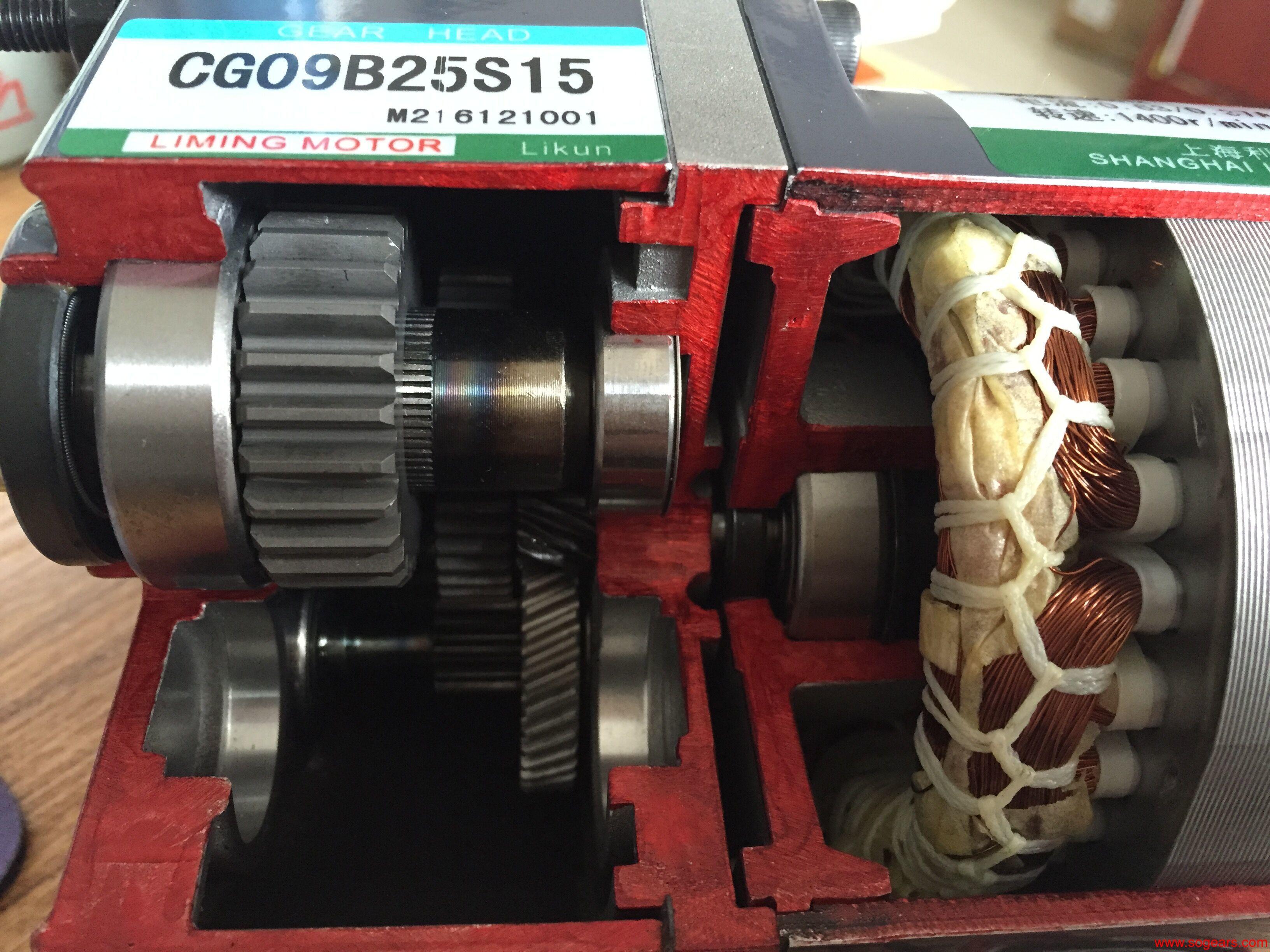

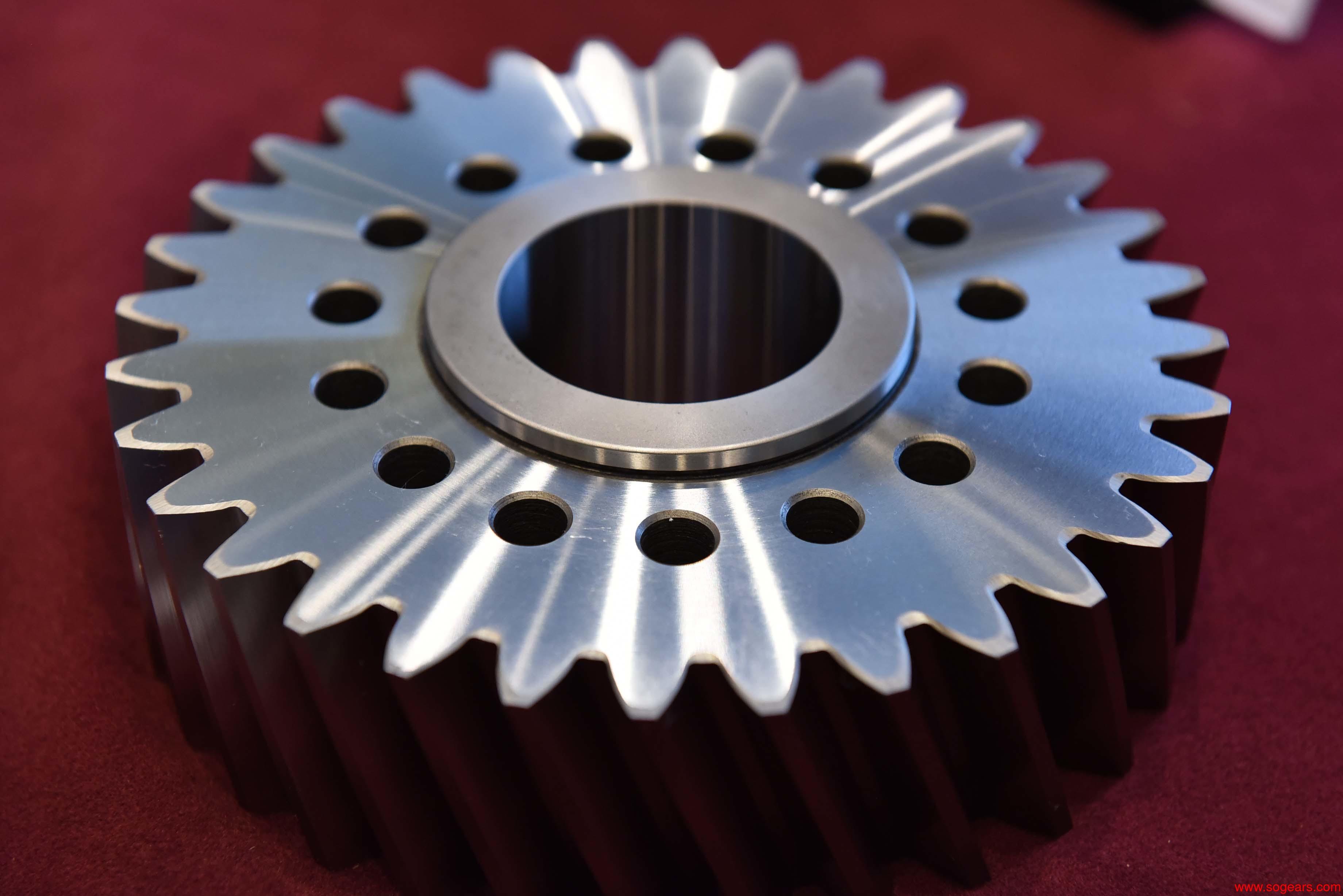

The helical gear worm gear motor adopts the direct connection mode of the motor, and the structure is a first stage helical gear plus a first stage worm gear transmission. The output is shaft mounted and comes in six basic mounting styles. It can be reversed and reversed. The helical gear adopts hard tooth surface, stable operation, large carrying capacity, working environment temperature -10 °C ~ 40 °C. This product has the characteristics of large speed variation range, compact structure and convenient installation compared with similar products.

Inline and bevel helical gear motors, parallel shaft speed gear motors, and worm gear boxes with AC motor. The range is built in aluminium or iron castings, and covers torques, with the Helical worm-geared motor new style version, A gear motor sizes could made in n2=22.8 rpm 1 hp, 230/400V 50Hz output side 5 efficiency class IE2, For operating instructions, please contact us.

S series helical gear worm gear motor (large speed ratio),

1. S series reducer has high technical content, and has a combination of helical gear and worm gear to improve the torque and efficiency of the machine. This series of products has complete specifications, wide speed range, good versatility, adapt to various installation methods, performance, safety and reliability, long service life, and implementation of international standards.

