Products

Right angle helical bevel geared motor

1.Our Right angle helical bevel geared motor Specifications in T Series spiral bevel gear motor, Aluminum Case Manure Spreader Agricultural Bevel Gearbox,

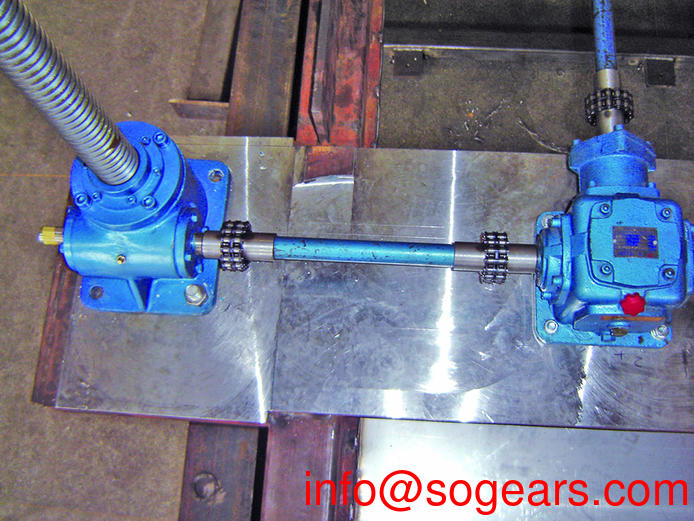

Our Right angle helical bevel geared motor Input mode: Motor connection flange, shaft input Right angle helical bevel geared motor

Our Right angle helical bevel geared motor reducer adopts the general design project, which can change them into special-for-industries Our Right angle helical bevel geared motor according to different requirements of customers.

The utility model discloses a three-stage Right angle helical bevel geared motor, including:Input flange, through the first screw connected with the input flange of the inner ring gear, through the second screw and the gear ring connected the output of the flange, it is set between the input flange and the gear ring transition flange, it is set by typing in transition flange bearing have input shaft, one end of the input shaft described into the input flange and referred to the other end of the input shaft into the shaft connected with the level of sun gear ring, it is first-class wheel set with the sun round the sun, as described in first round the sun and some level of planetary gears meshing with each other, as described within the first planetary gear and ring gear meshing each other,The one-stage planetary gear is arranged on the one-stage planetary gear pin shaft by rolling a one-stage full-roller pin bearing, and one end of the one-stage planetary gear pin shaft is extended and connected with the one-stage planetary gear frame.

Three Right angle helical bevel geared motor

1. Level 3 Right angle helical bevel geared motor, whose character is: including: input flange , through the first screw with input method phase I of the gear ring , by the second screw and internal gear ring the output of the connecting flange in, it is lost into the flange with the ring gear set up between the transition flange, it is the transition flange in by input bearing setting the input shaft , described in the input shaft into the input at the end of the flange, referred to the other end of the input shaft into inner gear ring shaft connected with the level of sun,It is level of wheel shaft the sun set on level 1 round the sun

described in the first round the sun and some level of planetary gear mesh, described in the level of planetary gear and the ring gear mutual engagement, described in the level of planetary gear by level 1 full set rolling needle roller bearings in the primary line of star gear pin , described in the level of planetary gear pin at one end of the first planetary gear and level of planet carrier is connected,Described primary planet carrier by primary planet carrier bearing turn the ring gear set, described in the level of planet carrier set on wheel shaft has a second level of the sun, it is the sun wheel shaft and 2 ^ have second round the sun, described in the second round the sun and if thousands of secondary planet gear mesh, described in the first planet fierce wheel and the ring gear mutual engagement, as described in the secondary planet gear through secondary full needle roll axis f set in the secondary planet gear on the pin shaft.

