Torque limiters

Torque limiter is a mechanical overload protection device, which is often installed between the drive side and the load side of the power transmission. Once overload occurs and the transmission torque exceeds the set value, it will disengage or slip, thereby causing the power transmission The active and passive sides of the machine are separated to protect the mechanical equipment from damage caused by overload.

·Common types are:

1. Ball type torque limiter;

2. Friction type torque limiter;

3. Pneumatic torque limiter;

4. Push/pull force limiter.

·The overload torque is adjustable; the overload electrical signal can be provided at the moment of overload; the torque accuracy is high and the response is sensitive.

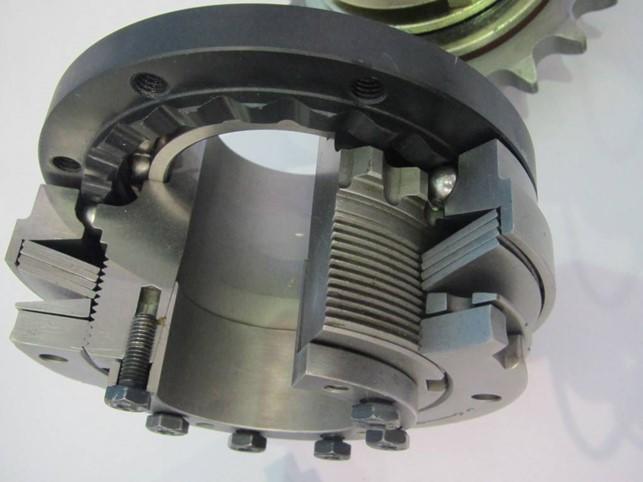

Friction type torque limiter

Pressure is applied by the disc spring to the friction plate, and when the torque exceeds the set value, friction and slippage will occur between the active and passive fingers;

The disengagement torque can be adjusted steplessly within a certain range through the dial;

The slipping time should not be too long, and it is suitable for intermittent and impact overload.

Friction structure, when the torque exceeds the set value, the drive side and load side will produce friction and slip

Customers can install pulleys, sprockets, gears and other components by themselves

Adjustable overload slip torque

The continuous slip time should not be too long, suitable for intermittent and impact overload occasions

The price is relatively economical and affordable.

Ball Torque Limiter

Built-in precision ball mechanism, when the torque exceeds the set value, the active and passive transmission will be disconnected, reaction time: 1-3 milliseconds;

The disengagement torque can be adjusted steplessly within a certain range through the dial, with high torque accuracy, sensitive response, safe and reliable;

Output overload electrical signal at the moment of disconnection.

Push-pull force limiter

A device dedicated to overload protection of linear transportation (push-pull force), with a built-in precision spring ball mechanism. When the thrust or pull force exceeds the set value, a buffer slip will be generated, and the sensor will send an electrical signal for instant shutdown;

The overload force setting value can be adjusted steplessly within a certain range through the dial (after setting, the overload thrust value and the overload tension value are equal)

It can output 24V DC signal at the moment of overload, which can be used to turn off the driver instantly, and it can also be used to start the alarm device.

Precision ball type torque limiter

·Built-in precision ball mechanism, when the torque exceeds the set value, the drive side and the load side are completely separated

·Response time: 3 milliseconds, safe and reliable mechanical overload protection device

·Use elastic coupling, both sides are shaft holes (with keyway, spline, expansion sleeve can be selected)

·The overload release torque is adjustable. Output electrical signal at the moment of overload for alarm or automatic shutdown.

