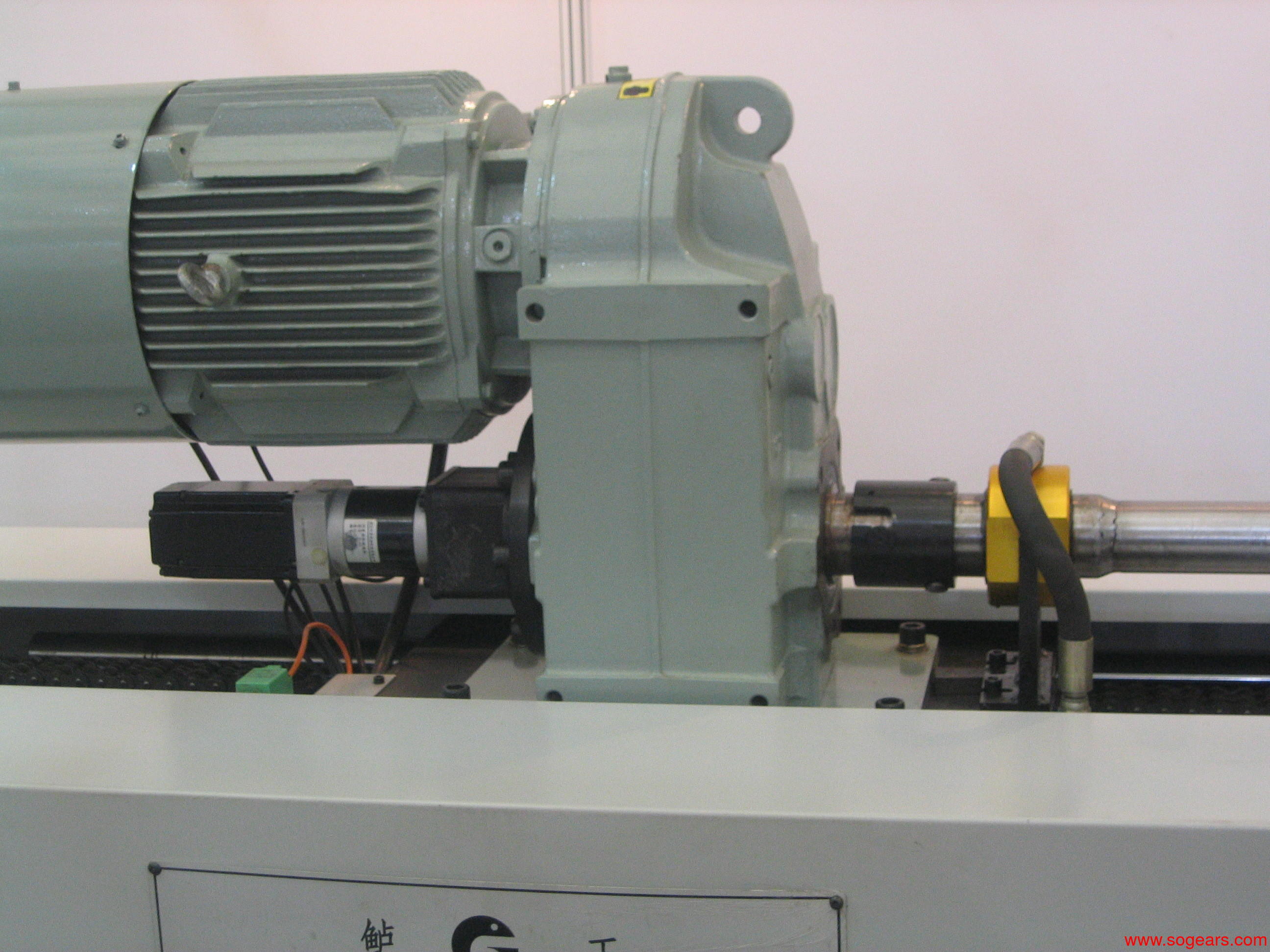

Linear motion gearbox

worm gear drive box, small linear motion gearbox, worm gear reduction box, worm gear drive, self locking linear motion gearbox, worm gear sets, hand crank linear motion gearbox