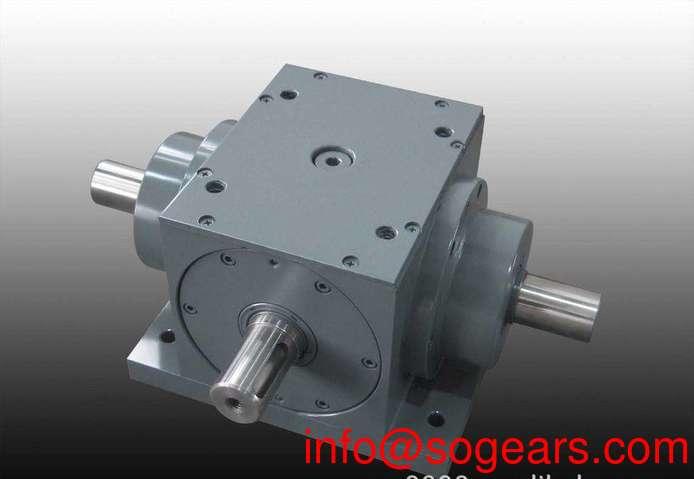

JTP65 Mini high torque right angle gearbox

1. bevel gear ratio 1:1

2. solid drive shafts diameter12mm

3. solid input and output shaft shafts

4. 2 way, 3 way, 4 way gearbox

5. input power maximum 1.8Kw

6. drive torque maximum 13.5Nm

7. maximum input 1500rpm

JTP90 high torque right angle gearbox

1. gear ratios 1:1, 1.5:1, 2:1, 3:1, 4:1 5:1

2. cubic, 6 mount positions, universal mount

3. solid shaft, hollow shaft, motor flange

4. 2 way, 3 way, 4 way gearbox

5. input power maximum 6Kw

6. drive torque maximum 43.3Nm

7. maximum input 1500rpm

JTP110 high torque right angle gearbox

1. gear ratios 1:1, 1.5:1, 2:1, 3:1, 4:1 5:1

2. cubic, 6 mount positions, universal mount

3. solid shaft, hollow shaft, motor flange

4. 2 way, 3 way, 4 way gearbox

5. input power maximum 11Kw

6. drive torque maximum 78.3Nm

7. maximum input 1500rpm

Described secondary planet gear pin at one end of the secondary planet gear connected to two levels of planetary frame, described the secondary planet carrier through the secondary planet carrier bearing turn the ring gear set, it is the secondary planet carrier is set on the three wheel shaft , the sun is above level 3 wheel shaft and the sun set level 3 round the sun is placed, as described in 3 and if the sun round thousand 3 planetary gears ^ mutually close, described ^ 2 planetary gears and the inner gear ring mutual engagement,Described three planetary gears through the three-level full roll ^ ^ axis (2 = rolling dynamic setting in the tertiary planet gear pin, described in the tertiary planet gear pin at one end of the three planetary gears connected to tertiary planet frame , described in the tertiary planet carrier through the three-level planet carrier bearing turn the set within the inner ring gearbox.

JTP140 high torque right angle gearbox

1. gear ratios 1:1, 1.5:1, 2:1, 3:1, 4:1 5:1

2. cubic, 6 mount positions, universal mount

3. solid shaft, hollow shaft, motor flange

4. 2 way, 3 way, 4 way gearbox

5. input power maximum 23. 9Kw

6. drive torque maximum 170Nm

7. maximum input 1500rpm

JTP170 high torque right angle gearbox

1. gear ratios 1:1, 1.5:1, 2:1, 3:1, 4:1 5:1

2. cubic, 6 mount positions, universal mount

3. solid shaft, hollow shaft, motor flange

4. 2 way, 3 way, 4 way gearbox

5. input power maximum 39.2Kw

6. drive torque maximum 290Nm

7. maximum input 1500rpm

it is the output flange by output within set output shaft bearing 'levies, the output ^ ^ at one end into inner gear ring connected to tertiary planet frame ,Stated out the other end of the output shaft output flange, it is inside the ring gear of the lateral sliding sleeve is equipped with the first lock ⑽ a screw and a second locking screw air \ 'it is the first locking screw within the inner ring gear set up with the first locking screw cooperate with each other the first ring , it is to enter the outer edge of the flange set has input flange lock male thread , it is transition, LAN set up have transition flange lock male thread.

JTP210 high torque right angle gearbox

1. gear ratios 1:1, 1.5:1, 2:1, 3:1, 4:1 5:1

2. cubic, 6 mount positions, universal mount

3. solid shaft, hollow shaft, motor flange

4. 2 way, 3 way, 4 way gearbox

5. input power maximum 67.5Kw

6. drive torque maximum 520Nm

7. maximum input 1500rpm

JTP240 high torque right angle gearbox

1. gear ratios 1:1, 1.5:1, 2:1, 3:1, 4:1 5:1

2. cubic, 6 mount positions, universal mount

3. solid shaft, hollow shaft, motor flange

4. 2 way, 3 way, 4 way gearbox

5. input power maximum 90.5Kw

6. drive torque maximum 694Nm

7. maximum input 1500rpm

JTP280 high torque right angle gearbox

1. gear ratios 1:1, 1.5:1, 2:1, 3:1, 4:1 5:1

2. cubic, 6 mount positions, universal mount

3. solid shaft, hollow shaft, motor flange

4. 2 way, 3 way, 4 way gearbox

5. input power maximum 156Kw

6. drive torque maximum 1199Nm

7. maximum input 1500rpm

It is the first locking screw is set to the input flange lock male threaded flange lock reciprocal input box and locking of the transition flange thread f1 match of transition flange lock box, it is the second lock nut within the inner ring gear set up the first lock nut reciprocal second limit ring , it is the output flange set has output flange lock ^ male thread ,In lai two locking screw ⑽ has with the output flange lock is installed inside the male thread ⑽ interaction of flange lock box.