The torque limiter is a component that connects the driving machine and the working machine. The main function is overload protection. The torque limiter is when the required torque exceeds the set value due to overload or mechanical failure, it limits the transmission system in the form of slip The torque of the transmission will automatically restore the connection when the overload situation disappears. This prevents mechanical damage and avoids expensive downtime losses.

definition:

Only a mechanical torque limiter can quickly cut off the connection between the motor and the spindle, thereby eliminating the destructive effect of inertial force. For ordinary machinery, including conveyor transmission, office machinery and various instruments and meters, mechanical torque limiters such as shear pin safety couplings and friction clutches can provide good safety protection. However, they still cannot meet the requirements of high-performance equipment such as machine tools. One of the problems faced is that the common decoupler and coupling transfer torque and deviation to the protected shaft. In special applications, there are other problems. However, the safety coupling is a new type of mechanical torque limiter, which can overcome the above-mentioned traditional problems. Safety couplings are most suitable to ensure that high-speed, high-precision driving devices are not damaged by overload. This kind of coupling is not a refinement of an ordinary torque limiter, but a product specially designed in cooperation with the machine tool manufacturer to meet certain specific requirements. The price of protection devices with safety couplings is also lower.

characteristic:

All safety couplings have the following characteristics:

1. There is no gap in the keyless sleeve connection;

2. High torsional rigidity, low moment of inertia, small size, and separation torque can be adjusted arbitrarily;

3. The original position can be kept unchanged after reconnecting the station;

4. It can alarm when overloaded;

5. Two types of automatic reconnection and non-automatic reconnection are available, with heat resistance (above 260℃). In addition, certain types of safety couplings also compensate for the axial, lateral, and angular displacement of the shaft. On the pulleys and sprockets, some have integral ball bearings. The above-mentioned characteristics make the safety coupling not only suitable for machine tool transmissions, but also for high-performance assembly lines, printing machinery, packaging machinery, etc.

classification:

1. Steel ball type safety coupling;

2. Steel sand type safety coupling;

3. Hydraulic safety coupling;

4. Friction type safety coupling;

5. Magnetic powder type safety coupling.

Features:

The internal tension type friction safety coupling is a structural type of the friction safety coupling. It uses two cylindrical coil springs to compress the arcuate friction plates through the intermediate ring to generate friction between the friction plates. The size determines the sliding torque of the coupling. Adjust the sliding torque of the coupling by replacing the spring. When the transmitted torque exceeds the sliding torque of the Lingsi coupling, the coupling's main and driven sides will slip; when the transmitted torque is lower than the sliding torque, the coupling will automatically recover without relative sliding on both sides normal work.

It works normally within the scope of use, and generally does not need to replace parts. Under the premise of correct use of the AMN type internal tension friction safety coupling, it can effectively partially reduce the impact load at the start of the shaft transmission and accelerate the machine At the same time, it can prevent the motor from burning due to overload. It can be used in conditions that require overload safety protection to avoid damage to key components.

The internal tension type friction safety coupling is a type of flexible safety coupling with elastic elements. The two halves of the Lingsi coupling are connected by a double-row roller chain. Relative sliding can occur between the sprocket and the friction plate. , Plays a role of safety protection, the torque is determined according to the compression amount of the butterfly spring, suitable for the transmission shaft system connecting two coaxial lines and parallel axes, and has the performance of compensating the relative deviation of the two shafts, and can limit the torque. Play the role of overload protection.

BML friction type torque limiter protection principle The friction type torque limiter uses a lock nut to make the spring generate elastic force, which acts on the friction plate, and the sprocket and other wheel objects are sandwiched between the two friction plates. The elastic force makes Friction is generated between the friction plate and the sprocket, which can transmit torque. When the equipment is overloaded, relative sliding occurs between the sprocket and the friction plate, but the torque between the two still maintains the slipping (there is still torque transmission, but the drive end is not driven), and the driving end is idling at this time. The transmission end stops. After eliminating the overload, the torque limiter will automatically reset.

