We are cycloidal gearbox manufacturers in china and The cycloidal gearbox is an internal meshing reduction mechanism that has a tooth difference of one tooth.

al pin wheel gear box, which belongs to the technical field of gear boxes; the utility model solves the problems of poor gearbox deceleration effect, small torque, poor load capacity of the output shaft and low working efficiency of the gear box in the prior art. The technical solution of the present invention is: a cycloidal pin gear box, a reduction gear box, a power output shaft, and a gear reduction mechanism in the reduction gear box, wherein the gear reduction mechanism includes gears that are sequentially meshed and connected. Gear 2, gear 3, the power output shaft is provided with an eccentric gear set, the eccentric gear set includes a gear 4 with a through hole in the middle, a gear 5 meshed with the gear four, and a power output disk connected to the gear 4 And the three are eccentrically set, the gear three is connected with the gear four interference, the power output disk is sleeved on the power output shaft and can drive the power output shaft to rotate; the beneficial effect is that the structure is more compact, the deceleration efficiency is enhanced, and the gearbox torque is increased. ,high working efficiency.

The reducer is a relatively precise machine that is used to reduce the speed and increase the torque. (Note: Reducer torque calculation formula)

It has a wide variety of models, different models, and different types of uses. There are many types of reducers. According to the transmission type, they can be divided into gear reducers, worm reducers and planetary gear reducers. According to the different drive stages, they can be divided into single-stage and multi-stage reducers. According to the gear shape, they can be divided into cylindrical gears. Machine, bevel gear reducer and cone-cylindrical gear reducer; according to the layout of the drive can be divided into expansion, split and coaxial reducer. cycloidal gearbox manufacturers in china

cycloidal gearbox manufacturers in china, Planetary cycloid reducer is a kind of planetary gear transmission principle. It adopts cycloidal pin wheel meshing, and has advanced design and novel structure. In most cases, this type of reducer has replaced two-stage and three-stage ordinary cylindrical gear reducers and cylindrical worm reducers in military, aerospace, metallurgy, mining, petroleum, chemical, shipbuilding, light industry, food, textile, Printing, dyeing, pharmaceutical, rubber, plastics, and lifting and transportation are increasingly used.

Features

1. The transmission ratio is large. The gear ratio is 1/6--1/87 at the first stage of deceleration. The transmission ratio of the two-stage deceleration is 1/99--1/7569; the transmission ratio of the three-stage transmission is 1/5841--1/658503. In addition, multi-level combinations can be used as needed, and the speed ratio is as large as specified.

2. Transmission efficiency is high. Since the meshing portion adopts rolling engagement, the first-stage transmission efficiency is generally 90% - 95%.

3. Compact structure, small size and light weight. The volume can be reduced by 2/1 - 2/3 compared to a conventional cylindrical gear reducer.

4. Less failure and long life. The main transmission meshing parts are manufactured by bearing steel grinding, so the mechanical properties and wear resistance are good, and because of the rolling friction, the failure is small and the service life is long.

5. Smooth and reliable operation. Because of the multi-tooth meshing during the transmission process, it is stable and reliable, and the noise is low.

6. Easy to disassemble and install, easy to repair.

7. Strong overload capability, impact resistance, small moment of inertia, suitable for frequent starting and reverse running.

The cycloidal pinwheel reducer is the most commonly used deceleration drive device in the industrial power transmission field in the world. The cycloidal pinwheel reducer is a transmission type that adopts the principle of cycloidal pin gear meshing planetary transmission. It is an ideal transmission device with many advantages, wide application and forward and reverse operation. The characteristics of the cycloidal pinwheel reducer: (Introduction to the planetary transmission principle) The reduction ratio and the efficiency of the single-machine deceleration can reach 1:87. If the multi-stage reduction ratio is adopted, the reduction ratio is larger and the efficiency is above 90%. Smooth operation and low noise. The cycloidal pin teeth have a large number of meshing teeth, a large overlap coefficient and a mechanical balance principle, which minimizes vibration and noise.Reliable use, long service life Because the main parts are high carbon steel, quenched (hrc58-62), and the running contact uses rolling friction, basically no wear, so durable. Compact and small size Thanks to the planetary drive, the input shaft and the output shaft are on the same axis, making the model as small as possible. The design is reasonable, the maintenance is convenient, the assembly is easy to disassemble, the minimum number of parts and the simple lubrication make the cycloidal pinwheel reducer deeply trusted by users.

