High torque right angle gearbox

high torque right angle gearbox, high rpm right angle gearbox, high speed right angle gearbox, high speed 90 degree gearbox, high-performance gears

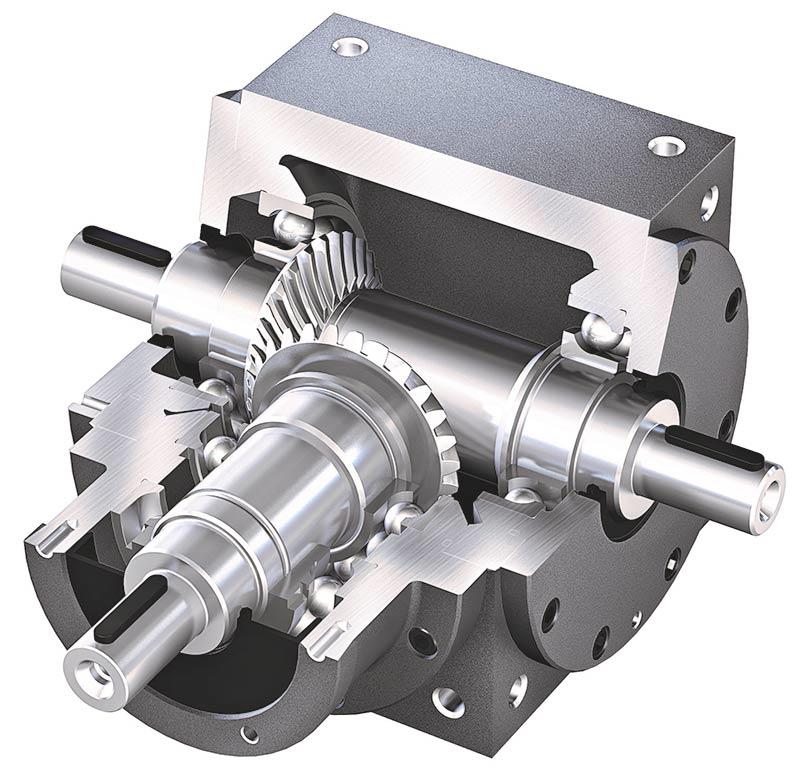

One-stage spiral bevel gear transmission box, standardized, multi-variety, speed ratio of 1:1, 1.5:1, 2.5:1, 3:1, 4:1, 5:1 are the actual transmission ratio. The average efficiency is 98%. There are single axis, double horizontal axis, single vertical axis, double vertical axis optional.

Introduction: It can be operated in forward and reverse directions, with low speed or high speed transmission, low noise, and low vibration resistance. Our business philosophy is based on product application and thoughtful service. Advanced technology and innovative management, and a strong production base have laid a good foundation for cooperation with our customers.

T series first-stage spiral bevel gear steering box, standardized, variety, speed reduction ratio 1:1, 1.5:1, 2:1, 2.5:1, 3:1 are

all actual transmission ratio, with single horizontal axis and double horizontal axis , single vertical axis, double vertical axis

selection

Performance characteristics: 1, T series spiral bevel gear steering box, standardization, multi-variety, speed ratio are all actual transmission ratio. The

average efficiency is 98%. 2. The spiral bevel gear steering box has single shaft, double horizontal shaft, single vertical shaft and double vertical shaft. 3. The gear steering box can be operated in forward and reverse directions, with low speed or high speed transmission, low

noise, low vibration and high endurance. 4. When the speed ratio is not 1:1, the horizontal axis input and the vertical axis output are decelerated, and the vertical

axis input and the horizontal axis output are increasing speed. 5. The gear steering box can be operated in forward and reverse directions, with low speed or high speed transmission, low

noise and low vibration.