2. The surface of the body has concave and convex heat dissipation, strong vibration absorption, low temperature rise and low noise.

3. The machine has good sealing performance and strong adaptability to the working environment.

4. S series helical gear worm gear reducer has high transmission precision, especially suitable for occasions with frequent starting. It can be connected with various speed reducers and equipped with various types of motor drive. It can be installed in 90 degree transmission operation.

position.

5, S helical gear reducer 20CrMnTi material, and after carburizing and quenching heat treatment, the surface hardness can reach 58-62HRC, the grinding tooth processing, the precision can be gray 5-6, with high processing precision, stable transmission, small volume bearing Features such as high capacity and long life.

6. The helical gear motor can be equipped with various types of motors to form an electromechanical integration, which fully guarantees the quality characteristics of the products.

Performance characteristics:

1. The combination of helical gear and worm gear has compact structure and large reduction ratio.

2, installation method: foot installation, hollow shaft installation, flange installation, torque arm installation, small flange installation.

3. Input mode: motor direct connection, motor belt connection or input shaft, coupling flange input.

4. Average efficiency: the reduction ratio is 77% for 7.5-69.39; 62% for 70.43-288; and 57% for S/R combination.

5, and the R series combination can get a larger speed ratio.

technical parameter:

Speed ratio range: basic type 9.96 ~ 244.74, S series / R series combination type can reach 8608

Torque range: 43~4200 Nm

Power range: 0.18~22 kW

structure type:

S-shaft extension joint SF-shaft extension type, flange installation

S...S- indicates axis input SA-axis mounted connection

SAF-shaft mounted, flange mounted SAT-shaft with torsion arm

This series of reducers is identical in shape to the K-Series reducers and can be used interchangeably. However, under the same power and frame number, the S series can achieve greater speed ratio deceleration.

The main models of S series helical gear-worm gear reducer are:

S/SA/SAF/SAT37, S/SA/SAF/SAT47, S/SA/SAF/SAT57, S/SA/SAF/SAT67, S/SA/SAF/SAT77, S/SA/SAF/SAT87, S/ SA/SAF/SAT97, S/SA/SAF/SAT107

