Products

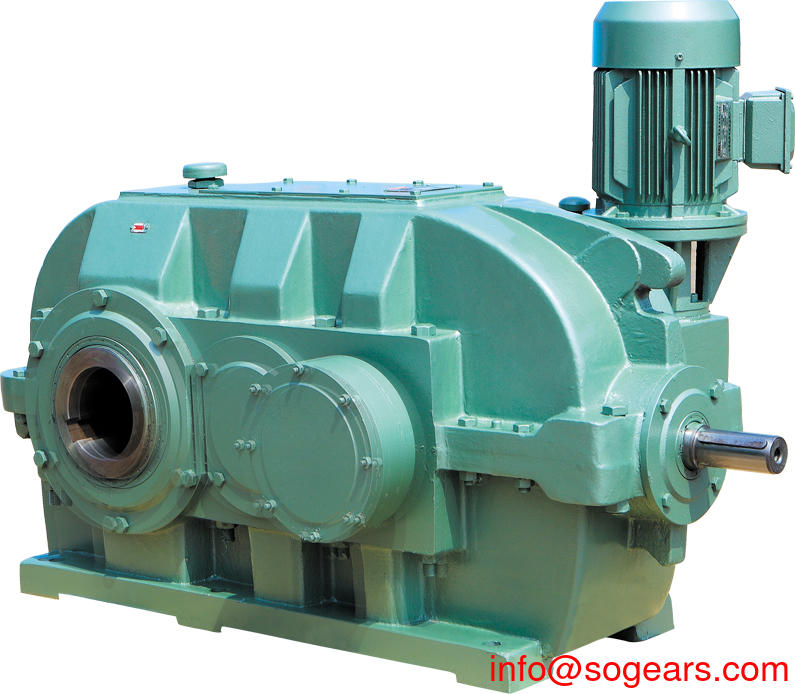

Bucket elevator gearbox

bucket elevator parts, bucket elevator gearbox, bucket elevator belt, bucket elevator chain.

DCY conical cylindrical bucket elevator parts includes: DCY160, DCY180, DCY200, DCY224, DCY250, DCY280, DCY315, DCY355,

DCY400, DCY450, DCY500, DCY560, DCY630, DCY710, DCY800.

The hardened bucket elevator parts mainly includes the parallel shaft series and the vertical shaft series. The parallel shaft Bucket elevator parts is produced according to the national standard (GBl9004—88). The product is optimized and has the international advanced level in the 1980s. It mainly includes ZDY (single). Four series, ZLY (two-stage), ZSY (three-stage) and ZFY (four-stage), vertical shaft Bucket elevator parts is produced according to national standard (JB/T9002-1999), and the input shaft is perpendicular to the output shaft. Directional transmission, which mainly includes three series of DBY, DCY and DFY.

Feature editing

(1) The main parameters such as center distance and nominal transmission ratio are optimized, and the main parts and parts are interchangeable.

(2) The bucket elevator gearbox are made of high-quality alloy steel by carburizing and quenching, and the hardness of the tooth surface reaches HRC54-62.

(3) Small size, light weight, high precision, large carrying capacity, high efficiency, long life, high reliability, stable transmission and low noise.

(4) Generally use oil pool lubrication, natural cooling, when the thermal power can not be met, you can use circulating oil lubrication or fan, cooling coil cooling.

Application scope

(3) Working environment—40~50°C. If it is lower than 0°C, the lubricating oil should be preheated to above 0°C before starting. The Bucket elevator parts can be used in both forward and reverse directions.

(4) It can be widely used in metallurgy, mining, chemical, building materials, lifting, transportation, textile, paper, equipment, plastics, rubber, engineering machinery, energy and other industrial sectors.

First, single-stage cylindrical bucket elevator parts: The rotating teeth can be made into straight teeth, helical teeth and herringbone teeth. Straight

teeth are used for lower speed (ν ≤ 8m / s) lighter load; helical bucket elevator gearbox are used for higher speed

transmissions, and herringbone bucket elevator gearbox are used for heavy load transmissions. The housing is

usually made of cast iron. Single or small batch production sometimes uses welded construction.