The performance characteristics of the T series steering box, the lifting speed of the WB series cycloid reducer and the screw

lift, and the bearing capacity. The shape of the T-series steering box is a positive main body, which can be applied to different orientations. It is widely

used in food machinery, chemical machinery, woodworking machinery, pharmaceutical machinery, agricultural machinery,

textile equipment, smelting equipment, medical equipment and other industries.

product description: 1. Case: casted with high-strength FC-25 cast iron; 2. Gear: It is made of high-quality and high-purity alloy steel 50CrMnT quenching and tempering, which is treated by

carburizing and quenching; 3, the main shaft: the use of high-quality high-purity alloy steel 40Cr quenching and tempering processing, with high hanging

load capacity. 4. Bearing: equipped with roller bearing with heavy load capacity; 5, oil seal: the use of imported double lip oil seal, with a very high dust and oil leakage.

technical parameter: Speed ratio range: 1:1 1.5:1 2:1 2.5:1 3:1 4:1 5:1 Torque range: 11.2 — 5713 Nm Power range: 0.014 — 335 kW

Precautions before installation: 1. The steering box should be cleaned before use, and the mounting shaft should be inspected for damage and dirt. If it is, it

should be completely cleaned. 2. The operating temperature of the steering box is 0~40 °C. 3. Check if the matching size of the hole connected with the steering box meets the requirements. The tolerance of the hole

should be H7. 4. Before use, replace the blockage at the highest position with the exhaust screw plug to ensure that the gas in the body is

discharged when the steering box is running.

Installation and maintenance: 1. The steering box can only be installed on a flat, shock-absorbing, torsion-resistant support structure. 2. Under no circumstances should the hammer, coupling, pinion or sprocket be hammered into the output shaft with a

hammer, which will damage the bearing and the shaft. 3. After the steering box is installed, check if it is flexible. For official use, please carry out the no-load test. If the operation is

normal, then gradually load the operation. 4. The steering box must not be used beyond the rated load. 5. The steering box should check whether the oil level is normal before and during use.

Run: 1. The initial use is two weeks or 100-200 hours. It is the initial friction period. There may be a little metal friction between

the two. Please clean the inside and replace it with new ones. 2. When using for a long time, replace the lubricating oil every six months to one year or 1000-2000 hours. 3. The steering gear lubricating oil adopts 90-120 degree full-effect gear oil of China National Petroleum Corporation. The

low-speed and light-load conditions are recommended. It is recommended to use full-effect gear oil 90 degrees, heavy load

and high temperature conditions. It is recommended to use full-effect gear oil 120 degrees.

product description: The steering box, also known as the commutator and the steering gear, is a power transmission mechanism and is a series

in the speed reducer, which has a wide range of applications in the industrial field. The steering box has now achieved

standardization and diversification of specifications. The steering box has a single axis, a double horizontal axis, a single

vertical axis, and the double vertical axis is optional. The speed ratio is 1:1, 1.5:1, 2:1, 2.5:1, 3:1, 4:1, and 5:1 are all actual

transmission ratios. The steering box can be operated in both forward and reverse directions, with low speed or high speed

transmission. When the steering gear ratio is not 1:1, the horizontal axis input and the vertical axis output are decelerated,

and the vertical axis input and the horizontal axis output are increasing speed.

