Products

Electric motor reducer

helical worm electric motor reducer for sale, helical worm gear, helical gear vs worm gear, worm electric motor reducer efficiency, double helical electric motor reducer, inline helical electric motor reducer, Introduction to worm electric motor reducer

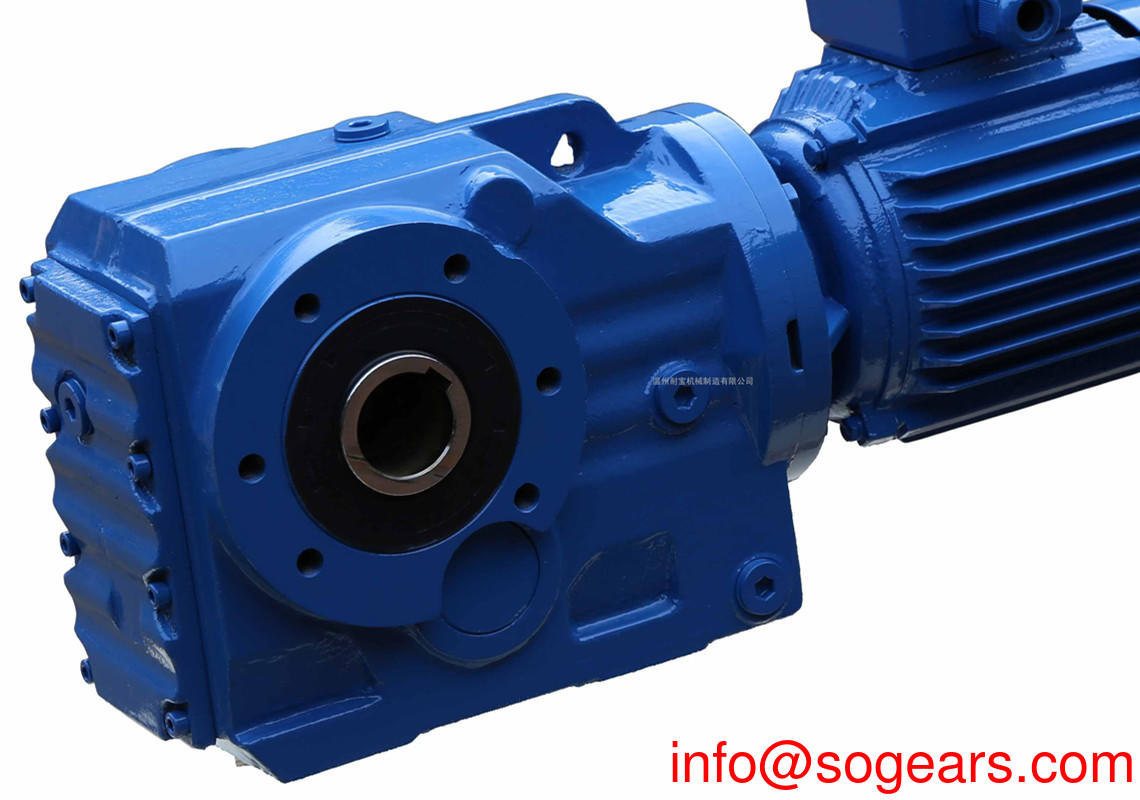

Do you want a drive solution with a high level of performance and energy efficiency? If yes, then we recommend our company's S..DR..

series of high quality helical gear-worm geared motors. These motors can be deployed separately in a modular system. This way, you get a

very wide range of sizes, reduction ratios and motor sizes. However, the biggest strength of the motor is its smooth running and extremely low running noise. Certainly - choose the S..DR.. series of

helical gears - worm geared motors, you have chosen a powerful drive solution that has hardly been heard of

ndex="0">The worm gear-helical gear reduction motor adopts the direct connection mode of the motor, and the structure is a first-stage helical gear

plus a first-stage worm gear transmission. The output is shaft mounted, There are six basic installation forms. It can be reversed and run, and the helical gear adopts hard tooth surface. Smooth operation, large carrying capacity, working environment temperature -10 ° C ~ 40 ° C, this product has the characteristics of large speed range, compact structure and convenient installation compared with

similar products. Can be widely used in metallurgy, mining, lifting, light industry, chemical, transportation, construction and other mechanical

equipment speed reduction mechanism.