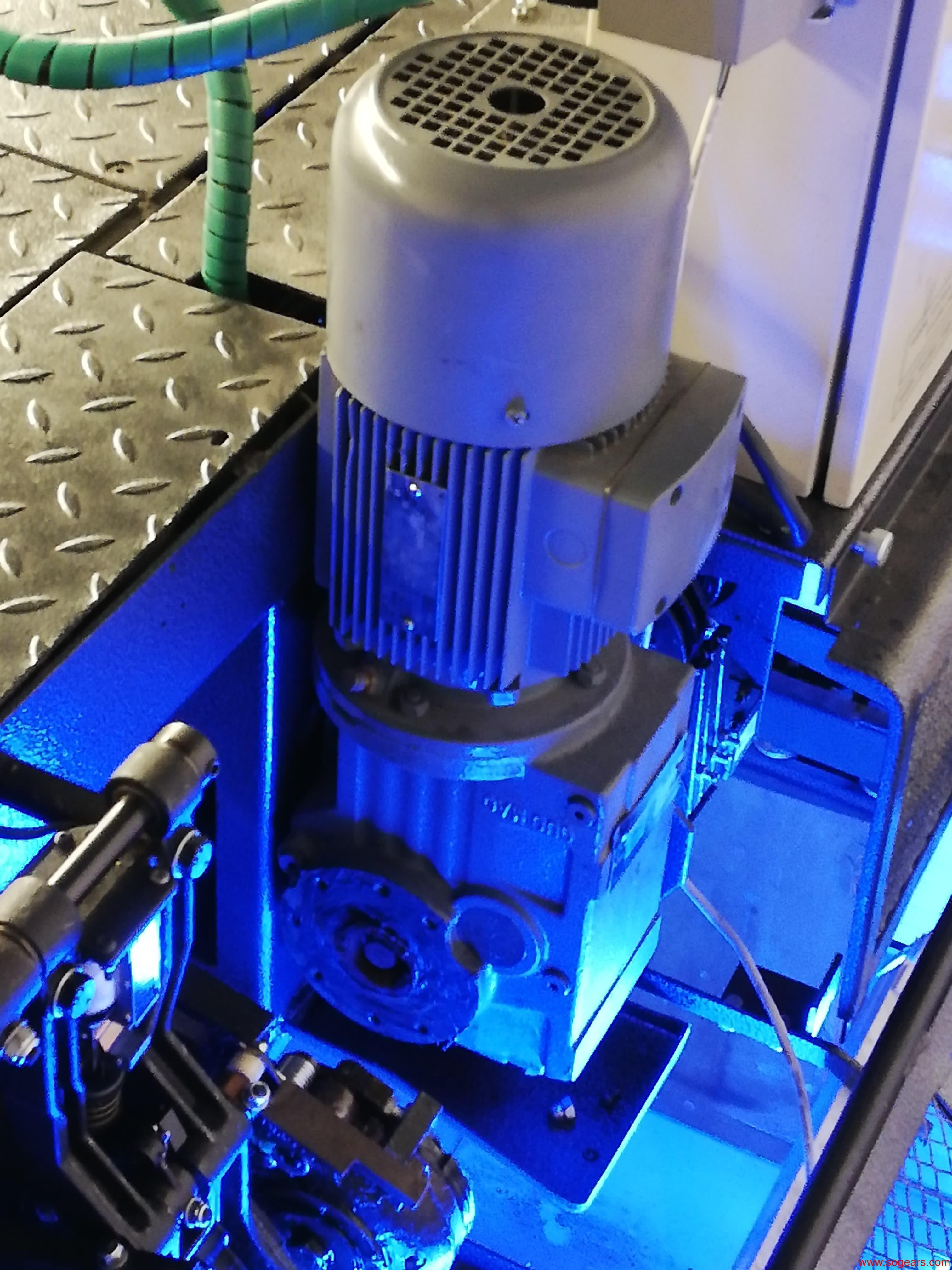

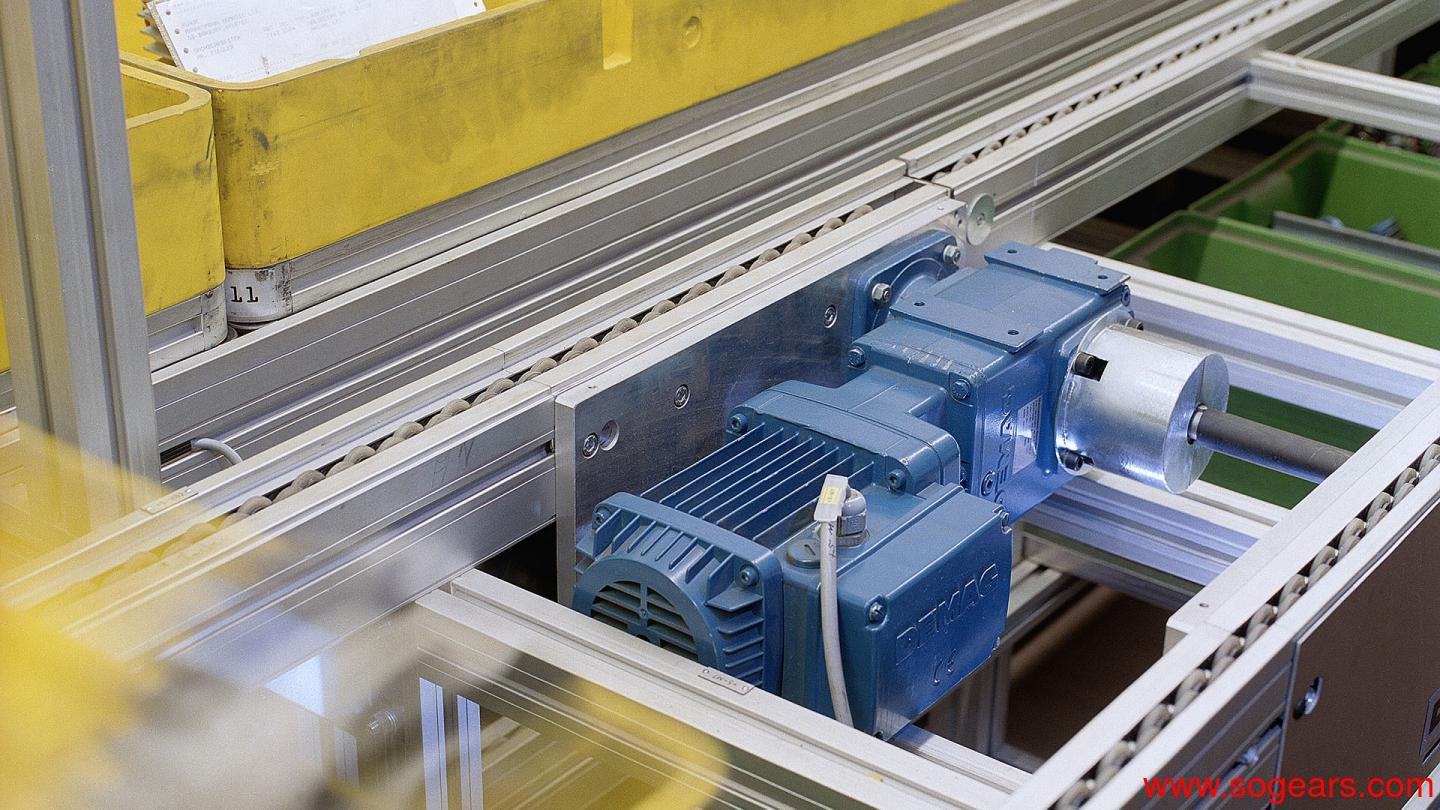

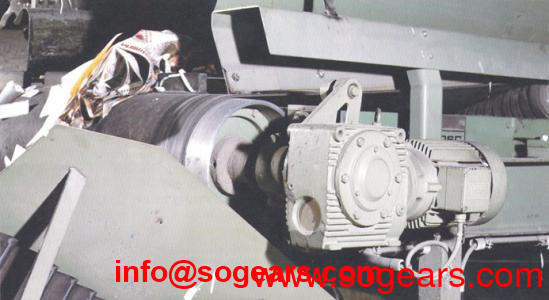

When use our modular concept and combine the helical worm gear units of the S series with an AC motor to be an helical-worm gearmotor, or with a servomotor. Same as mors of other China S Series Helical Worm gear motor, Speed gear motor, but you would Find lot details about China Worm gear motor manufacturer, the previous version gear motor and geared motor products which have been installed in our customers such as cement plant, watertreatment plant, oil press plant etc. and all The helical-worm gear motor is a particularly low-noise drive component. Ours Can be widely used in metallurgy, mining, lifting, light industry, chemical, transportation, construction and other mechanical equipment speed reduction mechanism.

1.Chemical industry and environmental protection

2.Metal processing

3.Building and construction

4.Agriculture and food

5.Textile and leather

6.Forest and paper

7.Car washing machinery

Taiwan S series HELICAL WORM gear motores, is high quality but much more expensive than ours and here you can Find Details about our S series HELICAL WORM gear motor is same but most competitive price. We, Sogears manufacturing reputed started in the year 1993 - Supplier, Trader and Exporter of high quality range of Helical Worm gearbo. As a geared motor manufacturer,Sogears also produces K/F/R series helical gear motors which is designed similar