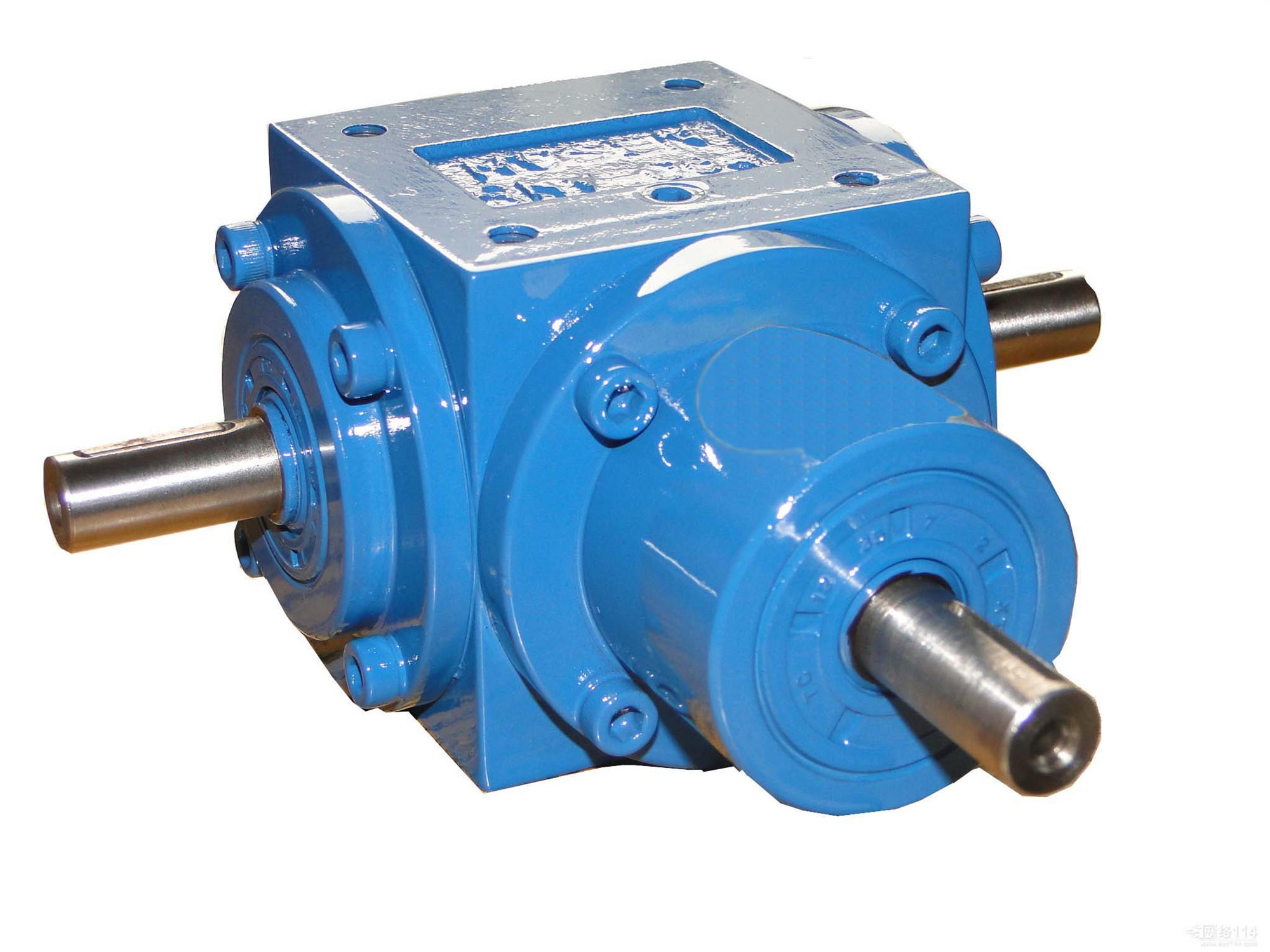

Angular gearbox

angular gearbox manufacturer, right angle gearbox, spiral bevel gear manufacturers

One-stage spiral bevel gear transmission box, standardized, multi-variety, speed ratio of 1:1, 1.5:1, 2.5:1, 3:1, 4:1, 5:1 are the actual transmission ratio. The average efficiency is 98%. There are single axis, double horizontal axis, single vertical axis, double vertical axis optional.