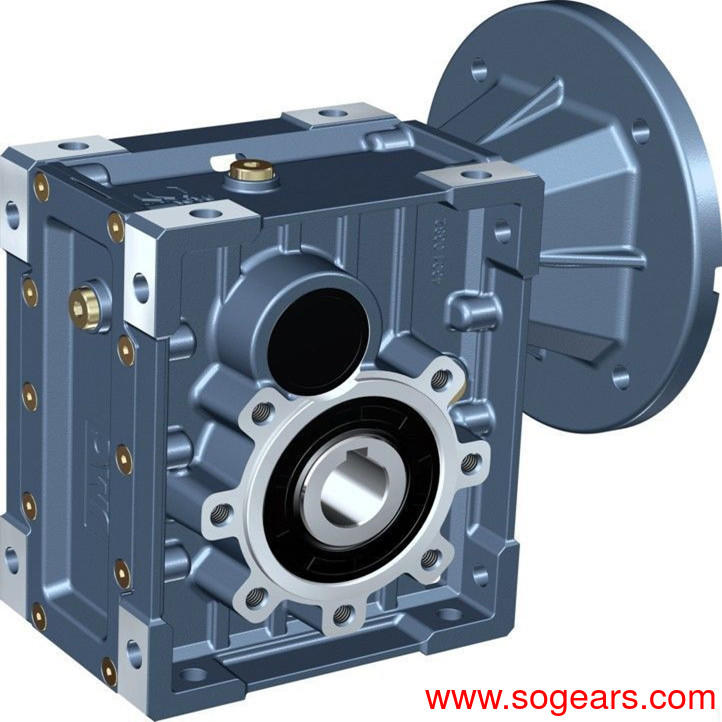

RV series linear motion gearbox is designed and manufactured according to technical quality standards. RV

series linear motion gearbox is based on the national standard GB10085-88 cylindrical worm gear parameters,

draws on advanced technology at home and abroad, has a unique "square box" shape structure, the box is

beautiful in appearance, and is made of high quality aluminum alloy die casting. to make. RV series worm

linear motion gearbox has been widely used in various industrial production process equipment mechanical

deceleration devices, is the best choice for modern industrial equipment to achieve high torque, high speed

ratio low noise, high stability mechanical reduction transmission control device. Characteristics 1. The mechanical structure is compact, the volume and shape are light, small and efficient; 2. Good heat exchange performance and fast heat dissipation; 3, easy to install, flexible and light, superior performance, easy to maintain and repair; 4. Smooth operation, low noise and durability; 5, strong use, safety and reliability;

RV gearbox is one of the more common gearboxs in the linear motion gearbox assembly design online family. It consists of a worm and a linear motion gearbox assembly. It has a compact structure, a large transmission ratio, and a transmission mechanism with self-locking function under certain conditions. It is the most commonly used. One of the linear motion gearbox assembly design online has low vibration, low noise and low energy consumption.

The basic structure of RV series aluminum alloy linear motion gearbox is mainly composed of worm gear, shaft

bearing, box and accessories. Can be divided into three basic structural parts: box, worm gear, bearing and

shaft combination. The box is the base of all the accessories in the linear motion gearbox. It is an important

part that supports the fixed shaft parts, ensures the correct relative position of the transmission parts and

supports the load acting on the linear motion gearboxes. The main function of the worm gear is to transmit the motion and

power between the two staggered shafts. The main function of the bearing and the shaft is power transmiss

ion, operation and efficiency.

The accessories of the linear motion gearbox are explained as follows:

Housing: aluminum alloy (frame: 025-090) cast iron (frame: 110-150);

Worm: 20Cr steel. Carbon and nitrogen co-seepage treatment (remaining tooth surface hardness HRC60

after finishing grinding, hardness thickness greater than 0.5mm);

Worm gear: special configuration of wear-resistant nickel bronze;

Oil cap/ventilator, mainly used to discharge gas in the linear motion gearbox case;

The end cover is divided into a large end cover and a small end cover. The end cover is an axial position of

the fixed shafting component and is subjected to an axial load, and both ends of the bearing seat hole are

closed by a bearing cover;

The oil seal is mainly used to prevent the leakage of lubricating oil inside the chassis and improve the use

time of the lubricating oil;

Oil drain plug, mainly used to discharge dirty oil and cleaning when replacing lubricating oil;

Oil cap/oil mark, mainly used to observe whether the oil inside the linear motion gearbox is up to standard.

