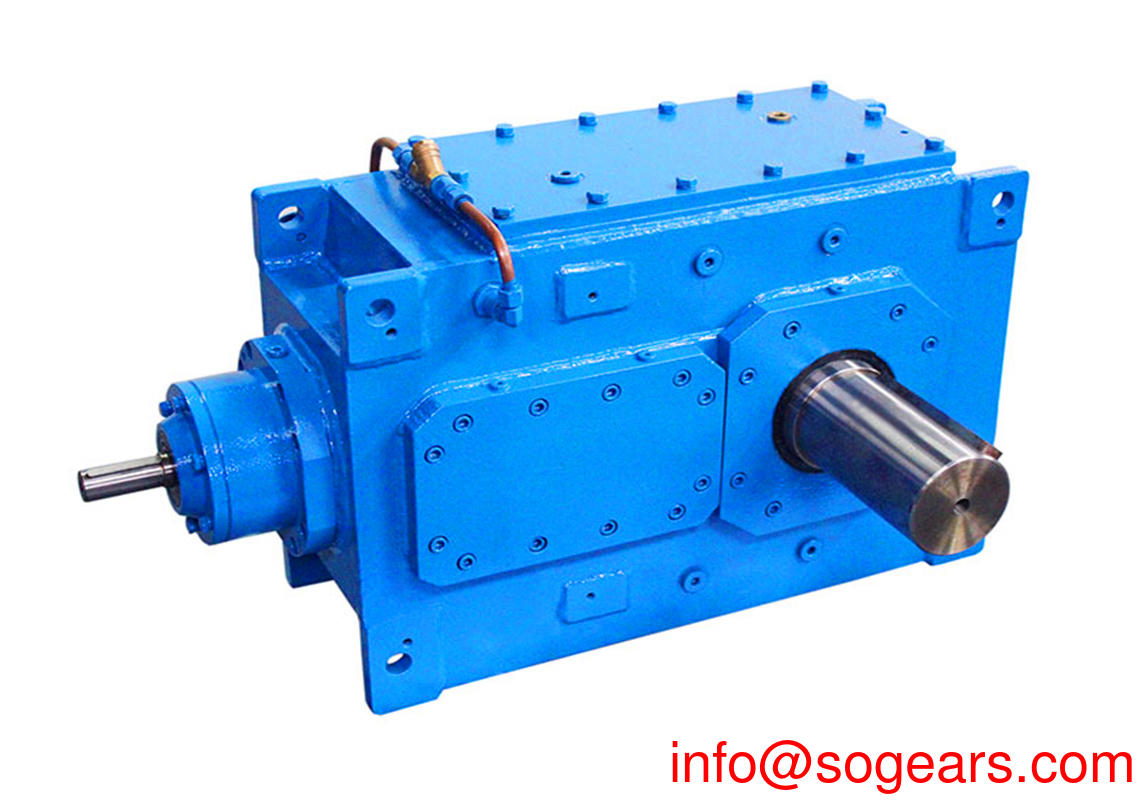

Reduction gearbox for electric motor

speed reducer for electric motor, right angle gearbox cheap

Wide range of torque coverage for a wide range of applications in heavy duty applications. It has high load carrying capacity, high life and low noise. It can be equipped with single-axis or dual-axis input and output. It has a simple structure and can be equipped with additional modules such as fan, water cooling, oil heater, forced lubrication and temperature detection according to user requirements. The compact structure and high torque transmission can be installed horizontally and vertically, and the installation method is flexible, adapting to various occasions.

Widely used in coal, port, metallurgy, alumina, power, building materials, mining, lifting, environmental protection, chemical, light industry, paper and other industries.

1. H, B series high-power Reduction gearbox for electric motor adopts universal design scheme, which can be changed into industry-specific gearbox according to customer requirements.

