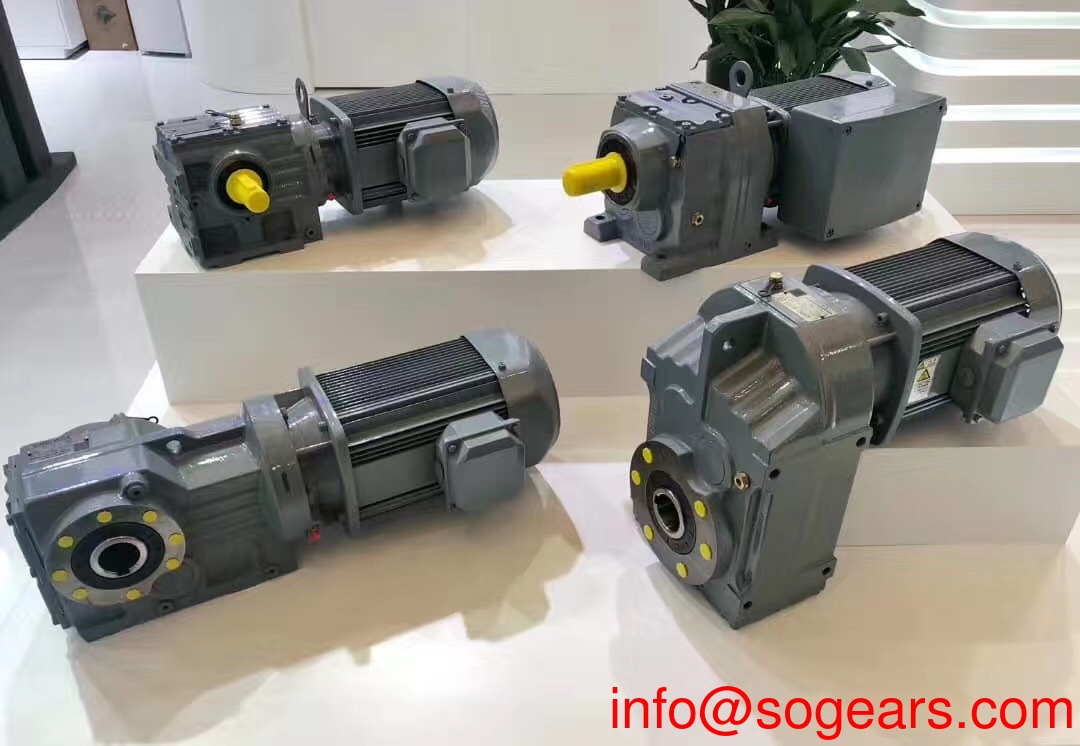

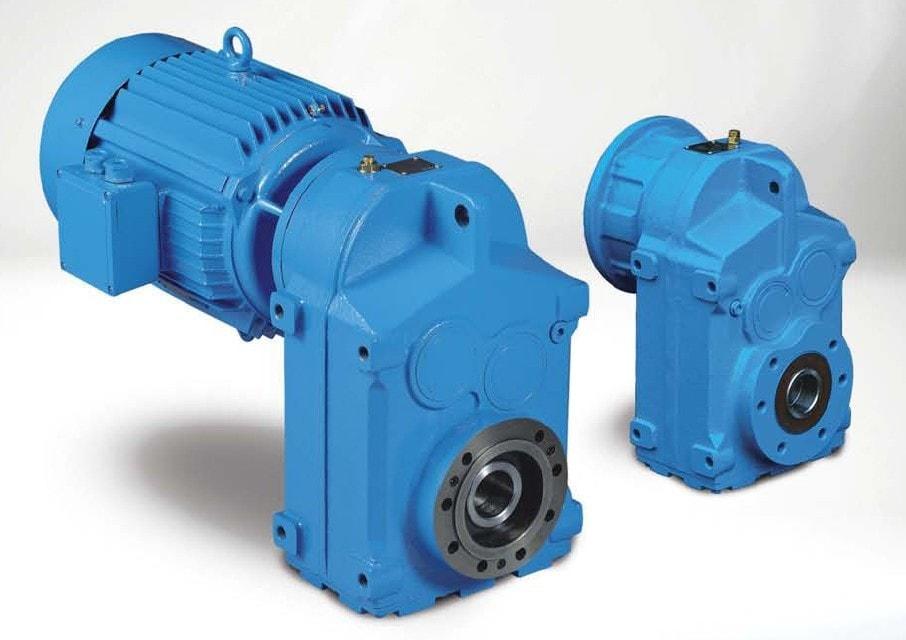

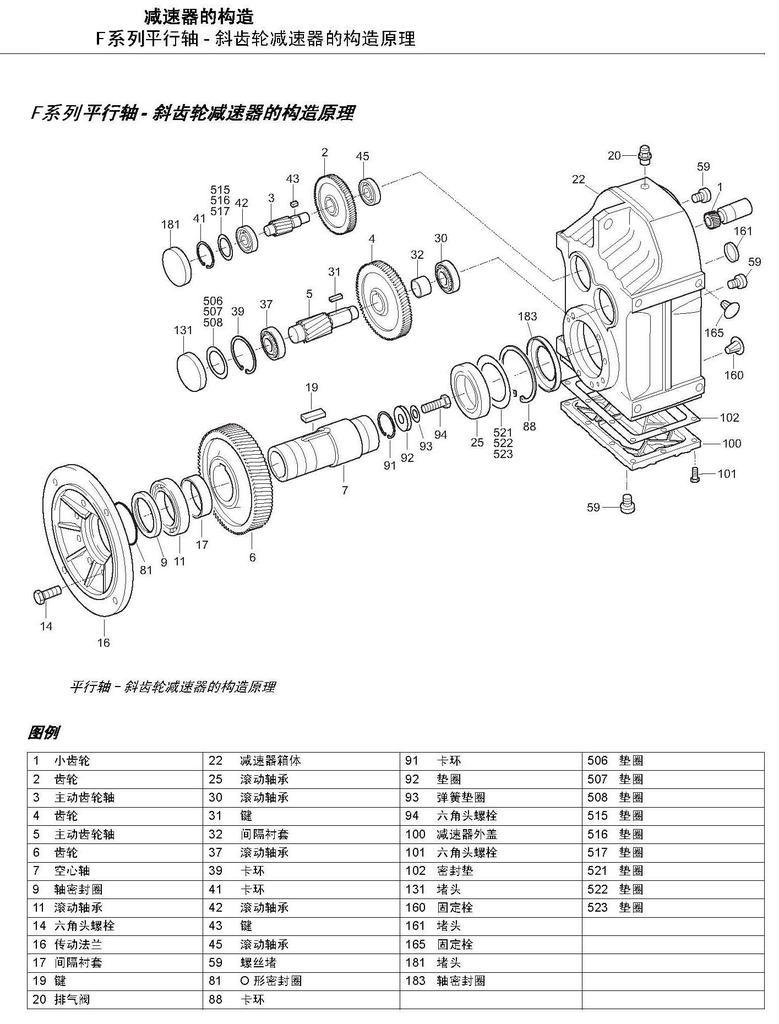

Shaft mounted geared motor in material handling industry

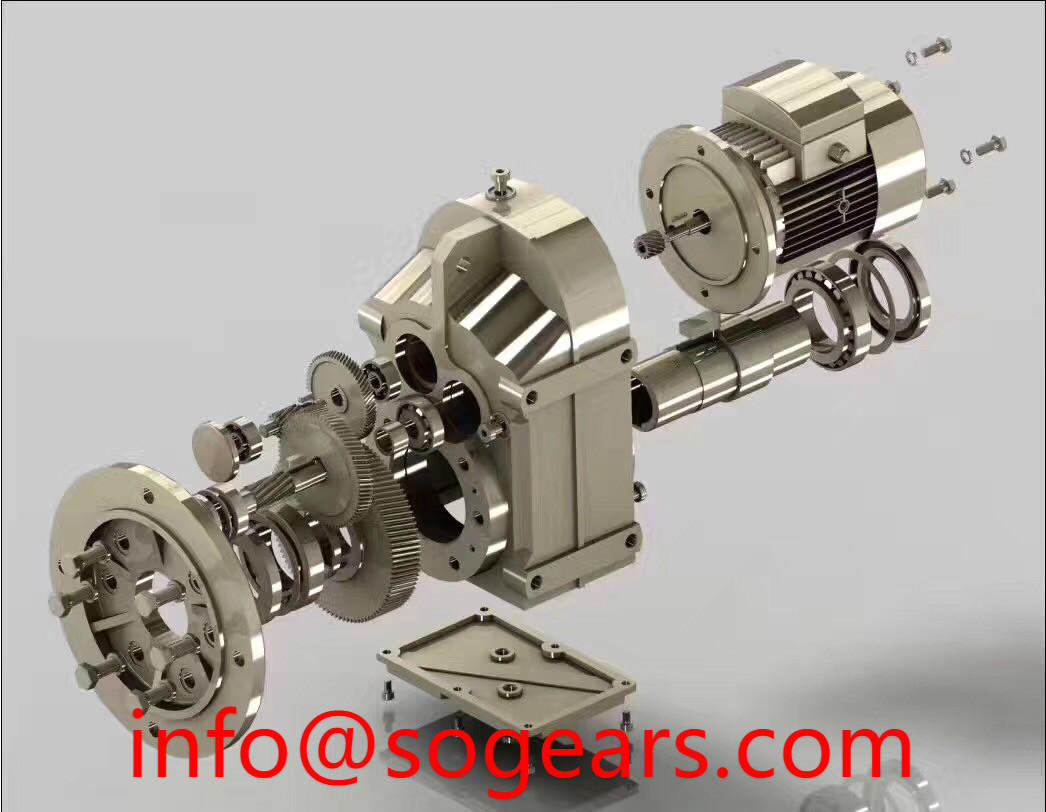

F series long service life shaft mounted geared motor in material handling industry using high-quality forged steel material, steel cast iron box body, the surface of the gear is subjected to high-frequency heat treatment, and precision machining ensures the parallelism of the shaft and the accuracy of positioning. All of these constitute the gear unit of the gear transmission assembly. The various types of electrodes form an electrode integration, which fully guarantees the quality of the product.