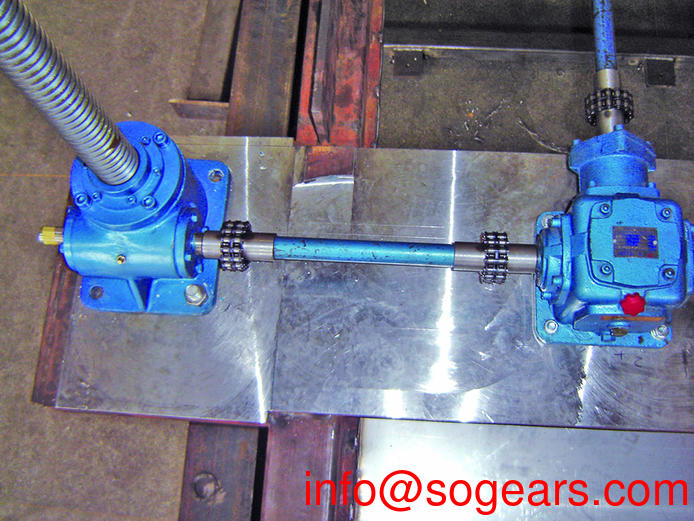

Side-by-side transfer: power is applied to the longitudinal axis to make the horizontal axis run synchronously. Lifting device: 1 reducer output left and right, after turning, simultaneously lifting Three-dimensional garage: one reducer drives the left and right sprocket to run synchronously Playground equipment: 1 vertical axis input, 2 horizontal axis opposite operation

Performance characteristics of steering box bevel gear: 1, T series spiral bevel gear steering box, standardization, multi-variety, speed ratio are all actual transmission ratio. The

average efficiency is 98%. 2, there are single axis, double horizontal axis, single vertical axis, double vertical axis optional. 3. The spiral bevel gear can be operated in forward and reverse directions, with low speed or high speed transmission and

low noise. The vibration is small and the bearing capacity is large. 4. When the speed ratio is not 1:1, the horizontal axis input and the vertical axis output are decelerated. The vertical axis

input and the horizontal axis output are increasing speed.

Performance characteristics of the steering box helical gear: 1, there are single axis, double horizontal axis, single vertical axis, double vertical axis optional. 2. Spiral bevel gears can be operated in forward and reverse directions, with low speed or high speed transmission, low noise

, low vibration and high endurance. 3. When the speed ratio is not 1:1, the horizontal axis input and vertical axis output are decelerated, and the vertical axis

input and horizontal axis output are increasing speed. 4, ARA series spiral bevel gear steering box features: small, all-round installation, light weight, alloy aluminum shell, shaft

need to use corrosion-resistant steel when ordering. The lubricant has been added at the factory.

T series helical gear steering box performance characteristics: 1. Case: casted with high-strength FC-25 cast iron; 2. Gear: It is made of high quality and high purity alloy steel 50CrMnT quenching and tempering, which is treated by

carburizing and quenching; 3, the main shaft: the use of high quality and high purity alloy steel 40Cr quenching and tempering processing, with high

suspension load capacity; 4. Bearing: equipped with roller bearing with heavy load capacity; 5. Oil seal: It adopts imported double lip oil seal and has high dustproof and oil leakage resistance.

The steering box, also known as the commutator and the steering gear, is a power transmission mechanism and is a series

in the speed reducer, which has a wide range of applications in the industrial field. The steering box has now achieved

standardization and diversification of specifications. The steering box has a single axis, a double horizontal axis, a single

vertical axis, and the double vertical axis is optional. The speed ratio is 1:1, 1.5:1, 2:1, 2.5:1, 3:1, 4:1, and 5:1 are all actual

transmission ratios. The steering box can be operated in both forward and reverse directions, with low speed or high speed

transmission. When the steering gear ratio is not 1:1, the horizontal axis input and the vertical axis output are decelerated,

and the vertical axis input and the horizontal axis output are increasing speed.

Use and maintenance / steering box a. Check that the steering box is flexible after installation. For official use, please carry out the no-load test. If the operation is

normal, then gradually load the operation. b. The steering box must not be used beyond the rated load. c. The steering box should be checked for proper oil level before and during use. Features: ◆ Standardized, multi-variety, speed ratio 1:1, 1.5:1, 2:1, 3:1 are all actual transmission ratios. ◆ When the speed ratio is not 1:1, the horizontal axis input and vertical axis output are decelerated, and the vertical axis

input and horizontal axis output are increasing speed. ◆ Spiral bevel gear structure, stable transmission, low noise, low vibration and strong carrying capacity. ◆ Available in dual input shaft form. ◆ Multiple shafts can be realized. ◆ Any installation location can be used. Product form ◆ Installation form: base installation. ◆ Axis configuration form: single input single output, single input dual output, single input three output, double input single

output. ◆ Output shaft: solid shaft.