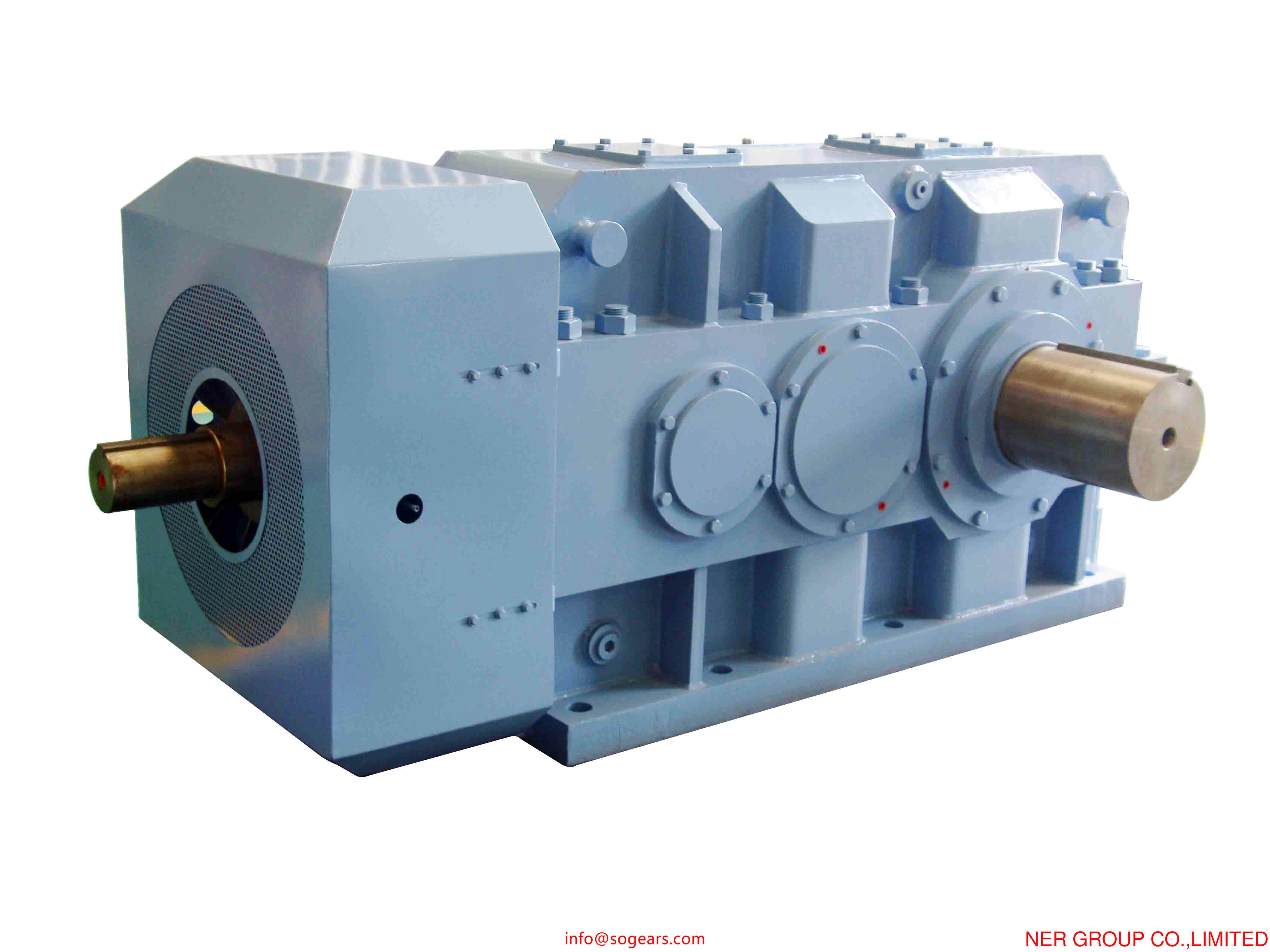

2. Realize parallel shaft, orthogonal shaft, vertical and horizontal general-purpose cabinets, with fewer types of parts and more specifications.

