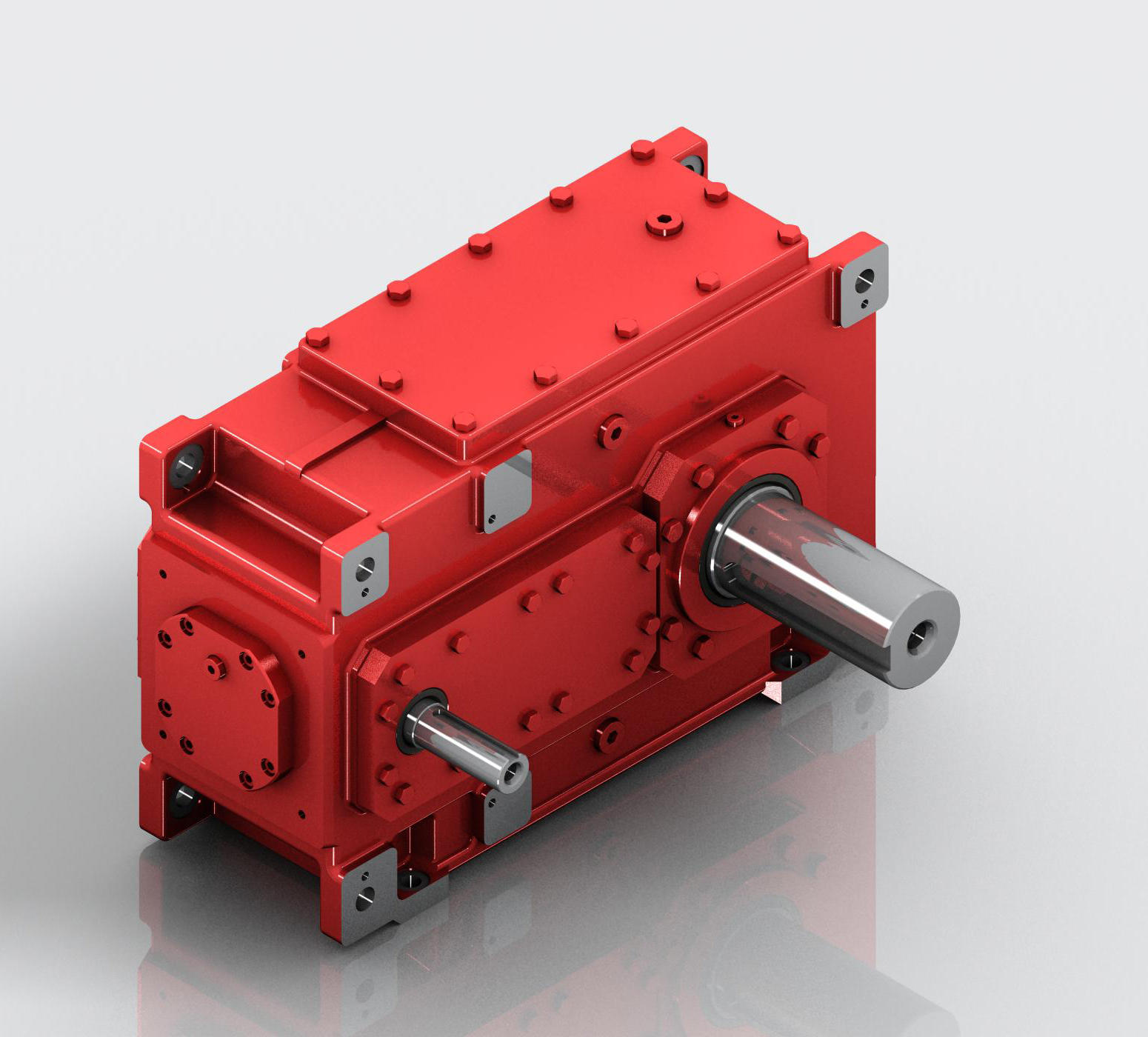

Speed reducer gearbox

HB series high power Speed reducer gearbox is one of the common equipments in industrial machinery. Its appearance is of great help to enterprise production applications, but these are based on good installation and maintenance. Any mechanical device has its own method of installation.