The main parameters such as center distance and nominal transmission ratio are optimized, and the main parts and parts are interchangeable. The gears are made of high-quality alloy steel by carburizing and quenching. The hardness of the tooth softener is 54-62HRC. The utility model has the advantages of small volume, light weight, high precision, large carrying capacity, high efficiency, long service life, high reliability, stable transmission and low noise.

F Series shaft mounted geared motor in material handling industry Product Overview:

1. F series shaft mounted geared motor in material handling industry is manufactured in accordance with international technical requirements and has high scientific and technological content.

2, space saving, reliable and durable, with high overload capacity, power up to 90KW or more.

3. F series parallel shaft helical shaft mounted geared motor in material handling industry has low energy consumption, superior performance and high efficiency of over 95%.

F shaft mounted geared motor in material handling industry, Shanghai tin blue shaft mounted geared motor in material handling industry

4. Parallel shaft helical shaft mounted geared motor in material handling industry has low vibration, low noise and high energy saving. It adopts high-quality section steel material and steel cast iron box body, and the gear surface is subjected to high-frequency heat treatment.

5, through precision machining, to ensure the parallelism of the shaft and the accuracy of positioning, all of which constitute the gear transmission assembly of the shaft mounted geared motor in material handling industry is equipped with various types of motors, forming a mechanical and electrical integration, fully guarantee the quality characteristics of the use of geared motors.

Performance characteristics:

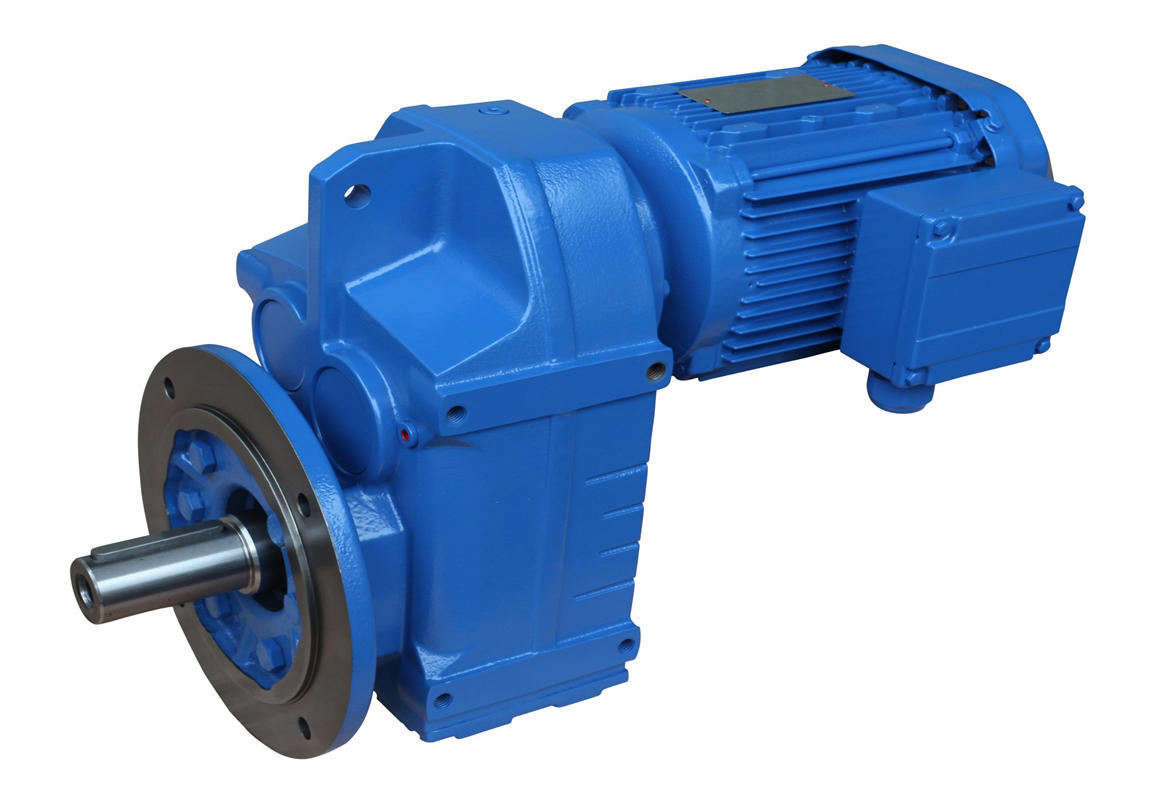

1. Parallel output, compact structure, large transmission torque, stable operation, low noise and long service life.

2, installation method: base installation, hollow shaft installation, flange installation, torque arm installation, small flange installation.

3, the basic type of secondary input and output rotation direction is the same, the third level is opposite; F / R combination when asked.

4. Output mode: hollow shaft output or solid shaft output.

5. Average efficiency: 96% for the second level, 94% for the third level, and 85% for the F series/R series.

Technical parameters: editing

Speed ratio range: basic type 3.81 ~ 281.71, F / R combination type can reach 31434

Torque range: 200~18000Nm

Power range: 0.18 ~ 200kW

F series shaft mounted geared motor in material handling industry

Made with international technical requirements, it has high scientific and technological content, saves space, is reliable and durable, with high overload capacity, power can be 90KW, low energy consumption, superior performance, speed reduction efficiency of over 95%, low vibration and low noise. High energy-saving, high-quality forged steel material, steel cast iron box body, gear surface after high-frequency heat treatment, after precision machining,

To ensure the parallelism of the shaft and the accuracy of the positioning, all of the gear units of the gear transmission assembly are equipped with various types of electrodes, forming an electrode integration, which fully guarantees the quality characteristics of the product.

technical parameter:

Power: 0.12KW ~ 200KW

Torque: 3N·m~22500N·m

Output speed: 0.06 ~ 374r / min

structure type:

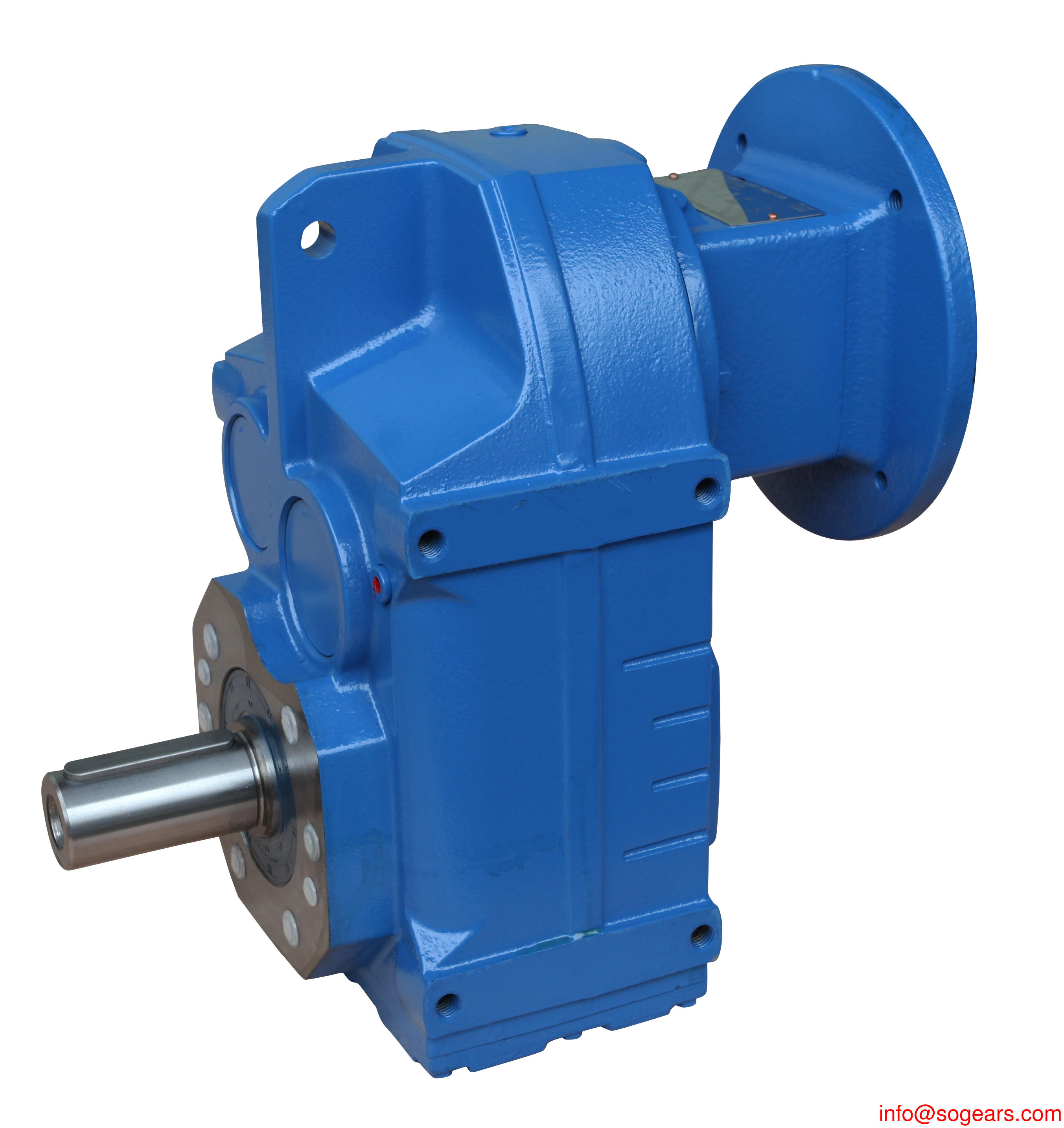

F-shaft extension, foot mounting FA-shaft mounting

FF-shaft extension type, flange connection FAF-shaft mounting type, flange mounting

structure type:

F-shaft extension type, foot mounting FF-shaft extension type, flange connection

S- indicates axis input FA-axis mounted connection

KAF-shaft mounted, flange mounted

F series shaft mounted geared motor in material handling industry model:

F37, F47, F57, F67, F77, F87, F97, F107, F127, F157

FA37, FA47, FA57, FA67, FA77, FA87, FA97, FA107, FA127, FA157

FF37, FF47, FF57, FF67, FF77, FF87, FF97, FF107, FF127, FF157

FAF37, FAF47, FAF57, FAF67, FAF77, FAF87, FAF97, FAF107, FAF127, FAF157

FAZ37, FAZ47, FAZ57, FAZ67, FAZ77, FAZ87, FAZ97, FAZ107, FAZ127, FAZ157

shaft mounted geared motor in material handling industry F series parallel shaft helical shaft mounted geared motor in material handling industry, combined with international technical requirements, with high technology content, space saving, reliable and durable, with high overload capacity, power can be 90KW, low energy consumption, superior performance, shaft mounted geared motor in material handling industry The effect is up to 95%, the vibration is low, the sound is low, the energy is high, the high-quality forged steel material, the steel cast iron box body, the gear surface is subjected to high-frequency heat treatment, and the precision machining ensures the parallelism of the shaft and the accuracy of the positioning. The shaft mounted geared motor in material handling industry of the gear transmission assembly is equipped with various types of electrodes, forming an electrode integration, which fully guarantees the quality characteristics of the product.

technical parameter:

Power: 0.12KW ~ 200KW

Torque: 3N·m~22500N·m

Output speed: 0.06 ~ 374r / min

structure type:

F-shaft extension, foot mounting FA-shaft mounting

FF-shaft extension type, flange connection KAF-shaft mounting type, flange mounting

D- indicates axis input

Generally used oil pool lubrication, natural cooling, when the thermal power can not be met, can use circulating oil lubrication or fan cooling, coil cooling.

F series shaft mounted geared motor in material handling industry, combined with international technical requirements, has high scientific and technological content, saves space, is reliable and durable, with high overload capacity, power can be 90KW, high energy consumption high speed mixer, superior performance, speed reduction efficiency up to 95% Above, low vibration, low noise, high energy saving, high quality forged steel material, steel cast iron box

The F-Series shaft mounted geared motor in material handling industry with MOTOX®-N parallel shaft gearboxes are part of the MOTOX®-N modular system. Together with coaxial, bevel gear, worm gear or variable speed gearbox and three-phase AC, one-way AC and brake motors can be combined into various types of drive equipment conceivable, including electronic speed control drives; Series shaft mounted geared motor in material handling industry have the following advantages

1. Carrying high-efficiency transmission power per unit volume

2. The gearbox housing made of grey cast iron has a solid structure and sound absorption and shock absorption.

3. Through the radial shaft seal with dust shield, it can avoid the loss of lubricating oil and the entry of dust or water droplets, and the life is longer.