Bearings generally use rolling bearings, and use sliding bearings for heavy loads or particularly

high speeds. Other types of bucket elevator parts are the same as this

Second, two-stage cylindrical bucket elevator parts: 1.Expandable The structure is simple, but the position of the bucket elevator gearbox relative to the bearing is asymmetrical, so

the shaft is required to have a large rigidity. The high-speed bucket elevator gearbox is arranged away from the

torque input end, so that the torsional deformation of the shaft under the action of the torque

and the bending deformation of the shaft under the bending moment can partially cancel each

other to slow the uneven distribution of the load along the tooth width. phenomenon. For

occasions where the load is relatively stable. The high speed stage is generally made of helical

teeth, and the low speed grade can be made into straight teeth.

2. Split type

The structure is complicated, but since the bucket elevator gearbox are symmetrically arranged with respect to the

bearing, the load is evenly distributed along the tooth width compared with the unfolding type,

and the bearing is uniformly loaded. The torque on the dangerous section of the intermediate

shaft is only half of the torque transmitted by the shaft. Suitable for variable load applications.

High-speed grades generally use helical teeth, and low-speed grades can use straight or

herringbone teeth.

3. Coaxial

The lateral dimension of the Bucket elevator parts is small, the depth of the two pairs of bucket elevator gearbox immersed in

the oil is about the same, but the axial dimension is large and the weight is large, and the

intermediate shaft is long and the rigidity is poor, so that the load distribution along the tooth

width is uneven. The bearing capacity of high-speed shaft is difficult to make full use of

4. Coaxial split type

Each pair of meshing bucket elevator gearbox transmits only half of the total load. The input and output shafts are

only subjected to torque. The intermediate shaft is only half of the total load, so the journal size

can be reduced compared to other bucket elevator parts that transmit the same power.

Third, single-stage bevel bucket elevator parts: The bucket elevator gearbox can be made as straight, helical or curved teeth. It can also be used in two-axis

vertical phase-shifting transmissions for transmissions with two axes perpendicular to each

other. Due to the complexity of manufacturing and installation, the cost is high, so it is only used

when the transmission arrangement needs it. Fourth,stage two-stage cone - cylindrical bucket elevator parts: Features the same as single-stage bevel bucket elevator parts, the bevel bucket elevator gearbox should be at high speed,

so that the size of the bevel bucket elevator gearbox is not too large, otherwise the processing is difficult Bucket elevator parts scope: 1. The high speed shaft rotation is not more than 1500 rpm. 2. The peripheral speed of the bucket elevator gearbox drive is not more than 20 m / s. 3. The working environment temperature is -40-45 °C. If it is lower than 0 °C, the lubricating oil

should be preheated to above 0 °C before starting. 4. The bucket elevator parts can be used in both forward and reverse directions.

The spur bucket elevator parts is a power transmission mechanism that uses a bucket elevator gearbox speed converter to

decelerate the number of revolutions of the motor to a desired number of revolutions and

obtain a device with a large torque.

Introduction: The spur bucket elevator parts is a relatively precise machine that is used to reduce the speed and

increase the torque.

Application: The bucket elevator gearbox of the cylindrical bucket elevator parts are carburized, quenched and geared, with high

bearing capacity and low noise. They are mainly used in belt conveyors and various

transportation machines, and can also be used in transmission mechanisms of other general

machinery. The utility model has the advantages of high bearing capacity, long service life,

small volume, high efficiency and light weight, and is used in a transmission device in which the

input shaft and the output shaft are arranged in a vertical direction. Cylindrical bucket elevator parts

are widely used in metallurgy, mining, lifting, transportation, cement, construction, chemical,

textile, printing and dyeing, pharmaceutical and other fields.