The overall solution also allows you to enjoy more practical product features and advantages. These advantages include that the helical

gear-worm gear combination is much more energy efficient than a single helical gear-turbo worm reducer. This is the way you save extra

energy in your system and significantly reduce your current operating costs. You will receive the S..DR.. series of low-noise helical gears - worm geared motors - with a wide range of AC motors to meet your individual

needs. Furthermore, you are free to configure all relevant properties. In this way, you can effectively take advantage of all the advantages

of this combination of low-noise helical gear-worm electric motor reducer and optimized motor. A more versatile combination is possible thanks to

flange-mounted or foot-mounted versions and the choice of solid or hollow shafts. Helical worm electric motor reducer The helical electric motor reducer is a novel reduction gear. Adopting the optimization, the advanced design concept of the modular combination

system has the characteristics of small size, light weight, large transmission torque, stable starting, fine classification of transmission ratio,

etc., and can be connected according to user requirements and a variety of installation positions.

The worm electric motor reducer is a power transmission mechanism that uses a gear speed converter to decelerate the number of revolutions of the motor (motor) to the required number of revolutions and obtain a mechanism with a large torque. In the mechanism for transmitting power and motion, the range of applications of the reducer is quite extensive.

Helical worm electric motor reduceres. Series S, The worm reduction gears come in two series: X and H. The series X, featuring a worm and worm wheel set, is available inApplication range, It can be seen in the transmission system of various types of machinery, from ships, cars, locomotives, heavy machinery for construction, processing equipment and automatic production equipment used in the machinery industry, to household appliances that are common in daily life. clocks, etc.

Its application can be seen from the transmission of large power, to small loads, accurate angular transmission can be seen in the application of the reducer, and in industrial applications, the reducer has the function of deceleration and increased torque. Therefore, it is widely used in speed and torque conversion equipment.

S series helical electric motor reducer hollow shaft Output torque can reach 20 and our shaft gear motor in stock, helical worm Gear motor for sale, we are the worm gear motor distributor, Classification of worm electric motor reducer, also the Manufacturer of electric motor reducer - Crusher Helical electric motor reducer, Shaft Mounted electric motor reducer, Fenner Shaft Mounted electric motor reducer electric motor reducer and Worm Reduction electric motor reducer.

Sogears Precision Planetary electric motor reducer helical electric motor reducer Ratio 5 serve motor sanem as the S series solid shaft helical worm motor reductor reverse trike kit electric motor reducer for heavy duty and High Quality NMRV Series worm gear motor for sale nmrv030 worm electric motor reducer motor . Main models: WP series worm electric motor reducer, WH series worm electric motor reducer and CW series worm electric motor reducer.

WP series:

Includes WPA/WPS/WPW/WPE/WPZ/WPD.

WH series:

Includes WHT/WHX/WHS/WHC.

CW series:

Includes CWU/CWS/CWO.

RV series:

Includes RV/NMRV/NRV.

Our Quality High Torque Helical Worm Gear Motor electric motor reducer For Industrial / Converter for sale. buy cheap High Torque Helical Worm Gear Motor electric motor reducer from sogears manufacturing, the China Helical Worm Reducer manufacturer, choose the high quality Worm Reduction Gear, Helical Worm Gear,Flange Mounted Reducer. Contact sogears now. Get the Sogears Drive Product Catalog and Engineering Manual, Double Enveloping Worm Gears & electric motor reducers.

Wholesale Trader of electric motor reduceres - Inline Helical electric motor reducer, Planetary electric motor reducer, Inline Helical electric motor reduceres and sogears Helical worm electric motor reducer offered by our Engineers, Call UsGet Best Price. We supply the best Power Transmission Solution, offers a tradition of leadership in custom and standard helical worm gear and helical gear products provide solutions. Lots of our Helical worm gearmotors achieve high torque at low speeds but with the affordable prices. They are assembled in the USA for the North American market. They have higher shock tolerance for shock loading compared to helical electric motor reducers. A worm electric motor reducer, like the worm model, is a right angle electric motor reducer.

We have gained vast expertise in offering a superior helical worm electric motor reducer for sale to our clients at effective prices. These are mostly found its perfect usages. also for our parallel shaft and a helical-worm electric motor reducer have an efficiency of 97% but costs half of the price of the helical worm electric motor reducer.