Our Right angle helical bevel geared motor apply sound-absorption box structure. The larger surface area and big fan, column gear and helical gearwheels all introduce the advanced gear-grinding craft which can lower the noise, improve the running reliability and efficiency of Right angle helical bevel geared motor. Meanwhile, Our Right angle helical bevel geared motor reducer we manufacture is in accord with the quality standards of both China and abroad.

Background technology:

Machine of decelerate of planet of the planetary gear in addition to like fixed axis gear around its own rotation axis rotation, their rotation axis and the planetary frame around the axis of the other gear wheel (the sun), spinning around its axis of rotation to become, revolves around other gear axis of rotation is called, as in the solar system planets, hence the name.It can be used in modern robot industry, such as parallel robot or linear robot, but also often used in CNC machine tools and machining center field, the application range is wide.Current machine of decelerate of planet of single-stage planetary gear structure is used in most of the single-stage planetary gear structure output torque is small, the applicable scope is small, the structure performance is poor, easy to damage, change frequently, at the same time, the existing input output flange, transition flange and flange are connected by screw and the gear ring, the connection is not tight, in the process of deceleration chance done vibration is larger, easy to cause the flange and the gear ring joint gap increases gradually, and eventually cause a dislocation of the Right angle helical bevel geared motor of gear, reducer failure even scrapped.

2.Characteristics of Right angle helical bevel geared motor:

Brand-new hard gear surface big power change gear set possesses big torque scope and adapts unit structure modularization design and can be installed horizontally and vertically and has solid shaft output, hollow shaft output and contract disk hollow shaft output. Right angle helical bevel geared motor reducer applied scope is wide.Our Right angle helical bevel geared motor is made of high strength quality alloy steel through quenching and possesses high efficiency and long life gear and can bear large axial and radial load. Right angle helical bevel geared motor reducer features low in run noise, high in reliability, compact and so on.

Technical implementation elements:

The technical problem to be solved by the invention is to provide a three-stage Right angle helical bevel geared motor flange locking structure with tight flange connection.

In order to solve the above technical problems, the technical solution adopted by the present invention is: flange locking structure of three-stage Right angle helical bevel geared motor, including:Input flange, through the first screw connected with the input flange of the inner ring gear, through the second screw and the gear ring connected the output of the flange, it is set between the input flange and the gear ring transition flange, it is set by typing in transition flange bearing have input shaft, one end of the input shaft described into the input flange and referred to the other end of the input shaft into the shaft connected with the level of sun gear ring, it is first-class wheel set with the sun round the sun, as described in first round the sun and some level of planetary gears meshing with each other, as described within the first planetary gear and ring gear meshing each other

Described in the level of planetary gear by level 1 full needle bearing rolling set on the level of the planetary gear pin shaft, described in the level of planetary gear pin out at the end of the level of planetary gear connected to the primary planet carrier, it is primary planet shelf with secondary sun wheel, it is the secondary setting of the sun on the shaft has a secondary round the sun, described in the second round the sun with a number of secondary planet gear meshing, described the secondary planet gear meshing with inner gear ring, described the secondary planet gear by secondary full needle bearing rolling set on the secondary planet gear pin shaft,Described the secondary planet gear pin out at the end of the secondary planet gear connected to the secondary planet carrier, it is the secondary planet shelf set three the sun wheel, it is 3 the sun wheel set with 3 round the sun, as described in 3 the sun wheel and a number of 3 planetary gears meshing with each other,

described three planetary gear meshing with inner gear ring, described in the tertiary planet gear by level 3 full needle bearing rolling set on the tertiary planet gear pin shaft, described in the tertiary planet gear pin out at the end of the tertiary planet gear connected to tertiary planet carrier, it is through the output shaft bearing set output flanges with output shaft,Described within the end into the ring gear output shaft connected to tertiary planet carrier, referred to the other end of the output shaft output flange,

it is inside the outer edge of the ring gear sliding sleeve is equipped with the first lock and the second lock screw, a screw it is the first locking screw within the circle of inner gear set has the co-ordination with the first lock screw the first limit ring, it is the input flange lateral set has input flange lock male thread, it is transition flange with transition flange lock male thread,It is the first locking screw is set to the input flange lock the input of the male thread together flange lock box and locking of the transition flange thread reciprocal transition flange lock box,

it is the second lock screw within the inner gear ring set with second in conjunction with the second lock screw spacing ring, it is set on output flanges are output flange lock male thread, it is the second lock nut is set up with the output flange lock the output of the male thread together flange lock box.