bucket elevator parts performance: 1. the bucket elevator gearbox is made of high-quality alloy steel for carburizing and quenching. The hardness of

the tooth surface is up to 60±2hrc, and the precision of the tooth surface grinding is up to 5-6. 2, using computer reshaping technology, pre-reform the bucket elevator gearbox, greatly improving the load capacit

y of the Bucket elevator parts. 3, from the box to the internal bucket elevator gearbox, using a completely modular structure design, suitable for

large-scale production and flexible selection. 4. The standard Bucket elevator parts model is divided according to the torque decrement form, which avoids

power waste compared with the traditional equal division. 5, using cad / cam design and manufacture to ensure the stability of quality. 6, using a variety of sealing structures to prevent oil leakage. 7, multi-directional noise reduction measures to ensure the excellent low noise performance of

the Bucket elevator parts.

ZQD cylindrical bucket elevator parts: The ZQD type reduction machine is based on the premise of not changing the position and

installation size of the input and output shaft of the ZQ type Bucket elevator parts. Adding a high-speed stage

is called a three-stage transmission, and the increased high-speed stage is above. ZQD type large transmission ratio cylindrical bucket elevator parts has six specifications: ZQD350+100,

ZQD400+100, ZQD650+150, ZQD850+250 and ZQD1000+250.

ZSC type cylindrical bucket elevator parts: ZSC reduction machine is based on the design and manufacturing experience of domestic and

foreign similar products, and has been refined and optimized to be widely used in metallurgy,

machinery, petroleum, chemical, construction, textile, light industry and other industries.

ZQA cylindrical bucket elevator parts:

ZQA type Bucket elevator parts is improved on the basis of ZQ type Bucket elevator parts. In order to improve bucket elevator gearbox bearing

capacity, it is easy to replace ZA type Bucket elevator parts. When the shape, shaft end and installation size

are the same, change the bucket elevator gearbox pinion material. the bucket elevator gearbox shaft is 42CrMo, the large bucket elevator gearbox is

ZG35CrMo, the quenched and tempered hardness bucket elevator gearbox shaft is 291-323HB, and the large bucket elevator gearbox

is 255-286HB. ZQA type Bucket elevator parts is mainly used in lifting, mining, general chemical, textile, light

bucket elevator parts is generally used for transmission equipment with low speed and high torque. The

ordinary Bucket elevator parts of the motor will also have several pairs of identical bucket elevator gearbox to achieve the

desired deceleration effect. The ratio of the number of teeth of the large and small bucket elevator gearbox is the

transmission ratio. With the continuous development of the Bucket elevator parts industry, more and more

enterprises have applied the Bucket elevator parts.

bucket elevator parts: 1. R series coaxial helical bucket elevator parts is manufactured according to international technical

requirements. It has high technical content

2. Space saving, reliable and durable, with high overload capacity and power up to 132KW.

3. Low energy consumption and superior performance. Bucket elevator parts efficiency is up to 95%;

4, low vibration, low noise, high energy saving;

5, high-quality forged steel material, steel cast iron box, bucket elevator gearbox surface after high-frequency heat

treatment;

6, precision machining to ensure shaft parallelism And positioning bearing requirements, the

Bucket elevator parts that forms the helical bucket elevator gearbox transmission assembly is equipped with various types of

motors, combined into mechatronics, fully guaranteeing the quality characteristics of the

product.

The bucket elevator parts uses the bucket elevator gearbox transmission of all stages to achieve the purpose of speed

reduction. The Bucket elevator parts is composed of bucket elevator gearbox pairs of various stages. For example, the bucket elevator gearbox can

be driven by a small bucket elevator gearbox to achieve a certain deceleration, and then a multi-stage structure is

adopted. , you can greatly reduce the speed.

In the long-term operation of the Bucket elevator parts, there are often faults such as wear and leakage. The

most important ones are: 1. The bearing chamber of the Bucket elevator parts is worn, which in turn includes the wear of the bearing

housing of the housing, the bearing chamber of the housing, and the bearing chamber of the

transmission. 2. The shaft diameter of the bucket elevator gearbox shaft of the Bucket elevator parts is worn, and the main wear parts are in

the shaft head and keyway. 3. The bearing position of the Bucket elevator parts drive shaft is worn. 4. The Bucket elevator parts joint surface leaks.