- Induction

One-stage spiral bevel gear transmission box adopts the structure of shaft input and shaft output, which can be used for single-axis and multi-axis output. Series product models mainly include: T2, T4, T6, T7, T8, T10, T12, T16, T20, T25. The actual transmission ratios are 1:1, 1.5:1, 2.5:1, 3:1, 4:1, 5:1. The average efficiency is 98%. There are single axis, double horizontal axis, single vertical axis, double vertical axis to choose from.

T-type steering box is favored by users with unique transmission mode and high-quality product performance. The steering

box body adopts high-quality aluminum alloy square box shape, and adopts high-purity alloy steel 20CrMnTiH carburized and

quenched gear and alloy steel quenching and tempering spindle. , roller bearing, double lip seal oil seal. It has many

advantages such as beautiful appearance, strong adaptability, good heat dissipation performance, strong carrying capacity

and long service life.

T-type steering box has various installation methods, adopts hollow output shaft structure, various input and output modes,

convenient combination with other machinery, strong adaptability and convenient configuration. And the transmission is

stable, high efficiency, low noise, safe and reliable.

T-type steering box can be equipped with single horizontal axis, double horizontal axis, single vertical axis, double vertical

axis T-type steering box speed ratio: 1:1, 1.5:1, 2:1, 2.5:1, 3:1, 4:1, 5:1

T-type steering box performance characteristics: 1. The steering box has single shaft, double horizontal axis, single vertical axis and double vertical axis. 2. The steering box has strong standardization and many varieties, and the speed ratio is all actual transmission ratio. The

average efficiency is 98%. 3. When the speed ratio is not 1:1, the horizontal axis input and the vertical axis output are decelerated, and the vertical

axis input and the horizontal axis output are increasing speed. 4. The T-type steering box can be operated in forward and reverse directions, with low speed or high speed transmission,

low noise, low vibration and high endurance. Mechanical lubrication: Proper use of lubricating oil can maximize the efficiency of the steering box and increase its working

life.

Scope of application: food machinery, chemical machinery, woodworking machinery, pharmaceutical machinery, agricultural

machinery, textile equipment, smelting equipment, medical equipment and other industries.

HD spiral bevel commutator features:

1. The shape of the HD spiral bevel gear commutator is a regular hexahedron, which can adapt to different orientations.

2. The spiral commutator has a long service life, large carrying capacity and stable transmission. The low noise line speed can

be as high as 40 m/s, and the transmission efficiency is as high as 94% to 98%.

3. The spiral-toothed bevel gear adopts high-quality low-carbon alloy structural steel, which is subjected to carburizing and

quenching heat treatment, and is ground and combined to achieve high precision hard-toothed closed-type transmission.

4, HD series commutator has a total of seven specifications, large selection range, output shaft in various forms, to meet the

needs of a variety of occasions.

5. The commutator can realize two transmission modes: deceleration and speed increase.

Introduction: Gear reducer is generally used for transmission equipment with low speed and high torque. The ordinary reducer

of the motor will also have several pairs of identical gears to achieve the desired deceleration effect. The ratio of the number

of teeth of the large and small gears is the transmission ratio. With the continuous development of the reducer industry,

more and more enterprises have applied the reducer.