Our linear motion gearbox Ratio 15/1 56C Worm linear motion gearbox with Double or signle stage, Worm linear motion gearbox NEMA23 Stepper Gearbox Ratio 10:1 for linear motion gearbox assembly. The most important applications of worm gears is used in worm linear motion gearboxes. A linear motion gearbox is called a worm motorreductors, linear motion gearbox or a worm drive gearbox. It consists of worm gears, shafts, bearings, and box frames. The worm gear, shafts, bearings load are supported by the box shell.

It is a power transmission component that can be used with transmission products such as ordinary motors

and continuously variable transmissions. Selection of linear motion gearbox frame. In principle, the frame type

is determined according to the output shaft diameter of the linear motion gearboxes. As long as the interface form and size

match, the output shaft size of the linear motion gearboxes can be floated up and down on the frame model within a

certain range. If the frame with the plate is selected, the installation size of the linear motion gearbox does

not match the frame, and the connection between the speed control plate and the linear motion gearboxes can be achieved

within a certain range to meet the user requirements. No support machine is strengthened. The machine

reinforces its own support points without shafts. The agitating shaft is the fulcrum of the two supporting

bearings of the output shaft of the linear motion gearbox, which can be used to transmit small power, is not

subject to or only subject to small axial load, and the stirring is not too strong.

There are two types of worm gears, cylindrical type (Worm Power Drive) Well-balanced in terms of performance, efficiency and cost, while achieving high effiency. Mechanical Transmission,Worm linear motion gearboxes Industrial Gearbox - Aluminum Housing Worm Gearbox is very good performance for most application. Left-Hand or right hand Shaft Worm Gearboxes.

The input form of RV gearbox is divided into: hole input, shaft input, extended worm shaft type;

When to choose a worm or helical gear, we have Full Line Popular RV Worm Gearbox By Low Price China Worm Gearbox, Worm Gearbox Manufacturers Conveyors: Belt, Roller, & More The RV gearbox output type is divided into: hole output, one-way axis output, and bidirectional axis output.

The speed ratio center distance

Center distance values: 25, 30, 40, 50, 63, 75, 90, 110, 130, 150.

In order to obtain a larger number ratio, two or more speed gearboxs can be combined to multiply the digital ratio.

The ratio of the two-stage gearbox: 100, 150, 200, 250, 300, 400, 500, 600, 750,

900, 1200, 1500, 1800, 2400, 3000, 3600, 4000, 5000

Product features

RV linear motion gearbox assembly design online is designed and manufactured according to Q/MDl-2.000 technical quality standard. Our customers can avail from us a specialized range of Worm Reduction linear motion gearboxes that are available 0.25 HP to 80 HP capacities. These precisely designed for good quality, offering 0.16HP To 20HP Worm Gearbox. Worm linear motion gearbox. Finishing: Galvanized, Paint Coated. Material: Aluminum And Casting. Feature: Light weight.

Sogers is Exporter of Worm linear motion gearboxes - Worm Reduction linear motion gearbox, and We make these gearboxes available at standard market prices to our customers. The primary feature of this high-efficiency linear motion gearbox is a worm gear, which locks the output shaft whenever the motor is not turning, IronHorse cast iron worm gearbox is heavy but prices start at $47 which is competitive; the full line is normally available for same-day shipping and is backed by a one-year warranty. Our clients are all over the world inclunding of Common conveyor types are belt conveyors, roller conveyors, motorized roller conveyors and overhead conveyors etc.

The linear motion gearbox is designed and manufactured according to Q/MD1-2000 technical quality standards

The product conforms to the national standard GB10085-88 worm and worm gear parameters, absorbs the

most advanced technology at home and abroad, and has a unique "square box" outer structure. The box

has a beautiful appearance and is die-casted with high quality aluminum alloy. Technical parameters: Power

: 0.06KW~7.5KW Torque: 2.6N·m~2379N·m Transmission ratio: 7.5-100 linear motion gearbox Model: RV25,

RV30, RV40, RV50, RV63, RV75, RV90, RV110, RV130 . Its role is to control the mechanical transmission

speed, widely used in the field of industrial machinery.

Can be installed according to the actual requirements, six sides can be installed

effect

The main functions of the linear motion gearboxes are:

1. Reduce the speed and increase the output torque at the same time. The torque output ratio is multiplied

by the motor output and the reduction ratio, but it should be noted that the rated torque of the linear motion gearboxes

cannot be exceeded.