The advantage of the present invention is: the tertiary Right angle helical bevel geared motor flange lock structure, adopts the tertiary planet Right angle helical bevel geared motor, large output torque, wide scope of application, structure performance is good, not easy to damage, at the same time, the input output flange, flange and flange with locking set of inner gear ring further lock is fixed, compact connection, can prevent deceleration chance the vibration caused in the process of the clearance between the inner gear ring joint and flange, good structural strength, put an end to happen the gear within the gear ring of the dislocation, effectively protect the reducer.

3.Details of Our Right angle helical bevel geared motor reducer:

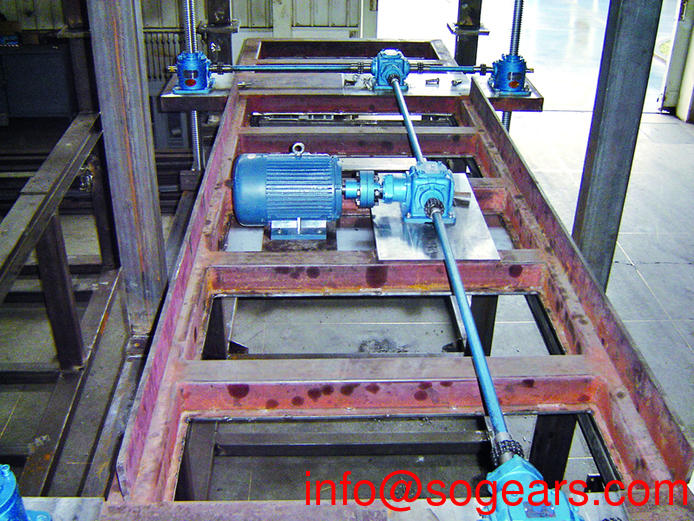

3.1 Our Right angle helical bevel geared motor: can perform vertical crossing axis, vertical functions, with its components species decreasing, and specs increasing.

3.2 Right angle helical bevel geared motor reducer Input mode: Motor connection flange, shaft input.

3.3 Our Right angle helical bevel geared motor Output mode: solid shaft with flat keys, hollow shaft with flat keys, bulge-tight discal coupling hollow shaft, spline coupling hollow shaft, spline coupling solid shaft and flange coupling solid shaft.

Reducer is an important transmission device connected motor and host device, is widely used in cement production line, especially the application of large-scale reducer is common, there are vertical mill, roller press of reducer reducer, tube mill reducer reducer, kiln, etc., can say large reducer drives the cement production line is the key equipment of the operation.With the rapid development of jidong cement group, the maintenance business volume of reducer keeps increasing. A reducer maintenance center has been set up, which is mainly responsible for offline and online repair of the reducer of vertical mill, roller press and pipe mill.

3.4 Right angle helical bevel geared motor reducer Installation type: horizontal, vertical, base-swing type, force arm-twisting types

3.5 Right angle helical bevel geared motor has specs ranging of 3~26, deceleration transmission grades range of 1~4, speed ratio: 1.25~450, if combined with our R K S series it will produce a higher speed ratio

Background technology:

Right angle helical bevel geared motor is a kind of high efficiency Right angle helical bevel geared motor which can increase the output torque and reduce the load

Equivalent inertia, efficiency up to 96%.MOTEC (China) has been working on precision Right angle helical bevel geared motor for many years

Production, provide four series of products hundreds of models, from economic to high precision, widely used in aerospace, aviation,

CNC, welding, cutting, packaging, printing and other industries.

In addition, we can also customize products according to customers' special requirements, such as expanding the temperature range, special size,

Key input, double shaft, foot installation, customized high precision.

Right angle helical bevel geared motor is a kind of efficient transmission device which can reduce the rotation speed and increase the torque through the transmission of planetary gear system, and reduce the load equivalent inertia.Each set of planetary gear train is composed of sun wheel, planetary wheel and inner gear ring (wheel).A planetary gear train is a set of concentric shaft gears.Compared with other types of Right angle helical bevel geared motor, Right angle helical bevel geared motor has the characteristics of high transmission efficiency, high precision, small size, smooth operation, maintenance-free, long life.MOTEC (China) has been committed to the production of precision planetary reducer for many years, to provide customers

Four series of products hundreds of models, widely used in aerospace, aviation, CNC, welding, cutting, packaging, printing and other industries.In addition, we can according to customer's special requirements customized products, such as widening the temperature range, special size, key input, double shaft, foot installation, customized high precision.