4. Single-stage gear set can produce a large transmission ratio

5. Irreversible direction of operation

6. The box has shock absorption and low noise when subjected to impact.

Arrangement

Our range of standard gearboxes can be installed in any position.

MOTOX®-N parallel shaft gearboxes are manufactured in two and three stages

The gearbox is either in the form of a solid shaft or connected by a flat key.

The plug shaft is made of a higher strength material such as 42CrMo4, 16MnCr5.

product description:

1. F series parallel shaft helical shaft mounted geared motor in material handling industry is manufactured in accordance with international technical requirements and has high technical content.

2, space saving, reliable and durable, with high overload capacity, power up to 90KW or more.

3. F parallel shaft helical shaft mounted geared motor in material handling industry has low energy consumption, superior performance and high efficiency of over 95%.

4. Parallel shaft helical shaft mounted geared motor in material handling industry has low vibration, low noise and high energy saving. It adopts high-quality section steel material and steel cast iron box body, and the gear surface is subjected to high-frequency heat treatment.

5, through precision machining, to ensure the parallelism of the shaft and the accuracy of positioning, all of which constitute the gear transmission assembly of the shaft mounted geared motor in material handling industry is equipped with various types of motors, forming a mechanical and electrical integration, fully guarantee the quality characteristics of the use of geared motors.

Performance characteristics:

1. Parallel output, compact structure, large transmission torque, stable operation, low noise and long service life.

2, installation method: base installation, hollow shaft installation, flange installation, torque arm installation, small flange installation.

3, the basic type of secondary input and output rotation direction is the same, the third level is opposite; F / R combination when asked.

4. Output mode: hollow shaft output or solid shaft output.

5. Average efficiency: 96% for the second level, 94% for the third level, and 85% for the F/R combination.

technical parameter:

Speed ratio range: basic type 3.81 ~ 281.71, F / R combination type can reach 31434

Torque range: 200~18000 Nm

Power range: 0.18 ~ 200 kW

structure type:

F-shaft extension type, foot mounting FF-shaft extension type, flange connection

S- indicates axis input FA-axis mounted connection

KAF-shaft mounted, flange mounted

Basic model:

F37, F47, F57, F67, F77, F87, F97, F107, F127, F157

FA37, FA47, FA57, FA67, FA77, FA87, FA97, FA107, FA127, FA157

FF37, FF47, FF57, FF67, FF77, FF87, FF97, FF107, FF127, FF157

FAF37, FAF47, FAF57, FAF67, FAF77, FAF87, FAF97, FAF107, FAF127, FAF157

FAZ37, FAZ47, FAZ57, FAZ67, FAZ77, FAZ87, FAZ97, FAZ107, FAZ127, FAZ157

FS37, FS47, FS57, FS67, FS77, FS87, FS97, FS107, FS127, FS157

F37R17, F47R17, F57R37, F67R37, F77R37, F87R57, F97R57, F107R77, F127R77, F107R77, F127R77, F127R87, F157R97

FAS37, FAS47, FAS57, FAS67, FAS77, FAS87, FAS97, FAS107, FAS127, FAS157

FA37R17, FA47R17, FA57R37, FA67R37, FA77R37, FA87R57, FA97R57, FA107R77, FA127R77, FA107R77, FA127R77, FA127R87, FA157R97

FFS37, FFS47, FFS57, FFS67, FFS77, FFS87, FFS97, FFS107, FFS127, FFS157

FF37R17, FF47R17, FF57R37, FF67R37, FF77R37, FF87R57, FF97R57, FF107R77, FF127R77, FF107R77, FF127R77, FF127R87, FF157R97

FAFS37, FAFS47, FAFS57, FAFS67, FAFS77, FAFS87, FAFS97, FAFS107, FAFS127, FAFS157

FAF37R17, FAF47R17, FAF57R37, FAF67R37, FAF77R37, FAF87R57, FAF97R57, FAF107R77, FAF127R77, FAF107R77, FAF127R77, FAF127R87, FAF157R97

FAZS37, FAZS47, FAZS57, FAZS67, FAZS77, FAZS87, FAZS97, FAZS107, FAZS127, FAZS157

FAZ37R17, FAZ47R17, FAZ57R37, FAZ67R37, FAZ77R37, FAZ87R57, FAZ97R57, FAZ107R77, FAZ127R77, FAZ107R77, FAZ127R77, FAZ127R87, FAZ157R97