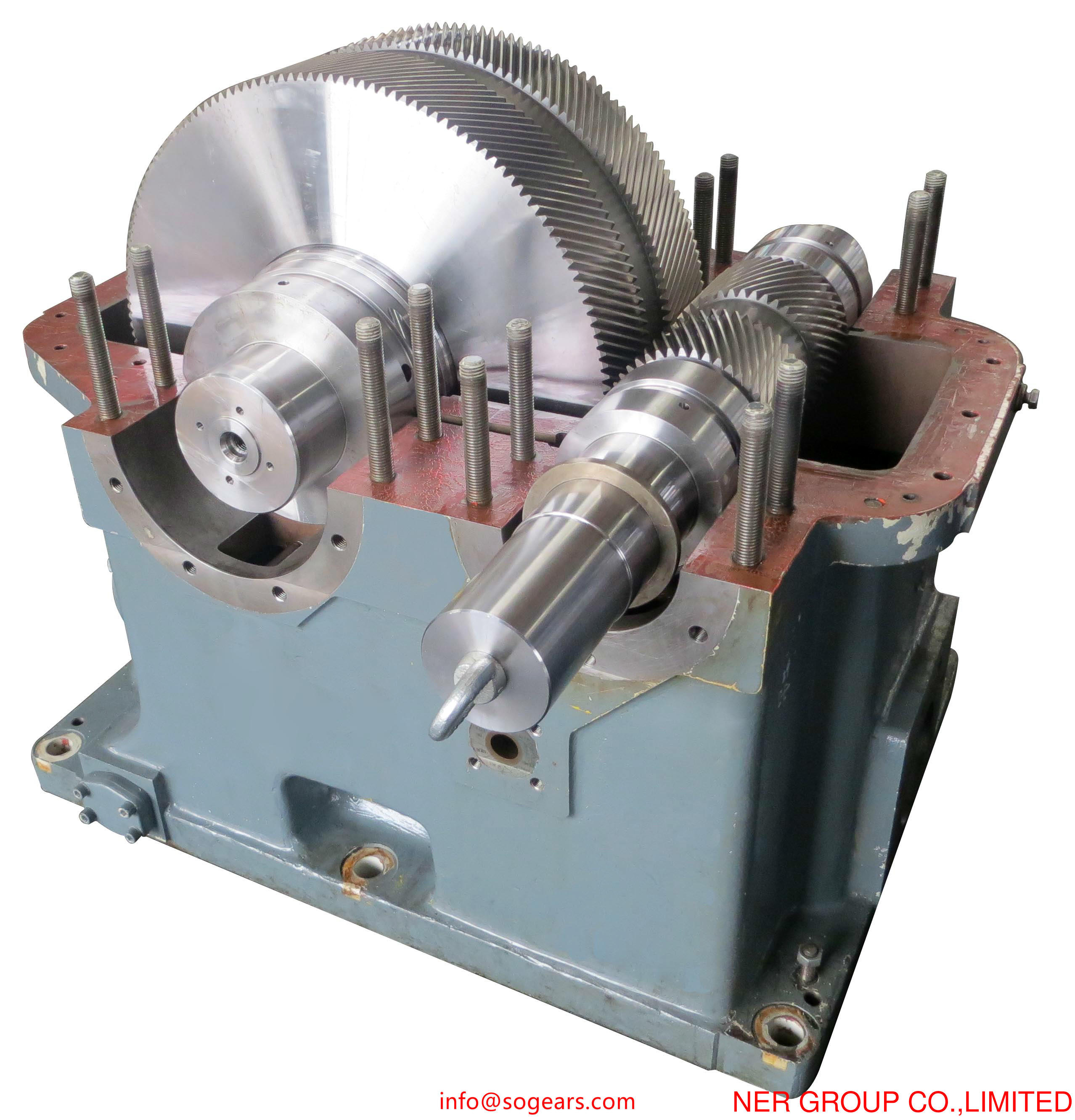

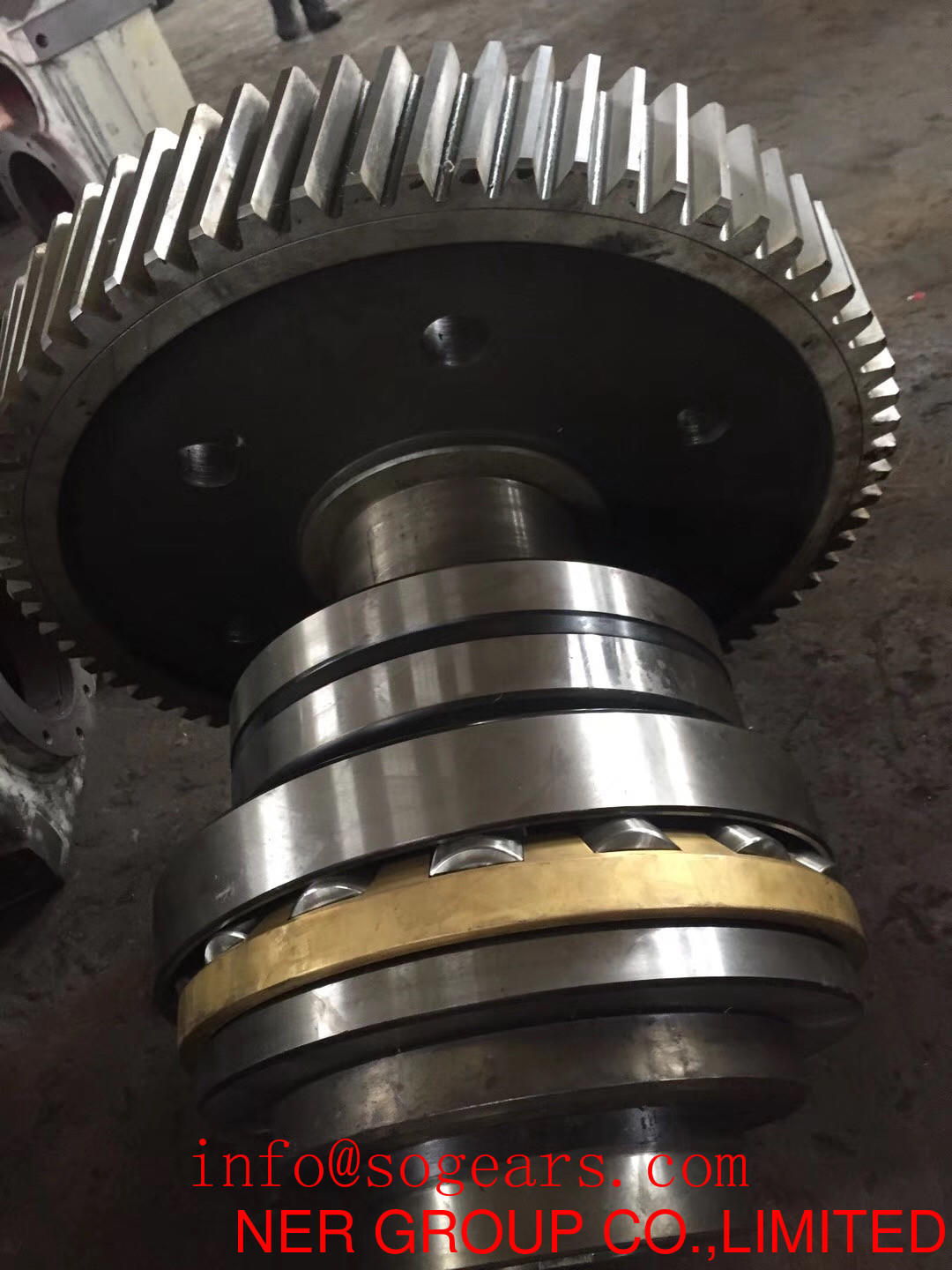

3. Adopting the structure of the suction box body, large cabinet surface area and large fan, cylindrical gear and spiral bevel gear adopt advanced grinding process to improve the temperature rise, noise reduction and reliability of the whole machine. The power is increased.