Gearboxes are an important mechanical component that is widely used in wind turbines. Its main function is to transmit the power generated by the wind wheel under the action of the wind to the generator and get the corresponding speed.

Usually, the speed of the wind wheel is very low, which is far from the speed required by the generator to generate electricity. It must be realized by the speed increasing action of the gear box gear pair. Therefore, the gear box is also called the speed increasing box.

The cycloidal pinwheel reducer is a novel transmission device that uses the planetary transmission principle and uses cycloidal pin gear meshing. The transmission of the cycloidal pinwheel reducer can be divided into three parts: the input part, the deceleration part and the output part. A double eccentric sleeve with a 180° misalignment is mounted on the input shaft, and two roller bearings called a jib are mounted on the eccentric sleeve. The central hole forming the H mechanism and the two cycloidal wheels is an eccentric sleeved slewing bearing. a raceway, and the cycloidal wheel and the needle gear are engaged with a set of annularly arranged pin teeth to form an internal meshing speed reduction mechanism with a tooth difference of one tooth (in order to reduce friction, in a speed reducer with a small speed ratio) , the needle teeth have a needle sleeve).

The gearbox is subjected to the force from the wind wheel and the reaction force generated during the gear transmission. It must have sufficient rigidity to withstand the force and torque to prevent deformation and ensure the transmission quality. The design of the gearbox housing should be in accordance with the layout, processing and assembly conditions of the wind turbine power transmission, and easy inspection and maintenance. With the rapid development of the gearbox industry, more and more industries and different enterprises have applied gearboxes, and more and more enterprises have grown stronger in the gearbox industry.According to the modular design principle of the unit structure, the gear box greatly reduces the types of parts and is suitable for large-scale production and flexible and variable selection. The spiral bevel gear and the helical gear of the reducer are all carburized and quenched with high-quality alloy steel. The hardness of the tooth surface is up to 60±2HRC, and the precision of the tooth surface grinding is up to 5-6.

The structural principle of cycloidal pinwheel deceleration:

1. Planetary cycloidal pinwheel reducer All transmissions can be divided into three parts: input part, deceleration part and output part.

2. A double eccentric sleeve with a 180o misalignment is mounted on the input shaft, and two roller bearings are mounted on the eccentric sleeve to form an H mechanism. The center hole of the two cycloidal needle wheels is the raceway of the eccentric sleeve upper arm bearing. And the cycloidal pin wheel meshes with a set of annularly arranged pin teeth on the pin gear to form a small tooth difference inner speed reduction mechanism (in order to reduce friction, in the gear reducer with a small speed ratio, the pin gear has Needle sleeve).

3. When the input shaft is driven by the eccentric sleeve for one week, the movement of the cycloidal wheel becomes a plane that has revolution and rotation due to the characteristics of the tooth corridor curve on the cycloidal wheel and the restriction of the needle teeth on the needle gear. Movement, when the input shaft rotates one revolution, the eccentric sleeve also rotates for one week, the cycloidal wheel rotates in a reverse direction by a tooth difference to obtain a deceleration, and then the W output mechanism is used to transmit the low speed rotation motion of the cycloidal wheel through the pin shaft. Give the output shaft a lower output speed.

Characteristics of cycloidal pinwheel reducer:

1, high speed ratio and efficiency

With a single-stage drive, a reduction ratio of 1:87 can be achieved with an efficiency of 90% if a multi-stage drive reduction ratio is used.

2, compact structure and small size

Due to the planetary transmission principle, the input shaft and the output shaft are on the same axis, so the structure is compact and the volume is small.

3, the speed is stable and the noise is low

The cycloidal pin teeth have a large number of meshing teeth, a large overlap coefficient and a mechanism for smoothing the machine, which reduces vibration and noise limitations.