The use of state of the art helical and worm gear combinations affords optimum performance fulfilling a wide variety of ratio requirements. Interchangeable with SEW brand's. but we have a short time deliver date. The main functions of the reducer are:

- Reduce the speed and increase the output torque at the same time. The torque output ratio is multiplied by the motor output and the reduction ratio, but it should be noted that the rated torque of the reducer cannot be exceeded.

- Deceleration also reduces the inertia of the load, and the reduction of inertia is the square of the reduction ratio. You can see that the general motor has an inertia value.

Sogears has seven types of worm reduction gear which are max21, standard, stage, mighty, century, and helical worm gear reduction gears, and screw jack, all is with Low price; Beautiful design : Standardized shape, and the appearance is giveing the good qulaity as the first fight.

product description: 1. S series helical gear worm reducer has high technical content. It has a combination of helical gear and worm gear to improve the torque

and efficiency of the machine. This series of products has complete specifications, wide speed range, good versatility, adapt to various

installation methods, performance, safety and reliability, long service life, and implementation of international standards. 2. The surface of the body has concave and convex heat dissipation, strong vibration absorption, low temperature rise and low noise. 3. The machine has good sealing performance and strong adaptability to the working environment. 4. The machine has high transmission precision, especially suitable for working in places with frequent start-up. It can be connected with

various types of reducers and equipped with various types of motor drives. It can be installed in the 90-degree transmission operation

position. 5. The key components of the geared motor adopt high wear-resistant materials and have undergone special heat treatment. It has the

characteristics of high processing precision, stable transmission, small volume bearing capacity and long service life. 6. The reducer can be equipped with various types of motors to form an electromechanical integration, which fully guarantees the quality

characteristics of the products. technical parameter: Power: 0.18KW ~ 22KW Torque: 10N·m~4890N·m Output speed: 0.12 ~ 397r / min structure type: S-shaft extension joint SF-shaft extension type, flange installation S...S- indicates axis input SA-axis mounted connection SAF-shaft mounted, flange mounted

The design is simple and cost-effective. Suitable for occasions where installation space is limited. Use S-Series reducers for simple tasks for

your machine or plant application. The combination of the worm gear and the helical gear is more efficient than a simple worm electric motor reducer. Sliding friction makes the reducer

run smoothly and quietly. Torque ranges from 92 Nm to 4,000 Nm. Using the modular concept, the S series reducer is connected to the AC motor to form a S..DR.. helical gear-worm geared motor, and

connected to the servo motor to form a S..CMP servo helical gear-worm gear reduction Motor.

You can also choose the AC motor or servo motor that meets your requirements.

Features of worm electric motor reducer:

- Advantages: Long service life, low input speed range, and large deceleration range. The self-locking function is suitable for lifting work, such as elevators, hoists, etc., and the worm electric motor reducer is indispensable.

- Disadvantages: Work efficiency is too low, only between 60% and 70%. Moreover, worm gears are usually output as shafts. It is difficult to control the air return, especially when the turbine and the worm are running for a long time, the air return is relatively large. Usually level.

Precautions:

- Do not hammer the casing of the reducer by gravity to avoid damage.

- Regularly check whether the installation foundation, seals, drive shafts, etc. are normal.

- If used normally, the maximum temperature of the lubricating oil should be less than 85 °C. If the oil temperature rises abnormally, and abnormal noise or other phenomena occur, it is necessary to stop the inspection immediately and remove the fault before continuing to use.

- Replacement of new spare parts must be officially used after running and load testing.

Application showing:

1. Beer equipment/device/facility/machinery factory/manufacturer (Recommend our G series gear motor including GR, GS, GF, GK; Cycloidal reducer, BYD drum motor)

2. Wine equipment/device/facility/machinery factory/manufacturer (Recommend our RV, WP worm reducer)

3. Environmental Protection Equipment/device/facility/machinery (Recommend our Cycloidal reducer, G series gear motor including GR, GS, GF, GK), such as sewage treatment, refuse treatment

4. Air Blower Factory

5. Chemical machinery/equipment/device/facility (Recommend our Cycloidal reducer, G series gear motor including GR, GS, GF, GK)

6. Building machinery (Recommend our Cycloidal reducer, G series gear motor including GR, GS, GF, GK)

7. Mining equipment/device/facility/machinery (Recommend our Cycloidal reducer, D&Z series hard gear surface electric motor reducer)