4. Input mode: motor coupling flange, shaft input.

5. Output mode: solid shaft with flat key, hollow shaft with flat key, hollow shaft with expansion joint, hollow shaft with spline joint, solid shaft with spline joint and solid shaft with flange joint.

6. Installation method: horizontal, vertical, swing base type, torsion arm type.

7.H, B series Reduction gearbox for electric motor have 3 to 26 specifications, the number of reduction transmission stages is 1 to 4, and the speed ratio is 1.25 to 450; and the combination of R, K and S series of our factory has a larger speed ratio.

Our Reduction gearbox for electric motor could be used for the following industry applcation:

Sucrose industry Sugar cane chopper Sugar cane mill Beet sugar production Beet mincer Extractor, mechanical chiller, cooker Beet cleaner Beet chopper

Cableway Cargo ropeway Round-trip system aerial ropeway T-bar lifts Continuous ropeway Cement industry Concrete mixers Crushers Rotary kiln Tube mills Separator Roller

Conveying machinery bucket conveyor winch winch belt conveyor scraper conveyor escalator track walking mechanism

Frequency conversion device Reciprocating compressor Hoisting machinery Slewing mechanism Traveling mechanism Lifting mechanism Slewing crane

Cooling tower cooling tower fan fan (axial flow and centrifugal food industry

Metalworking equipment, turning machine, pusher, winder, cold window traverse, roller straightening machine

Continuous casting machine drive unit Rolling mill Reversible blanking machine Reversible slab rolling mill Reversible wire rod mill Reversible sheet mill Reversible plate mill

Chemical Industry Extruder Mixer Rubber calender Cooling cylinder Mixer for uniform medium Non-uniform medium Mixer for uniform density medium Inhomogeneous medium Uneven gas absorption Oven Centrifuge

Dumping device Carter pillar walking device Bucket wheel excavator For picking up For coarse material Choppers Traveling mechanism Dredger Bucket transporter

Sewage treatment Concentrator (central drive) Compressor Floccule Aerator A collection device Longitudinal, rotary combined connection device Preconcentrator Screw pump Turbine pump Centrifugal pump Positive displacement pump.

JH/B series industrial gearbox Performance characteristics The parallel shaft and orthogonal shaft gearbox adopt a new design, and its unique innovations are: · Reduced parts and types, and increased specifications; · Increased operational reliability and increased transmission power; ·Using non-contact labyrinth seal with excellent performance; ·Flange output can be provided to make the gearbox meet the installation requirements of small space (according to customer requirements) Installation method JH/B gearbox can be installed horizontally as well Can be installed vertically. If the user makes a special request, other suitable installation methods can be used. Install the motor flange, the gearbox swing base and the torque support device can be ordered according to user requirements. The noise of the gearbox adopts the latest design idea to completely improve the noise characteristics of the gear through the following ways: ·The bevel gear adopts the grinding process; ·The computer simulation program is used to design the absorption noise box structure; ·The large tooth surface contact area ratio is adopted (The contact print area is large). Gearbox heat dissipation JH/B gearbox not only has high transmission efficiency, but also has good heat dissipation performance to ensure proper operating temperature of transmission parts and seals, mainly by the following methods; · Increase the surface area of the box. Non-contact labyrinth seal. · Large fan and new type of diversion fan cover. • Select the gearbox (sufficiently large thermal power margin) based on the lower maximum allowable oil temperature. In this way, the operating reliability of the equipment can be improved due to the longer oil change interval, and the maintenance cost of the equipment can be reduced. Supply JH/B gearboxes are designed according to the modular design of the unit structure, which greatly reduces the types of components, thus making it possible to increase the inventory of main parts and ensure short-term supply.

Our reduction gearbox has the following functions:

1. Accelerated deceleration is the variable speed gearbox that is often said.

2. Change the direction of the drive. For example, we use two sector gears to transmit the force vertically to the other.

3. Change the turning moment. Under the same power conditions, the faster the gear rotates, the smaller the torque the shaft receives, and vice versa.

4. Clutch function: We can separate the engine from the load by separating the two originally meshed gears. Such as brake clutches.

