Products

Gearbox for js500 concrete mixer

cement mixer gearbox, concrete mixer gearbox specifications, concrete mixer gearbox design, concrete mixer gearbox manufacturers, js concrete mixer reduction gearbox

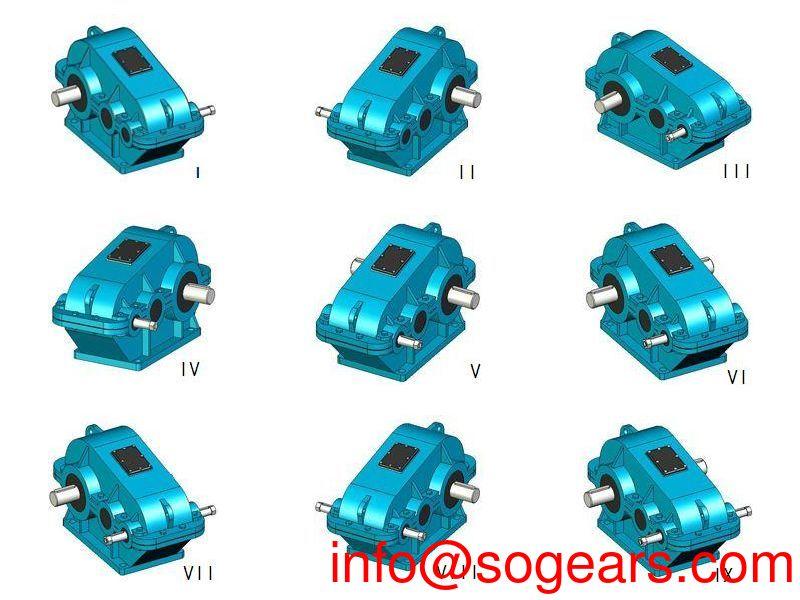

ZQ series The Gearbox for js concrete mixer is a cylindrical gear The Gearbox for js concrete mixer with two-stage cylindrical gear drive. Widely used in lifting machinery, mining machinery and general chemical industry, its working temperature is -40C ° ~ +45C °, the input speed is not higher than 1500 rev / min, the gear drive peripheral speed must not exceed 14 m / s, It can be operated in both forward and reverse directions.

Installation and maintenance

1. The gear is lubricated by closed transmission oil pool. The oil level of the lubricating oil is indicated by the circular oil mark on the machine base. When the speed The Gearbox for js concrete mixer is in the stop running state, the oil level is within the range indicated by the oil mark.

2. Lubricating oil is generally made of HJ40-50 mechanical oil. It is also possible to use HL20-30 gear oil.

3. The initial stage of the gearbox for js concrete mixer should pay special attention to the cleaning of the oil. If the oil is dirty (especially the mixing of metal foam), the oil should be changed immediately. When the oil is changed, the dirt in the body should be removed. The quality of the oil must be checked regularly (not less than once every six months).

4. The state of the meshing working surface should be checked regularly, especially when the tooth surface is scratched at the beginning of the work. If the area occupied by the scratch is not more than 20% of the tooth working surface (along the tooth length and the tooth height), it is allowed. The stone or scraper is slightly trimmed.

5. If you need to open the cover for repair, pay attention to whether the cover is coated with sealant. If there is sealant, use the screw hole on the cover to open with the screw. Do not hammer the close surface. Check the tightness after inspection. Whether the surface and the cover are scratched, the sealant is cleaned, or it will cause oil leakage.

product description: the gearbox for js concrete mixer for cranes is developed on the basis of the medium hardened The Gearbox for js concrete mixer for cranes.

The QY series The Gearbox for js concrete mixer includes two series of hardened gear Gearbox for js concrete mixer for QYS type (three-point

) and QYD type (base type). It has three types of three-stage, four-stage and three-four-stage

combination. The crane The Gearbox for js concrete mixer is welded by steel plate, the box is annealed and destressed,

the gear is made of high-quality low-carbon alloy steel, the tooth surface is treated by

carburizing and quenching, and Grinding processing, product quality and reliable performance.