For the wear problem, the traditional solution of the enterprise is repairing after repair welding

or brush plating, but both have certain drawbacks: the thermal stress generated by the repair

welding high temperature cannot be completely eliminated, which may cause damage to the

material and cause the parts to bend or break; Brush plating is limited by the thickness of the

coating, and it is easy to peel off. The above two methods use metal to repair the metal, which

can not change the "hard to hard" coordination relationship. Under the combined action of each

force, it will still cause re-wear.

For the leakage problem, the traditional method needs to disassemble and open the Bucket elevator parts,

replace the sealing gasket or apply the sealant, which is not only time-consuming and laborious,

but also difficult to ensure the sealing effect, and leakage will occur again during operation.

The polymer material can be used to treat leakage on site. The material has excellent adhesion,

oil resistance and 350% elongation, which overcomes the impact caused by the vibration of the

Bucket elevator parts, and solves the problem of leakage of the Bucket elevator parts for the enterprise.

A bucket elevator parts is a type of transmission that increases the wear of its internal transmission as

it works longer. So what aspects should we analyze the wear of the internal bucket elevator gearbox of the bucket elevator gearbox

Bucket elevator parts? The losses in the bucket elevator gearbox unit (bucket elevator gearbox frame and Bucket elevator parts) in the bucket elevator parts include the

following three aspects: 1. Sliding friction loss between teeth. 2. Loss in bearings, plain bearings and rolling bearings. 3. Splash and agitation of lubricant loss.

The loss problem in the bucket elevator parts is related to the friction loss in the bucket elevator gearbox transmission, the

friction loss of the rolling and sliding bearings, and the consumption and viscosity of the

lubricating oil.

There are many types of bucket elevator parts. The commonly used bucket elevator gearbox and worm Bucket elevator parts can be roughly

divided into three categories according to their transmission and structural characteristics: (1) bucket elevator parts mainly include three kinds of cylindrical bucket elevator parts, bevel bucket elevator parts

and conical-cylindrical bucket elevator parts. (2) The worm Bucket elevator parts mainly includes cylindrical worm Bucket elevator parts, arc bucket elevator gearbox worm Bucket elevator parts, cone

worm Bucket elevator parts and worm-bucket elevator parts. (3) Planetary bucket elevator parts mainly include involute planetary bucket elevator parts, cycloidal pinwheel

bucket elevator parts and harmonic bucket elevator parts.

bucket elevator parts working principle: Single-stage cylindrical bucket elevator parts split type double-stage cylindrical bucket elevator parts Coaxial double-stage cylindrical bucket elevator parts cone Bucket elevator parts Cone-cylindrical bucket elevator parts worm Bucket elevator parts

The bucket elevator parts can be divided into single-stage, two-stage, three-stage and multi-stage

bucket elevator parts according to the number of stages of the reduction bucket elevator gearbox; the mutual arrangement of

the shafts in space can be divided into two types: vertical and horizontal bucket elevator parts; The

characteristics of the motion diagram can be divided into expansion type, coaxial type and split

type speed Bucket elevator parts. The maximum bucket elevator gearbox ratio of single-stage spur bucket elevator parts is generally

8-10, which is mainly to avoid excessive size. If i>10 is required, a secondary cylindrical bucket elevator gearbox

Bucket elevator parts should be used. The secondary cylindrical bucket elevator parts is applied to the case where the sum of the center

distances of the i:8-50 and the high and low speed stages is 250-400 mm. The three-stage

cylindrical bucket elevator parts is shown for use in applications where the drive is required to be large.

Bevel bucket elevator parts and secondary conical-cylindrical bucket elevator parts In the transmission that requires the input shaft and the output shaft to be 90~ configured.