F series parallel shaft gear motor features:

1. F series helical shaft mounted geared motor in material handling industry, manufactured in accordance with international technical requirements, with high scientific and technological content

2, save space, reliable and durable, with high overload capacity, power up to 132KW;

3, low energy consumption, superior performance, the efficiency of the shaft mounted geared motor in material handling industry is as high as 95% or more;

4, low vibration, low noise, high energy saving;

5, the selection of high-quality forged steel materials, steel cast iron box, the surface of the gear after high-frequency heat treatment;

6. After precision machining to ensure the parallelism of the shaft and the requirements of the positioning bearing, the shaft mounted geared motor in material handling industry that forms the helical gear transmission assembly is equipped with various types of motors, which are combined into mechatronics, which fully guarantees the quality characteristics of the products.

F series parallel shaft helical shaft mounted geared motor in material handling industry has high technical content, saves space, is reliable and durable, with high overload capacity, power can be 90KW, energy consumption high speed mixer is low, performance is superior, and the speed reduction effect is over 95%. Low vibration, low energy, high energy saving, high-quality forged steel material, steel cast iron box, high-frequency heat treatment of gear surface, precision machining, ensuring shaft parallelism and positioning accuracy, all of which constitute the gear train assembly deceleration The machine is equipped with various types of electrodes of the shaft mounted geared motor in material handling industry to form an electrode integration, which fully guarantees the quality of the product. The hardened shaft mounted geared motor in material handling industry mainly includes the parallel shaft series and the vertical shaft series. The parallel shaft shaft mounted geared motor in material handling industry is produced according to national standards. The products have been optimized and have advanced international standards in the 1980s. It mainly includes ZDY (single-stage), ZLY (two-stage), ZSY (three-level) and ZFY (four-level) four-column cancer series. Vertical shaft shaft mounted geared motor in material handling industrys are produced to national standards.

Chinese name F series parallel shaft helical shaft mounted geared motor in material handling industry features space saving, reliable and durable power, 90KW, including DBY, dcy and DFY

F series shaft mounted geared motor in material handling industry, combined with international technical requirements, has high scientific and technological content, saves space, is reliable and durable, with high overload capacity, power can be 90KW, high energy consumption high speed mixer, superior performance, speed reduction efficiency up to 95% Above, the vibration is low, the sound is low, the energy is high, the high-quality forged steel material, the steel cast iron box body, the gear surface is subjected to high-frequency heat treatment, and the precision machining ensures the parallelism of the shaft and the positioning accuracy, which constitutes the gear transmission assembly. The shaft mounted geared motor in material handling industry is equipped with various types of electrodes of the shaft mounted geared motor in material handling industry, forming an electrode integration, which fully guarantees the quality of the product. The hardened shaft mounted geared motor in material handling industry mainly includes a parallel shaft series and a vertical shaft series, and the parallel shaft shaft mounted geared motor in material handling industry is produced according to national standards. The products have been optimized and have advanced international standards in the 1980s. It mainly includes ZDY (single-stage), ZLY (two-stage), ZSY (three-level) and ZFY (four-level) four-column cancer series. Vertical shaft shaft mounted geared motor in material handling industrys are produced to national standards. The transmission device is arranged in the vertical direction of the input shaft and the output shaft, and mainly includes three series of DBY, dcy and DFY.

The main parameters such as center distance and nominal transmission ratio are optimized, and the main parts and parts are interchangeable. The gears are made of high-quality alloy steel by carburizing and quenching. The hardness of the tooth softener is 54-62HRC. The utility model has the advantages of small volume, light weight, high precision, large carrying capacity, high efficiency, long service life, high reliability, stable transmission and low noise. Generally used oil pool lubrication, natural cooling, when the thermal power can not be met, you can use circulating oil lubrication or fan. Cooling Coil Cooling Parallel Shaft Series Gearbox Registration Hong Kong company's nominal input power PA is stable according to load, daily working time is less than or equal to 10h, no more than 5 times per hour, and the allowable starting torque is twice the working torque. To run, the safety factor of the contact strength of a single pair of gears is about 1, and the probability of failure is less than or equal to 1%. When the shaft mounted geared motor in material handling industry is running in both directions, the PA should be multiplied by the coefficient of O.8-1.O according to the top ten brands of paint. When the reverse load is large, the commutation is frequent, and the reliability coefficient KR is low, the coefficient is compared. Small value. On the contrary, take a larger value. The permissible thermal power Pr of the parallel shaft series gearbox is suitable for ambient temperature 20 ° C, 100% continuous operation and power utilization per hour, and must be corrected if conditions are different.