The working principle of the BMA steel ball torque limiter uses a precision spring to control the critical torque, which can reach a very precise torque value. For the same size product, different built-in springs can be replaced to determine different slip torque. It is used for one end of the shaft and the other end. The transmission installation can also be equipped with couplings according to customer requirements to facilitate customer shaft-to-shaft linking. When the equipment is overloaded, the transmission end will stop first, and the active end will run idly, but the steel ball type can move axially at the moment of overload, and give a displacement, and a proximity switch can detect this displacement and give a signal. Output, alarm or stop the motor motor to achieve complete automation. After eliminating the overload, the reset method is the only position in a circle (or multiple points as required).

use:

The characteristics and uses of safety couplings are analyzed as follows:

1. The torque control has a wide range and high control accuracy. The torque is proportional to the exciting current in a wide range, which can improve and simplify the control of the transmission torque, and can be used as a linear adjustment element.

2. It has constant torque. The torque depends only on the size of the exciting current, and has nothing to do with the relative torque of the master and slave sides. It has a constant torque and its static torque is the same as the dynamic torque.

3. It can transmit a certain torque without the same slip, no impact, vibration, no noise, stable operation, and can be used in occasions with higher working frequency.

4. Less power consumption and less control power. The residual torque when the excitation current is disconnected is very small, the disconnection performance is good, there is no heating phenomenon when idling, the torque stability is good, and it can be used for precise control.

5. Simple structure, small size, small quality, magnetic powder does not need to be dry, easy to maintain, magnetic powder has oxidation resistance, good heat resistance, long life and high reliability. When the driven part is fixed, the torque becomes the braking torque to the rotating part, which can become a magnetic powder coupling or a magnetic powder load.

Couplings and clutches:

Couplings and clutches are used to connect shafts and shafts to transmit motion and torque. Sometimes it can also be used as a safety device to prevent the connected parts from being subjected to excessive loads and play an overload protection role. When connecting two shafts with a coupling, the two shafts can be separated only after the machine stops. The clutch can connect and disconnect the two shafts at any time when the machine is running.

There are many types of couplings and clutches, most of which have been standardized and can be selected directly from the standards.

(1) Box conveying overload:

1.1. Under the power-on state, grab the box conveying guide belt and turn the manual wheel until you hear the engagement sound of the torque limiter and drive the box conveying guide belt to move;

1.2. Jog operation after reset to see if the operating angle of each mechanism of the cartoning machine is normal

(2) Material conveying overload:

2.1. Power on, grab the material trough, turn the manual wheel until you hear the sound of the torque limiter engaging and drive the material trough to rotate;

2.2. Jog operation after reset to see if the operating angle of each mechanism of the cartoning machine is normal.

(3) Box suction overload:

3.1. Power on, grab the box suction claw, turn the manual wheel until you hear the torque limiter meshing sound and drive the suction claw to move;

3.2. Jog operation after reset to see if the operating angle of each mechanism of the cartoning machine is normal (the carton sucking claw is vertical at 145°).

(4) Overload of cam divider:

4.1. In the power-off state, turn the manual wheel until you hear the torque limiter engaging sound and the manual cannot be turned;

4.2. Jog after power-on reset to see if the operating angle of each mechanism of the cartoning machine is normal.

2. Overload torque adjustment method

1. Around the dial, there are 3 "fastening screws" and 3 "wrench insertion holes" (filled with paraffin wax). Before adjustment, first loosen the 3 "fastening screws", and then empty the paraffin in the "wrench insertion hole" to facilitate the insertion of the wrench;

2. Adjust the torque. Viewed from the E-E direction, the clockwise direction is to decrease, and the counterclockwise direction is to increase. Please align the required torque scale with the "reference" marking line. The set torque must be between the maximum value and the minimum value, and cannot exceed the range, otherwise the product will be seriously damaged.

3. After setting, please tighten the fastening screws around the dial.

The best service from our transmission drive expert to your inbox directly.

Our Service

Get in Touch

Yantai Bonway Manufacturer Co.ltd

ANo.160 Changjiang Road, Yantai, Shandong, China(264006)

T+86 535 6330966

W+86 185 63806647