The T-type steering box is already a mature product in the domestic transmission industry. Even some small transmission

product manufacturers have a relatively regular steering box production line; the T-type steering box has been formed in the

domestic production industry from the design structure to the component selection. Mature rules. The T-type steering box is

equipped with single-axis, double-horizontal axis, single vertical axis and double vertical axis. It can be single-axis input

dual-axis output or dual-axis input single-axis output, and the bevel gear transmission can achieve the purpose of

deceleration or speed increase. The steering box body is made of ** aluminum alloy, which has many advantages such as

beautiful appearance, strong adaptability, good heat dissipation performance, strong carrying capacity and long service life.

T-type steering box has various installation methods, adopts hollow output shaft structure, various input and output modes,

convenient combination with other machinery, strong adaptability and convenient configuration. And the transmission is

stable, high efficiency, low noise, safe and reliable.

Product form

◆ Installation form: base installation.

◆ Axis configuration form: single input single output, single input dual output, single input three output, double input single output.

◆ Output shaft: solid shaft.

◆ Standardized, multi-variety, speed ratio 1:1, 1.5:1, 2:1, 3:1 are all actual transmission ratios. ◆ When the speed ratio is not 1:1, the horizontal axis input and vertical axis output are decelerated, and the vertical axis

input and horizontal axis output are increasing speed. ◆ Spiral bevel gear structure, stable transmission, low noise, low vibration and strong carrying capacity. ◆ Available in dual input shaft form. ◆ Multiple shafts can be realized. ◆ Can be used in any installation location

There have been many forms of steering gear in history, but many have been eliminated. Classified according to the form of

assist, the steering gear can be divided into mechanical (non-assisted) and dynamic (powered).

A rack and pinion steering gear is the simplest steering gear. Its advantages are simple structure, compact structure, high

rigidity, low cost, sensitive steering, high positive and reverse attack rate, easy to arrange, and especially suitable for use

with candle suspension and MacPherson suspension, and can also be directly The tie rod is driven to simplify the steering

mechanism. Therefore, it is widely used in cars and micro and light trucks.

The recirculating ball steering gear has high positive and negative strike rates, so it is light in operation, long in life and

stable and reliable in operation; however, due to the high rate of counterattack, it is easy to transmit the impact of the road

surface to the steering wheel. The power steering gear is actually a combination of a mechanical steering gear and a steering force device. Power steering

The power steering gear is actually a combination of a mechanical steering gear and a steering force device. Power steering

gears are available in both pneumatic and hydraulic versions depending on the energy transfer medium. Among them, the

hydraulic power steering gear can be divided into a whole type (mechanical steering gear, steering power cylinder and

according to the arrangement and connection relationship of the mechanical steering gear, the steering power cylinder and

the steering control valve in the steering device). The steering control valve is designed as one), semi-integral (designed

mechanical steering and steering control valves, steering power cylinder independent) and separate (mechanical steering

independent, steering control valve and steering power cylinder) Designed as one) three structural types.

It is worth noting that pneumatically loaded power steering gears should not be used for heavy-duty trucks because the

working pressure of the pneumatic system is low (generally not higher than 0.7 MPa), and the size of the components used

in heavy-duty vehicles will be too large. The working pressure of the hydraulic power steering gear can be as high as 10

MPa or more, so the size of the components is small. The hydraulic system works without noise, has a short working lag time,

and absorbs shocks from uneven road surfaces. Therefore, hydraulic power steering gear has been widely used in various

types of vehicles.

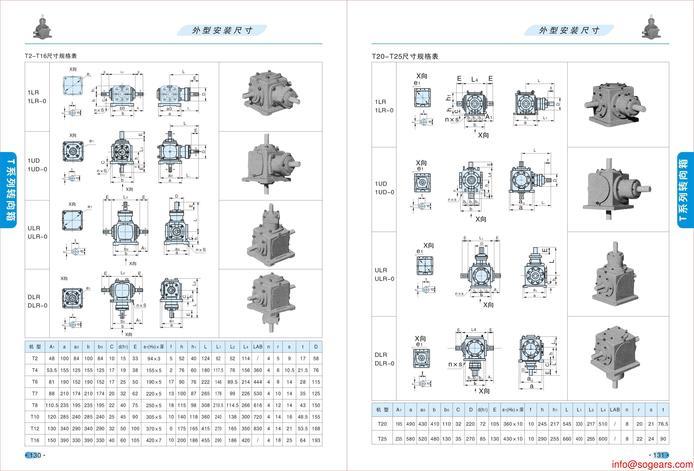

T gear steering gears are standardized, multi-variety, and have the advantages of single shaft, double horizontal axis, single

vertical axis and double vertical axis. It is widely used in metallurgy, mining, petrochemical, tobacco, ceramics, rubber and

plastics, grain and oil food, beer and beverage, transportation and domestic emerging logistics equipment, three-dimensional

garage, environmental protection and other industries. Spiral bevel gears can be used in forward and reverse, low speed or

high speed The transmission is smooth, and the noise is low, the vibration is small, and the bearing capacity is large. The

main product models are: T2, T4, T6, T7, T8, T10, T12, T16, T20, T25. The speed ratios of 1:1, 1.5:1, 2.5:1, 3:1, 4:1, and

5:1 are actual gear ratios. The average efficiency is 98%. There are single axis, double horizontal axis, single vertical axis

and double vertical axis.