5. Distribute power. For example, we can use one engine to drive multiple slave shafts through the gearbox main shaft, thus realizing the function of one engine to drive multiple loads.

Z series cylindrical Reduction gearbox for electric motors are widely used in metallurgy, mining, lifting, transportation, cement, textile, printing and dyeing, pharmaceutical and other industries. The utility model has the advantages of wide reduction ratio range, high mechanical operation efficiency, stable operation, low noise, small volume, light weight, long service life, high carrying capacity and easy maintenance. The transmission ratio is: 6.3 7.1 8 9 10 11.2 12.5 14 16 18 20 hardened cylindrical Reduction gearbox for electric motor is produced according to national standard (Gb19004-88), mainly including ZDY (single stage), ZLY (two stages), ZSY ( Three levels) and ZFY (four levels) four series.

Performance characteristics:

1. The center distance and transmission ratio are mainly optimized, and the main parts and components are interchangeable. 2. The gears are made of high-quality alloy steel carburized and quenched, and the gear hardness reaches HRC58-62. 3. Small volume, light weight, high precision, large carrying capacity, long service life, high reliability, stable transmission and low noise. 4. Generally use oil pool lubrication, natural cooling, when the thermal power can not be met, can use circulating oil lubrication or fan, cooling coil cooling <br />

Reduction gearbox for electric motor model, specifications and their representation methods: 1. Models include: ZDY/ZDZ single-stage cylindrical Reduction gearbox for electric motor; ZLY/ZLZ two-stage cylindrical Reduction gearbox for electric motor; ZSY/ZSZ three-stage cylindrical Reduction gearbox for electric motor; ZFY four-stage cylinder Reduction gearbox for electric motor. 2. Specifications are: single stage: ZDY80, ZDY100, ZDY125, ZDY160, ZDY200, ZDY250, ZDY280, ZDY315, ZDY355, ZDY400, ZDY450, ZDY500, ZDY560; two levels: ZLY112, ZLY125, ZLY140, ZLY160, ZLY180 , ZLY200, ZLY224, ZLY250, ZLY280, ZLY315, ZLY355, ZLY400, ZLY450, ZLY500, ZLY560, ZLY630, ZLY710; three levels: ZSY160, ZSY180, ZSY200, ZSY224, ZSY250, ZSY280, ZSY315, ZSY355, ZSY400, ZSY450, ZSY500, ZSY560, ZSY630, ZSY710. Four stages: ZFY180, ZFY200, ZFY224, ZFY250, ZFY280, ZFY320, ZFY360, ZFY400, ZFY450, ZFY500, ZFY560, ZFY630, ZFY710.

Our V series reduction gearbox is a new design, which has the following advantages: many specifications and models, high operational reliability, large transmission power, large torque, good impact resistance, and can provide blue disc output shaft, so that the gear can meet the installation in a small space.Our V series Reduction gearbox for electric motor are with the following models numbers:

V2DM15-5-A V2DM14-5-A V2DM13-5-A V2DM12-5-A V2DM11-5-A V2DM10-5-A

V2DM9-5-A V2DM8-5-A V2DM7-5-A V2DM6-5-A V2DM5-5-A V2DM4-5-A

V2DH18-5-A V2DH17-5-A V2DH16-5-A V2DH15-5-A V2DH14-5-A V2DH13-5-A

V2DH12-5-A V2DH11-5-A V2DH10-5-A V2DH9-5-A V2DH8-5-A V2DH7-5-A

V2DH6-5-A V2DH5-5-A V2DH4-5-A V2HM18-5-A V2HM17-5-A V2HM16-5-A

V2HM15-5-A V2HM14-5-A V2HM13-5-A V2HM12-5-A V2HM11-5-A V2HM10-5-A

V2HM9-5-A V2HM8-5-A V2HM7-5-A V2HM6-5-A V2HM5-5-A V2HM4-5-A

V2HV18-5-A V2HV17-5-A V2HV16-5-A V2HV15-5-A V2HV14-5-A V2HV13-5-A

V2HV12-5-A V2HV11-5-A V2HV10-5-A V2HV9-5-A V2HV8-5-A V2HV7-5-A

V2HV6-5-A V2HV5-5-A V2HV4-5-A V2HH18-5-A V2HH17-5-A V2HH16-5-A

V2HH15-5-A V2HH14-5-A V2HH13-5-A V2HH12-5-A V2HH11-5-A V2HH10-5-A

V2HH9-5-A V2HH8-5-A V2HH7-5-A V2HH6-5-A V2HH5-5-A V2HH4-5-A

V2SV18-5-A V2SV17-5-A V2SV16-5-A V2SV15-5-A V2SV14-5-A V2SV13-5-A

V2SV12-5-A V2SV11-5-A V2SV10-5-A V2SV9-5-A V2SV8-5-A V2SV7-5-A

V2SV6-5-A V2SV5-5-A V2SV4-5-A V2SM18-5-A V2SM17-5-A V2SM16-5-A

V2SM15-5-A V2SM14-5-A V2SM13-5-A V2SM12-5-A V2SM11-5-A V2SM10-5-A

V2SM9-5-A V2SM8-5-A V2SM7-5-A V2SM6-5-A V2SM5-5-A V2SM4-5-A

V2SH18-5-A V2SH17-5-A V2SH16-5-A V2SH15-5-A V2SH14-5-A V2SH13-5-A

V2SH12-5-A V2SH11-5-A

V4DV18 V4DV17 V4DV16 V4DV15

V4DV14 V4DV13 V4DV12 V4DV11 V4DV10 V4DV9

V4DV8 V4DV7 V4DV6 V4DV5 V4DV4 V3DV18

V3DV17 V3DV16 V3DV15 V3DV14 V3DV13 V3DV12

V3DV11 V3DV10 V3DV9 V3DV8 V3DV7 V3DV6

V3DV5 V3DV4 V2DV18 V2DV17 V2DV16 V2DV15

V2DV14 V2DV13 V2DV12 V2DV11 V2DV10 V2DV9

V2DV8 V2DV7 V2DV6 V2DV5 V2DV4 V4DM18

V4DM17 V4DM16 V4DM15 V4DM14 V4DM13 V4DM12

V4DM11 V4DM10 V4DM9 V4DM8 V4DM7 V4DM6

V4DM5 V4DM4 V3DM18 V3DM17 V3DM16 V3DM15

V3DM14 V3DM13 V3DM12 V3DM11 V3DM10 V3DM9

V3DM8 V3DM7 V3DM6 V3DM5 V3DM4 V2DM18

V2DM17 V2DM16 V2DM15 V2DM14 V2DM13 V2DM12

V2DM11 V2DM10 V2DM9 V2DM8 V2DM7 V2DM6

V2DM5 V2DM4 V4DH18 V4DH17 V4DH16 V4DH15

V4DH14 V4DH13 V4DH12 V4DH11 V4DH10 V4DH9

V4DH8 V4DH7 V4DH6 V4DH5 V4DH4 V3DH18

V3DH17 V3DH16 V3DH15 V3DH14 V3DH13 V3DH12

V3DH11 V3DH10 V3DH9 V3DH8 V3DH7 V3DH6

V3DH5 V3DH4 V2DH18 V2DH17 V2DH16 V2DH15

V2DH14 V2DH13 V2DH12 V2DH11 V2DH10 V2DH9

V2DH8 V2DH7 V2DH6 V2DH5 V2DH4 V4HM18

V4HM17 V4HM16 V4HM15 V4HM14 V4HM13 V4HM12

V4HM11 V4HM10 V4HM9 V4HM8 V4HM7 V4HM6

V4HM5 V4HM4 V3HM18 V3HM17 V3HM16 V3HM15

V3HM14 V3HM13 V3HM12 V3HM11 V3HM10 V3HM9

V3HM8 V3HM7 V3HM6 V3HM5 V3HM4 V2HM18

V2HM17 V2HM16 V2HM15 V2HM14 V2HM13 V2HM12

V2HM11 V2HM10 V2HM9 V2HM8 V2HM7 V2HM6

V2HM5 V2HM4 V4HV18 V4HV17 V4HV16 V4HV15

V4HV14 V4HV13 V4HV12 V4HV11 V4HV10 V4HV9

V4HV8 V4HV7 V4HV6 V4HV5 V4HV4 V3HV18

V3HV17 V3HV16 V3HV15 V3HV14 V3HV13 V3HV12

V3HV11 V3HV10

All our gearboxes are Twisted increase and decrease series, improve economical tooth surface modification, improve bearing capacity and noise reduction performance, various sealing forms, perfect anti-leakage performance, high modular design, rich optional accessories, short delivery time and great attraction Cost performance.

Maintenance ways for Sogears Reduction gearbox for electric motor

1. For gearboxes, the first oil change must be carried out after approximately 300 hours of gear running.) When changing oil, carefully flush the gearbox with a suitable cleaning agent. Do not mix mineral oil with synthetic oil.

2. Every 3000 working hours, zui low level for half a year, should check the oil and oil level. The oil seal is not tightly sealed to cause routine detection of dripping. If the IEC input Reduction gearbox for electric motor 2 test and check the elastomer. Replace if necessary.