Taking into account the working characteristics of the cranes, the range of transmission ratios,

and further improving the performance of the products, and adopting fewer specifications to

meet the requirements of users in various aspects, the characteristics of QY-type Gearbox for js concrete mixer are: 1) High carrying capacity. The gears are carburized, quenched and grounded, and the load carrying

capacity is greatly improved compared with the soft tooth surface and the medium hard tooth

surface gear The Gearbox for js concrete mixer of the tempering hobbing. 2) Small size and light weight. Compared with soft tooth surface and medium hard tooth surface

The Gearbox for js concrete mixer. The same load capacity The Gearbox for js concrete mixer can reduce 2-4 equivalent frame numbers. 3) High efficiency, low noise and low vibration. The grinding gear has improved the accuracy

grade, and the gear has been trimmed. The overall efficiency of each gear is 0.98, and the

vibration and noise are significantly reduced.

4) Adopt multi-level number to reduce single-stage speed ratio. The center distance can be

opened to reduce the height of the gearbox for js concrete mixer and meet the requirements of various cranes; the

maximum nominal transmission ratio of the gearbox for js concrete mixer reaches 400, which meets the requirements

of slow cranes.

5) Three-point The Gearbox for js concrete mixer can be installed in vertical, horizontal and even deflection angles, which

is convenient and flexible.

6) This series of Gearbox for js concrete mixer have three or four stages of combination (ie, three-stage assembly

type, four-stage transmission ratio) to provide the premise for the generalization of slow speed

cranes.

Working conditions:

1) The peripheral speed of the gear is not more than 20m/s;

2) The speed of the high speed shaft is not more than 1500r/min;

3) The working environment temperature is -40 to +45 °C;

4) It can be operated in both forward and reverse directions.

classification: According to the different lifting standards, they are generally divided into four categories: super

large, large, medium and small. 1) Super large lifting The Gearbox for js concrete mixer Mainly used in construction, dock and steel industry, generally carrying load above 150T 2) Large lifting The Gearbox for js concrete mixer Mainly used in steel industry, engineering machinery, etc., generally carrying load between

50-150T 3) Medium lifting The Gearbox for js concrete mixer Mainly used in factory buildings and small construction machinery, carrying load between 5-50T 4) Small lifting The Gearbox for js concrete mixer Mainly used in small factory buildings, bearing load below 5T, commonly known as electric

hoist.

The crane The Gearbox for js concrete mixer is divided into a hoist The Gearbox for js concrete mixer and a running The Gearbox for js concrete mixer. The hoist The Gearbox for js concrete mixer is the

key transmission device for the main lifting and auxiliary lifting of the crane. The running The Gearbox for js concrete mixer

is the key transmission device for the crane traveling and the trolley traveling mechanism. The

core components of the company's various types of large cranes. Widely used in metallurgy,

bridge, gantry cranes, CDQ hoists, nuclear power plant cranes, representative products are 520t

casting cranes, 1300t bridge cranes, 900t door type shipbuilding cranes, special cranes for

nuclear power plants, with advanced structure, Strong carrying capacity, safe and reliable. the gearbox for js concrete mixer is a separate component consisting of a gear drive, a worm drive, and a gear-worm

drive enclosed in a rigid housing. It is often used as a reduction gear between the prime mover

and the work machine. The function of matching the rotational speed and transmitting torque

between the prime mover and the working machine or the actuator is widely used in modern

machinery.

Introduction: the gearbox for js concrete mixer is generally used for transmission equipment with low speed and high torque. The

motor, internal combustion engine or other high-speed power is driven by the gears with few

teeth on the input shaft of the gearbox for js concrete mixer to mesh the large gear on the output shaft to achieve the

purpose of deceleration. the gearbox for js concrete mixer will also have several pairs of identical principle gears to

achieve the desired deceleration effect. The ratio of the number of teeth of the large and small

gears is the transmission ratio.

effect: 1. Reduce the speed and increase the output torque at the same time. The torque output ratio

is multiplied by the motor output and the reduction ratio, but it should be noted that the rated

torque of the gearbox for js concrete mixer cannot be exceeded. 2. Deceleration also reduces the inertia of the load, and the reduction of inertia is the square of

the reduction ratio.

Application areas: the gearbox for js concrete mixer is a mechanical transmission device in many fields of the national economy. The

product categories involved in the industry include various types of gear Gearbox for js concrete mixer, planetary

gear Gearbox for js concrete mixer and worm Gearbox for js concrete mixer, as well as various special transmission devices, such as

speed increase devices and speed control. Devices, and various types of composite transmissions

including flexible transmissions. The product service field covers metallurgy, nonferrous metals,

coal, building materials, ships, water conservancy, electric power, engineering machinery and

petrochemical industries.