The internal structure of the rolling mill reduction device adopts the plane double enveloping worm gear structure. On this

basis, the company's R&D department has made bold technological innovations. The worm and oil seal contact end adopts

super-sonic mirror surface treatment, and the oil seal is imported. High temperature resistant TTO/NAK, shaft end mirror

surface treatment, high precision, hardness increase of 20, to ensure no oil leakage; worms for dynamic balance test. The

carrying capacity is large; the structure is compact and reasonable. High transmission efficiency, stable operation, low noise,

long service life, etc. A200 for rolling mill presses, A710 rolling mill reduction reducer, steel mill rolling mill special Speed reducer gearbox helical, steel mill

non-standard rolling mill pressing A210 reducer, etc., have now become our main products, and applied to many units In

production.

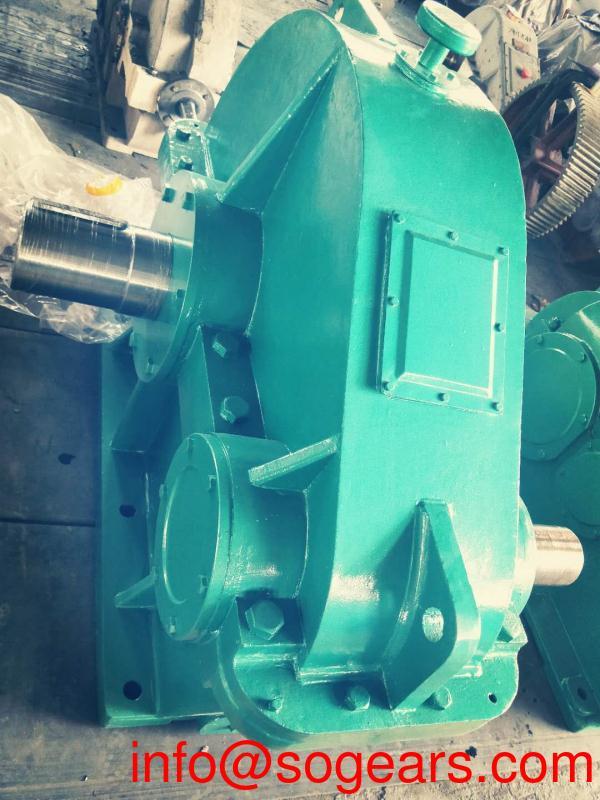

Since the advent of the rolling mill, the rolling mill reduction device is one of the important components of the rolling mill.

The rolling mill reduction Speed reducer gearbox is the core component of the rolling mill reduction device. Rolling mill reduction

gearboxes are usually composed of worm gears (or worm and spur gears), bearings, boxes, etc., and the worm drive form is

the key element of the reducer load capacity and service life.

1. Pressing the worm drive classification According to the shape of the worm indexing surface, the worm drive is usually divided into three categories: cylindrical

worm drive, toroidal worm drive, and conical worm drive. 2. There are several forms of rolling mill worm gears. At present, the rolling mill worm reducer mainly has three types of transmissions: straight profile toroidal worm drive

(commonly known as spherical worm drive), double enveloping toroidal worm drive and Niemann worm drive.

Features: 1) for the transmission of space between the two axes of motion and power, usually the two-axis stagger angle Σ = 90 °; (2) It can realize large transmission ratio staggered transmission, transmission power and movement; (3) The transmission is stable, and the vibration, impact and noise are relatively small; (4) multiple pairs of teeth mesh at the same time, and are in line contact, the bearing capacity is greater than the staggered

involute oblique cylindrical gear;speed reducer gearbox design, speed reducer for electric motor.  (5) It can obtain a large transmission ratio with a single-stage transmission, and has a compact structure; (6) When the gear is reduced, the range of the gear ratio u is 5 ≤ u ≤ 70, and the most commonly used is 15 ≤ u ≤ 50; (7) Single-head worm with self-locking action when the lead angle is less than 3.5°, but the efficiency is very low at this time,