Deceleration ratio: the ratio of output speed and input speed.

Series: refers to the number of sets of planetary gear planetary reducer.Because one set of planetary gears cannot meet the larger transmission ratio, sometimes two or three sets are needed to meet

User requirements for larger transmission ratio.As a result of increasing the number of planetary gears, so the length of the second or third Right angle helical bevel geared motor will be increased, the efficiency

It's going to go down.

Return clearance: when the output end is fixed and the input end is rotated clockwise and counterclockwise to produce rated torque ±2% at the output end, the input end of the reducer is

A small angular displacement, the angular displacement is the return clearance.The unit is "fen", one-sixtieth of a degree.The return journey given in this sample

Clearance value refers to the output end of the reducer, that is, the value divided by the deceleration ratio.

Moment of inertia: this value in this sample refers to the input end.

Full load efficiency: refers to the transmission efficiency of the reducer under the maximum load (the output torque of fault stop).

Average life: the continuous working time of the reducer at the highest input speed under the rated load.

Noise: measured in decibels (dB).This value is measured when the input speed is 3000 RPM without load and 1 meter away from the reducer.

Product performance profile of cycloid needle wheel reducer:

Main technical parameters and features: adopt the whole series of modular combined design and manufacturing, low noise, high torque, no oil leakage, a variety of installation methods, the formation of mechanical and electrical integration of the transmission device.Right angle helical bevel geared motor from 0.25KW-55KW, output torque up to 70N.M-20000N.M, if a lower output speed, can be used in the form of two-stage Right angle helical bevel geared motor or even three-stage combination.Can be equipped with different types of motor (ordinary motor, single-phase motor, explosion-proof motor, variable frequency motor, brake motor, etc.).Right angle helical bevel geared motor is widely used in food and grain machinery, printing and packaging machinery, environmental protection machinery, conveying equipment, chemical equipment, metallurgical mining equipment, iron and steel power equipment.

Basic principle of Right angle helical bevel geared motor:

The whole transmission device of Right angle helical bevel geared motor can be divided into three parts: input part, deceleration part and output part.

The input shaft is equipped with a double-eccentric sleeve with a displacement of 180°, and two roller bearings are installed on the eccentric sleeve to form H mechanism. The center hole of the two cycloid wheels is the raceway of the rotary arm bearing on the eccentric sleeve, and the cycloid wheel is meshed with a group of ring arranged needle gears on the needle gear to form a reduction gear mechanism with less tooth difference.In order to reduce the friction, in the speed ratio is small reducer, the needle tooth with a needle tooth cover.

When the input shaft with eccentric sleeve rotation for a week, as a result of the cycloid gear tooth profile curve characteristics and restricted by needle on the gear teeth, the movement of the cycloid gear becoming both revolution and rotation of the plane movement, as the input shaft is made for a week, eccentric sleeve also turn the week, cycloid gear in the opposite direction around a tooth difference reduction is obtained, then with the help of W output mechanism, the cycloid gear rotates at low speed movement through the pin shaft, passed to the output shaft, low output speed can be achieved.

Detail, parameters, performance, structure and representation of Right angle helical bevel geared motor:

A, cycloidal pinwheel reducer is a relatively new type of transmission mechanism, its unique stable structure, and in many cases the alternative ordinary cylindrical Right angle helical bevel geared motor, the worm gear and worm reducer, because of cycloidal pinwheel reducer machine has: high speed ratio and high efficiency, compact structure, small volume, smooth operation, low noise, reliable operation, long service life, reasonable design, easy to install decomposition, etc.

Second, cycloidal pinwheel reducer is a kind of less tooth differenced planetary transmission principle of adopting novel reduction gear, which can be widely used in petroleum, chemical, textile, pharmaceutical, food, printing, lifting, mining, metallurgy, construction, power generation, as a driver or reduction gear, suitable for working temperature of plus or minus 40 degrees, therefore, cycloidal pinwheel reducer is well accepted by users and has been widely used in various industries and fields.

With Best Regards,

Cherry Zhang ( Sales Department; Miss. )

NER GROUP CO.,LIMITED

Yantai Bonway Manufacturer Co., Ltd

Tel:+86-535-6330966

Mobile:+86-18865558975

The best service from our transmission drive expert to your inbox directly.

Our Service

Get in Touch

Yantai Bonway Manufacturer Co.ltd

ANo.160 Changjiang Road, Yantai, Shandong, China(264006)

T+86 535 6330966

W+86 185 63806647