3. According to different working conditions. Zui long inspection every three years. Replace mineral oil

4. Depending on the working conditions, replace the oil seal on the shaft of the Han.

5. When the product is in danger, do not disassemble the parts. After the after-sales service department of the company (provided the specifications of the Reduction gearbox for electric motor, date of manufacture, serial number, used time, host name, host production unit and fault type), take reasonable measures. Measures.

The following items should be strictly observed:

- The drawings in the sample are only examples and are not required to be strictly consistent, and the size noted may vary.

- The weight of the note is only an average and is not required to be strictly consistent.

- In order to prevent accidents, all rotating parts should be equipped with protective covers according to national and user local safety regulations.

- You must carefully read the equipment operating instructions before commissioning. The Reduction gearbox for electric motor is ready for operation when it is delivered, but it is not lubricated. - The amount of fuel given here is for reference only. The actual amount of oil should be based on the marking on the dipstick.

- Lubricating oil type viscosity must be specified in the product manual.

- The Reduction gearbox for electric motor is supplied with a radial oil seal. Other forms of sealing are available to the user upon special request.

The company has 9 sets of American Gleason Phoenix 275G/800G CNC arc bevel gear grinding machine, Germany Kappa CNC grinding center, Swiss Mage KS-42 high precision straight bevel gear grinding machine, Swiss Stuart high precision CNC The internal and external cylindrical grinding machine, the German Zeiss three-coordinate measuring instrument and the matching Gleason 1500GMM gear measuring center can collect and detect the profile of the tooth profile. It has a complete set of Ipsen controllable atmosphere multi-purpose furnace heat treatment production line, with a total of more than 120 main engines and supporting equipment. The product testing methods are complete, equipped with material physical and chemical analysis, mechanical performance testing, ultrasonic testing, magnetic particle testing and other heat treatment testing instruments. The gear processing modulus ranges from 1 to 20, and the high-precision grade can reach the international GB11365-89 level 4.

With professional manufacturing experience and strong design and development capabilities, the company can map and design various non-standard special high-precision gear parts according to the technical parameters provided by users. Strict IS09001: 2008 quality management system and perfect ERP process management to ensure the controllability of product quality, the company is well received by the industry for its excellent products, reasonable price, short production cycle and timely service.

Sogears adheres to the enterprise spirit of “diligence, pragmatism, pioneering and innovation”, the business philosophy of “professional casting quality, honesty and win the world”, shouldering the strong gear and strong equipment, strong national mission, and strive to make more for the world drive. Great contribution.

The best service from our transmission drive expert to your inbox directly.

Our Service

Get in Touch

Yantai Bonway Manufacturer Co.ltd

ANo.160 Changjiang Road, Yantai, Shandong, China(264006)

T+86 535 6330966

W+86 185 63806647