8. Conveying equipment/device/facility/machinery (Recommend our Cycloidal reducer, G series gear motor including GR, GS, GF, and GK)

9. Hoisting machinery/equipment/device/facility (Recommend our G series gear motor including GR,GS,GF,GK; D&Z series hard gear surface electric motor reducer; PV series equivalent as Flender HB series electric motor reducer)

10. Powder equipment/device/facility/machinery (Recommend our Cycloidal reducer)

11. Steel Factory/Manufacturer

12. Melting equipment/device/facility/machinery (Recommend our Cycloidal reducer and Worm reducer, such as RV, VF, and WP)

13. Plastic equipment/device/facility/machinery (Recommend our ZLYJ electric motor reducer especially designed for plastic extruder)

14. Cement equipment/device/facility/machinery (Recommend our D&Z series hard gear surface electric motor reducer, PV series equivalent as Flender HB series electric motor reducer; and MBY electric motor reducer)

15. Ceramic machine equipment/device/facility

16. Rubber/Tire equipment/device/facility/machinery (Recommend our Cycloidal reducer, G series gear motor including GR,GS,GF,GK equivalent as SEW, RV worm reducer)

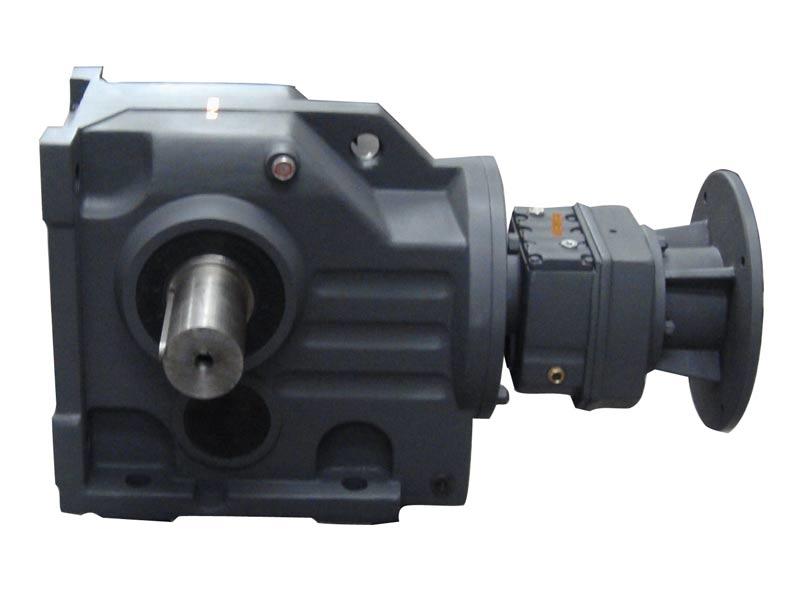

product description 1. The combination of helical gear and worm gear has compact structure and large reduction ratio. 2, installation method: foot installation, hollow shaft installation, flange installation, torque arm installation, small flange installation. 3. Input mode: motor direct connection, motor belt connection or input shaft, coupling flange input. 4. Average efficiency: the reduction ratio is 77% for 7.5-69.39; 62% for 70.43-288; and 57% for S/R combination. 5, and the R series combination can get a larger speed ratio.

6. S series spiral worm electric motor reducer is manufactured in accordance with international technical requirements and has high scientific and

technological content.

7, space saving, reliable and durable, with high overload capacity, power up to 200KW or more

8, low energy consumption, superior performance, reducer efficiency of up to 95%.

9. K spiral worm electric motor reducer has low vibration, low noise and high energy saving.

10, the selection of high-quality section steel material, steel cast iron box, the surface of the gear after high-frequency heat treatment.

11. After precision machining, the reducer that constitutes the helical gear, worm gear and worm gear transmission assembly is equipped

with various types of motors to form electromechanical integration, which fully guarantees the quality characteristics of the geared motor

products.