(5) It can obtain a large transmission ratio with a single-stage transmission, and has a compact structure; (6) When the gear is reduced, the range of the gear ratio u is 5 ≤ u ≤ 70, and the most commonly used is 15 ≤ u ≤ 50; (7) Single-head worm with self-locking action when the lead angle is less than 3.5°, but the efficiency is very low at this time,

and should be used as little as possible; (8) The meshing friction loss between the worm tooth surface and the worm gear tooth surface is relatively large, the

transmission efficiency is low, the tooth surface is easy to wear, and sometimes the temperature rise is too high; (9) Worm gear materials generally use anti-friction materials with good running performance, such as tin bronze, aluminum

bronze, etc., but the cost is high.

The rolling mill is an important equipment for rolling steel ingots or billets into steel, and has the advantages of high

productivity, easy mechanization, and automation. It is more widely used than forging, extrusion, drawing and other

equipment. The main function of the leveling is to improve the shape of the plate and eliminate the local thickness difference,

so that the plate has a good shape and good surface quality; in addition, the use of a small reduction can eliminate the

yielding platform and improve the deep drawing performance of the steel plate. The existing rare metal rolling mill has a

relatively simple function, and the cold rolling, hot rolling and leveling are completed by different equipments, and the

individual cold rolling has a flattening function, so that for small and medium-sized enterprises, different equipment is

required for rolling in different ways. The equipment purchase cost burden is increased and the maintenance cost is increased

The purpose of the utility model is to provide a rolling mill reduction speed reducing device, so that one rolling mill can realize

two functions of cold rolling and hot rolling, thereby reducing equipment procurement cost.

The technical scheme of the utility model is a rolling mill reduction speed reducing device, which comprises a first speed

reduction mechanism and a second speed reduction mechanism, wherein the transmission axes of the first speed reduction

mechanism and the second speed reduction mechanism are arranged perpendicular to each other, the first speed reduction

mechanism and the second stage The speed reduction mechanism realizes the clutch deceleration control through the clutch. The structure of the first speed reduction mechanism is that the motor is connected to the coupling, the clutch and the worm through the clutch in sequence, the worm is connected with the worm wheel, the worm wheel is connected with the pressed screw; the second speed reduction mechanism is The structure is that the motor B is connected to the worm B through the coupling B, the worm B is connected to the worm wheel B through the clutch, the worm wheel B is connected to the worm, the worm is connected to the worm wheel, and the worm wheel is connected with the screw.

The utility model has the beneficial effects that the first and second deceleration devices are respectively provided, so that

the reduction ratio range of the transmission is greatly increased, and the different pressing requirements of the cold and hot

rolling are satisfied, the structure is simple, the maintenance is convenient, and the reduction is reduced. Equipment cost.

The rolling mill reduction device of the utility model is mounted on a rolling mill, and the four roller systems can be simultaneously applied. -- Set of two-roll hot roll system, one set of two-roll cold roll system, two sets of four-roll cold roll system, which can be

realized Hot rolling can achieve cold rolling, balance flatness, reduce equipment costs, improve equipment utilization, and is particular

ly suitable for small and medium-sized metallurgical enterprises for rare metal rolling with low output.

development of: The development trend of modern rolling mills is continuous, automated and professional, with high product quality and low

consumption. Since the 1960s, great progress has been made in the design, research and manufacture of rolling mills, which

have improved the performance of strip hot and cold rolling mills, plate mills, high-speed wire mills, H-section mills and

continuous rolling mills. A series of advanced equipment such as wire rod mills, full continuous strip cold rolling mills, 5500

mm wide plate mills and continuous H-beam mills with speeds up to 115 m per second. The single-weight increase of raw

materials for rolling mills, hydraulic AGC, shape control, electronic computer program control and testing methods are more

and more perfect, and rolling varieties are expanding. Some new rolling mills suitable for continuous casting and rolling,

controlled rolling, and various special structures that are suitable for new product quality requirements and economic benefits

are under development.