4, reliable use, long life

Because the main parts are made of bearing steel, high strength is obtained by quenching treatment (HRC58-62), and rolling contact friction is adopted for some transmission contacts, so the durability is long.

5, reasonable design, easy maintenance, easy to disassemble and install, the minimum number of parts and simple lubrication, so that the cycloidal pinwheel reducer is deeply trusted by users.

The difference between cycloid reducer and ordinary reducer

1. Cycloidal pinwheels are usually output on the surface, empty back and backlash are small, and the inlet can usually be controlled within 10 arc minutes. Ordinary speed reducers are usually output as axes. It is difficult to control the empty return, and its empty back is relatively large;

2. The cycloidal pin wheel can generally be integrated with the planetary wheel, and its reduction ratio can be made very large; the speed range of the ordinary reducer that allows input is very low;

3. The structure and operation mode of the cycloidal pin wheel can refer to the harmonic reducer. The transmission of the ordinary reducer is relatively simple.

Cycloidal pinwheel reducer: It is a novel transmission device that uses the planetary transmission principle and uses cycloidal pin gear meshing. Cycloidal pinwheel reducer gearbox, bearing housing, thread seal, mechanical seal, etc., due to long-term high-torque mechanical movement, the gearbox meshing gap becomes larger, resulting in greater noise and equipment vibration. In addition, the sealing part is operated under high speed and high temperature for a long time, and oil leakage occurs at the sealing part. Due to the serious oil leakage during the operation of the equipment, many disadvantages are brought to the safety production. The traditional method requires long-term shutdown to disassemble and replace the gasket and handle the joint surface, and it is impossible to achieve effective treatment in the operation of the equipment.

Ordinary reducer: There are several pairs of identical principle gears to achieve the desired deceleration effect, the ratio of the number of teeth of the large and small gears is the transmission ratio.

The cylindrical gear reducer has low cost, large force distance and low noise, but the transmission ratio is small. In contrast, the force range of the cycloid reducer is not as large as the cylindrical gear, the cost is larger than that of the cylindrical tooth, the mechanical strength is not as large as the cylindrical tooth, the transmission ratio is large, and the volume is small. At that time, each type of reducer has its own advantages, and each has its own shortcomings. The installation method is also different. It depends on the actual use of the customer. Just choose the right reducer and it will provide a harmonious transmission for your equipment. .

The cycloidal pinwheel reducer is a kind of machine that takes advantage of the planetary gear transmission principle of small tooth difference and the cycloidal pin gear meshing to achieve deceleration.

The scope of use of cycloid reducer:

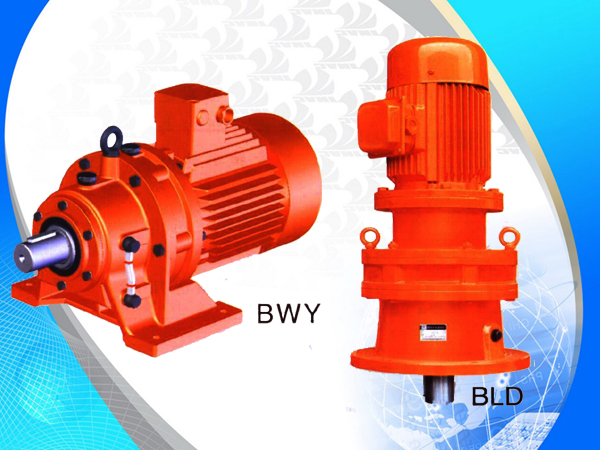

X, B series cycloidal pinwheel reducer is a kind of machine that realizes deceleration according to the principle of less tooth difference planetary transmission and cycloidal pin gear meshing. The machine is divided into horizontal, vertical, double-shaft and direct-coupled assembly methods, which are widely used in metallurgy, mining, construction, chemical, textile, light industry and other industries.

2 main characteristics of cycloid reducer

1. The reduction ratio is large and the efficiency is high: the first-stage transmission reduction ratio is 9~87, the double-stage transmission reduction ratio is 121~5133, the multi-stage combination can reach tens of thousands, and the needle-tooth meshing sleeve-type rolling friction has no meshing surface. Relative sliding, so the first-stage deceleration efficiency is 94%.