T series steering gear is used for reduction transmission. The gears are made of low carbon alloy steel and the tooth surface

is carburized and hardened. The series of steering gears have long service life, large ratio of input power and commutator

quality, stable operation, low noise and high transmission efficiency. (up to 95%-98%)

T series spiral bevel gear steering box, also known as T-type steering box, commutator and steering gear, is an essential

transmission product for the mechanical industry. Square box shape, high quality aluminum alloy die-casting box, beautiful and generous. Performance and installation: Excellent heat dissipation performance and large carrying capacity. The transmission is smooth, quiet, noiseless, safe, reliable

and efficient. Multi-faceted installation, hollow output shaft structure, and various input and output modes, and can be easily

combined with other machinery, and has strong adaptability.

T8 steering box manufacturers' main technical features: spiral bevel Angular gearbox standard universal type: It adopts the latest German SEW drawings and manufacturing process to ensure the

quality of Europe, and at the same time greatly shorten the delivery time and manufacturing cost, giving customers high

quality and low price. ★ From the cabinet to the internal gear, the advanced modular design greatly reduces the types and inventory of parts, and

greatly shortens the delivery time. It is more suitable for specification production and flexible selection. The gear is made of high-quality high-purity alloy steel 20CrMnTi carburizing and quenching, the tooth surface hardness is up

to 60±2HRC, and the tooth surface grinding precision is up to 5-6. The noise is reduced and the load capacity of the our Angular gearbox

is greatly improved. ★The worm gear is made of wear-resistant alloy bronze. The worm adopts the latest optimized design and uses the hardening

grinding process. The friction parts of the transmission are made of wear-resistant bearing steel, which greatly improves the

efficiency and life. The shafts are made of alloy steel, and the standard parts such as bearings and oil seals are international and domestic brand

s. ★Integrated high-strength casting box, the box structure has good rigidity, easy to improve the strength of the shaft and

bearing life, and the streamlined design of the casting box is easy for fan cooling. Aluminum alloy die-cast housing, beautiful

appearance, light weight, good heat dissipation. The product can be matched with various types of motors, and the installation method is flexible and easy to use.

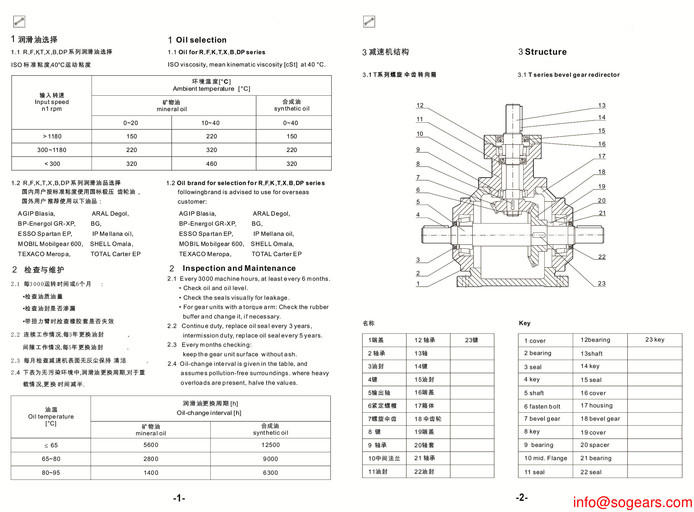

Gear commutator use and maintenance

1. After the commutator is installed, check for flexibility. For official use, please carry out the no-load test, and in the normal

operation, the load is gradually loaded.

2. The commutator must not be used beyond the rated load.

3. The commutator should check whether the oil level is normal before and during use. The machine has been filled with

lubricating oil before leaving the factory. The name of the lubricating oil: medium load industrial gear oil GB5903-86220.