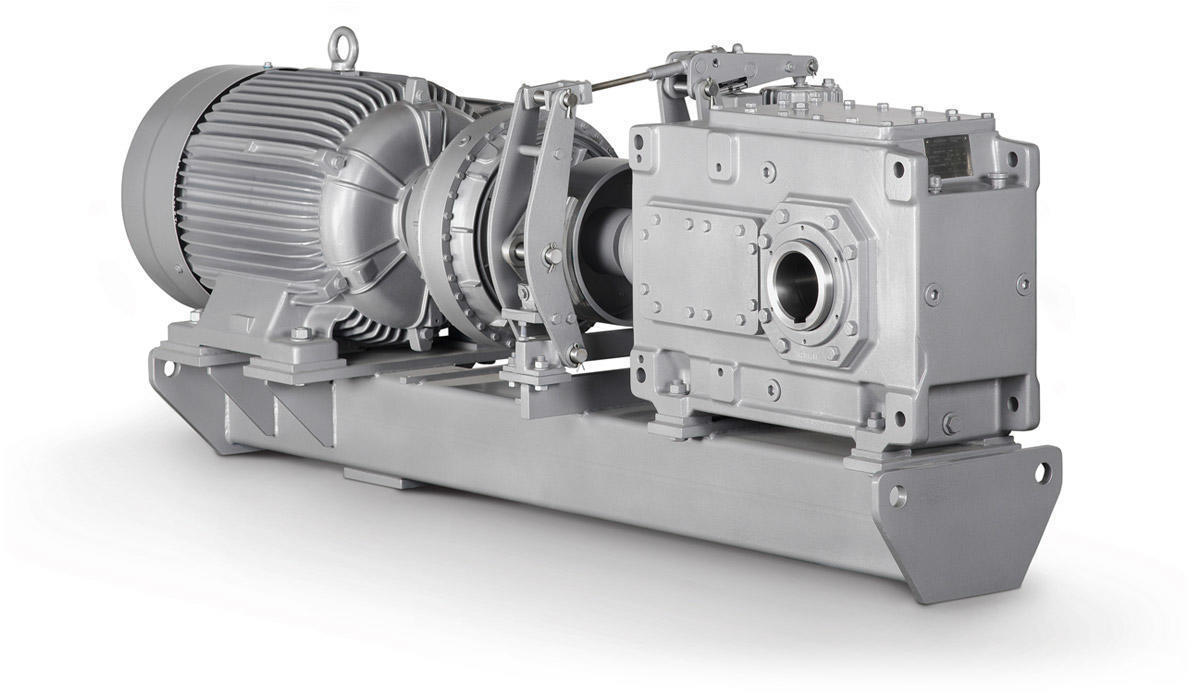

transmission: It consists of a motor, a reducer, a gear carrier and a connecting shaft. The gear carrier distributes the drive torque to two or

more rolls. Auxiliary equipment A device that includes a series of auxiliary processes during the rolling process. Such as raw material

preparation, heating, steel rolling, shearing, straightening, cooling, flaw detection, heat treatment, pickling and other

equipment. Lifting and transport equipment Cranes, transport vehicles, roller conveyors and transfer machines.

|

Size |

1~22 |

|

|

Input Shaft |

Solid(firm) Single input shaft. Left or right is allowed |

|

|

Cooling |

Please consider extra fan if needed |

|

|

Connect Method |

Coupling or V-belt |

|

|

Output Shaft |

Solid(firm) or hollow(bore)output shaft |

|

|

Ratio Scope(i) |

1-stage |

1.25~7.1 |

|

2-stage |

8.0~25 |

|

|

3-stage |

28~112 |

|

|

4-stage |

125~450 |

|

Introduction: Equipment for achieving metal rolling processes. Refers to the complete equipment for the whole process of rolling material

production, including unwinding machine, rolling system, drive system, hydraulic system, control system, and roll removing

device. However, the so-called rolling mills are often referred to only as the main equipment. It is said that there were mills

in Europe in the 14th century, but it is recorded that the 1480 Italian Leonardo da Vinci designed a sketch of the mill. In 1553

, the Frenchman Brulier rolled out gold and silver plates to make coins. Since then, rolling mills have appeared in Spain,

Belgium and the UK.