2. Smooth operation and low noise: There are many pairs of teeth in contact during operation, large coincidence, stable operation, strong overload capability, low vibration and noise, and low noise of various specifications.

3, reliable use, long life: because the main parts are made of high carbon alloy steel quenching treatment (HRC58-62), and then refined, and the cycloidal teeth and the pin gear sleeve meshed to the teeth to form rolling friction, friction The coefficient is small, so that the meshing zone has no relative sliding and the wear is extremely small, so it is durable.

4. Compact structure and small volume: Compared with other reducers of the same power, the weight is smaller than 1/3. Because it is a planetary transmission, the input shaft and the output shaft are on the same axis to obtain the smallest possible size.

A cycloidal gear is a general term for a cylindrical gear whose tooth profile is a variety of cycloid or its equidistant curve. The number of teeth of the cycloidal gear can be few, it is commonly used in instrumentation, and it is less used as a power transmission. Its derivative type cycloidal pinwheel transmission is used more.

Cycloid gear tooth profile

When a circle is purely rolled on the outer edge of another fixed circle, the trajectory at a point on the circumference is called an epicycloid. When a circle is purely rolled on the inner edge of another fixed circle, the trajectory at a point on the circumference is called a hypocycloid. The circle that is scrolled is called a circle, and the other circle is called a circle.

Cycloid gear features

Compared to involute gears, cycloidal gears have the following characteristics:

(1) The degree of coincidence is large and the transmission is more stable. At the same time, the wear is small and uniform, and the lubrication is good.

(2) The minimum number of teeth is relatively small, and its value is limited by the spheron.

(3) Poor interchangeability, not only the two modules are equal in modulus, but the two gears must also be used interchangeably.

(4) Manufacturing is difficult.

(5) It is not separable and the center distance must be accurate.

(6) The size of the meshing angle in the transmission is constantly changing, and the force is not stable enough.

The internal gear of the cycloidal pin wheel is widely used for planetary transmission, the internal gear is made into a pin wheel, and the external gear is a cycloidal gear.

The utility model discloses a planetary cycloidal pinion transmission gear box, which comprises a hand wheel, an eccentric shaft connected with the hand wheel and a main body. Wherein, an output sleeve is arranged in the main body, one end of the output sleeve is connected as an output to the valve shaft, and the other end is sleeved on the eccentric shaft, and is connected with the upper cover of the eccentric shaft through the guide pin in the pin sleeve, and the output is output. A gear is disposed between the sleeve and the upper cover in close contact with the eccentric portion of the eccentric shaft, and the gear meshes with the internal teeth of the main body. The upper cover is also provided with a sign. One side of the main body is also provided with an adjusting bolt. The planetary cycloidal pinion transmission gear box of the present invention has the following characteristics due to the above structure: 1. The transmission ratio is large, and various transmission ratios can be selected according to requirements; High transmission efficiency; 3. Small size and light weight; 4. The fault is short and the life is long; 5. The operation is reliable and stable, and the noise is low; Easy to disassemble and easy to repair; 7. It has strong overload capability, impact resistance, and low moment of inertia.

Cycloid gear transmission features:

Cycloidal gear drives are mostly used in watches and clocks, and compared to general gear transmissions, they are characterized by:

1 When the transmission is in a pair of tooth profiles, the concave hypocycloid meshes with the convex outer cycloidal line, so that the contact stress is small and the wear is uniform;

2 The tooth crown has a large degree of coincidence, which is beneficial to the improvement of the bending strength;

3 no root cutting phenomenon, the minimum number of teeth is not limited, so the structure is compact, and a larger transmission ratio can also be obtained;

4 The center distance of the meshing gears is required to be high. If the gear teeth are not properly meshed, the fixed gear ratio transmission will be affected;

5 The meshing line of this transmission is part of the arc, and the meshing angle is changed, so the gear teeth are subjected to alternating force, which affects the smoothness of the transmission;

6 Cycloidal gears have higher manufacturing precision requirements.