2. Deceleration also reduces the inertia of the load, and the reduction of inertia is the square of the

reduction ratio. You can see that the general motor has an inertia value.

Installation matters

1. Various installation forms can be used according to actual requirements, and all six sides can be installed.

2. The installation must be firm and reliable.

3. The working mechanism of the prime mover and linear motion gearboxes must be carefully centered, and the error

should not be greater than the allowable difference of the coupling used.

4. After turning by hand, it must be flexible and free from sticking.

The product conforms to the national standard GBl0085-88 cylindrical linear motion gearbox assembly parameters, absorbs the most advanced technology at home and abroad, and has a unique "square box" shape structure. The box has beautiful appearance and is die-casted with high quality aluminum alloy. linear motion gearbox assembly design online With the following advantages:

- The mechanical structure is compact, the volume and shape are light, small and efficient;

- Good heat exchange performance and fast heat dissipation;

3, easy to install, flexible and light, superior performance, easy maintenance and repair;

4, stable operation, low noise, durable;

- Applicability, safety and reliability.

Information on installation, disassembly, reassembly, lubrication and linear motion gearbox assembly The mounting instructions for the NMRV Series worm gearboxes. These RV Series miniature right angle gearboxes provide high torque values with very low backlash. tO Order our linear motion gearbox assemblies, PLEASE FEEL FREE TO CONTACT US.

Sogears is Wholesaler of linear motion gearbox with reasonable Price, get the Latest Price please send us email and we will quote you the best price and cost as soon as possible.

At present, it has been widely used in various industries to produce mechanical speed reduction devices. linear motion gearbox assembly design online is highly praised by users. It is the best choice for modern industrial equipment to achieve high torque, high speed ratio, low noise and high stability mechanical reduction transmission control device.

main function

The linear motion gearbox is divided into two types: common cast iron linear motion gearbox and aluminum alloy

linear motion gearbox.

Worm linear motion gearboxes are commonly used in high-torque, low-speed transmissions to reduce the speed and

increase the output torque by passing the motor and other higher-speed power through the worm gear

linear motion gearboxes. The linear motion gearbox is installed between the electric motor and the working unit, and the

electric motor transmits power, and the linear motion gearbox speeds down, so that the rotational speed and

the torque are transmitted from the output shaft to the working unit.

The number of transmission stages of the linear motion gearbox is divided into two stages and a single stage.

The number of transmission stages can be selected according to the actual needs of the mechanical

equipment, and the linear motion gearbox is usually used with the motor and the transmission. The

single-input two-axis linear motion gearbox can also be equipped with an electromagnetic clutch and an

electromagnetic brake at both ends of the input to form a superior linear motion gearboxes clutch brake combination with

the functions of deceleration, braking and clutching.

Working conditions

- The transmission is stable, the vibration, impact and noise are small, the reduction ratio is large, the versatility is wide, and it can be used with various mechanical equipments.

- linear motion gearbox assembly design online can obtain a large transmission ratio with single-stage transmission, and has a compact structure. Most models have better self-locking performance, and can save braking devices for mechanical equipment with braking requirements.

- The meshing friction loss of the worm screw tooth and the linear motion gearbox assembly tooth surface is large, so the transmission efficiency is lower than the gear, easy to heat and high temperature.

- Higher requirements for lubrication and cooling.

5, good interoperability, linear motion gearbox assemblys are manufactured according to national standards, bearings, oil seals, etc. are used standard parts.

6, the box type has a basic type (the box is a vertical or horizontal structure with a footboard) and a universal type (the box is a rectangular parallelepiped, with multiple fixed holes, no bottom plate or another bottom) Various types of structure such as foot board)

- There are two basic types of input shaft connection (single input shaft and double input shaft) and two types of motor flanges.

- The output and input shafts have the input shaft at the bottom and the top; the output shaft is up and down; the input shaft is up and down.

- Two or three gearboxs can be used to form a multi-stage gearbox to obtain a great gear ratio.

- They can be categorized as floor conveyors (mounted on the floor) or overhead conveyors. worm linear motion gearboxes are used to move products, create buffers and deliver products in sequence in a production process.