China's gearbox industry has a history of nearly 40 years. In all areas of the national economy

and the defense industry, The Gearbox for js concrete mixer products have a wide range of applications. Food light

industry, electric machinery, construction machinery, metallurgical machinery, cement machinery,

environmental protection machinery, electronic appliances, road construction machinery, water

conservancy machinery, chemical machinery, mining machinery, transportation machinery, building

materials machinery, rubber machinery, petroleum machinery and other industries The Gearbox for js concrete mixer

products have strong demand.

The market with great potential has spawned fierce competition in the industry. In the brutal

market competition, enterprises in the gearbox industry must speed up the elimination of

backward production capacity, vigorously develop high-efficiency energy-saving products,

make full use of the national energy-saving products, benefit the project policy opportunities,

and increase product renewal efforts. Adjust the product structure and pay attention to the

national industrial policy to cope with the complex and volatile economic environment and

maintain a good momentum of development.

Performance characteristics: 1 Compact, small size and light weight 2 high efficiency, low noise, low vibration 3 Increase the transmission center distance, reduce the height of the whole machine, and meet

the requirements of the operating mechanism. 4 Higher operational reliability and enhanced drive power 5 Long oil change intervals, reducing maintenance costs

A crane is a multi-action hoist that vertically lifts and horizontally carries heavy objects within a

certain range. Also known as the crane, aerial crane, crane. The main feature of the tire crane is that the driving cab and the lifting control room are combined

into one. It is evolved from a crawler crane (crawler crane), and the track and the walking

bracket of the traveling mechanism are turned into a chassis with a tire to overcome The crawler

crane (crawler crane) track plate has the disadvantage of causing damage to the road surface

and belongs to the material handling machinery.

Bridge cranes are lifting equipment that traverses materials in the workshop, warehouse and

stockyard. Because its two ends are located on tall cement columns or metal brackets, they are

shaped like bridges. The bridge of the bridge crane runs longitudinally along the rails laid on

the elevated sides of the bridge, which can make full use of the space under the bridge to lift

the materials without being obstructed by the ground equipment. It is the most widely used and

largest number of lifting appliances.

Some of the working characteristics of lifting equipment are intermittent movements, that is, the

corresponding mechanisms for taking, moving, unloading, etc. in one working cycle are alternately

working, and the development and use of cranes in the market is more and more extensive.

Because there are some accidents that often occur without the hoisting of the legs and heavy

lifting, the speed of driving is faster than that of the crawler crane (crawler crane); the operation

is stable, the lifting capacity is large, and the walking can be carried out within a certain range,

but the road must be flat and solid. The tire pressure meets the requirements and shall not

exceed 50 CM from the ground; it is forbidden to carry long distances with load. In order to

ensure the safety of the operation, at present, it is basically prohibited to carry out lifting operations

without using the legs. The ropes used in the cranes include phosphating coated steel wire ropes,

galvanized steel wire ropes and smooth steel wire ropes.

classification: The hoisting machinery used in the bridge construction project can be divided into four categories:

light and small lifting equipment, bridge type hoisting machinery and boom type cranes, and

cable cranes according to their different structures and performances. Light and small lifting

equipment such as: jack, pneumatic hoist, electric hoist, balance hoist (also known as balance

hoist), winch and so on. Bridge type lifting equipment such as beam cranes. Boom type cranes

such as fixed slewing cranes, tower cranes, truck cranes, tire cranes, crawler cranes, etc.

Cable cranes such as elevators.

According to the nature of lifting: mobile cranes, tower cranes, mast cranes.

According to the driving method: one type is centralized driving, that is, one motor drives the

long drive shaft to drive the active wheels on both sides; the other type is driven separately,

that is, the active wheels on both sides are driven by one motor. Medium and small bridge c

ranes use the "three-in-one" drive method in which the brakes, The Gearbox for js concrete mixer and electric motor are

combined. The common bridge crane with large lifting weight is easy to install and adjust, and

the drive unit often adopts universal joint.

According to the structure, the crane is mainly divided into light and small lifting equipment,

bridge type (bridge type, gantry crane), boom type (self-propelled, tower type, door seat type,

railway type, floating type, mast type crane). Cable type.