Gear commutator oil change system: Oil change for the first time After the machine is operated for 300 to 400 hours, the lubricant should be replaced, and the

lubricant should be replaced every 1500 to 2000 hours. In the workplace with harsh working conditions, high temperature

and high dust, the lubricating oil should be inspected every half month. It is found that the lubricating oil has dirt, that is, the

lubricating oil is replaced to keep it. Lubricating oil cleans, prolongs the life of the commutator and improves economic efficiency. Oil replacement The commutator should be changed in the moving state, because the viscosity of the lubricating oil after cooling is

increased, and it is difficult to discharge the oil. The our Angular gearbox is a power transmission mechanism that uses a gear speed converter to decelerate the number of revolutions of

the motor (motor) to the required number of revolutions and obtain a mechanism with a large torque. In the current

mechanisms for transmitting power and motion, the range of applications of the our Angular gearbox is quite extensive. It can be seen in

almost all types of mechanical transmission systems, from ships, cars, locomotives, heavy machinery for construction,

processing equipment and automated production equipment used in the machinery industry, to everyday life. Home

appliances, clocks, etc. Its application can be seen from the transmission of large power, to small loads, accurate angle

transmission can see the application of the our Angular gearbox, and in industrial applications, the our Angular gearbox has the function of deceleration

and increase torque. Therefore, it is widely used in speed and torque conversion equipment.

T series spiral bevel gear steering box, also known as T-type steering box, commutator and steering gear, is an essential

transmission product for the mechanical industry.

Performance and installation: Excellent heat dissipation performance and large carrying capacity. The transmission is smooth, quiet, noiseless, safe, reliable

and efficient. Multi-faceted installation, hollow output shaft structure, and various input and output modes, and can be easily

combined with other machinery, and has strong adaptability. Widely used in food machinery, chemical machinery, woodworking machinery, pharmaceutical machinery, agricultural

machinery, textile equipment, smelting equipment, medical equipment and other ideal products that require deceleration

transmission.

Features: 1. Case: casted with high-strength FC-25 cast iron; 2. Gear: It is made of high-quality and high-purity alloy steel 50CrMnT quenching and tempering, which is treated by

carburizing and quenching; 3, the main shaft: the use of high-quality high-purity alloy steel 40Cr quenching and tempering processing, with high hanging

load capacity. 4. Bearing: equipped with roller bearing with heavy load capacity; 5, oil seal: the use of imported double lip oil seal, with a very high dust and oil leakage. Data parameters? Can be equipped with single horizontal axis, double horizontal axis, single vertical axis, double vertical axis Speed ratio: 1:1, 1.5:1, 2:1, 2.5:1, 3:1, 4:1, 5:1

Product lubrication: Proper use of lubricating oil can make the steering machine more efficient and improve its operating life. 1, the initial use of two weeks or 100-200 hours, for the initial wear period, there may be a little metal wear particles between

the two, please be sure to clean the interior, and replace the new lubricant; 2. When using for a long time, replace the lubricating oil every six months - one year or 1000-2000 hours. Scope of application: food machinery, chemical machinery, woodworking machinery, pharmaceutical machinery, agricultural

machinery, textile equipment, smelting equipment, medical equipment and other industries

- Induction

One-stage spiral bevel gear transmission box adopts the structure of shaft input and shaft output, which can be used for single-axis and multi-axis output. Series product models mainly include: T2, T4, T6, T7, T8, T10, T12, T16, T20, T25. The actual transmission ratios are 1:1, 1.5:1, 2.5:1, 3:1, 4:1, 5:1. The average efficiency is 98%. There are single axis, double horizontal axis, single vertical axis, double vertical axis to choose from.

- Feature

The casing is made of high-strength FC-25 cast iron; the one-stage spiral bevel gear transmission box is made of high-quality and high-purity alloy steel 50CrMnT quenching and tempering, and is carburized and quenched and ground; the main shaft is made of high-quality high-purity alloy steel 40Cr quenching and tempering.

High suspension and heavy load capacity; Bearing: equipped with roller bearing with heavy load capacity; Oil seal: It adopts imported double lip oil seal, one-stage spiral bevel gear transmission box which has extremely high dustproof and oil leakage resistance.

The T-type steering gear is favored by users with its unique transmission mode and high-quality product performance. The

steering box body adopts _ aluminum alloy square box shape, and adopts high-purity alloy steel 20CrMnTiH carburizing and

quenching gear and alloy steel quenching and tempering spindle. , roller bearing, double lip seal oil seal. It has many

advantages such as beautiful appearance, strong adaptability, good heat dissipation performance, strong carrying capacity

and long service life.

T-type steering box has various installation methods, adopts hollow output shaft structure, various input and output modes,

convenient combination with other machinery, strong adaptability and convenient configuration. And the transmission is

stable, high efficiency, low noise, safe and reliable.