1.Chemical agitator

2.Hoist and transport

3.Steel and metallurgy

4.Electric power

5.Coal mining

6.Cement and construction

7.Paper and light industry

◆ Adopting the structure of the suction box body, large cabinet surface area and large fan, cylindrical gear and spiral bevel

gear adopt advanced grinding technology to improve the temperature rise, noise reduction and reliability of the whole

machine. Increase. ◆ The H and B series Speed reducer gearbox adopts the universal design scheme to realize the common housing of parallel shaft

and orthogonal shaft. The types of parts are reduced and the specifications and models are increased. ◆H, B standard Speed reducer gearbox has 3~26 type specifications, the number of reduction gear stages is 1~4, and the speed

ratio is 1.25~450.

|

Housing material

|

Cast iron HT250

|

|

Housing hardness

|

HBS190-240

|

|

Gear material

|

20CrMnTi alloy steel

|

|

Surface hardness of gears

|

HRC58°~62 °

|

|

Gear core hardness

|

HRC33~40

|

|

Input / Output shaft material

|

40CrMo alloy steel

|

|

Input / Output shaft hardness

|

HRC25~30

|

|

Machining precision of gears

|

accurate grinding, 6~5 Grade

|

|

Lubricating oil

|

GB L-CKC220-460, Shell Omala220-460

|

|

Heat treatment

|

tempering, cementiting, quenching, etc.

|

|

Efficiency

|

94%~96% (depends on the transmission stage)

|

|

Noise (MAX)

|

60~68dB

|

|

Temp. rise (MAX)

|

40°C

|

|

Temp. rise (Oil)(MAX)

|

50°C

|

|

Vibration

|

≤20µm

|

|

Backlash

|

≤20Arcmin

|

|

Brand of bearings

|

China top brand bearing, HRB/LYC/ZWZ/C&U. Or other brands requested, SKF, NSK.

|

|

Brand of oil seal

|

NAK --- Taiwan or other brands requested

|

◆ Installation method: base installation, hollow shaft installation, swing base installation, torque arm installation. ◆ Input mode: motor coupling flange, shaft input. ◆ Output mode: solid shaft with flat key, hollow shaft with flat key, hollow shaft with expansion disc, hollow shaft with spline

◆ Installation method: base installation, hollow shaft installation, swing base installation, torque arm installation. ◆ Input mode: motor coupling flange, shaft input. ◆ Output mode: solid shaft with flat key, hollow shaft with flat key, hollow shaft with expansion disc, hollow shaft with spline

coupling, solid shaft with spline coupling and solid shaft with flange coupling. ◆ Backstop can be equipped according to customer requirements. Combined with the R and K series to get a larger speed

ratio.

technical parameter: Speed ratio range: H series 1.25 ~ 450, B series 5 ~ 400 Torque range: H series 2 ~ 900 kNm, B series 5.8 ~ 900 kNm Power range: H series 4 ~ 5000 kW, B series 2.8 ~ 3000kW

The H and B high-power Speed reducer gearboxs adopt a universal design scheme, which can be transformed into an industry-specific

gearbox according to customer requirements. 2. Realize parallel shaft, orthogonal shaft, vertical and horizontal general-purpose cabinets, with fewer types of parts and

more specifications. 3. Adopting the structure of the suction box body, large cabinet surface area and large fan, cylindrical gear and spiral bevel

gear adopt advanced grinding process to improve the temperature rise, noise reduction and reliability of the whole machine.

The power is increased.