12.With modular design, the transmission ratio covers a wide range and the distribution is fine and reasonable;

13.After precision machining, the reducer that constitutes the helical gear and the gear transmission assembly is equipped with various types

of motors to form mechatronics, ensuring the quality characteristics of the products.

technical parameter: Power: 0.18KW ~ 200KW Torque: 10N·m~58500N·m Output speed: 0.08 ~ 263r / min Features: 1. The surface of the machine has heat dissipation, strong shock absorption, low temperature rise and low noise. 2. The machine

has good sealing performance and strong adaptability to the working environment. 3. S series helical gear worm electric motor reducer has high

transmission precision, especially suitable for working in places with frequent starting. 4, S key electric motor reducer key components use high

wear-resistant materials, and through special heat treatment, with high processing accuracy,

stable transmission, small volume bearing capacity, long life and so on. 5. The helical electric motor reducer can be equipped with various types of

motors to form an electromechanical integration, which fully guarantees

the quality characteristics of the products.

S series spiral worm electric motor reducer structure: K-Ordinary shaft extension, foot mounting KA-shaft mounting type (hollow shaft) KAZ-shaft mounting small flange type KF-shaft extension

type, flange mounting KAF-shaft mounted type (hollow shaft), flange mounting KAT : Shaft mounted with anti-rotation arm D- indicates normal shaft extension type, shaft input AD- indicates shaft type, shaft input FD-axis extension flange type, shaft input AFD-shaft

mounted flange type, shaft input

S series spiral worm electric motor reducer application range: Widely used in light industry, chemical, plastics, steel and metallurgy, mining, building materials machinery, shipbuilding, petroleum, food,

packaging, textile and paper, assembly line, medicine, environmental protection and other fields.

Characteristics ◆ Highly modular design. ◆ Strong carrying capacity, stable transmission and low noise. ◆ Good sealing performance and wide application conditions. ◆ High carrying capacity and reliable operation. ◆ High transmission efficiency and energy saving. ◆ High cost performance and low maintenance.

Helical gear-worm gear combination efficiency is much higher than that of worm gear only Ultra low noise operation Available variants: Foot or flange mounting B5 or B14 flange mounting Solid or hollow shaft Hollow shaft with keyway connection, locking disc, splined hollow shaft or TorqLOC®

S series worm electric motor reducer is designed and developed by our technicians according to the SEW product architecture model and the actual

use environment and mechanical performance requirements of China's industrial field. This series of products has strong versatility,

convenient use and maintenance, and low maintenance cost. Especially for the production line, only a few internal transmission parts are

needed to ensure the maintenance of the normal production of the whole line. Due to the modular design principle of the unit structure, the

number of parts and stocks is greatly reduced, and the delivery cycle is greatly shortened. High transmission efficiency, low energy

consumption and superior performance. High-rigidity cast iron box with ribs; hard-toothed gears are made of high-quality alloy steel, the

surface is hardened by carburizing and quenching, and the teeth are finished, the transmission is stable, the noise is low, the bearing capacity

is large, the temperature rise is low, and the service life is long. In addition, this series of products adopts a new type of sealing device,

which has good protection performance, strong adaptability to the environment, and can work continuously in harsh environments such as

corrosion and humidity.

After-sales service: According to the user's needs and working conditions, the industry electric motor reducer is customized, involved in different

industry fields, and makes reasonable application solutions for customers in different industries. Long-lasting service support, k-series

reducer size drawings and CAD drawings. The cycloidal pinwheel reducer is a novel transmission device that uses the planetary transmission principle and uses cycloidal pin gear

meshing. The transmission of the cycloidal pinwheel reducer can be divided into three parts: the input part, the deceleration part and the

output part. A double eccentric sleeve with a 180° misalignment is mounted on the input shaft, and two roller bearings called a jib are

mounted on the eccentric sleeve. The central hole forming the H mechanism and the two cycloidal wheels is an eccentric sleeved slewing

bearing. a raceway, and the cycloidal wheel and the needle gear are engaged with a set of annularly arranged pin teeth to form an internal

meshing speed reduction mechanism with a tooth difference of one tooth (in order to reduce friction, in a electric motor reducer with a small speed

ratio) With a needle sleeve on the needle)

Save time and money Once you have selected a geared motor from our company, your selection and project planning will start saving you time and money. This is

because our modular system makes it possible to combine numerous reducers and motors. So you can reduce operating costs, enjoy

extremely long service life and benefit from the simple maintenance that is unique to our company's brand.

The best service from our transmission drive expert to your inbox directly.

Our Service

Get in Touch

Yantai Bonway Manufacturer Co.ltd

ANo.160 Changjiang Road, Yantai, Shandong, China(264006)

T+86 535 6330966

W+86 185 63806647