T-type steering box technical parameters: T-type steering box power range: 0.014kW - 335 kW T-type steering box torque range: 11.2Nm - 5713 Nm T-type steering box can be equipped with single horizontal axis, double horizontal axis, single vertical axis, double vertical

axis T-type steering box speed ratio: 1:1, 1.5:1, 2:1, 2.5:1, 3:1, 4:1, 5:1 Housing: high rigidity FC-25 cast iron casting; Gear: The gear is made of _ high purity alloy just 20CrMnTiH carburized and quenched, and ground; Main shaft: The shaft type adopts alloy just-tempered and high-hanging heavy load; bearing: roller bearing with heavy load; Oil seal: oil seal of double-sealed lip, which has both dustproof and oil-proof resistance;

T-type steering box performance characteristics: 1. The steering box has single shaft, double horizontal axis, single vertical axis and double vertical axis. 2. The steering box has strong standardization and many varieties, and the speed ratio is all actual transmission ratio. The

average efficiency is 98%. 3. When the speed ratio is not 1:1, the horizontal axis input and the vertical axis output are decelerated, and the vertical

axis input and the horizontal axis output are increasing speed. 4. The T-type steering box can be operated in forward and reverse directions, with low speed or high speed transmission,

low noise, low vibration and high endurance.

- Ration Coverage

The one-stage spiral bevel gear transmission box, standardized, multi-variety, speed ratio 1:1, 1.5:1, 2:1, 2.5:1, 3:1, 4:1, 5:1 all are the actual transmission ratio. The average efficiency is 98%.

Appearance: 1. Case: casted with high-strength FC-25 cast iron; 2. Gear: It is made of high-quality and high-purity alloy steel 50CrMnT quenching and tempering, which is treated by

carburizing and quenching; 3, the main shaft: the use of high-quality high-purity alloy steel 40Cr quenching and tempering processing, with high

hanging load capacity. 4. Bearing: equipped with roller bearing with heavy load capacity; 5, oil seal: the use of imported double lip oil seal, with a very high dust and oil leakage.

- Main Advantages

T series one-stage spiral bevel gear transmission box, standardized, multi-variety, speed ratio 1:1, 1.5:1, 2:1, 2.5:1, 3:1, 4:1, 5:1 All the actual transmission ratio. The average efficiency is 98%. Available in single axis, double horizontal axis, single vertical axis, and double vertical axis.

one-stage spiral bevel gear transmission box can be operated in forward and reverse directions, with low speed or high speed transmission, low noise, low vibration and high endurance. When the speed ratio is not 1:1, the horizontal axis input and the vertical axis output are decelerated, and the vertical axis input and the horizontal axis output are increasing speed.

- Maintain

Initial use for two weeks or 100-200 hours, for the initial wear period, there may be a little metal wear particles between the two, please be sure to clean the interior, and replace the new lubricant; long-term use, every six months - a year or 1000-2000 Change the oil once an hour. The proper lubrication of the one-stage spiral bevel gear transmission box can make the steering machine more efficient and improve its operating life.

The T-type steering box is an essential transmission device for the transmission machinery industry. T-type steering box is favored by users with unique transmission mode and high-quality product performance. The steering

box body adopts high-quality aluminum alloy square box shape, and adopts high-purity alloy steel 20CrMnTiH carburized and

quenched gear and alloy steel quenching and tempering spindle. , roller bearing, double lip seal oil seal. It has many

advantages such as beautiful appearance, strong adaptability, good heat dissipation performance, strong carrying capacity

and long service life. T-type steering box has various installation methods, adopts hollow output shaft structure, various

input and output modes, convenient combination with other machinery, strong adaptability and convenient configuration.

And the transmission is stable, high efficiency, low noise, safe and reliable.

T-type steering box single-input shaft double-axis our Angular gearbox. In some applications, due to the limited installation space in one

direction, there is a mechanical device installed at the time that it cannot be directly installed on the device. You may need to

install the original space as small as possible, so in this case, some users consider installing a spiral bevel Angular gearbox or gear reduction

in the form of a steering gear on the drive. Motor

If you want to reduce the torque and increase the torque, then choose the two types of hardened gearbox K-type our Angular gearbox or

S-type worm spiral bevel Angular gearbox. If you only want to turn the function, then choose the following 1:1. Steering box. The results of

different usage requirements are different.

The best service from our transmission drive expert to your inbox directly.

Our Service

Get in Touch

Yantai Bonway Manufacturer Co.ltd

ANo.160 Changjiang Road, Yantai, Shandong, China(264006)

T+86 535 6330966

W+86 185 63806647