The gearbox has a new design and its unique innovation lies in 1. The number of parts and components is reduced. 2. Increased transmission power and improved operational reliability 3. Non-contact and wear-resistant labyrinth seals with excellent performance 4. Can provide flange shaft for narrow space installation

H3sh15 Type Standard Solid Shaft 3 Stage Transmission Hb Industrial Gearbox, Application: Motor, Electric Cars, Motorcycle, Machinery, Marine, Toy, Agricultural Machinery, Car

Function: Distribution Power, Clutch, Change Drive Torque, Change Drive Direction, Speed Changing, Speed Reduction, Speed Increase

Layout: Coaxial

Hardness: Hardened Tooth Surface

Installation: Horizontal Type

Step: Single-Step

Noise characteristics Using the latest design concepts and significantly improving the noise characteristics of the gearbox through the following

channels 1. Bevel gear grinding process 2. Using computer program to design the structure of the box that absorbs noise 3. Achieve extra large tooth surface contact ratio

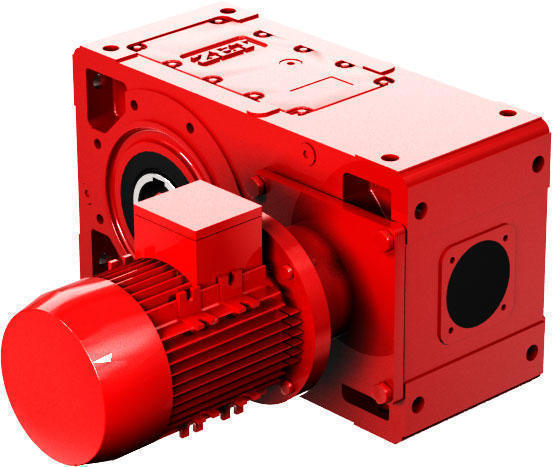

Bevel Helical Gear box Input mode: Motor connection flange, shaft input Gear Speed Reducer

Gearbox reducer adopts the general design project, which can change them into special-for-industries gearboxes according to different requirements of customers. Bevel Helical Gear box apply sound-absorption box structure. The larger surface area and big fan, column gear and helical gearwheels all introduce the advanced gear-grinding craft which can lower the noise, improve the running reliability and efficiency of speed reducers.

Thermal performance

The gearbox not only has high transmission efficiency, but also has good heat dissipation performance because

1. Increase the surface area of the box

2. Non-contact labyrinth seals can be used

3. Adopt large fan and new type of diversion

Application of HB series reducer in printing industry The printing paper-drawing roller of the traditional trademark printing machine is driven by the linkage mechanism, the

positioning precision is poor, affecting the printing effect, and the production efficiency is low. At present, it has been widely

replaced by the numerical control trademark printing machine controlled by the servo system, making the high-precision

planet for HB servo. Reducer is widely used in the trademark printing machine industry

Speed reducer gearbox is generally used for transmission equipment with low speed and high torque. The ordinary reducer of the

motor will also have several pairs of identical gears to achieve the desired deceleration effect. The ratio of the number of

teeth of the large and small gears is the transmission ratio. With the continuous development of the reducer industry, more

and more enterprises have applied the reducer.

Speed reducer gearbox: 1, R series coaxial helical Speed reducer gearbox combined with international technical requirements, with high technology

content

2, space saving, reliable and durable, with high overload capacity, power up to 132KW;

3, low energy consumption, Excellent performance, the speed reducer efficiency is up to 95%; 4, low vibration, low noise,high energy

saving;

5, high-quality forged steel material, steel cast iron box, gear surface after high-frequency heat treatment;

6, after precision machining, ensure Shaft parallelism and positioning bearing requirements, the reducer that forms the

helical gear transmission assembly is equipped with various types of motors, combined into mechatronics, which fully

guarantees the quality characteristics of the products.

working principle: The Speed reducer gearbox uses the gear transmission of all stages to achieve the purpose of speed reduction. The reducer is

composed of gear pairs of various stages. For example, the gear can be driven by a small gear to achieve a certain

deceleration, and then a multi-stage structure is adopted. , you can greatly reduce the speed.

performance: 1. The gear is made of high-quality alloy steel for carburizing and quenching. The hardness of the tooth surface is up to 60±2

hrc, and the precision of the tooth surface grinding is up to 5-6. 2, using computer reshaping technology, pre-reform the gear, greatly improving the load capacity of the reducer. 3, from the box to the internal gear, using a completely modular structure design, suitable for large-scale production and

flexible selection. 4. The standard reducer model is divided according to the torque decrement form, which avoids power waste compared with

4. The standard reducer model is divided according to the torque decrement form, which avoids power waste compared with

the traditional equal division. 5, using cad / cam design and manufacture to ensure the stability of quality. 6, using a variety of sealing structures to prevent oil leakage. 7, multi-directional noise reduction measures to ensure the excellent low noise performance of the reducer.