Because the large-sized bevel bucket elevator gearbox is difficult to manufacture accurately, the high-speed stage

of the conical-cylindrical bucket elevator parts always uses a bevel bucket elevator gearbox to reduce its size and improve

manufacturing precision. bucket elevator parts are characterized by high efficiency, long life and easy

maintenance, making them extremely versatile. Machine characteristics: 1. the bucket elevator gearbox is made of high-strength low-carbon alloy steel by carburizing and quenching. The

hardness of the tooth surface is up to HRC58-62. The bucket elevator gearbox are all CNC grinding technology

with high precision and good contact.

2. High transmission rate: single stage is greater than 96.5%, double level is greater than 93%,

and third level is greater than 90%.

3. Smooth operation and low noise.

4. Small size, light weight, long service life and high carrying capacity.

5. Easy to disassemble and easy to install

1. Use: The bevel bucket elevator parts is used for the transmission of the input shaft output shaft in a vertical

direction. Mainly used in belt conveyors and other transportation machinery, but also used in

metallurgy, mining, chemical, coal, building materials, light industry, petroleum and other

general machinery, in addition to large-scale Bucket elevator parts, mainly used in the cement industry.

2. Scope of application: The maximum speed of the input shaft of the Bucket elevator parts is not more than 1500r/min The peripheral speed of the bucket elevator gearbox is not more than 20m/s The working environment temperature is -40~+45°C. When the ambient temperature is lower

than 0 °C, the lubricating oil should be heated before starting (other distribution heat pipes)

3.Conical cylindrical bucket elevator parts form and marking: (1)Form The DBY type is a two-stage transmission Bucket elevator parts similar to the zdy Bucket elevator parts, but the difference

is that the first stage drive is a Gleason spiral bevel bucket elevator gearbox, and the second drive is an involute

cylindrical bevel bucket elevator gearbox. The Bucket elevator parts can be divided into four assembly forms I, II, III and IV according to the output

shaft form (see the assembly form diagram below). The rotation direction of the output shaft

can be divided into clockwise (S) and counterclockwise (N). (facing the output shaft).

(2)Mark: the bucket elevator gearbox unit's marking code includes the bucket elevator gearbox unit model, nominal center distance, nominal

bucket elevator gearbox ratio, assembly type and output shaft rotation direction. Tag example: Bucket elevator parts DBYK224–11.2–IS The form code is DBYK Nominal center distance is 224mm Nominal transmission ratio 11.2 Assembly form is the first type The output shaft rotates clockwise The backstop must be configured separately (see the backstop mounting dimensions for

dimensions) D is the belt conveyor type code, B-secondary transmission, Y-hard tooth surface bucket elevator gearbox,

K-hollow shaft

Conical cylindrical bucket elevator parts assembly form diagram Conical cylindrical bucket elevator parts mainly

has two types of DBY Bucket elevator parts and DCY Bucket elevator parts, which is an external bucket elevator gearbox transmission

mechanism with input and output shafts in vertical state, conical cylindrical bucket elevator parts and

cylindrical bucket elevator parts In the similar characteristics, the main transmission parts are made of

high quality alloy steel. the bucket elevator gearbox is made by carburizing, quenching and grinding, with 6 levels

of precision. The product has the advantages of high carrying capacity, long life, small size,

high efficiency and light weight.

Use, maintenance and precautions for bucket elevator parts: 1. The Bucket elevator parts adopts 460# medium load industrial bucket elevator gearbox oil, and the working environment

temperature is 0~40°C. 2, after the first use for 100 hours, the inner cavity should be cleaned and replaced with new

bucket elevator gearbox oil, and the oil should be changed every 2000 hours. 3. When disassembling and installing the Bucket elevator parts, hammering should be avoided as much as

possible to avoid damage to normal parts. 4. If it is found that there is oil leakage at the shaft extension or joint during use, the seals such

as the skeleton oil seal should be replaced in time.

The best service from our transmission drive expert to your inbox directly.

Our Service

Get in Touch

Yantai Bonway Manufacturer Co.ltd

ANo.160 Changjiang Road, Yantai, Shandong, China(264006)

T+86 535 6330966

W+86 185 63806647