as SEW brands'. We provide all SEW Eurodrive standard Helical Gear Motors, MOVITRAC, Helical Bevel Gear Motors, Helical Worm Gear Motors, Parallel Shaft Helical Gearmotors. Our factory also offers customized and wholesale service. Feel free to buy discount price helical worm gear motores S series made in China in stock here from our factory.

|

Housing material |

Cast iron/Ductile iron |

|

Housing hardness |

HBS190-240 |

|

Gear material |

20CrMnTi alloy steel |

|

Surface hardness of gears |

HRC58°~62 ° |

|

Gear core hardness |

HRC33~40 |

|

Input / Output shaft material |

40CrMo alloy steel |

|

Input / Output shaft hardness |

HRC25~30 |

|

Machining precision of gears |

accurate grinding, 6~5 Grade |

|

Lubricating oil |

GB L-CKC220-460, Shell Omala220-460 |

|

Heat treatment |

tempering, cementiting, quenching, etc. |

|

Efficiency |

94%~96% (depends on the transmission stage) |

|

Noise (MAX) |

60~68dB |

|

Temp. rise (MAX) |

40°C |

|

Temp. rise (Oil)(MAX) |

50°C |

|

Vibration |

≤20µm |

|

Backlash |

≤20Arcmin |

|

Brand of bearings |

China top brand quality bearing, HRB/LYC/ZWZ/C&U. Or other brands requested, SKF, FAG, INA, NSK. |

1.Our Services

1.1.We provide 15 months Warranty. We are your expert for single- and multi-stage helical worm gears. We are your partner for most of the famous machine and projects company all over the world. Type from with motor flange and motor coupling for IEC motors to soild shaft only.