Troubleshooting: In the long-term operation of the reducer, there are often faults such as wear and leakage. The most important ones are: 1. The bearing chamber of the reducer is worn, which in turn includes the wear of the bearing housing of the housing, the

bearing chamber of the housing, and the bearing chamber of the transmission. 2. The shaft diameter of the gear shaft of the reducer is worn, and the main wear parts are in the shaft head and keyway. 3. The bearing position of the reducer drive shaft is worn. 4. The reducer joint surface leaks.

For the leakage problem, the traditional method needs to disassemble and open the reducer, replace the sealing gasket or

apply the sealant, which is not only time-consuming and laborious, but also difficult to ensure the sealing effect, and leakage

will occur again during operation. The polymer material can be used to treat leakage on site. The material has excellent

adhesion, oil resistance and 350% elongation, which overcomes the impact caused by the vibration of the reducer, and

solves the problem of leakage of the reducer for the enterprise.

transmission: A Speed reducer gearbox is a type of transmission that increases the wear of its internal transmission as it works longer.

So what aspects should we analyze the wear of the internal gear of the Speed reducer gearbox? The losses in the gear unit (gear frame

and reducer) in the Speed reducer gearbox

include the following three aspects:

1. Sliding friction loss between teeth.

2. Loss in bearings, plain bearings and rolling bearings.

3. Splash and agitation of lubricant loss.

Precautions during installation and use:

- The HB series high power Speed reducer gearboxshould be firmly installed on a stable level foundation or base. The oil in the oil drain should be removed and the cooling air circulation should be smooth. The foundation is unreliable, causing vibration and noise during operation and causing damage to bearings and gears. When the transmission coupling has protrusions or gears and sprocket transmissions, it should be considered to install a protective device. When the output shaft is subjected to a large radial load, the reinforcement type should be selected.

- According to the specified installation device, the staff can conveniently approach the oil mark, the vent plug and the drain plug. After the installation is in place, the accuracy of the installation position should be thoroughly checked in order, and the reliability of each fastener should be flexibly rotated after installation. The HB series high power Speed reducer gearboxis splashed and lubricated by the oil pool. Before running, the user needs to remove the screw plug of the vent hole and replace it with the vent plug. According to different installation positions, and open the oil level plug screw to check the height of the oil level line, refuel from the oil level plug until the oil overflows from the oil level plug screw hole, and then screw the oil level plug to make sure it is correct before emptying The test run shall be no less than 2 hours. The operation should be stable, without impact, vibration, noise and oil leakage. If abnormalities are found, they should be eliminated in time.

- When installing the HB series high power Speed reducer gearbox, the center of the drive shaft should be centered, and the error should not be greater than the compensation amount of the coupling used. Good alignment can extend the service life and achieve the desired transmission efficiency.

- When installing the transmission member on the output shaft, it is not allowed to strike with a hammer. Usually, the internal thread of the assembly jig and the shaft end is used, and the transmission member is pressed by the bolt, otherwise the internal parts of the HB series high power Speed reducer gearboxmay be damaged. It is better not to use a steel fixed coupling. Due to improper installation of this type of coupling, unnecessary external loads may be caused, resulting in early damage of the bearing and even breakage of the output shaft in severe cases.

The above is the precautions in the installation and use of the HB series high power Speed reducer gearbox. We should pay attention to these problems in the first use, so that our production operations become more efficient and reliable.

The best service from our transmission drive expert to your inbox directly.

Our Service

Get in Touch

Yantai Bonway Manufacturer Co.ltd

ANo.160 Changjiang Road, Yantai, Shandong, China(264006)

T+86 535 6330966

W+86 185 63806647