F series shaft mounted geared motor in material handling industry is manufactured with international technical requirements. It has high technology content, saves space, is reliable and durable, with high overload capacity, power can be 90KW, low energy consumption, superior performance, and the speed reduction efficiency is over 95%. Low-pitched sound, high energy-saving, high-quality forged steel material, steel cast iron box, gear surface after high-frequency heat treatment, after precision machining,

To ensure the parallelism of the shaft and the accuracy of the positioning, all of the gear units of the gear transmission assembly are equipped with various types of electrodes, forming an electrode integration, which fully guarantees the quality characteristics of the product.

technical parameter:

F series helical gear parallel shaft shaft mounted geared motor in material handling industry

First, F series shaft mounted geared motor in material handling industry overview

F series shaft mounted geared motor in material handling industry is manufactured with technical requirements, with high technology content, space saving, reliable and durable.

F series shaft mounted geared motor in material handling industry has high overload capacity, power can be more than 90KW, low energy consumption, superior performance, speed reduction efficiency of more than 95%, low vibration, low noise and high energy saving.

The F series shaft mounted geared motor in material handling industry is made of forged steel material and steel cast iron box. The surface of the gear is subjected to high-frequency heat treatment and precision machining to ensure the parallelism of the shaft and the accuracy of positioning. All of these constitute the shaft mounted geared motor in material handling industry of the gear transmission assembly. The electrode-like electrode forms an electrode integration, which ensures the quality characteristics of the product.

Second, F series shaft mounted geared motor in material handling industry product characteristics

1. Highly modular design: It can be easily equipped with various types of motors or other power inputs. The same type of machine can be equipped with a variety of power motors. It is easy to realize the combined connection between each model.

2, F series shaft mounted geared motor in material handling industry transmission ratio: thin, wide range. The combined model can form a large gear ratio, that is, the output is extremely low.

3, F series shaft mounted geared motor in material handling industry installation form: installation position is not limited.

4, high strength, small size: the box is made of high-strength cast iron. The gear and gear shaft adopts a gas carburizing and quenching refining process, so the bearing capacity per unit volume is high.

5、F series shaft mounted geared motor in material handling industry has long service life: under the condition of correct selection (including selection of appropriate use factor) and normal use and maintenance, the life of main parts of shaft mounted geared motor in material handling industry (except wearing parts) is generally not less than 20,000 hours. . Consumables include lubricants, oil seals, and bearings.

6. Low noise: The main components of the shaft mounted geared motor in material handling industry are precision machined and assembled and tested, so the shaft mounted geared motor in material handling industry has low noise.

7. F series shaft mounted geared motor in material handling industry has high efficiency: the efficiency of single type is not less than 95%.

8, can withstand large radial loads.

9. Axial load that can withstand no more than 15% of radial force

Third, F series shaft mounted geared motor in material handling industry technical parameters: power: 0.12KW ~ 200KW

F series shaft mounted geared motor in material handling industry torque: 3N·m~22500N·m

F series shaft mounted geared motor in material handling industry output speed: 0.06 ~ 374r / min

F series shaft mounted geared motor in material handling industry model:

1. F-type-----normal shaft extension coupling parallel shaft helical shaft mounted geared motor in material handling industry;

2, FA type --- shaft-mounted parallel shaft helical shaft mounted geared motor in material handling industry;

3, FF type --- flange type parallel shaft helical shaft mounted geared motor in material handling industry;

4, FAF type — shaft mounted flange type parallel shaft helical shaft mounted geared motor in material handling industry.

The nominal input power of the Parallel shaft hardened gearbox is stable according to the load. The working time per day is less than or equal to 10h, and the starting time is no more than 5 times per hour. The allowable starting torque is twice the working torque, one-way operation, single-pair gear The contact strength safety factor is about 1, and the failure probability is less than or equal to 1%.

With Best Regards,

Cherry Zhang ( Sales Department; Miss. )

NER GROUP CO.,LIMITED

Yantai Bonway Manufacturer Co., Ltd

Tel:+86-535-6330966

Mobile:+86-18865558975

www.planetary-gearbox.com

https://twitter.com/gearboxmotor

https://www.facebook.com/sogears1993

Viber/Line/Whatsapp/Wechat: 008618865558975

E-mail:

Add:No.5 Wanshoushan Road Yantai city Shandong Province, China

The best service from our transmission drive expert to your inbox directly.

Our Service

Get in Touch

Yantai Bonway Manufacturer Co.ltd

ANo.160 Changjiang Road, Yantai, Shandong, China(264006)

T+86 535 6330966

W+86 185 63806647