Gear reducer: 1. R series coaxial helical gear reducer is manufactured according to international technical requirements. It has high

technical content

2. Space saving, reliable and durable, with high overload capacity and power up to 132KW.

3. Low energy consumption and superior performance. Reducer efficiency is up to 95%;

4, low vibration, low noise, high energy saving;

5, high-quality forged steel material, steel cast iron box, gear surface after high-frequency heat treatment;

6, precision machining to ensure shaft parallelism And positioning bearing requirements, the reducer that forms the helical

gear transmission assembly is equipped with various types of motors, combined into mechatronics, fully guaranteeing the

quality characteristics of the product.

performance: 1. The gear is made of high-quality alloy steel for carburizing and quenching. The hardness of the tooth surface is up to 60±2

hrc, and the precision of the tooth surface grinding is up to 5-6. 2, using computer reshaping technology, pre-reform the gear, greatly improving the load capacity of the reducer. 3, from the box to the internal gear, using a completely modular structure design, suitable for large-scale production and

flexible selection. 4. The standard reducer model is divided according to the torque decrement form, which avoids power waste compared with

the traditional equal division. 5, using cad / cam design and manufacture to ensure the stability of quality. 6, using a variety of sealing structures to prevent oil leakage. 7, multi-directional noise reduction measures to ensure the excellent low noise performance of the reducer.

For the leakage problem, the traditional method needs to disassemble and open the reducer, replace the sealing gasket or

apply the sealant, which is not only time-consuming and laborious, but also difficult to ensure the sealing effect, and leakage

will occur again during operation. The polymer material can be used to treat leakage on site. The material has excellent

adhesion, oil resistance and 350% elongation, which overcomes the impact caused by the vibration of the reducer, and

solves the problem of leakage of the reducer for the enterprise.

For the wear problem, the traditional solution of the enterprise is repairing after repair welding or brush plating, but both

have certain drawbacks: the thermal stress generated by the repair welding high temperature cannot be completely

eliminated, which may cause damage to the material and cause the parts to bend or break; Brush plating is limited by the

thickness of the coating, and it is easy to peel off. The above two methods use metal to repair the metal, which can not

change the "hard to hard" coordination relationship. Under the combined action of each force, it will still cause re-wear.

- Feature

The casing is made of high-strength FC-25 cast iron; the one-stage spiral bevel gear transmission box is made of high-quality and high-purity alloy steel 50CrMnT quenching and tempering, and is carburized and quenched and ground; the main shaft is made of high-quality high-purity alloy steel 40Cr quenching and tempering.

High suspension and heavy load capacity; Bearing: equipped with roller bearing with heavy load capacity; Oil seal: It adopts imported double lip oil seal, one-stage spiral bevel gear transmission box which has extremely high dustproof and oil leakage resistance.

- Ration Coverage

The one-stage spiral bevel gear transmission box, standardized, multi-variety, speed ratio 1:1, 1.5:1, 2:1, 2.5:1, 3:1, 4:1, 5:1 all are the actual transmission ratio. The average efficiency is 98%.

- Main Advantages

T series one-stage spiral bevel gear transmission box, standardized, multi-variety, speed ratio 1:1, 1.5:1, 2:1, 2.5:1, 3:1, 4:1, 5:1 All the actual transmission ratio. The average efficiency is 98%. Available in single axis, double horizontal axis, single vertical axis, and double vertical axis.

one-stage spiral bevel gear transmission box can be operated in forward and reverse directions, with low speed or high speed transmission, low noise, low vibration and high endurance. When the speed ratio is not 1:1, the horizontal axis input and the vertical axis output are decelerated, and the vertical axis input and the horizontal axis output are increasing speed.

- Maintain

Initial use for two weeks or 100-200 hours, for the initial wear period, there may be a little metal wear particles between the two, please be sure to clean the interior, and replace the new lubricant; long-term use, every six months - a year or 1000-2000 Change the oil once an hour. The proper lubrication of the one-stage spiral bevel gear transmission box can make the steering machine more efficient and improve its operating life.

The best service from our transmission drive expert to your inbox directly.

Our Service

Get in Touch

Yantai Bonway Manufacturer Co.ltd

ANo.160 Changjiang Road, Yantai, Shandong, China(264006)

T+86 535 6330966

W+86 185 63806647