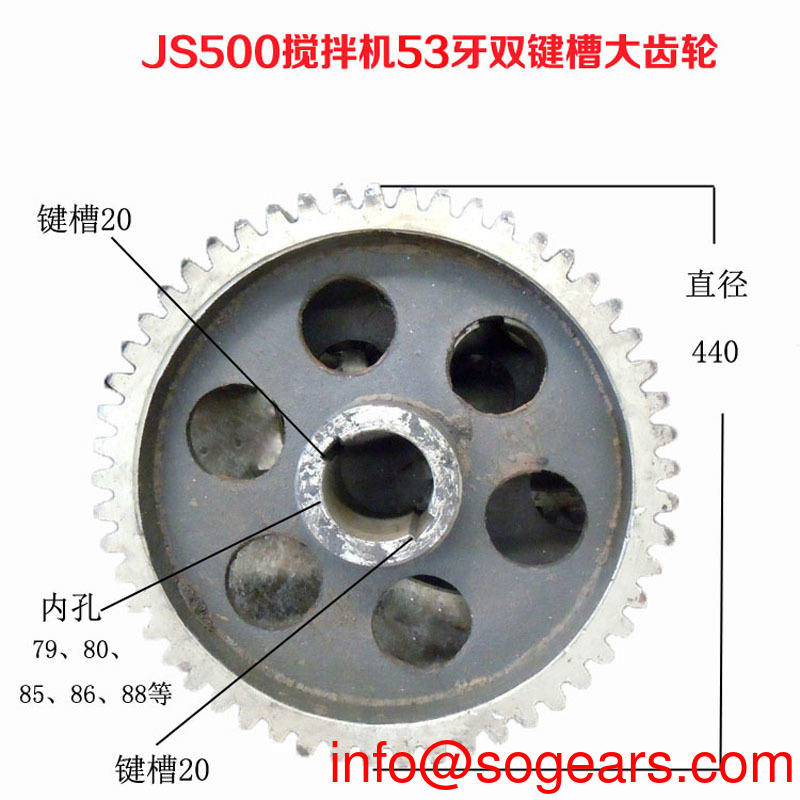

The working conditions, type, gear parameters, external dimensions and installation dimensions

of the gearbox for js concrete mixer are exactly the same as those of the ZQ The Gearbox for js concrete mixer. Refer to the relevant diagram of

the ZQ The Gearbox for js concrete mixer. The material of the gear shaft and the gear is changed to alloy steel, the large

gear is in a quenched and tempered state, and the gear shaft and the pinion are in a surface

quenching state, that is, a hardened-twisted pair. PJ gear The Gearbox for js concrete mixer has the characteristics of good

mechanical performance, reliable operation, convenient maintenance and overload capability, impact

resistance and small moment of inertia. Suitable for lifting, transportation, metallurgy, mining,

construction, chemical, textile and other industries. The applicable conditions are as follows: the

peripheral speed of the gearbox for js concrete mixer gear is not more than 10m/s; the speed of the high-speed

shaft is not more than 1450 to reach the gearbox for js concrete mixer

Product details: Compared with ZQH cylindrical gear The Gearbox for js concrete mixer, ZQ is the same except for the tooth shape. The ZQ type is an involute cylindrical gear The Gearbox for js concrete mixer, and the ZQH type is a cylindrical gear The Gearbox for js concrete mixer,

which is formed on the basis of the ZQ type involute cylindrical gear The Gearbox for js concrete mixer series. Time proves that

the arc gear has longer life, higher capacity, higher strength and less tooth surface wear than the

involute gear of the same specification. These two types of Gearbox for js concrete mixer are mainly used for lifting machinery, and can also be used in general

equipment such as mining machinery, chemical industry, and light industry. The adaptation conditions

are as follows: the high speed shaft speed is not more than 1500r/min; the working ambient temperature

is -40 to +45 degrees. It is suitable for both forward and reverse directions.

JZQ500 gearbox The Gearbox for js concrete mixer, JZQ series The Gearbox for js concrete mixer: The product has been optimized and has reached the

international equivalent level. The Gearbox for js concrete mixer is widely used in construction, lifting, metallurgy, transportation,

cement, chemical, light industry, energy and paper industries, and plays a role in transmission and

deceleration.

The high speed shaft speed is no more than 1500 rpm. The ambient temperature of the work is -40

degrees Celsius to +45 degrees Celsius. Because the box structure is horizontally divided and fully

enclosed, the mechanical properties are good, the work is reliable, and the maintenance is convenient.