1.2. We have thousands of gear motor gear motors. From Input Power 0.06KW to 200KW, Ratio 1.3-289.74, Output speed 0-1095rpm and Output torque 1.4-62800Nm. They can meet your all different requirements for different industries. A helical worm drive is a helical gear arrangement in which a worm meshes with a worm gear, This motor with helical worm drive system is often used in toys and other small system. A right hand helical gear or right hand worm is one in which the teeth twist .

1.3. We provide E-catalog or Paper catalog,so you can select the model easily according to your requirements

1.4.You are welcome to visit our factory to check our products,we can help you to book the hotel or ticket

2.Company Information

2.1.Our Company:

We specialized in reduction gears transmission drive for over 20years! The most popular top 5 China suppliers.China sogears Gear motor manufacturer, high quality gear reduction motor and supplying electric Motors, gear motor manufacturer. Production Capacity:more than half a million sets of speed gear motor per year.

2.2.Our People:

The company has a strong technical force. It has more than 400 employees at present, including more than 40 engineering technicians and 10 experts and senior engineers enjoying special allowances of the State Council. We produce Helical Worm Gearboxes, Bevel Gearboxes, Helical Gear Box, also we are a Siemens Authorized Distributor, Supplier, Dealer to both China & India.

2.3. Our Certificates:

Passed " ISO 9001 International Quality System Certificate", "International Quality Credit AAA++ Ceritifacte" , " Swiss SGS Certificate", Iconic Brand in Chinese Electromechanical Industry", " and so on.

3. FAQ

Q:What kinds of gear motor can you produce for us?

A:Main products of our company: JWB-X series mechanical continuously variable transmission, RV series worm gear motor, B/JXJ cycloidal pin gear speed gear motor, NCJ series gear motor, and R, F K, S series helical-tooth gear motor (similar to SEW), more than one hundred models and thousands of specifications.

Q:What are the application of the gear motor?

A:Products are widely used in ceramic, glass, food, metallurgy, beer & drink, printing and dyeing, textile, petrochemical engineering, warehouse logistics, wood-working machine, environmental protection equipment, printing and packaging, pharmacy, and leather. Products are sold in some countries and regions, such as Europe, America, and Southeast Asia, and it possesses dozens of distributors and after-sale service agents.

Q:What is the material you use?

A1: Aluminum Housing body ( For the RV series worm gear motor Size 30~90) Helical worm gear motors achieve high torque at low speeds and affordable prices. They are assembled in helical and worm gears. For helical worm gear motor header, it is a very reasonable priced worm gear. Worm gears in size SB025 – SB090 are made in aluminum and SB110-SB150 in cast iron.

A2: Cast iron(For the RV series worm gear motor, Size 110-150, For the NCJ & F/R/S/K series helical gear motor)

Sogears brand Helical Worm motors and gear servo-motors. With emphasis on the lower performance range, worm gear units with integral servo-motor, it is become the favorably-priced solution for drives with angular geared motors. The efficiency is significantly better than that of pure worm gears. More details are as followings:

|

SIZE

|

Shaft Dia.(mm)

Solid Hallow

|

Center Height

|

Output Flange Dia.(mm)

|

Power(kw)

|

Ratio

|

Permissible Torque(N.m)

|

Weight(KGS)

|

|

|

37

|

φ20k6

|

φ20h7

|

82

|

φ120/160

|

0.18-0.75

|

10.27-165.71

|

90

|

7

|

|

47

|

φ25k6

|

φ25h7

|

100

|

φ160

|

0.18-1.50

|

11.46-244.74

|

170

|

10

|

|

57

|

φ30k6

|

φ30h7/35h7

|

180

|

φ200

|

0.18-3.0

|

10.78-196.21

|

300

|

14

|

|

67

|

φ35k6

|

φ40h7/45h7

|

140

|

φ200

|

0.25-5.50

|

11.55-227.20

|

520

|

26

|

|

77

|

φ45k6

|

φ50h7/60h7

|

180

|

φ250

|

0.55-7.50

|

9.96-241.09

|

1270

|

50

|

|

87

|

φ60m6

|

φ60h7/70h7

|

225

|

φ350

|

0.75-15.0

|

11.83-223.26

|

2280

|

100

|

|

97

|

φ70m6

|

φ70h7/90h7

|

280

|

φ450

|

1.50-22.0

|

12.5-230.48

|

4000

|

170

|

The best service from our transmission drive expert to your inbox directly.

Our Service

Get in Touch

Yantai Bonway Manufacturer Co.ltd

ANo.160 Changjiang Road, Yantai, Shandong, China(264006)

T+86 535 6330966

W+86 185 63806647