Precautions

1. The linear motion gearbox must not hammer the casing of the linear motion gearboxes to avoid damage; check whether the

installation foundation, seals and drive shaft are normal. For normal use, the maximum temperature of the

lubricant should be less than 85 °C. If the oil temperature rises abnormally, and abnormal noise or other

phenomena occur, it is necessary to stop the inspection immediately and remove the fault before continuing

to use.

2. The first time or the new worm gear is replaced, the oil is changed after 150-400 hours of operation, and

the linear motion gearbox cycle is less than or equal to 4000 hours after the oil change. The oil filling amount

shall be in accordance with the requirements of the table. Oils of different grades are forbidden to be mixed.

Oils with the same grade and different viscosity are allowed to be mixed.

3. Regularly check the amount and quality of the oil, retain enough oil, and replace the oil mixed with

impurities or deterioration in time. The operating temperature of the linear motion gearboxes is -40 to +40 °C. When the

ambient temperature is below 0 °C, the lubricant must be heated above 0 °C or a low freezing point

lubricant before starting.

Maintenance instructions

1.When the new linear motion gearboxes is used, it needs to be replaced with new oil after 300 hours of continuous rotation.

After that, it needs to change oil every 2500 hours. However, the quality of the oil should be checked regularly

during the use. If the oil has impurities, aging and deterioration. Must be replaced at any time.

2.The gear unit of the fixed brand and number should be used for the linear motion gearboxes. It should not be mixed with

different brands, numbers or different types of oil. During the oil change process, the inside of the linear motion gearboxes

should be cleaned first, and new oil should be injected.

3.During use, when the oil temperature is too high (above 80 °C) and abnormal noise, stop using it

immediately and check the cause. You can continue to use it after troubleshooting or replacing the oil.

4.If the extreme cold is below -10 °C, the influence of the ring temperature on the linear motion gearboxes should be

considered in the selection. Consider the configuration of the electric heater. This is very important for the l

ubrication maintenance of the linear motion gearbox. Regularly observe the oil level movement. Observe

whether there is any abnormality such as noise and vibration.

5.Proper maintenance uses a linear motion gearbox to maximize its effectiveness.

Maintenance method

For the wear problem, the traditional solution of the enterprise is repairing after repair welding or brush

plating, but both have certain drawbacks: the thermal stress generated by the repair welding high

temperature cannot be completely eliminated, which may cause damage to the material and cause the

parts to bend or break; Brush plating is limited by the thickness of the coating, and it is easy to peel off.

The above two methods use metal to repair the metal, which can not change the "hard to hard" coordination

relationship. Under the combined action of each force, it will still cause re-wear. For some large bearing

companies, it is often impossible to solve on-site and rely on external repair. In the contemporary Western

countries, the repair methods of polymer composite materials are often used for the above problems, and

the application of Mikawara technology products with more applications has superior adhesion and excellent

compressive strength. The application of polymer material repair can be free of disassembly and machining

without the influence of repair welding thermal stress, and the thickness of the repair is not limited. At the

same time, the metal material of the product does not have the concession, which can absorb the shock

vibration of the equipment and avoid the wear again. It is possible, and greatly extends the service life of

equipment components, saving a lot of downtime for the enterprise and creating huge economic value.

For the leakage problem, the traditional method needs to disassemble and open the linear motion gearboxes, replace the

sealing gasket or apply the sealant, which is not only time-consuming and laborious, but also difficult to

ensure the sealing effect, and leakage will occur again during operation. The polymer material can be used

to treat leakage on the spot. The material has excellent adhesion, oil resistance and 350% elongation,

which overcomes the impact caused by the vibration of the linear motion gearboxes, and solves the problem of leakage of

the linear motion gearboxes for the enterprise.

Analysis of common problems of linear motion gearbox: Gear-linear motion gearbox is a transmission machine

with compact structure, large transmission ratio and self-locking function under certain conditions. Moreover,

the installation is convenient, the structure is reasonable, and the application is more and more widely used.

It is equipped with a helical linear motion gearbox at the input end of the linear motion gearbox. The multi-stage

linear motion gearboxes can achieve very low output speed, higher efficiency than single-stage linear motion gearbox, and low

vibration, noise and energy. low

The best service from our transmission drive expert to your inbox directly.

Our Service

Get in Touch

Yantai Bonway Manufacturer Co.ltd

ANo.160 Changjiang Road, Yantai, Shandong, China(264006)

T+86 535 6330966

W+86 185 63806647