This machine has been unanimously affirmed by customers in the heavy machinery industry. The

machine also has strong overload capability, impact resistance and small moment of inertia. It is suitable

for frequent lifting and positive and negative running.

Zq The Gearbox for js concrete mixer model example

The total center distance of ZQ series The Gearbox for js concrete mixer is 500mm, the speed ratio is i=40.17 (here we are talking

about the actual transmission ratio, the nominal transmission ratio of zq The Gearbox for js concrete mixer and the actual transmission

ratio are shown in the table below), the assembly form is II, the output shaft C gear type

ZQ The Gearbox for js concrete mixer ZQ200 The Gearbox for js concrete mixer ZQ200, ZQH200, JZQ200 cylindrical gear The Gearbox for js concrete mixer ZQ The Gearbox for js concrete mixer ZQ250

The Gearbox for js concrete mixer ZQ250, ZQH250, JZQ 250 cylindrical gear The Gearbox for js concrete mixer, ZQ350, ZQH350, JZQ 350 cylindrical

gear The Gearbox for js concrete mixer, ZQ400, ZQH400, JZQ 400 cylinder Gear The Gearbox for js concrete mixer, ZQ500, ZQH500, JZQ 500

cylindrical gear The Gearbox for js concrete mixer, ZQ650, ZQH650, JZQ 650 cylindrical gear The Gearbox for js concrete mixer, ZQ850, ZQH850,

JZQ 850 cylindrical gear The Gearbox for js concrete mixer, ZQ1000, ZQH1000, JZQ 1000 cylindrical gear The Gearbox for js concrete mixer. ZQ type

It is an involute cylindrical gear The Gearbox for js concrete mixer, and the ZQH type is an arcuate cylindrical gear The Gearbox for js concrete mixer.

Each type of The Gearbox for js concrete mixer is suitable for building materials, lifting, transportation, metallurgy, chemical

and light industry. The speed of the high speed shaft does not exceed 1500r/min, the peripheral

speed of the gear is not more than 12m/s, the efficiency is not lower than 0.94, and the working

environment is -40°C-+40°C, which can run in reverse rotation.

Analysis of the reasons for the oil leakage of the gearbox for js concrete mixer: 1. The pressure difference between the inside and outside of the gearbox for js concrete mixer: During the operation

of the gearbox for js concrete mixer, the friction of the motion pair is heated and affected by the ambient temperature,

so that the temperature of the gearbox for js concrete mixer rises. If there is no vent hole or the vent hole is blocked,

the pressure inside the machine gradually increases. The higher the internal temperature, the

greater the pressure difference from the outside, and the lubricating oil leaks from the gap

under the pressure difference. 2. The structure design of the gearbox for js concrete mixer is unreasonable. 1) Check that the hole cover is too thin, and it is easy to deform after tightening the bolt, so that

the joint surface is not flat and oil leakage from the contact gap; 2) During the manufacturing process of the gearbox for js concrete mixer, the casting is not annealed or aging treated,

the internal stress is not eliminated, deformation is inevitable, and a gap is generated, resulting

in leakage; 3) There is no oil return tank on the tank, and the lubricating oil accumulates in the shaft seal,

the end cover, the joint surface, etc., and leaks from the gap under the pressure difference; 4) The design of the shaft seal structure is unreasonable. In the early stage, the oil The Gearbox for js concrete mixer and

the felt ring type shaft seal structure were mostly used, and the felt was compressed and

deformed during assembly, and the joint surface gap was sealed. If the journal is not ideally in

contact with the seal, the seal will fail in a short period of time due to the extremely poor compensation

performance of the felt. Although there are oil return holes in the oil groove, it is easy to block,

and it is difficult to play back the oil.

3. Too much fuel: During the operation of the gearbox for js concrete mixer, the oil pool is agitated very much. The

lubricating oil splashes everywhere in the machine. If the amount of oil is too much, a large

amount of lubricating oil will accumulate in the shaft seal, joint surface, etc. Causes a leak.

4, improper maintenance process: in the equipment maintenance, due to the incomplete

removal of dirt on the bonding surface, or the improper selection of sealant, the reverse

direction of the seal, the replacement of seals in time, etc. will also cause oil leakage

The best service from our transmission drive expert to your inbox directly.

Our Service

Get in Touch

Yantai Bonway Manufacturer Co.ltd

ANo.160 Changjiang Road, Yantai, Shandong, China(264006)

T+86 535 6330966

W+86 185 63806647